Displaying items by tag: Andritz

ANDRITZ to supply a sludge handling system to Monalisa Co. Ltd., South Korea

International technology Group ANDRITZ has received an order from Monalisa Co. Ltd., Seoul, South Korea, to supply the key components for a new sludge dewatering process to be installed at its tissue production line in Jeonju. Start-up is scheduled for the end of 2017.

The tissue production line produces sanitary tissue products using mixed office waste and virgin pulp as raw material. In order to achieve optimum results in dewatering of the sludge coming from the recycled fiber processing line, ANDRITZ will supply a thickening drum and sludge screw press. As a result, the costs for transporting the sludge to a subsequent treatment facility will be cut significantly.

The tissue production line produces sanitary tissue products using mixed office waste and virgin pulp as raw material. In order to achieve optimum results in dewatering of the sludge coming from the recycled fiber processing line, ANDRITZ will supply a thickening drum and sludge screw press. As a result, the costs for transporting the sludge to a subsequent treatment facility will be cut significantly.

The technological features of the dewatering equipment as well as information and impressions gained from a previous visit to a reference plant in Korea were decisive in the customer placing the order with ANDRITZ.

Monalisa Co. Ltd. is an established producer of domestic hygiene products sold under several brand names, including "Bellagio", "The Rich House", and "Nox Premium". The company is based in Seoul, South Korea.

ANDRITZ to supply tissue production line with the latest shoe press technology to Vajda Papír

International technology Group ANDRITZ has received an order from Vajda Papír to supply a complete tissue production line for its mill in Dunaföldvár, Hungary. Start-up is scheduled for March 2018.

The order comprises a PrimeLineCOMPACT VI tissue machine with steel Yankee and shoe press as well as a complete stock preparation system, including pumps, automation, electrification, all auxiliaries, and services.

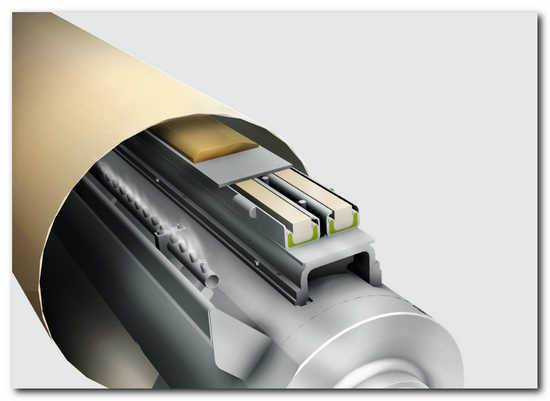

PrimePress XT Evo, the latest ANDRITZ shoe press technology. “Photo: ANDRITZ”.

PrimePress XT Evo, the latest ANDRITZ shoe press technology. “Photo: ANDRITZ”.

The stock preparation system includes an FSV pulper, which is equipped with the latest design of energy-saving rotor, three proven ANDRITZ double-disc TwinFlo refiners, a ModuScreen CP protection screen with rotating cylinder, and a low-energy ModuScreen HBE headbox screen.

The ANDRITZ tissue machine has a design speed of 2,200 m/min and a width of 2.74 m. It is equipped with a PrimePress XT Evo, the latest ANDRITZ shoe press technology. PrimePress XT Evo ensures both improved dewatering and better product quality, thus reducing the need for thermal drying. As a result, the energy demand of the tissue machine with shoe press is substantially lower. Perfect edge control is provided by a new, patented control system. The 16 ft. Yankee is made entirely of steel, thus enabling safe operation and efficient drying.

This order once again confirms ANDRITZ’s excellent position as one of the global innovation drivers in the tissue market. ANDRITZ has numerous successful reference plants across the globe, thus demonstrating its strong market position as one of the world market leaders for supply of complete tissue production lines, key components, and services.

Vajda Papír is one of Europe’s most dynamically expanding tissue producers. The 100% Hungarian-owned private company operates tissue production mills in Hungary and Norway and covers the complete tissue product range. Vajda Papír, with its top-quality “Ooops!” brand and many other retail brands that are also supplied to international customers, has gained a leading position as supplier in Hungary as well as playing an acknowledged and dominant role in the Scandinavian markets. During its history covering almost two decades, the company has also won several regional and national awards for its business and product quality and strongly focuses on environmentally friendly tissue production, while meeting the highest standards for all internationally known certificates, such as Nordic Ecolabel and BRC.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors as well as for animal feed and biomass pelleting. Other important business segments include automation and service business. In addition, the international Group is also active in the power generating sector (steam boiler plants, biomass boilers, recovery boilers, and gasification plants) and in environmental technology (flue gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard as well as recycling plants. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,200 employees. ANDRITZ operates more than 250 sites in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

ANDRITZ and Metsä Fibre successfully perform joint program to eliminate fossil fuel use in lime kiln at Joutseno mill, Finland

Metsä Fibre’s CFB gasification plant in Joutseno, Finland “Photo: ANDRITZ”.ANDRITZ and Metsä Fibre have successfully collaborated on a program to maximize reduction of the use of fossil fuels, as well as improve the overall performance of the lime kiln at the Joutseno mill in Finland. The goal of the program, entitled “Gasification Plant 100% Utilization Rate”, was to maximize the availability of all equipment, including the wood processing plant, dryer, gasification plant, and lime kiln, as well as the lime kiln burner and its heat transfer system.

Metsä Fibre’s CFB gasification plant in Joutseno, Finland “Photo: ANDRITZ”.ANDRITZ and Metsä Fibre have successfully collaborated on a program to maximize reduction of the use of fossil fuels, as well as improve the overall performance of the lime kiln at the Joutseno mill in Finland. The goal of the program, entitled “Gasification Plant 100% Utilization Rate”, was to maximize the availability of all equipment, including the wood processing plant, dryer, gasification plant, and lime kiln, as well as the lime kiln burner and its heat transfer system.

As a result of the program, the Joutseno mill has now replaced 95% of natural gas being used in the lime kiln with biomass (bark) derived gas. Moreover, the quality of lime product has markedly improved. The cooperation between the two companies will continue with Overall Production Efficiency (OPE) agreements to further fine tune the systems.

The Joutseno 48 MW gasification plant is based on the Circulating Fluidized Bed (CFB) technology developed by ANDRITZ. Other CFB references include a 65 MW CFB gasification plant supplied to Zhanjiang Chenming Pulp & Paper mill in China; which replaces the heavy fuel oil it used earlier in the lime kiln; and a repeat order from Chenming Group in 2015 with a 80 MW CFB gasification plant for its new greenfield pulp mill, Shouguang Meilun in China.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors as well as for animal feed and biomass pelleting. Other important business segments include automation and service business. In addition, the international group is also active in the energy generating sector (steam boiler plants, biomass boilers, recovery boilers, and gasification plants) and in environmental technology (flue gas cleaning plants), and offers equipment for the production of nonwovens, dissolving pulp, and panelboard (MDF). The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,200 employees. ANDRITZ operates more than 250 sites in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

ANDRITZ AUTOMATION opens two new offices to expand its presence in North America

ANDRITZ AUTOMATION, part of international technology Group ANDRITZ, has opened two new US locations in Pensacola, Florida, and Eugene, Oregon, thus demonstrating its commitment to provide its customers with individual and local support.

The local teams are committed to delivering progressive solutions and high-quality support for their customers’ electrical, control, and instrumentation systems in those regions.

ANDRITZ AUTOMATION offices in North America

ANDRITZ AUTOMATION offices in North America

“The decision to increase our presence in the US was a strategic step in our business growth strategy,” said Milind Karkare, Senior Vice President for the ANDRITZ AUTOMATION Solutions division, which is responsible for serving the automation, electrification, instrumentation, and training needs for a wide range of industries, including local pulp and paper, mining, and lime customers. “These two locations bring us closer to our customers and also increase our ability to serve current and future markets as well as new industries”.

Address and contact details of the two new offices:

ANDRITZ AUTOMATION, Pensacola, Florida:

Contact: Mr. Stephen Stepp, Branch Manager

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Mobile: +1 (850) 460 4436

ANDRITZ AUTOMATION, Eugene, Oregon

Contact: Mr. Carl Robichaud, Branch Manager

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Mobile: +1 (541) 213 1791

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors as well as for animal feed and biomass pelleting. Other important business segments include automation and service business. In addition, the international Group is also active in the power generating sector (steam boiler plants, biomass boilers, recovery boilers, and gasification plants) and in environmental technology (flue gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard as well as recycling plants. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,200 employees. ANDRITZ operates more than 250 sites in over 40 countries.

ANDRITZ AUTOMATION

More than 2,000 ANDRITZ employees worldwide develop automation solutions and products for digitization and

networking of systems and components. ANDRITZ AUTOMATION helps industrial facilities around the world to realize their full potential by maximizing output, minimizing costs, and optimizing operations. The experienced ANDRITZ

AUTOMATION team focuses on the design of electrical, control, and instrumentation systems, drawing on some of the world’s leading simulation, advanced process control, and operator training tools.

ANDRITZ and PulpEye enter into cooperation agreement

International technology Group ANDRITZ and PulpEye have entered into a cooperation agreement to promote, market, and sell PulpEye analyzer technology exclusively in ANDRITZ PULP & PAPER package offerings.

This ANDRITZ and PulpEye cooperation will enable customers to benefit from improved online chip and fiber datalytics in order to optimize the right process parameters in fiberlines and pulping processes, for instance by improving yield and optimizing chemical consumption. Furthermore, ANDRITZ and PulpEye can also provide customers with a remote online platform for operations support through IoT solutions.

PulpEye sampling and analyzing cabinet

PulpEye sampling and analyzing cabinet

PulpEye is an innovative measurement technology company focusing globally on online pulp quality analysis applications for the pulp and paper industry. The PulpEye equipment is used to control the quality of any kind of pulp – sulfate and sulfite pulps, both short and long fiber, bleached and unbleached, TMP, CTMP and BCTMP as well as NSSC, OCC, and de-inked pulps. Recent product launches include modules measuring vessel cells and fiber wall thickness, as well as a fast consistency calibration module.

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

ANDRITZ to rebuild board machine for Knauf Petroboard

International technology Group ANDRITZ has received an order from AO Knauf Petroboard to rebuild the KM 2 board machine at its mill in Kommunar, Russia. The board machine – with a basis weight range from 100-320 g/m2, a working width of 4,260 mm, and a design speed of 700 m/min – has an annual capacity of 155,000 t/a for production of gypsum board made of 100% waste paper raw material. Start-up is scheduled for the fourth quarter of 2018.

The rebuild includes the supply of a new wire section with three PrimeForm SW Fourdrinier wires and new PrimeFlow SW headboxes, one of which contains a PrimeProfiler F consistency profiling system.

ANDRITZ will also supply the main components in the approach flow systems for the top, filler, and back layers at KM 2. The scope of supply comprises several ModuScreen HB-E screens, which combine lowest energy requirements with minimum pulsations at lowest fiber loss. A new ANDRITZ couch pit pulper will manage broke handling. In order to significantly improve water management of the mill, a fiber recovery system with an ANDRITZ save-all Disc Filter will be installed.

ANDRITZ will supply a new wire section with three Fourdrinier wires to Knauf Petroboard, Russia. “Photo: ANDRITZ”.

ANDRITZ will supply a new wire section with three Fourdrinier wires to Knauf Petroboard, Russia. “Photo: ANDRITZ”.

ANDRITZ AUTOMATION will deliver a complete new Multi Motor Drive for the entire machine as well as the electrification and automation equipment. The delivery will be handled on an EPC basis, where ANDRITZ takes responsibility for the installation work, including piping and cabling, as well as the required supervision works related to erection, commissioning, and training.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors as well as for animal feed and biomass pelleting. Other important business segments include automation and service business. In addition, the international Group is also active in the power generating sector (steam boiler plants, biomass boilers, recovery boilers, and gasification plants) and in environmental technology (flue gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard as well as recycling plants. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,200 employees. ANDRITZ operates more than 250 sites in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

Knauf – a family business

Knauf is one of the leading manufacturers of building materials and systems in Europe and far beyond. Knauf is operating worldwide, with production facilities and sales organizations on all five continents in more than 80 countries and at more than 220 locations. Knauf plants produce modern dry-lining systems, plasters and accessories, thermal insulation composite systems, paints, floor screed and floor systems, equipment and tools for applying these products, as well as insulation materials.

AO KNAUF PETROBOARD

AO KNAUF PETROBOARD is a Russian structural unit of the international KNAUF Group, which has been investing in Russia for almost 25 years. KNAUF has 15 new or fully renovated production companies in Russia, with 36 production plants manufacturing 1,400 products.

KNAUF PETROBOARD has a leading position on the markets in Russia and the CIS countries in manufacture of packaging and wall lining board used to make gypsum plasterboard. The main raw material used in the manufacture of lining board is waste paper. Implementation of this project will provide the means to cover the growing demand for lining board from companies in Russia and the CIS countries and make them less dependent on import of these products.

ANDRITZ successfully starts up second tissue machine with steel Yankee for Hebei Yihoucheng, China

International technology Group ANDRITZ has successfully completed start-up of the second tissue machine supplied to Hebei Yihoucheng, China.

The PrimeLineCOMPACT tissue machine has a design speed of 1,650 m/min and a width of 2.85 m. The Yankee, manufactured entirely of steel, has a diameter of 3.65 m. It is the “twin” of its predecessor, the TM1, that was started-up successfully in 2014.

The start-up teams of Hebei Yihoucheng and ANDRITZ celebrate the first paper on reel. “Photo: ANDRITZ”

The start-up teams of Hebei Yihoucheng and ANDRITZ celebrate the first paper on reel. “Photo: ANDRITZ”

The order also included supply of the complete stock preparation plant, automation, and drives. The tissue machine and its components were manufactured at ANDRITZ production sites in Europe and China. With this turnkey delivery, ANDRITZ is once more strengthening its position as one of the leading suppliers of tissue machines and services to the Chinese paper industry.

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

ANDRITZ presents “Metris – Industrial IoT Solutions”

International technology Group ANDRITZ has combined its innovative IoT (Internet of Things) solutions, which are field-proven in many reference plants, with immediate effect under the technology brand “Metris – Industrial IoT Solutions”. Metris technologies are the very latest state-of-the-art in the IoT/Industry 4.0 sector and can be fully tailored to individual customer requirements.

Substantial customer benefits

Based on extensive and long-term experience as a supplier of technologies and systems for various industries, ANDRITZ offers a broad portfolio of intelligent, digital solutions that provide significant support to customers in achieving their production and corporate goals:

- Enhancing plant efficiency and profitability

- Optimizing the use of resources

- Constant and highest product quality

- Avoiding production downtime

- Maximum user-friendliness, for example easy control via smartphone or tablet PC

Metris is based on three pillars of technology: Smart Sensors, Big Data, and Augmented Reality.

In addition to the use of conventional Smart Sensor technologies for analysis of measurements and signals, ANDRITZ offers micro and wireless sensors as well. This can be used to optimize operation of the plants or systems by analyzing specific parameters that are freely selected by the customer.

Metris – Industrial IoT Solutions: technology brand of the ANDRITZ GROUP for innovative IoT solutions for various industries Photo - Andritz

Metris – Industrial IoT Solutions: technology brand of the ANDRITZ GROUP for innovative IoT solutions for various industries Photo - Andritz

In the Big Data sector, Metris products calculate any deviations in production in advance by means of field-proven simulation processes and use them to derive the control actions required. In this way, for example, production downtime can be avoided or the use of consumables reduced.

With Augmented Reality applications, information is made visible where it is needed, which is on the spot at the plant itself. The technology focuses on showing the information in context so that the operating personnel gets the best possible support, particularly for complex control actions.

ANDRITZ OPP: successful IoT solution already in use for many years

Over ten years ago, ANDRITZ developed OPP (Optimization of Process Performance) – a system to optimize equipment and plants in the pulp and paper industry – for the PULP & PAPER business area and has continued to improve it further on the basis of customer experience. The OPP system detects any anomalies and deviations in pulp and paper production at an early stage by analyzing production data. Sheet breaks or other adverse effects on production can thus be predicted at an early stage.

As a result, countermeasures can be implemented in good time, guaranteeing reliable production and also optimizing operations and the use of resources. ANDRITZ OPP systems are being used successfully all over the world. Large corporations like Metsä Fibre, Smurfit Kappa, or Fibria have relied on the success of the OPP system for many years.

Now ANDRITZ has developed OPP further for use in other business areas and is offering solutions for different sectors. The technologies used are adapted to the requirements and needs of each individual customer.

Gerhard Schiefer, head of ANDRITZ AUTOMATION: “With Metris, we are combining all of the ANDRITZ GROUP’s IoT solutions under a single technology brand that stands for innovation and know-how. We offer scalable, multi-branch IoT solutions down to machine level that can be used for new and also existing machines and systems and support our customers substantially in achieving their goals in terms of productivity and efficiency in the best possible way.”

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors as well as for animal feed and biomass pelleting. Other important business segments include automation and service business. In addition, the international group is also active in the energy generating sector (steam boiler plants, biomass boilers, recovery boilers, and gasification plants) and in environmental technology (flue gas cleaning plants), and offers equipment for the production of nonwovens, dissolving pulp, and panelboard (MDF). The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,200 employees. ANDRITZ operates more than 250 sites in over 40 countries.

ANDRITZ AUTOMATION

More than 2,000 ANDRITZ employees worldwide develop automation solutions and products for digitization and

networking of systems and components. ANDRITZ AUTOMATION helps industrial facilities around the world to realize their full potential by maximizing output, minimizing costs, and optimizing operations. The experienced ANDRITZ

AUTOMATION team focuses on the design of electrical, control, and instrumentation systems, drawing on some of the world’s leading simulation, advanced process control, and operator training tools.

ANDRITZ to acquire Paperchine, USA

International technology Group ANDRITZ has signed a contract for acquisition of Paperchine, Inc., owned by AstenJohnson Holdings Ltd., headquartered in Charleston, SC. Paperchine and its subsidiaries have approximately 180 employees in total and manufacturing facilities in the USA (Rockton, IL, Springfield, MA, and Tucker, GA), Canada (Vancouver), Thailand (Bangkok), and Germany (Maintal). The purchase is subject to approval by the antitrust authorities and is expected to be closed by the end of June 2017.

Paperchine is a global supplier of highly engineered equipment and services to the paper industry’s leading manufacturers. For ANDRITZ, the acquisition of Paperchine strengthens its presence in North America and adds new products, such as the horizontal GapFormer, SigmaPro headbox, dewatering elements (former Johnson Foils), moisturizer (former VIB), and related service to its offerings for international clients. “We are very excited about this complementary acquisition that extends the ANDRITZ product range for paper and board machines,” says Michael Pichler, SVP ANDRITZ Global Pulp Drying and Paper Division Manager.

Paperchine is a global supplier of highly engineered equipment and services to the paper industry’s leading manufacturers. For ANDRITZ, the acquisition of Paperchine strengthens its presence in North America and adds new products, such as the horizontal GapFormer, SigmaPro headbox, dewatering elements (former Johnson Foils), moisturizer (former VIB), and related service to its offerings for international clients. “We are very excited about this complementary acquisition that extends the ANDRITZ product range for paper and board machines,” says Michael Pichler, SVP ANDRITZ Global Pulp Drying and Paper Division Manager.

AstenJohnson CEO, Kevin Frank, comments: “The sale of Paperchine fits with our strategy to focus on growth in technical textiles, including paper machine clothing, advanced fabric, and nonwovens. Our friends and associates at Paperchine have successfully positioned the company as a leading global brand. They will have the opportunity to continue to grow with the support of ANDRITZ, while building on the strong foundation they have established as a part of the AstenJohnson family.”

The two companies are excited to be working together on a formal marketing alliance with the equipment supplied by Paperchine and ANDRITZ to better support paper industry customers. More details will be forthcoming as the agreement is finalized.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors as well as for animal feed and biomass pelleting. Other important business segments include automation and service business. In addition, the international Group is also active in the power generating sector (steam boiler plants, biomass boilers, recovery boilers, and gasification plants) and in environmental technology (flue gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard as well as recycling plants. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,200 employees. ANDRITZ operates more than 250 sites in over 40 countries.

About AstenJohnson

AstenJohnson is a global manufacturer of pulp & paper machine clothing, advanced and filtration fabrics, filaments, and nonwoven fabrics for filtration, automotive, cure-in-place piping and composites. As a supplier to the paper industry since 1790, it has a thorough knowledge of technical textiles and processes – and knows how to apply its expertise to help customers be more profitable. The company employs approximately 2,000 people. Its corporate headquarters are in Charleston, South Carolina, USA.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

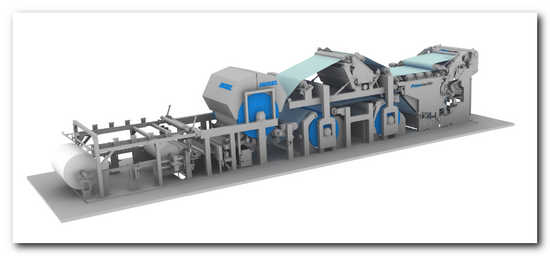

ANDRITZ to supply TAD tissue machine to First Quality Tissue, USA

International technology Group ANDRITZ has received an order from First Quality Tissue to supply a PrimeLineTAD tissue machine with complete stock preparation for its mill in Lock Haven, USA. Start-up is scheduled for 2019.

The TAD (Through-Air-Drying) tissue machine has a capacity of approximately 70,000 tons per year. The improved softness, absorbency, and bulk generated by the TAD technology give these products superiority over products made using conventional processes. ANDRITZ has supplied two TAD machines previously to First Quality Tissue’s Lock Haven mill.

3D sketch of an ANDRITZ PrimeLineTAD tissue machine. “Photo: ANDRITZ”.

3D sketch of an ANDRITZ PrimeLineTAD tissue machine. “Photo: ANDRITZ”.

First Quality Tissue, which markets its products under the brand name “PlentyTM”, is one of the leading private label producers worldwide of TAD premium quality tissue and towel products. It currently operates five tissue machines in the USA (two at Lock Haven, Pennsylvania and three at Anderson, South Carolina).

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.