Displaying items by tag: Toscotec

Toscotec steps up Yankee hood efficiency with TT Drying Equilibrium

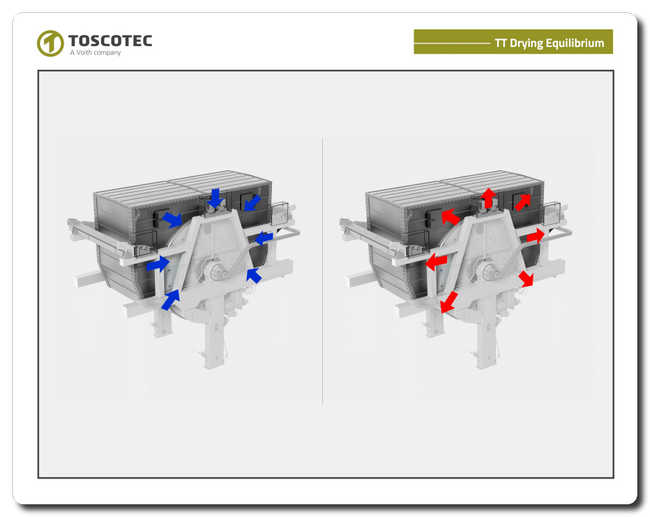

Toscotec boosts the drying efficiency of its tissue lines with TT Drying Equilibrium, a simple and reliable system that ensures an optimal and automatic regulation of the air balance in the Yankee hoods and air system. The system was originally designed by Voith and transferred to Toscotec for further development in the synergy-creating cooperation established with the acquisition. TT Drying Equilibrium measures several attributes of the air going in and out of the hoods, and automatically adjusts the system to guarantee the highest productivity and energy efficiency.

Stefano Pecchia, Energy Technology Director at Toscotec, says: “In a properly balanced hood system, the masses of gases - vapour and dry air - that are fed into the system are equal to those that go out through the chimney as exhaust air. This balance is crucial to avoid fresh air getting in and hot air going out during manufacturing; in this way, you can achieve maximum drying efficiency. We recommend the automatic balancing system especially on tissue machines that frequently change basis weight during the production cycle. It would be more complicated for operators to balance the system manually at every change; TT Drying Equilibrium makes these adjustments automatically, in a much faster and more effective way.”

The control and regulation logics are managed by a dedicated PLC (Programmable Logic Controller) that communicates with the DCS (Distributed Control System) of the tissue machine. The mill can easily access the data collected, stored and organized by the PLC on local monitors, tablets, or smartphones, through a remote connection.

Ensure product quality

A lack of balance in the hoods can be triggered both by over-pressure that causes hot air to go out, and by under-pressure that causes cold air to be pulled into system through the gap between the Yankee and the hoods. These imbalances will reduce energy efficiency, give rise to paper quality issues, cause environment-related issues, and potentially be unsafe to personnel. In fact, in the event of air suction, cold air on the paper can lead to its detachment from the Yankee surface and to an uneven moisture profile. In case of over-pressure, hot air can cause overheating of the surrounding area with increased fire risks, discomfort or danger for operators, possible damage to adjacent equipment, and deterioration of the environmental conditions of the machine hall. By ensuring hood balance, TT Drying Equilibrium contributes to effectively avoid these issues and deliver the best possible product quality.

An effective twofold Balance Control

TT Drying Equilibrium consists of a set of various transmitters of physical data, including speed, flow rate, temperature, humidity, and pressure, and of a data acquisition and processing system.

The calculation algorithms produce the mass flow rates inside all the air ducts leading into and out of the Yankee hoods, including outgoing air, make-up air, and combustive air both on wet-end and dry-end.

The combustion air is regulated by the burner control system, while the flow of exhaust air can be regulated by the moisture control loop. TT Drying Equilibrium controls the dampers that allow for make-up air to enter the system, thereby maintaining a condition of balance over time.

In addition to controlling the air mass flows, the system also checks the actual balance using temperature sensors installed just outside the Yankee-Hoods gap and of pressure transmitters inside the hoods. As a result, TT Drying Equilibrium delivers an effective twofold balance control in real time, based on the calculated balance of the masses, and on the confirmation that hot air is not escaping or cool air is not being pulled in around Yankee and Hoods.

A key tool to monitor Machine Efficiency & optimize Production and Maintenance

TT Drying Equilibrium also enables real time monitoring of the energy performance of the tissue machine. It processes production data acquired from the DCS and produces precise figures or trends relating to the tissue machine’s energy consumptions, including steam, gas, and electrical power consumption.

It also acquires key data of the air system’s heat recovery units, including inlet and outlet temperatures and flow rates, to monitor their performance, and plan maintenance activities. This allows the mill to check production efficiency by product over time, and to perform preventive maintenance.

For more information, please contact:

Marco Dalle Piagge, Sales Director, Toscotec Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Toscotec to supply a wet end rebuild to Dunn Paper in Michigan

Dunn Paper selected Toscotec for the rebuild of the wet section of PM2 at its Menominee paper mill in Michigan, USA. The paper machine produces specialty papers including MG grades and flexible packaging products.

In 2017, Toscotec had installed a custom-made TT Headbox at Dunn Paper’s St. Catharines paper mill in Canada. Based on the successful experience of this rebuild, Dunn Paper Menominee asked Toscotec to create a preliminary engineering solution that met PM2’s production and quality targets. Finally, Dunn Paper awarded the rebuild order to Toscotec, valuing the importance of a fully-customized technical offer based on the analysis of the machine’s operating data. Toscotec will supply the approach flow system, and a hydraulic TT Headbox-SL fitted with dilution control. The service package includes erection supervision, commissioning, and start-up assistance.

Steve Michalko, Dunn Paper Manufacturing Director, says: “In recent years Dunn Paper has been making significant investments into our mills and processes in order to better ourselves and meet the demands of the ever changing market and standards of our growing customer base. By upgrading to a Toscotec dilution profiled headbox in addition to their screening and water system improvements, we will improve the uniformity and formation of our base sheet, increasing our capability to meet current and future customer requirements. A big thanks to Toscotec for helping with this mill improvement.”

Fabrizio Charrier, Toscotec Sales Manager, says, “Having the chance to support Dunn Paper Menominee on this rebuild makes me very proud. Toscotec’s TT Headbox-SL has a consolidated design that has proved successful on numerous references over the years. This important project confirms that Toscotec can rebuild all sections of the paper machine, and this will open up new opportunities for Toscotec in North America to supply key paper machine components, project studies and tailor-made solutions.”

About Dunn Paper

Established in 1924, Dunn Paper is a tissue and specialty paper manufacturer and converter. It operates 7 paper mills throughout the USA and Canada. With a focus on product development and sustainability, Dunn Paper caters to top brands and converters across North America, creating innovative sustainable paper products for food services, the medical and retail industries, as well as hygiene products.

For further information, please contact:

Fabrizio Charrier, Sales Manager, Toscotec Paper & Board division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Sofidel attains high efficiency and premium quality on Toscotec’s lines.

In 2020, Sofidel added 120,000 tons a year to its production capacity in the USA with two Toscotec AHEAD 2.0L paper machines in 5,500 millimetre format with an operating speed of 2,000 metres a minute. Toscotec has delivered a turnkey product for the tissue-making area of Sofidel America’s integrated paper mill in Inola, Oklahoma. Since the launch of two new lines, Sofidel has been manufacturing premium quality tissue paper, in compliance with its rigorous quality standards, and has maintained a high level of operating efficiency, fully benefiting from the energy and environmental efficiency of Toscotec’s AHEAD lines, which feature the TT SYD Steel Yankee Dryer and high energy recovery TT Hoods. In this interview, Simone Capuano, the Executive VP, Operations & Supply Chain, of Sofidel America Corp. discloses the strategy underpinning this investment and tells us what Sofidel has achieved so far at its Inola production base.

Sofidel America’s new integrated production base in Inola: what were the reasons for this expansion and for choosing Toscotec’s technology?

The construction of an integrated plant in Inola (Oklahoma) is an important part of the growth strategy that Sofidel has implemented in the USA since its arrival in the country in 2012. After Circleville (Ohio), this is the second greenfield investment of our Group in the USA, aimed at increasing our production capacity and our geographical coverage, which means having plants close to our customers - in this case, specifically, we are in the southern region - in order to improve our service and contain logistical costs. In this context, Toscotec was the right choice, because its technology is efficient both from the energy and environmental points of view, and because of the experience and flexibility they have gained in our sector.

Toscotec was your turnkey supplier for paper mill production on the Inola project. Was it helpful for you to have a single company as your reference point for this part of the supply?

Building a new paper mill from scratch is never an easy task, both for technical and organizational reasons. In Oklahoma, like everywhere else in the USA, we have been able to count on excellent collaboration from local institutions and partners. We certainly found it very helpful to have a single supplier as our contact for the paper mill production part, especially since part of the project was carried out in the first and most complicated stage of the COVID-19 emergency, with all the problems that implied.

Are you satisfied with Toscotec’s management at this time of global emergency?

Even though we had to face unpredictable and complicated situations, Toscotec's flexibility, contribution and spirit of collaboration have never been lacking. We appreciated their dedication and problem-solving skills.

Once Toscotec’s machines came on line, did you see an increase in the OEE (Overall Equipment Effectiveness) compared to processing reels from other production sites, as you were doing before? Has converting efficiency improved? If yes, why?

Having an integrated plant has already improved production efficiency. Furthermore, the AHEAD 2.0L machines used on our lines represent a tried and tested technology that did not require any fine-tuning. As we expected, they were immediately found to be in line with the needs of our customers. The fact that we could count on reels with a larger diameter and constant quality has definitely allowed us to increase the efficiency of our converting lines.

What grades are you currently manufacturing on PM1 and PM2? What is your assessment of product quality?

The quality standard is high and meets our customers’ requirements and, at the same time, it allows us to achieve excellent performances at the plant in terms of energy efficiency and optimization of raw material use. This is in line with Sofidel's commitment to reconcile the market and consumption needs with those of sustainability. On the two machines, we are producing various grades both for toilet tissues, with particular attention to Super Soft papers, and kitchen towels.

Are you satisfied with the specific consumption of chemical products per ton of paper produced that is being recorded by the two machines?

Yes, we are also recording significant improvements in this area, although the optimizing of the entire system must continue.

Overall, how would you describe the cooperation with Toscotec?

A positive cooperation built on hard work and mutual commitment to continuous improvement.

Toscotec’s new tissue line starts up at Thai C.A.S. Paper Mill.

The new AHEAD 1.5S machine has a trim width of 2,850 mm, an operating speed of 1,850 m/min, and produces more than 30,000 tpy of premium quality tissue. The machine configuration is designed to guarantee top energy efficiency with TT NextPress shoe press design, TT SYD Steel Yankee Dryer, and steam-heated TT Hood-Hybrid.

The supply included the stock preparation equipment and accessories, the patented TT SAF (Short Approach Flow) system, the fiber recovery system, dust and mist removal systems, and a complete slitter rewinder line, with dedicated dust removal system. Toscotec also provided a comprehensive service package, including the tissue machine’s erection, erection supervision, commissioning, training and start-up assistance, as well as YES-CONNECT-VISION augmented reality solution for remote service.

Torpong Thongcharoen, Managing Director of C.A.S. Paper Mill, said: “With this new line C.A.S. Group enters the tissue market. We are already producing high quality tissue, and we expect to kick off distribution very quickly. Throughout the entire project, including the hardest times during the pandemic, we always had a very good cooperation with Toscotec, who proved to be the experienced and skilled supplier we expected, managing the project with great flexibility and supporting us all the way to our target.”

Marco Dalle Piagge, Toscotec Sales Director, comments: “This start-up is a reward to us all for the hard work we put into this project in order to successfully complete it during Covid-19. This AHEAD line is designed to deliver top energy efficiency that results in low energy consumptions and low operating costs. C.A.S. Paper Mill is now fully equipped to enter the tissue market from an advantage position.”

About C.A.S. Paper Mill Co., Ltd.

C.A.S. Paper Mill Co., Ltd is part of the Charoen Aksorn Holding Group (C.A.S. Group). Established in 1963, C.A.S. group is a well-established paper trading company in Thailand. In 2013, the Group acquired from Norske Skog (Thailand) a newsprint mill in operations since 1994, and it was named C.A.S. Paper Mill. The company operates a pulp and paper mill situated in Sing Buri, near Bangkok, Thailand.

For further information, please contact:

Gabriele Martinelli, Sales Manager, Toscotec Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Toscotec accomplishes a dryer section rebuild at Cartiera di Ferrara, Italy

After a complete dryer section rebuild supplied by Toscotec, Cartiera di Ferrara fired up PM1 at its mill in Ferrara, Italy. Toscotec modified the entire dryer section, without changing its overall length and therefore leaving the positions of the press and the pope reel unchanged. This allowed for a very short shutdowntime because civil works were not necessary to achieve the planned production increase. The paper machine achieved stable production immediately after start-up.

Toscotec refurbished the first dryer section with the supply of new felt rolls, guide and stretchers, and a modification of the frame structure. The second section was completely rebuilt with 16 new TT SteelDryers of 1,829 mm diameter designed for an operating steam pressure of 10 barg. Toscotec supplied new silent drives for the transmission of the entire dryer section that significantly improved PM1’s conditions for operation and maintenance. The scope comprised a full set of services, including mechanical erection, supervision, commissioning, and start-up assistance.

Cartiera di Ferrara, Italy.

Cartiera di Ferrara, Italy.

Alessandro Castelletti, Mill Manager of Cartiera di Ferrara, says: “Toscotec executed the rebuild with competence and according to the agreed time plan. We boosted PM1’s operating speed because of the increased drying capacity of our new dryer section. We will progressively continue to raise the speed as we still have margin. The production is stable, and we are happy with the results we achieved so far.”

Stefano Baldi, Toscotec Project Manager, says: “We lived up to the double challenge of a tight project schedule that began right before Italy enforced nationwide Covid-19 restrictions. We managed to complete on time the pre-assembly phases during lockdown, and then finalized the installation according to schedule. We are happy to see that Cartiera di Ferrara is already increasing their production capacity as a result of this rebuild.”

About Cartiera di Ferrara S.p.A.

Established in the 1940s, Cartiera di Ferrara is an integrated paper mill producing high quality core board and high-resistance tubes and cores. It operates one paper machine at its production base in Ferrara (Italy). Its products are sold to the Italian and export markets.

For further information, please contact:

Enrico Fazio, Head of Sales, Toscotec Paper & Board division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Toscotec finalizes a drying section rebuild at Cartiera San Giorgio, Italy.

Cartiera San Giorgio successfully started up its PM1 after the complete rebuilt of its dryer section by Toscotec. PM1 has a trim width of 2,500 mm, and produces wet creped tissue in the basis weight range from 30 to 50 gsm, using virgin cellulose and recycled paper.

Following the installation of a TT SYD Steel Yankee Dryer that replaced PM1’s existing cast-iron Yankee in 2012, Toscotec has now completed the full upgrade of the drying section of this paper machine by rebuilding the post-dryer section. The rebuild supply included eight TT SteelDryers designed for an operating steam pressure of 10 barg, and the tail threading system installed between the TT SYD and the post-dryer section. The project also includes the engineering design, on site erection, commissioning and start-up assistance.

Alessandro Ardinghi, owner of Cartiera San Giorgio, comments: “The targets of this rebuild have been fully accomplished. We optimized PM1’s production and significantly improved the moisture profile on the edges. We have known Toscotec for many years, and we are happy with how they managed the project and delivered on the results we expected.”

Gian Luca Fornesi, Head of Sales Application at Toscotec, says, “With this project, Toscotec confirmed its ability to address and resolve specific production problems. For Cartiera San Giorgio, we carried out a survey and developed a custom-made design for their TT SteelDryers, in order to meet their needs and eliminate their production bottlenecks.”

About Cartiera San Giorgio

Founded in 1974, Cartiera San Giorgio manufactures wet creped tissue jumbo rolls and tissue products for the AfH market. The current production capacity is 21,000 tpy. Its product range for the AfH and private label markets includes towels dispensers and tissue products used in working environments.

For further information, please contact:

Gian Luca Fornesi, Head of Sales Application, Toscotec Paper & Board division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Lucart validates Toscotec’s TT Defender ability to increase Yankee efficiency.

Toscotec has recently introduced TT Defender, a leading-edge patented innovation that provides Yankee dryers with an effective internal protection coating against corrosive steam. Toscotec has successfully tested TT Defender at Lucart Group’s Diecimo tissue mill in Italy on a TT SYD that came online in February 2020.

Danilo Calamari, Lucart’s Paper Mill Senior Engineer & Cogeneration Plants Manager, is the technical expert who closely followed the project in Lucart. In this interview, he shares Lucart’s experience with TT Defender and his professional views on the results they achieved so far.

The TT SYD installed on your PM5 in Diecimo is fitted with TT Defender. During the regular checks you performed 6 months after start-up, you personally entered inside the Yankee. Which conditions did you find?

The TT SYD installed on your PM5 in Diecimo is fitted with TT Defender. During the regular checks you performed 6 months after start-up, you personally entered inside the Yankee. Which conditions did you find?

D.C.: I was pleasantly surprised at how good the Yankee looked inside. During our regular Yankee checks, we often find some magnetite deposits and soda straw blockage. Instead, the TT SYD on PM5 appeared as if it were new, or even better: the entire internal surface and all the straw pipes were perfectly clean. Evidently, during its six months of operation, no magnetite deposits had formed inside the Yankee. This result validated our decision to participate in this project. To be honest, at the beginning when Toscotec suggested they test this new technology on our TT SYD, we were not entirely convinced. Finally, we decided to get on board, because we have had a very good cooperation with them for many years, and we trust their professionalism and reliability as a supplier.

Mill technicians know very well that in the ordinary operation of the steam and condensate system, it is quite common to go through transitory phases or issues that cause some of the chemical and physical values under control to fall short of the requirements for the proper functioning of the plant. Does TT Defender represent an additional security in this regard? Do you think that it allows your Yankee to have a greater tolerance to these kind of normal variations?

D.C.: Yes, we do. TT Defender allows us to overcome some possibly critical issues in the chemical treatment of the steam and condensate system of PM5 without consequences. We can now successfully manage these phases that are completely normal throughout the year.

Before the TT SYD with TT Defender, Toscotec had installed another TT SYD on your PM6, which is right next to PM5 and shares the same steam and condensate system. In terms of drying performances, did you find that the drying capacity of the steel Yankee with TT Defender was any different from the other?

D.C.: Apart from TT Defender, the two TT SYDs installed on PM5 and PM6 have the same characteristics, so we could easily compare their performances under various operating conditions. We did not find any limitation in the drying capacity of the TT SYD with TT Defender. Before the application, one might wonder if TT Defender could hinder the heat exchange between the Yankee’s internal and external surface on which its drying capacity is based upon. The actual result is that TT Defender does not affect the Yankee’s thermal efficiency in any way. In one year of operations, we found that the two TT SYDs on PM5 and PM6 perform equally well.

Do you think that TT Defender allows you to eliminate the risk of longer maintenance stops due to the obstruction of soda straws?

D.C.: At Lucart, we perform one regular internal Yankee inspection per year. We will check PM5’s TT SYD this summer, but what we can say now is that we are not experiencing any issues with tissue quality that could point to soda straw blockage. The paper we are producing on PM5 is high quality and has a very uniform cross-direction moisture profile. This suggests that when we will open up the Yankee later this year, we will most likely do just a quick check, without allocating extra personnel and extend the downtime in order to clean or replace soda straws. With TT Defender, we expect to find a Yankee that is always clean, and allows us to realize the best production efficiency in terms of both quality and quantity.

For further information, please contact:

Marco Dalle Piagge, Sales Director, Toscotec Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Toscotec launches new YES-CONNECT-VISION AR system for effective remote service

Toscotec upgraded its YES-CONNECT-VISION AR (Augmented Reality) system to provide faster and more effectiveremote services. After launching the first version in 2018, Toscotec perfected the system based on user feedback and practice in the field. With this improved tool, mill operators wearing an ergonomic helmet fitted with a high definition camera send out high-resolution images and audio in real time, becoming the eyes and the ears of Toscotec’s service team inside the mill.

Toscotec’s experts can actively interact with these inputs in real time by highlighting components in the operator’s field of view, sending relevant documentation to their helmet’s visor and guiding them on adjusting the machine. Toscotec’s service team can acquire all the information they need to provide solutions, get around lack of technical know-how, or language-related issues in communication.

Toscotec’s YES-CONNECT-VISION AR system.

Toscotec’s YES-CONNECT-VISION AR system.

YES-CONNECT-VISION is designed to ensure maximum safety to the operator who is wearing the helmet with dust-tight and watertight hardware. With an easily adjustable binocular visor, a wide angle camera that offers a 150-degree visual field, a selective microphone and noise-cancelling headset, technicians can safely move around in the mill with large visibility of surroundings, and operate hands-free, while receiving clear audio signals even in highly noisy areas.

YES-CONNECT-VISION digital solution increases service efficiency, thereby reducing downtime and boosting production efficiency. When travel options are limited or if it’s desired to retain the option of on-demand remote service, Toscotec offers an effective tool that reduces downtime, costs and carbon emissions.

Girolamo Panepinto, Toscotec Start-up & Service Software Engineer, says: “YES-CONNECT-VISION is perfectly suited for trouble-shooting service, on-remote factory acceptance tests, and commissioning tests. Customers can also use it for one on one training at the customer site, or group training from the Toscotec factory floor. For instance, a Toscotec engineer could demonstrate a maintenance task with up to 11 remote connected viewers. With price-competitive service subscriptions, paper mills can get 24/7, worry-free service. We are simply a phone call away from the solution to their technical problem.”

For further information, please contact:

Girolamo Panepinto, Toscotec Start-up & Service Software Engineer, This email address is being protected from spambots. You need JavaScript enabled to view it.

JSC Yarpaper successfully starts up PM1 after major rebuild by Toscotec

Toscotec successfully accomplished an extensive rebuild of Russian containerboard manufacturer JSC Yarpaper’s PM1 at their mill in Yaroslavl, near Moscow. PM1 has a wire width of 2,830 mm and produces 100% recycled-based fluting and test liner in the range from 90 to 175 gsm.

The rebuild has optimized the entire paper machine, from the approach flow system to the dryer section, and has achieved the targets of production increase and quality upgrade.

The scope of the rebuild included the approach flow system, with screens, fan pumps, a TT Headbox-H equipped with TT D-Profiler dilution control system, a newly designed Fourdrinier make up, and the optimization of the sheet path in the press section.

Toscotec installed a completely new dryer section, fitted with 35 TT SteelDryers designed for 10 barg operating pressure, structural frame, canvas rolls, doctors, stabilization boxes, stretchers, guiding, tail threading system, oil lubrication unit, as well as mechanical drives for the entire line.

The project also included a complete service package with engineering, erection supervision, commissioning, start-up assistance, and training.

Igor Noskov, Project Manager of JSC Yarpaper, says, “We successfully completed a major rebuilding operation on our paper machine in difficult times during Covid-19. We have expanded our range of high quality containerboard papers to 90-175 gsm and have increased our reel width to 2,500 mm. This will allow us to better serve our Russian customers, and expand to Europe and the Middle East.”

Luca Nesi, Toscotec Start-up Engineer, comments, “The cooperation with Yarpaper was very good throughout the entire project. They provided the best conditions for Toscotec to work on site during the pandemic. We could thoroughly prepare the machine, so that at start-up we got paper on the pope reel shortly after sending stock to the new TT Headbox. It is a great satisfaction to witness the successful completion of such an extensive rebuild, where we newly designed or extensively rebuilt most sections of the paper machine to deliver a significant production increase.”

About JSC Yarpaper

Established in 2003, JSC Yarpaper specializes in the production of paper and cardboard, using 100% recycled raw materials that are certified according to FSC requirements. In 2020, it recycled 65,000 tons of waste paper. It currently produces 70,000 t/y of fluting and test liner. Its customer base is made of leading Russian corrugated packaging producers, including GOTEK, ARCHBUM, Stora Enso Packaging, Mondi Group, Yaroslavsky Karton.

For further information, please contact:

Gian Luca Fornesi, Head of Sales Application, Toscotec Paper & Board division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Toscotec to supply an AHEAD 2.2S tissue line to Europap Tezol Kağit in Turkey

Europap Tezol Kağit will boost capacity with a Toscotec-supplied AHEAD 2.2S tissue machine at its integrated production base in Mersin, Turkey. This is a repeat order for Toscotec who already supplied a TT SYD steel Yankee dryer installed on their PM1 in 2012. The new line is scheduled for start-up in mid-2022.

The AHEAD 2.2S machine has a sheet trim width of 2,920 mm, a maximum operating speed of 2,100 mpm, and an annual production capacity of over 40,000 tons. It is equipped with TT NextPress with upgraded design, third-generation TT SYD, TT Reel-BulkyReel for optimal preservation of bulk and softness, and high efficiency TT Hood with automatic balancing system.

The supply features the complete stock preparation system and Toscotec’s patented TT SAF® (Short Approach Flow) equipped with a double dilution system to ensure electrical consumption reduction. The scope also includes Toscotec’s proprietary DCS system, electrification and controls, as well as dust and mist removal systems. Two OPTIMA slitter rewinders fitted with an automatic shaft puller complete the supply. Toscotec will provide a complete service package with detailed mill engineering, erection supervision, commissioning, training, and start-up assistance.

Ersin Tezol, CEO of Europap Tezol Kağit, says, “Our production capacity expansion required the most advanced technology at a cost-attractive price. Toscotec’s technology was the best choice to meet the strict environmental requirements of our company and the high quality standards of our super-prime brands, especially for softness and hand feel.”

Matteo Giorgio Marrano, Toscotec’s sales manager, says, “This AHEAD 2.2S machine will allow Europap Tezol to achieve its target of production increase and prime quality. The configuration with TT NextPress and TT SYD of new generation and high recovery TT Hood aims to provide the highest possible level of energy efficiency on a tissue production line. Toscotec also strengthens its presence in the Turkish market, which is growing into a key market in the EMEA region.”

About Europap Tezol Kağit San. Tic. Inc.

Established in 2004, Europap Tezol is a major manufacturer in the Turkish tissue market and it operates two tissue mills with integrated converting, in Torbali-Izmir and in Mersin-Tarsus (Turkey), with an annual production of 100,000 tons. Tezol distributes its branded products and AfH tissue, including wipes, napkin, toilet and towels, in Turkey, as well as Europe, the Middle East, Russia and Latin America.

For further information, please contact:

Matteo Giorgio Marrano, Area Sales Manager, Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.