Displaying items by tag: valmet

Valmet to supply an extensive paper machine grade conversion rebuild to Modern Karton in Turkey

Valmet will supply an extensive paper machine grade conversion rebuild and a wide scope of automation to Modern Karton Sanayii Ve Ticaret at its Tekirdağ Mill in Turkey. In the project, paper machine PM 3 which is currently producing recycled containerboard, will be rebuilt to produce high quality coated containerboard grades. The start-up of the rebuilt paper machine is scheduled for the beginning of 2022.

The order is included in Valmet's orders received of the third quarter 2020. The value of the order will not be disclosed. The value of an order of this type is typically around EUR 40-50 million.

“We chose Valmet as our strategic partner to support our growth strategy. We value Valmet’s high technical expertise and expect to have excellent cooperation in the project,” says Hamdullah Eren, Chairman of the Board of Modern Karton.

“We chose Valmet as our strategic partner to support our growth strategy. We value Valmet’s high technical expertise and expect to have excellent cooperation in the project,” says Hamdullah Eren, Chairman of the Board of Modern Karton.

“The cooperation during the sales phase was excellent, which sets a good foundation for the project. Valmet’s coating process knowhow and the convincing references made our solution very appealing to the customer,” says Petteri Soini, Senior Sales Manager, Valmet.

Technical details about the delivery

Valmet's grade conversion delivery will include modifications in the existing stock preparation line and paper machine. The scope includes broke collection system, white water system and modifications to the approach flow system. The delivery in the existing paper machine will include three new OptiFlo Foudrinier headboxes, modifications to forming, press, pre-drying and sizing sections. The delivery will also include a completely new coating section with OptiCoat Layer curtain coating station, OptiCoat Jet blade coating station, a coating color preparation system, supply systems for both coating stations, an OptiCalender Soft calender and an OptiReel Linear center-driven reel.

The delivery will also include rebuilding of the existing air systems with e.g. new open hood, heat recovery system and OptiDry Coat air dying units. The delivery will be complemented with an automation package including machine control, quality management, condition monitoring systems and retention measurement. In addition to the on-site support, the start-up and the further optimization of the rebuilt machine will be supported remotely from Valmet Performance Center.

The 5,600-mm wide (wire) containerboard machine PM 3 will produce recycled white-top testliner, coated white top testliner, recycled fluting and testliner grades with a basis weight range of 105-225 g/m2 and design speed of 1,300 m/min.

Information about the customer Modern Karton

Modern Karton Sanayi Ve Ticaret A.Ş, which was founded in 1974, is part of Eren Holding and is based in Istanbul. It is Turkey's largest corrugated fiberboard producer and among the largest in Europe. The facility uses waste paper in its production and has an annual production capacity of 1,050,000 tonnes.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2019 were approximately EUR 3.5 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

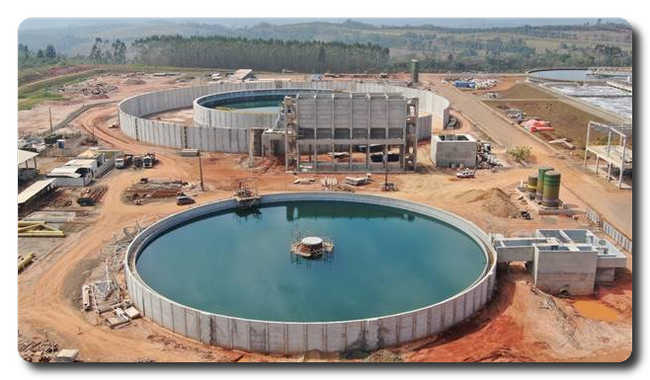

Valmet Total Solids Measurements selected for Klabin’s Puma II project in Brazil

Six Valmet Total Solids Measurements (Valmet TS) will be supplied as part of the delivery by SUEZ Water Technologies & Solutions of water and wastewater treatment plants for Klabin’s Puma II project in Brazil. The Puma Project II consists of the construction of two new paper machines, along with production of integrated pulp, situated at the same industrial unit (Puma I Unit) that Klabin operates in the municipality of Ortigueira in the state of Paraná, in southern Brazil. The order was included in Valmet's orders received of the second quarter 2020.

The SUEZ delivery, where the Valmet measurements will be installed, includes expansion of the water production plant from 141,600 cubic meters per day to 213,600 cubic meters per day and 50 percent increase in the treatment capacity of the industrial effluent treatment plant. Valmet TS provides the capability of mass flow-based controls to achieve substantial savings in polymer dosage, energy and transportation, as well as further advancing the environmental benefits.

Four in-line Valmet TS measurements will control primary, secondary, tertiary and homogenized primary sludge consistencies in the wastewater treatment plant. The fifth unit will be installed to control sludge consistency in the water treatment plant. The sixth unit will be installed to control tertiary sludge consistency in the wastewater treatment plant in Puma I.

The Valmet TS microwave measurement, now in its fourth generation, is designed specifically as the most reliable and accurate inline solids measurement for the range of 0-50 percent in wastewater applications. Two third generation Valmet TS measurements have already been in use since September 2019 at the wastewater treatment plant of the existing Puma pulp mill that started production in 2016. Delivery of the six new Valmet TS measurements will be towards the end of the year 2020.

Six Valmet Total Solids Measurements (Valmet TS) will be supplied as part of the delivery by SUEZ Water Technologies & Solutions of water and wastewater treatment plants for Klabin’s Puma II project in Brazil.

Six Valmet Total Solids Measurements (Valmet TS) will be supplied as part of the delivery by SUEZ Water Technologies & Solutions of water and wastewater treatment plants for Klabin’s Puma II project in Brazil.

Technical details about Valmet TS

Valmet TS offers a reliable and accurate real time measurement used to control and optimize the solids treatment process, giving operators information on total solids 24 hours a day, 7 days a week. As the most reliable and accurate analyzer for wastewater applications, Valmet TS allows savings in polymer dosing, energy and transportation. Valmet TS utilizes microwave technology to determine total organic and inorganic solids content in the range of 0-50 percent. Controlling and developing the process can be enhanced through accurate and fast measurements, which improves the overall efficiency of a wastewater plant and provides crucial data for dewatering optimization.

Information about the customer Klabin

Klabin is the largest producer and exporter of paper for packaging in Brazil, its only company offering one-stop shop solutions in hardwood, softwood and fluff pulp, and the leader in corrugated board packaging and industrial bags. Founded in 1899, it has 18 industrial units in Brazil and one in Argentina.

Read more about Valmet TS: https://www.valmet.com/valmetts

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2019 were approximately EUR 3.5 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet takes its services to the next level for the best customer experience

Valmet streamlines its services to customers globally by introducing ‘Valmet’s way to serve’ concept. The aim is to provide the best customer experience in all the touch points of the customer journey. Valmet’s services are based on comprehensive services offering, lifecycle collaboration and core commitments.

“Over the years we have been constantly developing our services to improve the reliability and performance of our customers’ production processes. Valmet’s unique combination of process technology, services and automation and over 200 years of industrial experience form a strong basis to help our customers to reach the wanted maintenance and operational results of their production process,” says Aki Niemi, Business Line President, Services business line, Valmet.

Right combination of services for every stage in the lifecycle

Valmet’s services offering is designed to match customer’s specific need, whether it’s reduced energy and raw material costs, reduced process variability, optimized quality and production or enhanced environmental performance.

Valmet streamlines the way it serves customers globally by introducing ‘Valmet’s way to serve’.

Valmet streamlines the way it serves customers globally by introducing ‘Valmet’s way to serve’.

The services offering ranges from spare and process parts, workshop and roll services, and fabrics all the way to field services, maintenance development and outsourcing as well as process upgrades. The services are complemented with Industrial Internet solutions on-site and remotely. Depending on the need, the service solution can be provided as a one-time delivery or as a longer-term partnership through service agreements.

The key driver in Valmet’s way to serve is the lifecycle collaboration between the customer and Valmet.

“When planning the investment, together with the customer we can set the foundation for optimized operational results for the production process to come. Services can help to accelerate the start-up curve when ramping up the production. By working together in maintenance and operations, we can ensure maximized reliability and optimized performance of the production process,” Niemi says.

Safety comes first in all operations

Valmet’s four core commitments to customers are: ‘Safety comes first,’ ‘Close to you,’ ‘Solutions to your needs’ and ‘People you can trust’.

“Safety is put before anything else in our daily operations. We support customers in reaching their safety targets. Our professionals work close to customers, through a network of over 100 service centers. Our experts are also available remotely with the help of Industrial Internet and remote technologies. We work closely with our customers to find exactly the right solution to their needs. We know that trust has to be earned, and we work hard to reach that goal every day”, concludes Niemi.

Valmet to supply Metsä Board’s Kemi mill with Industrial Internet solutions to enhance end-product quality and the mill’s productivity

Valmet and Metsä Board have signed an agreement on data-driven optimization of paperboard quality of the board machine at Metsä Board’s Kemi mill. The machine produces premium quality white top kraftliner. Valmet will supply the mill with Valmet Industrial Internet VII Data Discovery and VII for Paper Quality solutions.

The order was included in Valmet’s orders received of the second quarter 2020. The value of the order is not disclosed.

The agreement is the first step in a jointly built digital roadmap between Metsä Board and Valmet. The target of this first step is to ensure top-quality end-product to enable smooth runnability in the paperboard converting process. A mill-wide action plan will be created by combining historical mill process data, converting data from Metsä Board’s customer and Valmet’s expertise to discover the improvement potential of the board machine BM1 production process. This is enabled by Valmet’s VII Data Discovery solution.

The agreement is the first step in a jointly built digital roadmap between Metsä Board and Valmet. The target of this first step is to ensure top-quality end-product to enable smooth runnability in the paperboard converting process. A mill-wide action plan will be created by combining historical mill process data, converting data from Metsä Board’s customer and Valmet’s expertise to discover the improvement potential of the board machine BM1 production process. This is enabled by Valmet’s VII Data Discovery solution.

“Metsä Board’s products are known for high quality consistency and converting runnability, and we are committed to continuous improvement. With virtual sensors for quality management using artificial intelligence we can reach even better performance. We chose Valmet as our partner based on technical expertise and long-term trust between our companies,” says Tomi Vähä-Ruohola, Technical Development Manager, Metsä Board.

“This project is a good example of how we can use VII Data Discovery findings to build a mill-wide action plan and create the right artificial intelligence-based VII solutions for the customer’s needs. With this first step in our common digital roadmap, we are together moving towards data-based optimization of the entire value chain from pulping to converting,” says Arttu-Matti Matinlauri, Director, Analytics and Applications, Automation business line, Valmet.

Further details about Valmet’s delivery

The VII for Paper Quality solution, including Valmet’s artificial intelligence-based applications and the Valmet IQ Quality Management System are used to predict and autonomously optimize paperboard surface quality in real time.

A key part of the VII for Paper Quality solution is the world’s first predictive application for online optimization of paperboard surface quality. It helps maintain high end-product quality and optimize the usage of raw material.

Another important application in this solution is the Dynamic Centerline Advisor, which builds optimal production recipes for each operating mode, ensuring maximized overall equipment effectiveness.

Information about the customer Metsä Board

Metsä Board is a leading European producer of premium fresh fibre paperboards and forerunner in sustainability. Metsä Board produces premium lightweight folding boxboards, food service boards and white kraftliners for consumer goods packaging as well as retail-ready and food service applications. In 2019, the company’s sales totalled EUR 1.9 billion, and it has approximately 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2019 were approximately EUR 3.5 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet strengthens its business by acquiring PMP Group, a provider of technologies and services for the paper industry

Valmet has on September 11, 2020 entered into an agreement to acquire PMP Group in Poland. The enterprise value of the acquisition is approximately EUR 64 million, plus a conditional and capped earn-out component. The acquisition is estimated to be completed on October 1, 2020 at the earliest.

PMP Group supplies process technologies and services for tissue, board and paper machines globally, focusing on small and medium-sized tissue machines and board and paper machine rebuilds. The net sales of the company were approximately EUR 70 million in the fiscal year 2019. The company employs about 650 people, the majority of whom are located in Poland and the rest in China, USA and Italy.

PMP Group supplies process technologies and services for tissue, board and paper machines globally, focusing on small and medium-sized tissue machines and board and paper machine rebuilds. The net sales of the company were approximately EUR 70 million in the fiscal year 2019. The company employs about 650 people, the majority of whom are located in Poland and the rest in China, USA and Italy.

Jari Vähäpesola, Business Line President, Paper in Valmet:

“The acquisition will bring two companies with different offerings and customer segments together. PMP’s technology and services portfolio for small and medium-sized tissue, board and paper machines will be a very good complement to Valmet’s current paper technology and services for wide and fast machines and rebuilds. Together with PMP’s product portfolio, their competence and presence in strategic markets, we will create new business opportunities and further strengthen our capabilities to serve paper, board and tissue producers globally. PMP has a very skilled team and I am happy to warmly welcome them to Valmet,” says Jari Vähäpesola, Business Line President, Paper business line, Valmet.

Mirosław Pietraszek, PMP Group President:

“Joining to Valmet opens a new chapter in PMP’s rich history in the pulp and paper industry and represents a huge leap forward for our future development. I am convinced that the joint technological, production and human resources in our key markets will allow us to reach new heights and ultimately benefit the advancement of the entire paper industry,” says Miroslaw Pietraszek, PMP Group President.

PMP Group - a company with a long history in the pulp and paper industry

PMP Group is a provider of tissue, paper and board machinery and services. The company has been serving the pulp and paper industry for over 165 years. The 650 employees are located in Jelenia Góra and Świecie in Poland, Changzhou in China, South Beloit in USA and Lucca in Italy.

Valmet to supply new bleach plant and upgrade of batch cooking and fiberline to ITC's Bhadrachalam pulp mill in India

Valmet will deliver a new bleach plant and upgrade of the batch cooking and fiberline to ITC's Bhadrachalam pulp mill in India.

The order is included in Valmet's orders received of the third quarter 2020. The order value will not be disclosed. An order of this scope is typically around EUR 20-30 million. The start-up is scheduled for 2022.

The Bhadrachalam pulp mill has an increased demand of pulp due to continuous expansion in board production. The company has recently invested in Valmet’s board machine, a new high power recovery boiler and ash leaching plant.

“Valmet has been a trusted partner for our paperboard and chemical pulp lines and has constantly put efforts in research and development of the operation issues and input condition changes. For this reason, ITC's management chose Valmet as the supplier of the new bleach plant,” says Sanjay Singh, Divisional Chief Executive, ITC Limited, Paperboards and Specialty Papers Division.

“Valmet has been a trusted partner for our paperboard and chemical pulp lines and has constantly put efforts in research and development of the operation issues and input condition changes. For this reason, ITC's management chose Valmet as the supplier of the new bleach plant,” says Sanjay Singh, Divisional Chief Executive, ITC Limited, Paperboards and Specialty Papers Division.

"Valmet and ITC have put a lot of effort into a thorough pre-engineering aiming at increasing the production, reducing operating costs and improving the fiberline’s availability. I am happy to say that the outcome is a state-of-the-art process solution combining existing equipment with the latest technology, which will allow ITC to increase its pulp production with improved pulp quality at reduced cost per ton of pulp. This project is the result of good cooperation between ITC and Valmet, and we are committed to continuing to support ITC with the latest technology and strong local presence in India," says Varun Jain, Director, India Region, Valmet.

Information about Valmet’s delivery

Valmet’s delivery includes new bleach plant, batch cooking extension and fiberline upgrade. The supply scope consists of main equipment, basic engineering, training, site services and corresponding spare parts. In addition to this, the delivery also includes Valmet Industrial Internet VII for Pulp Quality solutions for the new bleach plant in order to secure reliable and efficient operation.

Information about the customer ITC Limited

ITC Paperboards and Specialty Papers Division is among the leaders in the paper and paperboard business with solutions to meet a diverse cross-section of packaging and communication needs. With emphasis on harnessing technology, the company has emerged as the largest manufacturer of packaging and graphic boards in South Asia. ITC's Paper Board and Specialty Paper's Division has eleven machines at three locations with production capacity of 800,000 tons per annum. End-market products are surface sized printing and writing papers, non-surface sized printing and writing papers, paperboards and coated boards.

Valmet to supply Valmet IQ quality management system to PJSC Kyiv Cardboard and Paper Mill in Ukraine

Valmet will supply Valmet IQ quality management system to PJSC Kyiv Cardboard and Paper Mill in Kiev, Ukraine. The new system will be installed in the corrugated packaging plant of the mill which is undertaking modernization actions. The investment is targeted to improve the quality of the corrugated board, and to increase productivity and profitability in converting operations.

The order was included in Valmet's orders received of the second quarter 2020. The delivery is scheduled by the end of September 2020.

“We are happy that PJSC Kyiv Cardboard has chosen Valmet IQ to improve their corrugated board quality and plant productivity. Our experience and results from Valmet IQ’s previous installations for corrugator had a big role in this decision. It is great to see that we can help PJSC to move their performance forward with this moisture-based quality control system,” says Mikko Talonen, Business Manager, Automation, Valmet.

“We are happy that PJSC Kyiv Cardboard has chosen Valmet IQ to improve their corrugated board quality and plant productivity. Our experience and results from Valmet IQ’s previous installations for corrugator had a big role in this decision. It is great to see that we can help PJSC to move their performance forward with this moisture-based quality control system,” says Mikko Talonen, Business Manager, Automation, Valmet.

Technical details about the delivery

The Valmet IQ quality management system is specifically designed for Corrugator plants and combines precise online moisture, temperature and warp measurements with reliable closed-loop controls and moisturizers including reporting system. It comprises Valmet IQ Multipoint moisture measurement system with IQ Wet-End Control, Valmet IQ Moisturizer, Valmet IQ Converting Scanners and Valmet IQ Warp Measurement with IQ Dry-End Control.

Information about the customer PJSC Kyiv Cardboard and Paper Mill

Kyiv Cardboard and Paper Mill Private Joint-stock Company is part of the Austrian company Pulp Mill Holding and one of the largest European producers of paper-based products. In terms of total output, the facility produces 30% of all paper products in Ukraine. Recycled paper is the main raw material used in production, and more than 1,000 tons of recycled material is processed at the mill daily. The box and packing cardboard produced at the facility is utilized in the fabrication of packaging for various consumer products.

Valmet to supply start-up clothing to Stora Enso’s Oulu Mill in Finland

Valmet will supply start-up clothing to Stora Enso’s Oulu Mill in Finland. The start-up clothing includes forming fabrics, press felts, shoe press belts and dryer fabrics. The clothing order is related to Stora Enso’s paper machine (PM 7) grade conversion project delivered by Valmet.

The order is included in Valmet’s orders received of the third quarter 2020. The clothing will be delivered for the start-up of the rebuilt BM 7, which is scheduled for the end of 2020. The value of the order is not disclosed.

“Valmet has been our main clothing supplier in Oulu for a long time. We are pleased to continue working together in this strategic project, too, as the performance of the fabrics and felts is crucial for end product quality and production efficiency. We have set high requirements for the technical support at the start-up and during optimization. We trust that Valmet can meet our expectations,” says Janne Myllykangas, Area Manager BM 7 and Deputy Project Director at Stora Enso.

“Valmet has been our main clothing supplier in Oulu for a long time. We are pleased to continue working together in this strategic project, too, as the performance of the fabrics and felts is crucial for end product quality and production efficiency. We have set high requirements for the technical support at the start-up and during optimization. We trust that Valmet can meet our expectations,” says Janne Myllykangas, Area Manager BM 7 and Deputy Project Director at Stora Enso.

“We are happy that Stora Enso has chosen our clothing for the start-up of BM 7. All in all, the order includes 50 percent of the forming fabrics and press felts, and 100 percent of the dryer fabrics for the first two years with an option for the third year. Valmet Black Belt shoe press belts were already included in Stora Enso’s earlier order for this project. Our Industrial Internet application for PMC (paper machine clothing) remote analytics is also included into the delivery,” says Martti Heinola, Director, Paper Machine Clothing, Valmet.

Valmet and Stora Enso have also signed a Performance Agreement including technical support to accelerate the start-up curve.

Information about the customer Stora Enso

Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions, and paper. The company employs some 26,000 people in more than 30 countries. The Oulu Mill in northern Finland currently produces wood-free coated paper and bleached softwood pulp.

Valmet receives the eighth tissue line order from Hayat Kimya

Valmet will supply the eighth tissue line delivery including an extensive automation package to Turkish tissue producer Hayat Kimya. The company has decided to invest in a third machine in Russia in order to meet the increasing demand for their high-quality tissue products. This is the first machine at their new mill outside Moscow. The new line will add 70,000 tons of tissue to company’s current production of facial, toilet and towel tissues.

The order is included in Valmet’s orders received of the second quarter 2020. The value of the order will not be disclosed.

Hayat Kimya, the current world speed record holder with their TM2 tissue machine in Turkey supplied by Valmet, is constantly targeting latest technology to reach the highest efficiency and the lowest possible energy consumption. Previously the company has installed six Valmet Advantage DCT 200TS tissue production lines to its mills in Turkey, Russia and Egypt with one more starting-up in 2021.

“Our ambition is to run at high efficiency and Valmet’s technology is certainly supporting that target. We are regularly updating our machine fleet to make sure we always operate at optimum production level. We find both Valmet’s technology and people easy to deal with,” says Lütfi Aydin, Director, Paper Group, Hayat Kimya.

“We are excited to be part of Hayat Kimya’s successful journey. The company started only fourteen years ago and is already a world player, who will soon have nine tissue lines in operation,” says Björn Magnus, Sales Director, Tissue Mills business unit, Paper business line, Valmet.

Valmet receives its eighth tissue line order from Hayat Kimya

Valmet receives its eighth tissue line order from Hayat Kimya

Technical information

The new tissue machine TM9 will have a width of 5.6 m and a design speed of 2,200 m/min.

The raw material to be used in the tissue production will be virgin fiber. The new production line is optimized to save energy and to enhance the quality of the final product.

Valmet’s scope of delivery will comprise a complete tissue production line featuring stock preparation systems and a Valmet Advantage DCT 200 TS tissue machine. The machine will be equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including ViscoNip press, an AirCap Heli hood and air system prepared for co-generation, WetDust dust system, sheet transfer system and a SoftReel L reel. The line also includes a Valmet F(O)CUS Rewinder. The stock preparation line will consist of OptiSlush pulpers, OptiFiner conical refiners and OptiScreen machine screens.

Furthermore, the delivery will include an extensive Valmet automation package with Valmet DNA machine controls, process controls and Valmet IQ quality controls. Complete engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

Information about Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the home care, hygiene and tissue categories for the consumer goods industry. Hayat has continued to invest significantly since their entrance into the tissue category 14 years ago and today the Group carries "The Largest Tissue Manufacturer of Africa, Middle East and Eastern Europe" title with 490,000 tonnes production capacity/year.

Valmet to supply pulp production upgrade technology to PT. Tanjungenim Lestari Pulp and Paper in Indonesia

Valmet will supply pulp production upgrade technology to PT. Tanjungenim Lestari Pulp and Paper (PT TEL) in Indonesia. The delivery includes an upgrade of continuous cooking system, with a design capacity of 1,800 air dried tonnes per day, and two sets of new automatic baling equipment. With the new investments, PT TEL targets to increase its pulp production capability and improve its pulp quality.

The order is included in Valmet's orders received of the second quarter 2020. The value of the order will not be disclosed. An order with this scope of supply and delivery is usually valued in the range of EUR 10-12 million.

A new Valmet ImpBin will be installed prior to the existing digester vessel, which will be upgraded with Continuous Cooking G3 features.“Our target in the cooking system upgrade is to reduce our unit wood consumption by increasing the pulp yield and reducing reject content, to enhance our pulp quality and to lower the specific load on the recovery boiler. By upgrading to Valmet’s latest continuous cooking system we will significantly increase the pulp yield which will reduce our operating costs and allow us to be capable to increase the overall mill pulp production. Moreover, with the two new sets of baling equipment, we aim at improving availability and production stability. We have logically selected the advanced and reliable technology that supports us in achieving our target in this project,” says Hiroyuki Moriyasu, President Director, PT TEL.

A new Valmet ImpBin will be installed prior to the existing digester vessel, which will be upgraded with Continuous Cooking G3 features.“Our target in the cooking system upgrade is to reduce our unit wood consumption by increasing the pulp yield and reducing reject content, to enhance our pulp quality and to lower the specific load on the recovery boiler. By upgrading to Valmet’s latest continuous cooking system we will significantly increase the pulp yield which will reduce our operating costs and allow us to be capable to increase the overall mill pulp production. Moreover, with the two new sets of baling equipment, we aim at improving availability and production stability. We have logically selected the advanced and reliable technology that supports us in achieving our target in this project,” says Hiroyuki Moriyasu, President Director, PT TEL.

“Valmet’s continuous cooking technology fits the customer’s requirement of cost-efficient pulp production with high pulp yield and low reject content, while also ensuring excellent pulp quality. Furthermore, this repeat order of baling machines shows that customer trusts our technology and our previous delivery of three baling machines in 2019 have met the customer’s expectation. We are happy to continue the cooperation with PT TEL,” says Fredrik Wilgotson, Vice President, Pulp and Energy, Asia Pacific, Valmet.

Information about the delivery

This upgrade project will add the Valmet Continuous Cooking G3 technology to PT TEL’s existing cooking system. A new Valmet ImpBin will be installed prior to the existing digester vessel, which will be upgraded with Continuous Cooking G3 features. ImpBin ensures homogeneous chip steaming and impregnation, which is the key to produce high quality pulp with high pulp yield and low reject content. The upgrade also includes Valmet’s latest technology for chip pumping. The start-up is scheduled for the fourth quarter of 2021.

In addition, the delivery includes a modern Valmet Wire Tyer, which is operated by electrical servo motors, resulting in exact and gentle wire feeding. The Valmet Wire Tyer ensures a reliable system for bale wire application that can process up to 300 bales in an hour. The new baling equipment is scheduled to be delivered in late 2020 and the startup is planned for the first quarter of 2021.

Information about PT. Tanjungenim Lestari Pulp and Paper

PT. Tanjungenim Lestari Pulp and Paper (PT TEL), a subsidiary of Marubeni Corporation, produces high-quality, bleached-hardwood kraft pulp with 100 percent plantation grown Eucalyptus Pellita and Acacia mangium trees.