Displaying items by tag: valmet

Unique program promoting the employment of young people organized by Valmet and the Children and Youth Foundation continues

The second part of the youth program started by Valmet and the Children and Youth Foundation in the spring has started today, November 15, at several of Valmet's units in Finland. As a part of the program Valmet enables paid practical training of three weeks for 100 young people. The participants to the unique program include young people aged 16-29 years who may, for instance, have challenges in finding their own path or with their basic working life skills.

Ninety people applied for the fall program, and the 55 who were chosen started today in the following Valmet units: Espoo, Jyväskylä, Järvenpää, Raisio and Tampere. In the spring, young people also participated at the Tampere, Pori, Ulvila and Kajaani units.

Ninety people applied for the fall program, and the 55 who were chosen started today in the following Valmet units: Espoo, Jyväskylä, Järvenpää, Raisio and Tampere. In the spring, young people also participated at the Tampere, Pori, Ulvila and Kajaani units.

"We wanted to celebrate Valmet's 220-year industrial history and the centenary of Finland's independence in a truly valuable way. Promoting employment among young people is important for society and an investment in the future. I hope that other companies will follow our example and provide young people with paid practical training and opportunities to learn working life skills," says Pasi Laine, President and CEO of Valmet.

Mentors and partners play a significant role in supporting the young people

Valmet's program was planned and is executed in cooperation with the Children and Youth Foundation, Academic Work and WorkPilots. Valmet plans and offers paid training and mentors from Valmet for the young people. The Children and Youth Foundation is responsible for recruiting young people for the program and for coaching their mentors. Academic Work provides the participants with coaching in job seeking and study-related issues as part of the program. WorkPilots helps young people in finding paths for continuing their journey.

"Each of the participants gets a personal mentor from Valmet, responsible for creating a safe and inspiring environment for the trainees and providing meaningful assignments that help them practice their working life skills and build their self-confidence. I am glad that so many Valmeteers have been ready to help these young people and act as mentors," says Anu Salonsaari-Posti from Valmet's working group for the youth program.

Excellent experiences from the first part of the program

Those who participated in the program in the spring said that they received new self-confidence and courage. Especially important for them was to receive positive feedback, gain feelings of success and to be part of the work community. Working within a work community helped the young people meet new people and act in new situations. As their favorite job assignments, the young participants listed, among other things, preparing PowerPoint presentations, taking photos, filing documents and scanning.

"The practice opportunity in the spring provided many young people with important lessons for the future. The first experiences at work are very important. They will be used to build an image of one's own skills, interests and the future working life. Successful experiences strengthen the young people's self-esteem, provide courage and spur them to try things out. Valmet has worked hard to provide an opportunity for young people to get successful experiences and strengthen their working life skills in an encouraging environment. We are happy to participate in cooperation where the young people's path toward the working life is supported with consideration of their starting point," says Tuula Colliander, Executive Director of the Children and Youth Foundation.

"Academic Work supports and helps young people specifically at the beginning of their path in working life, so this cooperation program was fully in line with our values. In addition, meeting young people in various situations in life also provides a learning opportunity to our own personnel, and we are eagerly anticipating this stage of the project. More than 20 people from Academic Work will participate in mentoring the young trainees in different locations in Finland," says Laura Korpilauri from Academic Work.

Read more about Valmet's 220 years of industrial history: www.valmet.com/220years

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet recognized as a global leader in climate action by CDP

Valmet has been recognized for its actions and strategy to mitigate climate change by CDP, the international not-for-profit organization that promotes sustainability. Valmet maintains its leadership position in CDP's climate program ranking by achieving the second-best A- rating. The CDP's climate change program results were released on October 24, 2017.

"This year, CDP had set the threshold higher than in the previous years which makes our achievement even more significant. This is a great acknowledgement of our contribution to climate change mitigation. We are continuously developing technologies that enable the use of renewable raw materials and increase raw material efficiency. We also have a systematic program to reduce CO2 emissions in our own operations. Recently, we set new targets for this program spanning to year 2030 to drive continuous improvement in environmental performance in the long term," says Pasi Laine, President and CEO of Valmet.

"This year, CDP had set the threshold higher than in the previous years which makes our achievement even more significant. This is a great acknowledgement of our contribution to climate change mitigation. We are continuously developing technologies that enable the use of renewable raw materials and increase raw material efficiency. We also have a systematic program to reduce CO2 emissions in our own operations. Recently, we set new targets for this program spanning to year 2030 to drive continuous improvement in environmental performance in the long term," says Pasi Laine, President and CEO of Valmet.

Valmet's mission is to convert renewable resources into sustainable results. Valmet's comprehensive Sustainability360º agenda focuses on five core areas: sustainable supply chain; health, safety and environment; people and performance; sustainable solutions, and corporate citizenship.

In September 2017, Valmet was recognized for its consistent progress in sustainability as it was included in the Dow Jones Sustainability World and Europe indices for the fourth consecutive year. Valmet was also reconfirmed as a constituent of the Ethibel Sustainability Index Excellence Europe.

About CDP

CDP, formerly the Carbon Disclosure Project, is an international not-for-profit organization that runs a global disclosure system enabling companies, cities, states and regions to measure and manage their environmental impacts.

The CDP Global Climate Change Report 2017 with the climate scores of all companies publicly taking part in CDP's climate change program this year, is available on CDP's website http://www.cdp.net.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

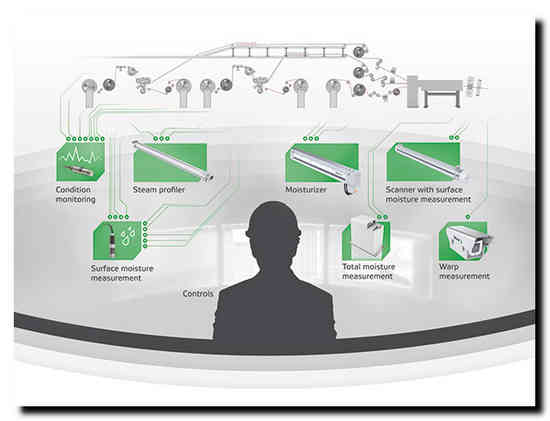

Valmet's new scanner offers corrugated board manufacturers a more economical way to measure liner moisture levels

Valmet introduces a new scanner, Valmet IQ Converting Scanner, for corrugated board. It is a long-awaited addition to Valmet's quality management control concept for corrugators and other board converting machines.

"IQ Converting Scanner offers corrugated board manufacturers a more economical way to measure liner moisture levels. It enables the use of Valmet IQ CD/MD controls in corrugators, resulting in higher quality as well as improved productivity," says Mikko Talonen, Business Manager, Automation, Valmet.

Valmet IQ Converting Scanner can be easily installed in different process locations, thanks to its innovative sensor support technology. The scanner enables direct moisture measurements to be positioned in an optimum process location from a quality and performance point of view.

The new scanner with online moisture measurement enables the utilization of machine and cross-direction controls in converting machines. These control solutions improve and stabilize the end-product quality, decrease the amount of broke and allow operators to concentrate on quality management and production optimization.

A comprehensive quality management solution for corrugators

Valmet offers a comprehensive quality management solution for corrugators. The solution features a wide range of online quality measurements to get accurate and fast information from the process, web inspection and monitoring systems to help detect quality defects and identify their root causes. It also includes a water spray system to control warp and moisture levels, as well as CD/MD controls.

All IQ solution components are based on Valmet's extensive process knowledge and experience in the pulp & paper industry and backed by expert services.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet will supply an automation system for Blue Paper's new SRF boiler in Strasbourg, France

Valmet has been selected to supply a Valmet DNA Control System for the new Solid Recovered Fuels (SRF) boiler Blue Paper SAS is building in its site in Strasbourg, France. The order was included in Valmet's third quarter of 2017 orders received. The value of the order will not be disclosed. The delivery is scheduled for early 2018, and process start-up is planned for spring 2018.

"We already use Valmet DNA system to control the major part of our Energy and Paper making processes. It will be for sure an advantage for our operators and maintenance technicians to keep the same DCS environment also for the new SRF plant. Indeed, our know-how and experience of many years with this system, as well as also our good cooperation with Valmet, will be beneficial for the project phase and later on for the ownership of the new process," says Vincent Muller, Electrical and Automation Manager for Blue Paper, in charge of the new DCS project.

"I am pleased that Blue Paper selected our Valmet DNA for their biggest investment since machine start-up. After the successful project done with the machine rebuilt in 2013, the choice of Blue Paper strengthens us in our partnership and I am proud of the work accomplished by our teams," says Patrick Rojo, Automation sales account manager, Valmet.

Blue Paper, Strasbourg, France.

Blue Paper, Strasbourg, France.

Information about Valmet's delivery

Valmet delivery will consist of an 800 I/O's Valmet DNA automation system that will control the new steam production plant: boiler, fuel storage and supply and utilities, with integration to the current Valmet automation system used in the paper mill and communication with the external systems like analyzers and unloading system.

Valmet's automation solution is a part of a global EUR 24 million investment. Blue Paper is currently processing to install a new 22 MW steam production plant based on Solid Recovered Fuels that will replace the two gas boilers of the mill, with the output of 30 tons/h of steam. The project is supported by French Environment and Energy Management Agency (ADEME) through the "CSR - Combustibles Solides de Récupération" (SRF) call for projects for which Blue Paper has been selected. Blue Paper is on par with the mill's strategy to continuously reduce the carbon footprint of its operations and products throughout the life cycle, with the goal to reduce gas consumption by 80% and to produce 40% of the steam needed by its operations. Blue Paper will also contribute to the local circular economy by converting part of local waste into renewable energy together with the waste coming from its own operations.

Valmet DNA automation system is a highly integrated automation system for power plant control and monitoring. In addition to offering a modern DCS system it has integrated turbine control and protection, machine condition monitoring and protection, electrical power distribution, and performance monitoring and reporting. The advanced and integrated solution improves the cost efficiency of the power plant's operation and simplifies the system maintenance.

Information about the customer Blue Paper

Blue Paper's Strasbourg mill produces corrugated case material, and its products are made solely of 100% recovered paper in an environmentally friendly process. Blue Paper SAS was established in 2013 after UPM Kymmene group, previous owner of the Strasbourg newsprint mill, sold the mill to the Klingele Group (Germany) and the VPK Packaging Group (Belgium), who converted the magazine paper mill into one of the biggest plants for the production of corrugating base paper in Europe. The 150 Blue Paper employees can produce over 400,000 tons of corrugating base paper per year.

For further information, please contact:

Etienne Guyon, Sales Manager France and North Africa, Valmet, Automation Business Line Tel: + 33 6 88 06 49 05

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Expanded applications with new Valmet Optical Consistency Transmitters

Valmet Optical Consistency Transmitter (Valmet OC) has gained a deserved reputation for accuracy, reliability and ease of installation since its introduction four years ago. Now Valmet introduces three new models for applications that have been particularly challenging for inline optical consistency transmitters in the past. This includes measurement of eucalyptus pulp, recycled fiber and chemical pulps.

"Valmet's continuous development expands reliable consistency measurement applications. Sharing the same basic components and modules, each new transmitter has a probe and total consistency measurement method optimized for use in special process environment i.e. recycled fiber," says Heikki Föhr, Product Manager, Valmet.

Click the picture below to see more

Eucalyptus pulp applications

Eucalyptus pulp has different optical properties compared to other pulps; which has led to the design of the special optical sensor and measurement method of the Valmet OCE. Results with the new transmitter in several commercial installations have already been successful in applications where competing inline optical transmitters have failed. A typical application is the control of LC-refiner feed consistency, where improved refiner freeness results and reduced specific energy consumption have been reported.

OCC and RCF applications

OCC and RCF processes are a challenge for any measuring device, where sand, metal and other contaminants as well as non-organic fillers are present. The Valmet OCR features a robust probe to survive the harsh physical environment and a measurement that tolerates the ash variations that prevent the use of other inline optical consistency transmitters. Installations in OCC processes before coarse screening have proved the probe's robustness and the total consistency measurement accuracy is excellent throughout the stock preparation area even with wide ash variations.

Chemical pulping applications

The Valmet OCS now features a sapphire window to withstand chemicals used in chemical pulping. All three new transmitters have passive measuring probes, connected via fiber optic cable to the measuring unit, that are temperature and vibration resistant as well as self-cleaning even in the demanding environment of recycled fiber processing. Offering simple and low cost installation, the 12 mm diameter probe with ball valve also makes insertion and removal possible without special tools or process stop required.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet grows its Industrial Internet ecosystem and starts partnership with Kemira

Valmet has taken a new, important step in building a leading Industrial Internet ecosystem by signing a partnership agreement with Kemira. The purpose of the agreement is to bring added value to pulp and paper customers by combining the know-how of the two companies in utilizing process data to improve the customers' processes.

In June this year, Valmet announced a similar Industrial Internet ecosystem agreement with Tieto. The target of the ecosystem being built is to bring leading industry players together to provide a comprehensive Industrial Internet offering to pulp, paper and energy customers and to continuously create new value adding applications.

In June this year, Valmet announced a similar Industrial Internet ecosystem agreement with Tieto. The target of the ecosystem being built is to bring leading industry players together to provide a comprehensive Industrial Internet offering to pulp, paper and energy customers and to continuously create new value adding applications.

"Through this cooperation and the companies' complementary know-how, customers' production process data can be integrated and optimized for the customers' benefit. This provides superior performance for the customers instead of each actor operating independently," says Jari Almi, Director, Industrial Internet, Valmet.

"Kemira and Valmet are leading suppliers to the industry globally and both companies are also actively developing digital solutions. Ultimately, the goal is to improve the speed, quality, reliability, predictability and performance of our customers' business. With these synergies, it makes great sense to join forces to create value and reshape business collaboration models," says Antti Matula, Vice President of Product Lines and Business Development at Kemira.

Valmet has renewed its Industrial Internet offering which is built on the company's long experience as the process technology, services and automation provider to the pulp, paper and energy industries. Building a strong Industrial Internet ecosystem of key actors serving these industries is an important part of Valmet's aim to bring the leading Industrial Internet services to its customers globally.

Link to valmet.com: Valmet Industrial Internet

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com, www.twitter.com/valmetglobal

Kemira is a global chemicals company serving customers in water intensive industries. We provide expertise, application know-how and chemicals that improve our customers' product quality, process and resource efficiency. Our focus is on pulp & paper, oil & gas and water treatment. In 2016, Kemira had annual revenue of around EUR 2.4 billion and 4,800 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd.

www.kemira.com

Related Article from Kemira

Kemira and Valmet partner for the development of industrial internet solutions for pulp and paper industry

Two global leaders, chemicals company Kemira and process technology, automation and services company Valmet, have signed a partnership agreement for the development of digitalized data-based applications and services for their customers in the pulp and paper industry.

“Kemira and Valmet are leading suppliers to the industry globally and both companies are also actively developing digital solutions. Ultimately, the goal is to improve the speed, quality, reliability, predictability and performance of our customers’ business. With these synergies, it makes great sense to join forces to create value and reshape business collaboration models,” says Antti Matula, Vice President of Product Lines and Business Development at Kemira.

"Through this cooperation and the companies' complementary know-how, customers’ production process data can be integrated and optimized for the customers' benefit. This provides superior performance for the customers instead of each actor operating independently," says Jari Almi, Director of Industrial Internet at Valmet.

Kemira is a global chemicals company serving customers in water intensive industries. We provide expertise, application know-how and chemicals that improve our customers' product quality, process and resource efficiency. Our focus is on pulp & paper, oil & gas and water treatment. In 2016, Kemira had annual revenue of around EUR 2.4 billion and 4,800 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd.

www.kemira.com

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

www.valmet.com

Valmet to supply a grade conversion rebuild for Sappi Lanaken Mill in Belgium

Valmet will supply a vast grade conversion rebuild with a wide scope of automation for Sappi Lanaken Mill in Belgium. In the project, the mill's paper machine 8 (PM8) currently producing lightweight coated (LWC) paper grades will be rebuilt to also produce lightweight and high-quality woodfree coated paper grades, which the mill will gradually start producing. The start-up of the rebuilt machine is scheduled for 2019. The project is an EPC delivery (engineering, procurement and construction) with an extensive site operation scope.

The order was included in Valmet's third quarter of 2017 orders received. The value of the order will not be disclosed. The value of an order of this type is typically around EUR 60-80 million.

"Sappi has been relying solidly on Valmet in the past years, and the excellent collaboration and results from the previous projects were certainly an asset in the negotiations. In addition to this new, extensive rebuild for Lanaken, five other major ongoing or already started-up projects for Sappi are Valmet-supplied (Sappi Maastricht 2018, Sappi Sommerset 2018, Sappi Kirkniemi 2016, Sappi Gratkorn 2014 and Sappi Alfeld 2013). These projects have led into a true partnership between Sappi and Valmet. Valmet has been able to offer just the right solutions to fulfil the customer needs. To ensure the selected concept, pilot trials were run at Valmet Paper Technology Centers," says Robert Mohr, Vice President of Central Europe Sales, Valmet.

Signing the contract at the Sappi Lanaken Mill. From left Werner Reiter, Bernhard Zottler, Günther Engelen, Wim Devens, Eric Raedts (all from Sappi), Marko Oinonen (Valmet) and Robert Mohr (Valmet).

Signing the contract at the Sappi Lanaken Mill. From left Werner Reiter, Bernhard Zottler, Günther Engelen, Wim Devens, Eric Raedts (all from Sappi), Marko Oinonen (Valmet) and Robert Mohr (Valmet).

Technical details about the delivery

Valmet's delivery includes modifications to stock preparation and pulp bale de-wiring system, paper machine, air systems and major changes and improvements in the automation systems. The paper machine modifications include rebuilds in the forming section, press section, dryer section, and coating section, a new sizer, calender and reel. The re-reeler will be relocated. Automation delivery includes quality management system, machine and process control systems, as well as web inspection system. All the equipment will be delivered with installation.

PM 8 will be producing lightweight coated paper grades in the dimensional weight of 115 g/m². The mill has a total capacity of 530,000 tonnes/year.

Information about the customer Sappi Europe

Headquartered in Brussels, Belgium, Sappi Europe is the leading European producer and supplier of coated fine paper, packaging and specialty papers. In Europe, the company has seven mills, 14 sales offices and 5,100 employees. Lanaken Mill in Belgium produces a variety of pulp and high-quality fine coated papers.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply a new Valmet Brown Stock Quality Analyzer for CMPC Celulosa in Chile

Valmet will supply a Valmet Brown Stock Quality Analyzer (Valmet Kappa Q1) for CMPC Celulosa in Santa Fe, Chile for its fiber line 1 producing ECF (Elemental Chlorine Free) bleached eucalyptus pulp. To be installed in the blow line of the continuous digester, the Valmet Kappa Q1 will provide rapid and frequent Kappa number information for better digester and subsequent O2 stage control. Two larger multiline Valmet Kappa Analyzers have been successfully operating on the mill's larger fiber line 2 since startup in 2006.  The process sampling device is safely accessible without a process shutdown."Safety was an important factor in our decision and the design of Valmet Kappa Q1 avoids unnecessary exposure to risk when maintenance is required. We have always had good experiences of Valmet products, fast and good support, with both existing Valmet Kappa Analyzers consistently providing better uptime compared with other devices in the mill," says Patricio Montanares, Mill Technician, CMPC Celulosa.

The process sampling device is safely accessible without a process shutdown."Safety was an important factor in our decision and the design of Valmet Kappa Q1 avoids unnecessary exposure to risk when maintenance is required. We have always had good experiences of Valmet products, fast and good support, with both existing Valmet Kappa Analyzers consistently providing better uptime compared with other devices in the mill," says Patricio Montanares, Mill Technician, CMPC Celulosa.

About the Valmet Kappa Q1

The new Valmet Kappa Q1 has been developed as a stage specific analyzer to provide increased measurement frequency of Kappa number in high yield kraft pulping. Using a similar sweep measurement (pat. pending) as Valmet's very successful multi-point kappa analyzer, the advanced technology ensures exceptional accuracy and stability. The analyzer utilizes well proven sampling device technology with a new and innovative sample handling principle to the nearby compact measuring unit where it is washed and pulp Kappa number measured. Unlike single point Kappa measurements mounted directly to process piping, only the process sampling device is connected to the pressurized process, the measurement itself is thus unaffected by vibration and safely accessible without a process shutdown.

"The increased measurement frequency fulfills all pulping process control needs and safely provides the genuine pulp Kappa number in dedicated process stage applications from unbleached brown stock pulp to oxygen delignification," says Risto Rinne, Fiberline Analyzer Business Manager, Valmet.

Self-adjusting process sampling and sample transportation, optimized sample washing and pre-calibration with customer pulp samples all make commissioning exceptionally fast and easy. Two models are available with measurement characteristics optimized for Kappa ranges of 9 to 50 or 35 to 120. User safety is further improved with the built-in laboratory sample collector isolated from the process. The analyzer requires minimal maintenance and features chemical based self-cleaning for trouble free operation. With the built-in touch screen display, all analyzer operating parameters, operating sequences and diagnostics together with operating instruction are all instantly available. Remote configuration and operation as well as Industrial Internet capabilities also provide the possibilities of remote specialist support from Valmet.

About the customer

Santa Fe is the largest Bleached Eucalyptus Kraft pulp mill in Chile with production capacity of 1,425,000 ADt/year. It is located 500 km south of Santiago in Bío Bío region.

This CMPC Pulp mill began operating in 1991. It currently houses two production lines that meet the most stringent environmental standards for the industry in the world.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet's IQ Moisturizers start up and improve corrugated box quality at Dunapack Mosburger in Austria

The three Valmet IQ Moisturizers delivered to Dunapack Mosburger's corrugated line in Strasswalchen, Austria, have been successfully started up. With the new solutions, the plant will be able to improve corrugated box quality and plant performance.

Since 2012-2013, Dunapack Packaging has invested more than EUR 30 million in its Mosburger Strasswalchen production site, including a new 2.8-meter-wide corrugated line.

"Higher quality, more diverse papers together with improved production and smaller, just-in-time orders make it more and more challenging to act against warp with standard temperature, speed and glue settings. We were looking for a device to do it. When Valmet presented its control technology that is widely proven in paper production, we were convinced that this will work on our corrugated line, too," says August Hauser, Corrugated Line Manager at Dunapack Mosburger Strasswalchen.

"Valmet's IQ quality control solutions are established on paper machines worldwide. However, it takes innovative people to adopt them in the converting and corrugated industry, too. Innovation is definitely an attitude shown by the Dunapack Mosburger team," summarizes Christian Kallich, Country Manager, Austria and Eastern Europe, Automation, Valmet.

Technical information about Valmet IQ Moisturizer

The Valmet IQ Moisturizer profiler is used to correct all kinds of warping, decrease cracking tendency and optimize glue consumption by adding a fine and controlled water mist onto the liners with 60 mm or 120 mm resolution in a cross direction. IQ Moisturizer's two-stage spray head contributes to a balanced and application-matched mixture of air and water. The system is used via an IQ Moisturizer operator interface and integrated into the existing process controls.

Information about the customer Dunapack Packaging

Dunapack Packaging is part of the Austrian family-owned Prinzhorn Group. With more than 6,000 people in 15 countries, Prinzhorn Group is one of the European market leaders in the recycling, paper and packaging industry with an annual turnover of approximately EUR 1.2 billion.

Dunapack Packaging operates at 18 sites in 10 different countries and has an annual sales volume of 1.9 billion m² of corrugated board, mainly made from recycled papers.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet reconfirmed as a constituent of the Ethibel Sustainability Index Excellence Europe

Valmet has been reconfirmed as a constituent of the Ethibel Sustainability Index (ESI) Excellence Europe since 20 September 2017. The index contains 200 of the European stock listed companies that display the best performance in terms of corporate social responsibility (CSR).

Ethibel is constantly looking out for companies which may be eligible for ethical investments and to be included in its ethical investment register. From the investment register 200 of the best companies are selected to the Ethibel Sustainability Index. Main areas of assessment are human capital, environmental management, market ethics, governance, social impact and human rights. The assessment is based on external information sources such as sustainability reporting and company web sites.

Ethibel is constantly looking out for companies which may be eligible for ethical investments and to be included in its ethical investment register. From the investment register 200 of the best companies are selected to the Ethibel Sustainability Index. Main areas of assessment are human capital, environmental management, market ethics, governance, social impact and human rights. The assessment is based on external information sources such as sustainability reporting and company web sites.

"The reconfirmation as a constituent in the Ethibel Sustainability Index is a recognition of Valmet's strong focus and consistent progress in sustainability. For investors Valmet's inclusion in this index provides further assurance of the company as an ethical investment target. In its assessment, Ethibel is using only external information sources, and thus the inclusion in the index is also a recognition for Valmet's transparent and comprehensive reporting and communications around sustainability," says Anu Salonsaari-Posti, SVP, Marketing, Communications and Sustainability at Valmet.

In September 2017, it was announced that Valmet was included in the Dow Jones Sustainability World and Europe indices for the fourth consecutive year. Valmet is also included in the CDP Climate A-list for its actions and strategy to mitigate climate change.

About the Ethibel Sustainability Index Excellence Europe

The Ethibel Sustainability Index Excellence Europe includes the 200 best performing European companies in the field of corporate social responsibility. The analysis is based on research carried out by the rating agency Vigeo Eiris. Ethibel actively promotes socially responsible investing and corporate social responsibility on the financial markets. Read more

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.