Super User

Lee & Man Paper Manufacturing orders 5th ANDRITZ shoe press to boost energy efficiency

International technology group ANDRITZ has received an order from Lee & Man Paper Manufacturing Ltd., Malaysia, for a PrimePress X shoe press at their mill in Banting, Malaysia. Start-up is planned for end of 2023.

Jiang Weiqiang (left), Sales Director Paper and Board, ANDRITZ China, and Chen Liming, Senior Manager of the Project Department, Lee & Man. Photo AndritzThe newly ordered shoe press will be installed in the PM23 containerboard machine that runs with a design speed of 900 m/min and produces high-quality testliner of basis weights of 110 – 200 gsm. Equipped with an ANDRITZ Impulse grooved shoe press belt, it will replace the conventional first press to boost energy efficiency and dewatering performance. A couple of months ago, ANDRITZ had already received a similar order for Lee & Man’s PM25.

Jiang Weiqiang (left), Sales Director Paper and Board, ANDRITZ China, and Chen Liming, Senior Manager of the Project Department, Lee & Man. Photo AndritzThe newly ordered shoe press will be installed in the PM23 containerboard machine that runs with a design speed of 900 m/min and produces high-quality testliner of basis weights of 110 – 200 gsm. Equipped with an ANDRITZ Impulse grooved shoe press belt, it will replace the conventional first press to boost energy efficiency and dewatering performance. A couple of months ago, ANDRITZ had already received a similar order for Lee & Man’s PM25.

Three PrimePress X shoe presses (PM23, PM25, PM27) installed in 2020, 2021 and 2022 are already in operation. Besides the energy savings, they also offer a significant quality increase.

Chen Liming, Head of Projects Lee & Man Paper Manufacturing, explains: “The performance of our three PrimePress X shoe presses at our Banting mill is excellent. No wonder that we chose ANDRITZ as partner again to supply two additional ones to further reduce specific energy demand and to further improve the machines’ performance. This investment fully contributes to our sustainability strategy.”

Established in 1994, Lee & Man Paper manufactures linerboards of various grades and corrugating medium of different specifications used for several industrial packaging purposes. The group runs five paper mills and one pulp mill in China as well as several production bases in Vietnam, Malaysia and other countries.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Stora Enso contributes to a sustainable FIS Nordic World Ski Championships in Planica

As the presenting sponsor of the FIS Nordic World Ski Championships in Planica, Slovenia taking place between 21 February and 5 March 2023, Stora Enso will provide wood-based renewable and recyclable products and innovations to contribute to a world-class sustainable and climate-friendly event.

“The ski championships in Planica will reach a total audience of around 450 million people, enabling the opportunity to promote Stora Enso’s renewable materials while demonstrating that people can make real carbon reductions in their everyday choices. In addition to contributing renewable products and solutions at the games, we engage with the local Planica community to make a difference when it comes to awareness around sustainable sporting event actions,” says René Hansen, Stora Enso’s EVP Brand and Communications.

Stora Enso is Supporting Green Planica 2023 with eco-friendly products

Stora Enso will also support the Green Planica 2023 commitment through its renewable products designed to replace plastic and other fossil-based materials. Eco-friendly products used at the games by athletes, volunteers, media, and event staff include wooden podiums and building materials for the arenas, drinking cups, catering trays for volunteers, and 3D-printed bio composite furniture for the VIP area, all made from renewable and recyclable materials. Moreover, flowers in the medal ceremony will be replaced by spruce seedlings, devoted for planting in growing forests.

Sustainability engagement with the local community

Stora Enso will support the local community in Planica with two activities; supporting spectators with their walk from Kranjska Gora to Planica to advance sustainable mobility, and promoting a local competition between 21 schools on how to become an environmentally friendly fan at sports events. Both actions are taken together with the Planica organizing committee.

Long-term commitment

Stora Enso has committed to long term sponsorship support of the FIS Nordic World Ski Championships. Planica 2023 marks the fifth time the Group will sponsor the championships, having served as presenting sponsor for the 2021 event in Oberstdorf, Germany, 2019 in Seefeld, Austria, and 2017 in Lahti, Finland, as well as being the main sponsor in Falun, Sweden in 2015. Stora Enso will also be the presenting sponsor Trondheim, Norway 2025.

For more information about Stora Enso’s presence in the FIS Nordic World Ski Championships in Planica 2023, visit: Stora Enso in Planica 2023

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials and wooden construction, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 21,000 employees and our sales in 2022 were EUR 11.7 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com

Toscotec to supply a turnkey tissue line to GrandBay Papeles Nacionales in Colombia

GrandBay Papeles Nacionales has selected Toscotec for the turnkey supply of a new AHEAD 2.2 tissue line (PM5) at its Pereira production base in Colombia. This is Toscotec’s second project with GrandBay who is currently installing a complete AHEAD 2.2L tissue line at GrandBay Papelera Internacional in Guatemala. The new PM5 in Colombia is scheduled to start up in 2024.

The AHEAD 2.2 machine has a sheet trim width of 3,600 mm, a design speed of 2,200 m/min and an annual production capacity of over 40,000 tons. Designed to deliver the highest drying efficiency with the lowest possible energy usage, it features TT NextPress latest shoe press generation, a third-generation design TT SYD Steel Yankee Dryer with patented heads insulation system, and high efficiency TT Hood.

The turnkey supply includes the complete stock preparation system, Toscotec’s patented TT SAF® DD (Short Approach Flow system with Double Dilution), fiber recovery and water clarification systems, the complete tissue line with electrification and controls, as well as dust and mist removal systems. A full service package complements the turnkey scope with erection and supervision, training, commissioning, and start-up assistance.

GrandBay and Toscotec’s teams at contract signature (from left to right): Alexander Schuler, GrandBay COO; Gabriele Romanini, Toscotec Sales Manager; Alberto Matos, GrandBay Project Engineering Manager; Carlos Martin, Toscotec’s agent; Alejandro Piedrahita, GrandBay Papeles Nacionales Operations Director; Marco Dalle Piagge, Toscotec Sales Director; Ricardo Martin, Toscotec’s agent; Luis Henao, GrandBay Technical Manager; Juan Andres Mesa, GrandBay Production Manager.

GrandBay and Toscotec’s teams at contract signature (from left to right): Alexander Schuler, GrandBay COO; Gabriele Romanini, Toscotec Sales Manager; Alberto Matos, GrandBay Project Engineering Manager; Carlos Martin, Toscotec’s agent; Alejandro Piedrahita, GrandBay Papeles Nacionales Operations Director; Marco Dalle Piagge, Toscotec Sales Director; Ricardo Martin, Toscotec’s agent; Luis Henao, GrandBay Technical Manager; Juan Andres Mesa, GrandBay Production Manager.

Cesar Solano, Chief Executive Officer of GrandBay Group, says, “Continuing to grow with the market, satisfying the needs of the consumers with products of the best quality and accompanying the growth of our clients are guiding principles of our vision, which are supported by investment in the best technology.”

Alexander Schuler, Chief Operation Officer of GrandBay Group, says, “We selected Toscotec for this important project in Pereira, because we have seen firsthand their ability to manage complex projects in Latin America. The turnkey supply gives us the highest performance guarantees for success.”

Gabriele Romanini, Toscotec Sales Manager, says, “The configuration of Papeles Nacionales’ new line is state-of-the-art. It features Toscotec’s first-in-class energy efficient technology including the winning combination of our upgraded TT NextPress shoe press technology and Steel Yankee.”

About GrandBay Papeles Nacionales S.A.

Papeles Nacionales operates a tissue mill in Pereira (Colombia) and is part of the GrandBay Group, a leading Latin American company established in 1953 and dedicated to the manufacturing, converting and sales of personal care and home products of premium quality, with presence in more than 25 countries in Central America, the Andean and Caribbean region.

A collaboration between the paper industry & heat pump producers could halve its energy needs & help decarbonise the sector

A recent collaboration between associations representing the paper manufacturing and heat pump sectors, Cepi and EHPA, has resulted in innovation which could produce energy savings of 50% in paper manufacturing. It could also be key in decarbonising one of Europe’s energy-intensive sectors. But EU regulators need to speed up incentives for affordable clean energy.

Already today, heat pumps are enabling energy savings for many industries. They provide about 10% of final industrial energy demand in Europe, and help to lower industrial emissions across many sectors. A recent development is that commercially available large heat pumps and steam compressors can now heat up to 200°C, meeting the pulp and paper industry’s needs. The innovation has been encouraged by exchanges between both industries at European level.

A joint working group between members of the European paper and heat pump industries calculated potential energy savings in paper drying of more than 50%, and a joint Cepi-EHPA paper detailing how heat pumps could be integrated into paper mills has now been published.

A joint working group between members of the European paper and heat pump industries calculated potential energy savings in paper drying of more than 50%, and a joint Cepi-EHPA paper detailing how heat pumps could be integrated into paper mills has now been published.

The partnership between EHPA and Cepi tells the story of how collaboration can result in innovation breakthroughs, with real decarbonisation impacts. This is the purpose of Cepi’s Energy Efficiency Solutions Forum (EESF), hosting the joint working group, where front-running companies can exchange and learn from each other’s efforts to implement cutting edge technologies. The format of the EESF is frequently hailed as a model for other industries’ collaborative decarbonisation efforts.

Whether or not heat pumps can be rapidly deployed in paper mills across Europe now depends on the regulatory incentives that national government and EU Institutions can provide for electrifying the sector, which will require large amounts of affordable clean energy to meet the challenges set in the recently announced EU Green Deal Industry Plan.

Quotes

“The progressive phase-out of the fossil fuel alternative in industrial applications will be essential to building a business case. It will also be driven by high energy costs and the increasing CO2 price where clean energy clearly offers a beneficial solution.”

Thomas Nowak Secretary General EHPA (European Heat Pump Association)

“When Cepi launched the Energy Efficiency Solutions Forum exactly three years ago, heat pumps were investigated but were not yet reaching high enough temperatures. Through the candid collaboration between both sectorial associations, the technology now matches our needs. It will be an important building block in reducing the energy needs in the paper industry.”

“The industry will continue doing its part in reducing energy consumption and heat pumps can play an important role in that. Combined with access to affordable fossil-free energy heat pumps will allow for a full transition towards a decarbonised and circular economy based on bio-products.”

Jori Ringman, Director General – Cepi (Confederation of the European Paper Industries)

About Cepi :

Cepi is the European association representing the paper industry. We offer a wide range of renewable and recyclable wood-based fibre solutions to EU citizens: from packaging to textile, hygiene and tissue products, printing and graphic papers as well as speciality papers, but also bio-chemicals for food and pharmaceuticals, bio-composites and bioenergy. We are a responsible industry: 85% of our raw materials are sourced from within the European Union, 92% of the water we use is returned in good condition to the environment. We are the world champion in recycling at the rate of 71.4%. At the forefront of the decarbonisation and industrial transformation of our economy, we embrace digitalisation and bring 21 billion value addition to the European economy and €4.5 billion investments annually. Through its 18 national associations, Cepi gathers 490 companies operating 885 mills across Europe and directly employing more than 179,000 people.

IDM Test to represent emtec Electronic at SPaper Expo

The 3rd international exhibition of machinery and equipment for pulp, paper and cardboard, SPAPER, will take place from March 7-9, 2023 in Zaragoza, Spain. emtec Electronic GmbH will be represented at the event by IDM Test.

In the face of current economic and environmental challenges, paper manufacturers are increasingly looking for innovative technologies and equipment to streamline production processes and reduce waste. In March, the 3rd edition of the Feria de Zaragoza SPaper convention will bring together industry professionals from all over to present management solutions for the entire paper production cycle – from the sourcing of raw material to post-production waste management. Previous showings attracted more than 10,000 professional visitors and approximately 150 exhibitors, according to SPaper organizers.

In the face of current economic and environmental challenges, paper manufacturers are increasingly looking for innovative technologies and equipment to streamline production processes and reduce waste. In March, the 3rd edition of the Feria de Zaragoza SPaper convention will bring together industry professionals from all over to present management solutions for the entire paper production cycle – from the sourcing of raw material to post-production waste management. Previous showings attracted more than 10,000 professional visitors and approximately 150 exhibitors, according to SPaper organizers.

Instruments such as the CAS touch! Charge Analyzing System and the FPA touch! Fiber Potential Analyzer from emtec Electronic will be among those presented by IDM Test at SPaper 2023 at the Zaragoza Exhibition Center. These two portable lab devices deliver reliable data regarding the cationic demand of the pulp and zeta potential of the fibers. Specific knowledge of these parameters helps manufacturers optimize process runnability by pinpointing the correct dosage of chemicals to add in the wet-end, resulting in a higher product quality and less resource waste. The devices’ small size and light weight make them easy to transport in a carry-on suitcase, which is especially beneficial for chemical suppliers providing on-the-go measurements and troubleshooting.

Visitors to the SPaper 2023 are encouraged to stop by the IDM Test booth and talk to representatives Iker Elorriaga and Patxi Arizmendi for more information about the measuring principles and application examples of the devices.

More information about the SPaper exhibition is available at the following link.

About emtec Electronic

Emtec Electronic GmbH develops, produces and distributes worldwide testing and measuring devices for the detection of relevant processing properties of paper, board, nonwoven and textile materials. The portable measuring devices enable manufacturers and converters of paper, nonwoven and textile products for example, to control and optimize the manufacturing and converting processes during ongoing production. From the wet end to the final product, the application of the devices enables an efficient process to achieve and ensure the best possible quality with the least possible effort.

For 27 years, we have relied on innovative, highly specialized measuring instruments combined with a high degree of service orientation. Since the company was founded, we have been intensively involved in scientific cooperation with institutes and companies, further developing instruments for our customers and offering a broad network in over 80 countries from our Leipzig location.

For more information about emtec Electronic, please visit the website:

Toscotec to supply a complete packaging paper machine to INDEVCO Group in Greece

UNIPAKHELLAS, a member of INDEVCO Group, contracted with Toscotec for the supply of a complete paper production line to be installed at UNIPAKHELLAS Central (UHC) mill in Pelasgia, region of Fthiotida, Greece. UNIPAKHELLAS aims to produce high quality test liner and fluting grades to Greek and export markets. The paper machine is scheduled to start up soon.

Toscotec has been selected as the main machinery supplier due to its proven engineering capabilities and history of successfully managing complex installation and start-up projects. INDEVCO, through its engineering company Phoenix, will realize all the auxiliary plants.

The new machine has a wire width of 3,000 mm and will produce corrugated paper in the range of 90 to 200 gsm at the maximum operating speed of 800 m/min, processing 100% waste paper. It features a two-layer Fourdrinier configuration with a hydraulic TT Headbox-SL. It is equipped with Toscotec’s shoe press TT Xpress, as well as TT SteelDryers, steam and condensate system, and stabilization boxes in the dryer section. The supply also includes a hard nip calender, a hydraulic pope reel and the tail threading system. The scope is completed by mechanical drives, an enclosed hood, and air and ventilation systems. UNIPAKHELLAS selected a comprehensive service package with engineering, erection supervision, commissioning, training, and start-up assistance.

Toscotec-supplied paper machine at UNIPAKHELLAS Central mill in Pelasgia, Greece.

Toscotec-supplied paper machine at UNIPAKHELLAS Central mill in Pelasgia, Greece.

Fayssal Frem, Chairman of the Board and CEO of UNIPAKHELLAS, says, “Our decision to invest in Greece testifies to our belief that Greece is an actively growing market due to its geography and most importantly its human talents. The choice of Pelasgia’s strategic location not only makes commercial sense, but it is primarily driven by INDEVCO’s philosophy of furthering community development. We are confident that Toscotec will deliver on our expectations of high performance.”

Imad Issa El Khoury, Executive Vice President of INDEVCO Paper Making, says, “We are very excited to partner with Toscotec on our first big project, which will enable UHC to serve the Greek and export markets with a wide range of high quality containerboard grades, supporting corrugated businesses to excel locally and in the European and Mediterranean markets.”

Enrico Fazio, Sales Director of Toscotec P&B division, says, “We are proud to have been awarded the contract of a complete paper line to be installed in Europe. The new machine will feature all of Toscotec’s state-of-the-art technology from TT Headbox-SL to TT Xpress, TT SteelDryers, and the hard nip calender. We got off to a very good start with INDEVCO team collaborating closely on all aspects of the project. This is the perfect opportunity for Toscotec to prove its ability to successfully manage such a challenging project.”

About UNIPAKHELLAS S.A.

Established in 2008, UNIPAKHELLAS S.A. is an international company and member of INDEVCO Group, a multinational corporation with diversified manufacturing, technical and consultancy services. UNIPAKHELLAS operates several facilities in Greece, including locations in Athens, Pelasgia, Thiva, Thessaloniki and Crete. It has a leading role in the paper and packaging market with a strong belief in the need to develop innovative, eco-friendly solutions.

Printed matter and white packaging are valuable raw materials for deinkers

The recycling paper industry needs raw material – fewer newspapers, less advertisement also after the Corona pandemic and increased electronic communication lead to decreasing amounts of paper for recycling. Where will our raw material come from in the future? "What is growing? What is shrinking? Who needs which fibres?" asks Arne Kant (AFRY Management Consulting) and shows the market, but also possible alternatives if it no longer supplies the paper needed.

Still, too much of the collected paper for recycling bypasses the sorting plants and thus the deinking plants of the paper mills and goes directly towards packaging – there, demand continues to rise due to the ongoing "Amazonitis". Do we need regulatory assistance for paper recycling here? In any case, we need the white packaging. In year 4 after the new German packaging law, INGEDE asks representatives of the packaging industry: Which alternatives to plastic have become established, what does the market want, what not? Answers are provided by Jürgen Schwald of BMS Papier Concept, who supplies the market leaders with packaging, and Urban Buschmann, once the father of the paper freezer bag at FRoSTA.

Still, too much of the collected paper for recycling bypasses the sorting plants and thus the deinking plants of the paper mills and goes directly towards packaging – there, demand continues to rise due to the ongoing "Amazonitis". Do we need regulatory assistance for paper recycling here? In any case, we need the white packaging. In year 4 after the new German packaging law, INGEDE asks representatives of the packaging industry: Which alternatives to plastic have become established, what does the market want, what not? Answers are provided by Jürgen Schwald of BMS Papier Concept, who supplies the market leaders with packaging, and Urban Buschmann, once the father of the paper freezer bag at FRoSTA.

In order to achieve the properties of plastics here, barriers are necessary – barriers also for recycling? What problems does this cause in the paper mill? And how do we ensure that only white packaging is directed towards deinking during sorting, and not more brown cardboard? The solution is promised by camera systems and artificial intelligence, which is the subject of the contributions by Michael Lindner (UPM), Jake Woolfenden (TrueCircle, London) and John Schulz (BTG Instruments). Arne Krolle (INGEDE) promises "more revenue and fewer returns" through "certification of sorting plants".

The accompanying regulatory framework is explained by Martin Drews (DIE PAPIERINDUSTRIE) with a contribution on the new voluntary commitment and Ulrich Leberle (Cepi, Brussels). He answers the questions on European packaging legislation: How does the Commission proposal affect the recycling industry, especially deinkers?

These and more expert speakers will show options for future sustainable raw material management in order to save more white fibres for the white cycle. More details about the programme on our website, please register here for three sessions packed with up-to-date information! The INGEDE Symposium is the only annual international event covering all paper recycling aspects from printing inks to collection and sorting to deinking technology.

The INGEDE Symposium will be a hybrid event – we hope to see you in Munich again for more background talks but will also provide an online stream.

We look forward to welcoming you in person in Munich again or online at your laptop!

New #VoithCares program gets underway: Voith supports 50 social projects worldwide

Technology Group Voith is conscious of its social responsibilities and for a long time now has been demonstrating its commitment to society through a wide range of measures. Last year, Voith stepped up its commitment by launching the #VoithCares program. Within the scope of this initiative, Voith employees from all locations were invited to nominate projects at non-profit organizations where they volunteer to receive support from Voith. During the submission period, around 100 applications were received from employees from all around the world. The #VoithCares committee has now selected 50 projects from among all the submissions to receive support in fiscal 2022/23. The total funding amount is €50,000, half of which will be covered by the Hanns Voith Foundation. The program provides for selected projects to receive €1,000 a year.

The #VoithCares program aims to use the selected projects to continue to breathe life into the Voith DNA “developing sustainable technologies for future generations” as a reflection of the company’s commitment to society. As well as educational, environmental and cultural projects, the program supports infrastructure, integration and inclusion measures, and projects to help people in need.

Twenty-six projects in Europe and Africa will now receive €1,000 each. These include a housing project for people with disabilities in Waischenfeld; support for the organization “Heidenheim for Ukraine”; musical culture projects in Heidenheim and Armenia; a center of competence for canine search and rescue in Heidenheim; the construction of a woodworking training workshop in Nepal, and a youth center for educational support in Ghana. #VoithCares is also supporting nine charitable organization projects in North America and nine in Asia, and another six projects in South America.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Metsä Group invests in fossil free future by modernising and expanding Mariestad mill in Sweden

Metsä Group, through its tissue business Metsä Tissue, has made a decision to invest in world leading environmental performance in tissue production by modernising and expanding Metsä Tissue’s Mariestad tissue paper mill in Sweden. The investment will increase the availability of locally and sustainably produced tissue products in the Scandinavian market, in which approximately 40% of tissue usage is currently imported. The value of the investment is EUR 370 million and it is one of the largest in the tissue business in Europe and the largest within Metsä Tissue. The construction works will start during spring 2023 and the renewed mill is planned to be operational in the second half of 2025.

With this investment Metsä Tissue will be a forerunning company in investing into sustainable tissue production in Sweden and Scandinavia with its strong brands Lambi, Serla and Katrin. The investment will help to safeguard the security of supply in daily hygiene tissue products with the state-of-the-art mill expansion utilizing most advanced technology. The modernisation and expansion investment is part of Metsä Tissue´s Future Mill Programme which targets world leading environmental and operational performance in tissue production.

”Tissue production is local and it is not sustainable to transport tissue products across long distances. These daily necessity products need to be available in all situations and sustainable local production helps to safeguard the security of supply in the market. This investment aims at just that – availability of sustainable, locally made tissues in a region, which is currently one of the largest net importers of tissue finished goods in Europe. We are proud to develop this business to even more sustainable and locally driven to make what we think are the best tissues in the world, available to consumers in all situations”, says CEO Esa Kaikkonen, Metsä Tissue.

The mill produces high quality Lambi, Serla and Katrin tissue products for both consumer and professional use and the current capacity will be doubled to approximately 145,000 t/a. After the expansion the mill will have a new modern tissue paper machine with the capacity of 70,000 t/a, three new converting lines, for both rolled and folded tissues. Also a fully automated warehouse for finished goods and raw material handling will be built as well as a new office facility.

Mariestad mill in Sweden

Mariestad mill in Sweden

Improved energy efficiency, lower emissions and improved noise and odor plans used as design criteria in the new expansion

- The expansion of the Mariestad mill will bring considerable improvements in the environmental performance of tissue production. Despite the doubled production capacity, the fossil CO2 emissions will drop to zero latest by 2030 due to new technology in use.

- The expansion will focus purely on sustainable fresh fibre production, after which the total fresh fibre share at the mill is 80%.

- The water consumption per ton will be diminished by 50% to 10 m3/t because of the new paper machine technology, fresh fibre based production and effluent plant modernization which is enabling better utilization of purified water in the Mariestad’s mill water circulation.

- Tissue as a bulky product with high air content is not economically viable nor sustainable to transport long distances. Logistics emissions are planned to drop by 25% per year due to replacing paper imports with local production.

- The modernisation brings improvements also to the mill’s neighborhood. With the modern production technology, the mill will have lower noise and odor levels than today. A new noise barrier will lower the noise levels by 3-5 dBA because of new embankments between the mill and residential area and additional 26 silencers will block noise effectively.

- The mill will be equipped with new technology for water management and more efficient technology for purification, which will have a positive effect on odors. The majority of the new water treatment equipment will be covered, further improving the odour management.

Significant impact on local employment

Through this investment Metsä Tissue will be hiring around 100 people at the mill before the new extension is in operation. The majority, approximately 75%, will be multiskilled production workers with technical competences. The recruitment for the key positions, like Production Engineers and Automation Specialists, will begin already this year. During the construction phase, the total employment impact is estimated to be around 2,000 person-years.

Manufacturing at the mill will continue normally during the expansion.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 6 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by nearly 100,000 forest owners.

Metsä Tissue

www.metsagroup.com/metsatissue

Metsä Tissue creates a cleaner everyday life. We are one of the leading tissue paper suppliers in Europe to households and professionals and one of the leading greaseproof paper suppliers globally.

Our brands are Lambi, Serla, Mola, Tento, Katrin and SAGA. With production units in five countries, we employ around 2,500 people. In 2021, our sales totalled EUR 0.9 billion. Metsä Tissue is part of Metsä Group.

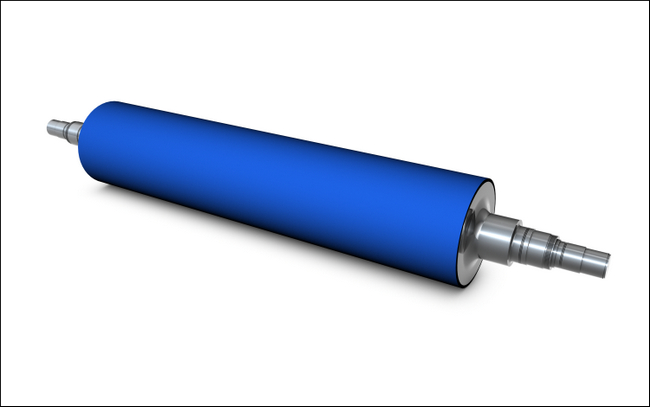

OceanCoat P: Voith launches new coater backing roll cover

As an addition to the proven OceanCoat roll cover, Voith has now developed the OceanCoat P. The new coater backing roll cover is specially made for high-demand positions in blade coater applications. Due to its new polyurethane chemistry and unique filler concept, OceanCoat P is optimized to meet the requirements of stable profile conditions and highest wear resistance.

- Optimally designed for high-demand positions in blade coater applications

- Meets the requirements of stable profile conditions and highest wear resistance

- Made with a new polyurethane chemistry and unique filler concept

OceanCoat P is confirmed to be very resistant to over pressing. Due to the resistant polymer matrix enhanced with fillers, a constant cover surface including very high abrasion resistance can be ensured. This is an important advantage in coater backing roll applications, as paper breaks may lead to over pressing on standard covers and can shorten the cover lifetime. Another decisive advantage of OceanCoat P is its high chemical resistance. All features increase the running time of the roll, simplify work processes, and thus increase the machine’s productivity.

OceanCoat P

OceanCoat P

“We are extremely satisfied with the OceanCoat P. After six months in operation, the roll is still in very good condition,” confirms Markus Krall, Production Manager Coating & Finishing Line 4 at Norske Skog Bruck. “The runtime, which is usually 180 days in this position and shows wear especially in the edge area, was achieved without difficulty. OceanCoat P shows no wear and is used without regrinding.”

Voith offers the best solution for demanding coater backing roll applications and is an expert in the whole process. Especially when combined with ceramic coated high-performance blades, OceanCoat P offers the potential to reduce overall production costs for the customer.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.