Displaying items by tag: valmet

Valmet to supply the final stage of forming section rebuild to Stora Enso’s Skoghall Mill in Sweden

Valmet will supply the final stage of its four-stage forming section rebuild to Stora Enso’s Skoghall Mill in Sweden. The target of Valmet’s four-stage development project is to further improve production capabilities of the Stora Enso Skoghall Mill forming section.

The latest order is included in Valmet's orders received of the first quarter 2020. The value of the order will not be disclosed.

The latest order is included in Valmet's orders received of the first quarter 2020. The value of the order will not be disclosed.

“Innovation and continuous long-term development describe well our cooperation with Valmet. Together we came up with a solution that fulfils our targets for this upgrade project,” says Marie Morin, Mill Director from Stora Enso.

“Stora Enso Skoghall Mill is committed to long-term development of its machines. This type of cooperation is based on trust and openness and we look forward to successfully conclude the last phase of this project,” says Kirsi Peltola, Sales Manager from Valmet.

Valmet supplied the first stage in 2017 and has since then upgraded other parts of the forming section step-by-step on an annual basis. The last stage of the rebuild will be started up at the end of year 2020.

Information about the customer Stora Enso

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. The company employs some 26,000 people in more than 30 countries. Skoghall Mill in western Sweden is a modern world-class producer of cartonboard for demanding consumer packaging and printing purposes, including liquid packaging and dry foodstuffs board.

Valmet to supply cooking and fiberline to Tamil Nadu Newsprint and Papers Ltd. in India

Valmet will deliver cooking and fiberline to Tamil Nadu Newsprint and Papers Ltd. (TNPL) for their unit 2, located in Mondipatti in the Trichy District, India. The site has a 200,000 tons per year multilayer board machine, which has been in operation since 2016. The new pulp mill will have a capacity of 165,000 tons per year of bleached hardwood kraft pulp and the start-up is planned for the first quarter of 2021.

The order is included in Valmet’s orders received of the fourth quarter 2019. The value of the order will not be disclosed. An order with this scope of supply is usually valued in the range of EUR 20-30 million.

Valmet has a long-term relationship with TNPL. Valmet has previously supplied two fiberlines based on hardwood and bagasse respectively to their unit 1, located in Kagithapuram in the Karur District, India.

Managing Director and the mill management team of TNPL together with Valmet’s sales management team

Managing Director and the mill management team of TNPL together with Valmet’s sales management team

“Valmet’s technology is proven to meet TNPL’s strict requirements for low water consumption and raw material efficiency, which have special importance in this region. Since the launch of our latest third generation continuous cooking system in late 2018, we have been well received by the market and this order is yet another acknowledgment of that. Furthermore, this will be Valmet’s first modern reference in India for a continuous digester system, so we are proud and grateful to be a part of the project together with TNPL,” says Eva Engelfeldt, Senior Sales Manager, Fiber Processing Business Unit, Valmet.

“The unit 2 is a leading manufacturer of pulp and paper board in India. The new pulp mill with Valmet’s cooking and fiberline technology will further strengthen our ambition to maintain the leading position,” says S J Varadarajan, General Manager (Projects), TNPL. “The Valmet fiberline brings the latest technology to the TNPL Unit 2 with thrust on water conservation and environment protection. This fiberline will go a long way in making the operations of our unit 2 profitable,” says S V R Krishnan, Executive Director (Operations), TNPL.

Information about Valmet’s delivery

The scope of Valmet’s supply includes main equipment and process design for continuous cooking, deknotting, screening, brown stock washing, oxygen delignification, a three stage ECF bleaching and DNCG systems including pressure vessels, instruments and pumps.

Information about Tamil Nadu Newsprint and Papers Ltd.

Tamil Nadu Newsprint and Papers is situated at Kagithapuram in the Karur District of the Tamil Nadu province in India. The company produces newsprint and printing & writing papers using hardwood and bagasse as the primary raw materials.

Valmet introduces a full range of Industrial Internet solutions to pulp, board, paper, tissue and energy producers

Valmet introduces a full range of new, data-driven Industrial Internet solutions to pulp, board, paper, tissue and energy producers. The Valmet Industrial Internet (VII) solutions combine advanced monitoring and prediction applications, Advanced Process Controls (APC), dynamic process simulators and remote services from Valmet Performance Centers into comprehensive solutions that provide tangible benefits to customers.

VII solutions are tailored for each customer industry

The new VII solutions have been created for the specific needs of pulp, board, paper, tissue and energy producers. The purpose is to efficiently utilize data and Valmet’s expertise to reduce energy consumption, improve chemical and environmental efficiency, optimize pulp and paper quality, increase process reliability, maximize production and enable efficient management of the customer’s equipment fleet.

Performance Centers and Valmet Customer Portal are key elements of the VII solutions

Remote services from Valmet’s eight Performance Centers are a key part of the VII solutions. The Performance Centers make Valmet’s expertise easily available for customers through remote connections and tools.

Customers can collaborate with Performance Center experts, access the Industrial Internet applications, follow-up their Key Performance Indicators and see performance reports via Valmet Customer Portal.

Customers can collaborate with Performance Center experts, access the Industrial Internet applications, follow-up their Key Performance Indicators and see performance reports via Valmet Customer Portal.

“Our customers’ needs have been the starting point of developing these data driven Industrial Internet solutions. We have integrated our process, automation and services know-how and extensive Industrial Internet application portfolio into a value-added solution offering. Ultimately, the aim is to empower our customers to move toward autonomous plants or mills, which will result in significantly more efficient production processes and operations. We want to engage our customers in a dialogue with data to move their performance forward,” says Jari Almi, Vice President, Industrial Internet, Automation business line, Valmet.

Valmet to deliver defibrator system to Qinzhou Lvyuan Wood in China

Valmet will supply a Defibrator™ system and a Steam Separator PV system to Qinzhou Lvyuan Wood Co., Ltd. in China. The start-up of the system is planned for spring 2020.

The order was included in Valmet’s orders received of the fourth quarter 2019. The value of the order will not be disclosed.

Qinzhou Lvyuan project is a new investment of Lvyuan Group to expand its production and diversify its product range. The project is located in Guangxi autonomous region. In recent years, Guangxi has actively developed the forestry industry, expanded the industrial chain and built industrial clusters.

"We studied the equipment configuration of this project and compared several suppliers on their equipment performance parameters and actual use conditions in detail. After that, we chose Valmet to provide us the related fiber preparation equipment, which included the new generation of defibrator system and steam recovery system. It will enable an environmental production with lowest operation cost and the best fiber quality,” says Xu Zhaohui, Chairman of Lvyuan Group.

"Valmet’s employees are real professionals in fiber technology, and they are very hardworking and dedicated. Valmet provided us professional technical support and services to ensure the success of our project," says Wang Zhenhua, Qinzhou Lvyuan Wood Project Manager.

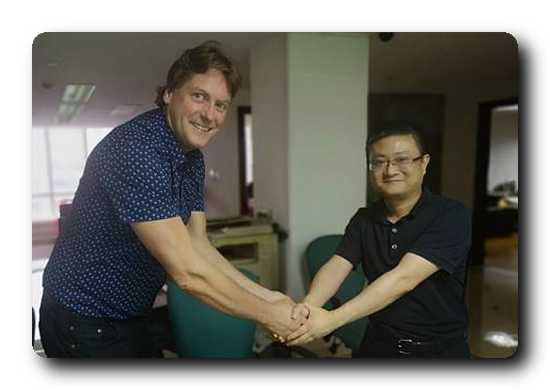

Leif Sundberg, Sales Manager, Pulp and Energy business line, Valmet, shaking hands with Xu Zhaohui, Chairman of Lvyuan Group

Leif Sundberg, Sales Manager, Pulp and Energy business line, Valmet, shaking hands with Xu Zhaohui, Chairman of Lvyuan Group

“This is an important prestige order for Valmet, since it is the first time Lvyuan group buys from us. The delivery will give us important references in China and Asia,” says Leif Sundberg, Sales Manager, Pulp and Energy, Valmet.

Information about Valmet’s delivery

Valmet’s scope of supply includes the newly released Defibrator Gen2 EVO 56 system and the Valmet Steam Separator PV. Valmet's defibrators are known for their reliability and provide homogenous fiber material of highest quality. The Steam Separator PV recovers process steam from the blow line that can be reused for preheating of the chips. This will reduce the fresh steam consumption significantly. This delivery will provide the highest performing and most energy efficient fiberboard front-end system on the market.

Information about the customer Qinzhou Lvyuan Wood Co., Ltd.

Qinzhou Lvyuan Wood Co., Ltd. was founded in 2001 and is one of the large-scale MDF manufacturers in China with annual production capacity of more than 750,000 cubic meters.

It has four subsidiaries, which are located in Zhejiang, Guangdong, Fujian, and Anhui province, and four production lines, including three production lines with an annual output of 200,000 cubic meters, and one imported production line with an annual output of 150,000 cubic meters.

Valmet to supply a new evaporation line to Century Pulp and Paper in India

Valmet will supply an evaporation line to Century Pulp and Paper’s (CPP) pulp mill in Lalkuan, India. The new evaporation line will meet the future needs of the mill's ongoing pulp production capacity expansion, together with the existing evaporation line. This investment will also improve the overall steam economy of the mill.

The order was included in Valmet’s orders received of the fourth quarter 2019. The value of an order of this size and delivery scope is typically below EUR 10 million. The new evaporation line is planned to start up during latter part of 2020.

“In an Integrated pulp and paper mill, the recovery line is a vital part in securing the mill’s operations. In view of this, we decided to go with the latest and most advanced evaporation technology. We evaluated different alternatives and decided to choose Valmet. Our new plant should be commissioned by December 2020,” says P.K. Mittal, Head of Process, Century Pulp and Paper.

“In an Integrated pulp and paper mill, the recovery line is a vital part in securing the mill’s operations. In view of this, we decided to go with the latest and most advanced evaporation technology. We evaluated different alternatives and decided to choose Valmet. Our new plant should be commissioned by December 2020,” says P.K. Mittal, Head of Process, Century Pulp and Paper.

“Century has always been in the forefront of implementing efficient technologies across the entire value chain and the Valmet Evaporator is another step in this direction,” says J.P. Narain, CEO, Century Pulp and Paper.

“This is Valmet’s first evaporation plant installation in India. We were able to offer clear technical advantages through our customized and detailed design done by our technical team, and the solution was appreciated by the customer. The project execution has started in a very smooth way and both the customer and Valmet’s teams work as one team for successful execution of the project. We are looking forward to creating a good reference with leading technology in India,” says Varun Jain, Director, India Region, Valmet.

Details about Valmet's delivery

Valmet’s delivery includes a new 7-effect evaporation plant with a design capacity of 275 tons of evaporated water per hour, producing heavy liquor of 75% dry solids. The plant is designed to handle black liquor based on 60% bagasse and 40% wood. The delivery covers main evaporator effects, a surface condenser, an integrated foul condensate treatment plant, flash tanks, main supporting structures, and a vacuum system.

The new evaporation line is based on proven tube evaporator design and will feature Valmet’s patented vapor recycling technology. The new evaporator line includes a stripper to treat foul condensate and ICT (Internal Condensate Treatment) for producing more clean-quality condensate for recycling in the mill.

Information about the customer Century Pulp and Paper

Century Pulp and Paper (CPP) is a division of Century Textile and Industries Ltd (CTIL). The company’s manufacturing unit, located in Lalkuan, Uttarakhand, manufactures a wide range of paper products including writing and printing paper, tissue paper, and paper board. The premises also house a manufacturing facility for producing raw material for viscose filament yarn, staple fibre, and paper grade pulp. Over the years, the company has augmented its capacities by commissioning a prime-grade tissue paper plant along with three sheet-cutting units across the northern and eastern part of India.

Valmet to deliver Defibrator system to Guangxi Shangsi Hualin in China

Valmet will supply a Defibrator system to Guangxi Shangsi Hualin Forestry Industry Co., Ltd. in China. The start-up of the system is planned for the middle of 2020.

The order was included in Valmet’s orders received of the fourth quarter 2019. The value of the order will not be disclosed. An order with this scope of supply is usually valued in the range of EUR 2-5 million.

“We set many evaluation indicators when selecting the suppliers, and Valmet’s score was the highest. It is not difficult to reach our capability demands, but it is a difficult to reach our quality requirements. Our main product is ultra-thin board, which requires extra high-quality fiber, and that is Valmet’s advantage. Valmet’s technology know-how, equipment performance, reputation and references also received high scores. We are confident that our future cooperation will be very fruitful, and this project will be very successful,” says Zheng Shengjun, President at Guangxi Shangsi Hualin Forestry Industry Co., Ltd.

From left: Jansen Shang, Senior Sales Mangager, China (Valmet), Zheng Shengjun, President (Guangxi Shangsi Hualin), Lin Guicheng, President (Guangxi Forestry Product Group) and Pontus Nilsson, Senior Process Engineer (Valmet)

From left: Jansen Shang, Senior Sales Mangager, China (Valmet), Zheng Shengjun, President (Guangxi Shangsi Hualin), Lin Guicheng, President (Guangxi Forestry Product Group) and Pontus Nilsson, Senior Process Engineer (Valmet)

“We are facing a tight schedule, but with close collaboration we can make it. We expect to receive technical support and service from Valmet, not only for the project period, but also for after sales services. We are aiming for long term partnership,” says Chen Yuankun, Technical Manager at Guangxi Shangsi Hualin Forestry Industry Co., Ltd.

“This is an important prestige order for Valmet, since it is the first project with Guangxi Forest Group. The delivery will give us important references in China and Asia,” says Leif Sundberg, Sales Manager, Pulp and Energy, Valmet.

Information about Valmet’s delivery

Valmet’s scope of supply includes the newly released second generation Defibrator system. The new system is a further refinement of the Valmet Defibrator EVO, already known for the reliable performance and high fiber quality.

With the Defibrator EVO 64, Valmet will further strengthen its position as a supplier of the highest performing fiberboard front-end system.

Information about the customer Guangxi Shangsi Hualin Forestry Industry Co., Ltd.

Guangxi Shangsi Hualin Forestry Industry Co., Ltd. was founded in 2004. Main business of the company is forestry and products including wood, timber, and panel. The company is a state-owned company and belongs to Guangxi Forestry Product Group.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2019 were approximately EUR 3.5 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply cooking and fiberline to Tamil Nadu Newsprint and Papers Ltd. in India

Valmet will deliver cooking and fiberline to Tamil Nadu Newsprint and Papers Ltd. (TNPL) for their unit 2, located in Mondipatti in the Trichy District, India. The site has a 200,000 tons per year multilayer board machine, which has been in operation since 2016. The new pulp mill will have a capacity of 165,000 tons per year of bleached hardwood kraft pulp and the start-up is planned for the first quarter of 2021.

The order is included in Valmet’s orders received of the fourth quarter 2019. The value of the order will not be disclosed. An order with this scope of supply is usually valued in the range of EUR 20-30 million.

Managing Director and the mill management team of TNPL together with Valmet’s sales management team.

Managing Director and the mill management team of TNPL together with Valmet’s sales management team.

Valmet has a long-term relationship with TNPL. Valmet has previously supplied two fiberlines based on hardwood and bagasse respectively to their unit 1, located in Kagithapuram in the Karur District, India.

“Valmet’s technology is proven to meet TNPL’s strict requirements for low water consumption and raw material efficiency, which have special importance in this region. Furthermore since the launch of our latest third generation continuous cooking system in late 2018, we have been well received by the market and this order is yet another acknowledgment of that. This will be Valmet’s first modern reference in India for a continuous digester system, so we are proud and grateful to be a part of the project together with TNPL,” says Eva Engelfeldt, Senior Sales Manager, Fiber Processing Business Unit, Valmet.

“The unit 2 is a leading manufacturer of pulp and paper board in India. The new pulp mill with Valmet’s cooking and fiberline technology will further strengthen our ambition to maintain the leading position,” says S J Varadarajan, General Manager (Projects), TNPL. “The Valmet fiberline brings the latest technology to the TNPL Unit 2 with thrust on water conservation and environment protection. This fiberline will go a long way in making the operations of our unit 2 profitable,” says S V R Krishnan, Executive Director (Operations), TNPL.

Information about Valmet’s delivery

The scope of Valmet’s supply includes main equipment and process design for continuous cooking, deknotting, screening, brown stock washing, oxygen delignification, a three stage ECF bleaching and DNCG systems including pressure vessels, instruments and pumps.

Information about Tamil Nadu Newsprint and Papers Ltd.

Tamil Nadu Newsprint and Papers is situated at Kagithapuram in the Karur District of the Tamil Nadu province in India. The company produces newsprint and printing & writing papers using hardwood and bagasse as the primary raw materials.

Valmet introduces a full range of Industrial Internet solutions to pulp, board, paper, tissue and energy producers

Valmet introduces a full range of new, data-driven Industrial Internet solutions to pulp, board, paper, tissue and energy producers. The Valmet Industrial Internet (VII) solutions combine advanced monitoring and prediction applications, Advanced Process Controls (APC), dynamic process simulators and remote services from Valmet Performance Centers into comprehensive solutions that provide tangible benefits to customers.

VII solutions are tailored for each customer industry

The new VII solutions have been created for the specific needs of pulp, board, paper, tissue and energy producers. The purpose is to efficiently utilize data and Valmet’s expertise to reduce energy consumption, improve chemical and environmental efficiency, optimize pulp and paper quality, increase process reliability, maximize production and enable efficient management of the customer’s equipment fleet.

Performance Centers and Valmet Customer Portal are key elements of the VII solutions

Remote services from Valmet’s eight Performance Centers are a key part of the VII solutions. The Performance Centers make Valmet’s expertise easily available for customers through remote connections and tools.

Customers can collaborate with Performance Center experts, access the Industrial Internet applications, follow-up their Key Performance Indicators and see performance reports via Valmet Customer Portal.

Customers can collaborate with Performance Center experts, access the Industrial Internet applications, follow-up their Key Performance Indicators and see performance reports via Valmet Customer Portal.

“Our customers’ needs have been the starting point of developing these data driven Industrial Internet solutions. We have integrated our process, automation and services know-how and extensive Industrial Internet application portfolio into a value-added solution offering. Ultimately, the aim is to empower our customers to move toward autonomous plants or mills, which will result in significantly more efficient production processes and operations. We want to engage our customers in a dialogue with data to move their performance forward,” says Jari Almi, Vice President, Industrial Internet, Automation business line, Valmet.

Valmet to deliver defibrator system to Çamsan Entegre in Turkey

Valmet will supply a Defibrator™ system to Çamsan Entegre Ağaç Sanayi ve Ticaret A.Ş in Turkey. The start-up of the system is planned for the middle of 2020.

The order is included in Valmet’s orders received of the fourth quarter 2019. The value of the order will not be disclosed. An order with this scope of supply is usually valued in the range of EUR 2-5 million.

The order is included in Valmet’s orders received of the fourth quarter 2019. The value of the order will not be disclosed. An order with this scope of supply is usually valued in the range of EUR 2-5 million.

"The EVO 64 system is specially designed for production levels up to 35 tons per hour, which will be perfect for Çamsan Entegre in this case. We are really pleased that Valmet was chosen as the supplier in this project," says Leif Sundberg, Sales Manager, Pulp and Energy, Valmet.

Information about Valmet’s delivery

The scope of Valmet’s supply includes a complete EVO 64 defibrator system with a steam separator. This is the first steam separator delivery for Valmet in Turkey.

Information about the customer Çamsan Entegre Ağaç Sanayi ve Ticaret A.Ş

Çamsan Entegre is a Turkish Medium Density Fiberboard (MDF) and laminated parquet flooring producer. Their paper impregnation capacity is 90.000.000 m² per year. Çamsan Entegre is a domestic leader and is mainly exporting to Iran, Egypt, Iraq, T.R.N.C., Azerbaijan, Kuwait, Greece, Albania, Tunisia, Bulgaria, Kosova, Georgia, Turkmenistan and Afghanistan.

Valmet to deliver key pulp mill technology and automation for Lenzing’s and Duratex’s joint pulp mill project in Brazil

Valmet will deliver key process islands for Lenzing’s and Duratex’s joint venture named LD Celulose S.A. The new 500,000 ton/year dissolving pulp mill is located in the cities of Indianópolis and Araguari in Minas Gerais state, Brazil. Valmet’s delivery includes a fiber line, a pulp drying and baling line, an evaporation plant, a white liquor plant and a mill-wide automation system.

The order is included in Valmet's orders received of the first quarter 2020. The value of the order is not disclosed. The value of a delivery of this size and scope is typically around EUR 200-250 million.

Valmet’s delivery is part of the Lenzing and Duratex joint venture investment of approximately USD 1.3 bn in the 500,000 tonnes dissolving wood pulp mill where Lenzing holds a 51 percent and Duratex a 49 percent stake. The start-up of the new mill is planned for the first half of 2022 and will create approximately 8,000 direct jobs during the construction phase. When it is ready, LD Celulose S.A. will employ approximately 1,100 people to operate the industrial plant and the plantations that will supply it. The dissolving pulp is a key raw material for manufacturing Lenzing’s wood-based textile and speciality fibers.

“Wood-based cellulosic fibers offer an important contribution to enhance sustainability in the textile industry and this investment is in line with our growth strategy and a key milestone to structurally strengthen our cost leadership position. In planning the new production facility, particular importance was given to sustainability aspects. The plant will be among the most productive and energy-efficient mills in the world,” states Stefan Doboczky, CEO of the Lenzing Group.

“LD Celulose S.A. will bring a positive socioeconomic impact throughout the region. We are working with the best environmental practices and with leading companies in the pulp industry, such as Valmet,” emphasizes Luís Künzel, CEO of LD Celulose S.A.

“With our good references in dissolving pulp production technology and strong presence in Brazil we were able to meet the customer’s needs of high quality and energy efficiency as well as supporting high productivity and reliability with our automation solutions. We are happy to be a key partner in delivering a world class mill for Lenzing and Duratex and thus being part of turning renewable raw materials for sustainable textile fibers,” says Bertel Karlstedt, President, Pulp and Energy Business Line, Valmet.

The new 500,000 tonnes dissolving wood pulp mill is being built in Minas Gerais state, Brazil.

The new 500,000 tonnes dissolving wood pulp mill is being built in Minas Gerais state, Brazil.

Information about Valmet’s delivery

Valmet will supply key process islands with an extended scope of supply. Valmet’s technology is proven for dissolving pulp production with several references. The equipment for this project is tailored for high availability and energy efficiency resulting in low operating costs.

The fiber line features Valmet TwinRoll technology for high washing efficiency with low chemical and water consumption. The pulp drying and baling line secures flexibility and high-quality pulp with easy operation supported by Valmet Quality Control System. The evaporation plant features Valmet Tubel technology for high availability and produces clean condensate quality for 100% reuse in the mill. The white liquor plant includes recausticizing and lime kiln and is designed for high reliability and less maintenance.

The mill-wide automation system, Valmet DNA, offers unique integration with process solutions including process analyzers. In addition, the delivery includes Valmet Industrial Internet solutions for Operator Training Simulator for the whole plant as well as basic hardware for connectivity for Performance Center services.

Information about the customers Lenzing and Duratex

The Lenzing Group headquartered in Austria is an international company of wood-based cellulose fibers. These high quality fibers are used in the textile industry, in the nonwovens industry for hygiene products and are also used in work and protective wear and in industrial applications. Dissolving wood pulp is subsequently processed from the raw material wood and marketed under the brands TENCEL™ for textile applications, VEOCEL™ for nonwovens and LENZING™ for special fiber applications in other areas and other products. The annual turnover of the Lenzing Group is above EUR 2,000 million.

Duratex is the largest producer of industrialized wood panels in the southern hemisphere. The company has three business areas: Wood, Ceramic tiles and Sanitary ware, metals, electric showerheads and faucets. The Wood division covers wood products and forestry, producing eucalyptus in more than 251 thousand hectares of forests. Duratex’s head quarter is located in the city and state of São Paulo and it has seven forestry units and 16 industrial facilities in Brazil and three production facilities in Colombia.