Super User

Valmet to deliver the world’s first electrical folding machine for pulp bales to Södra Cell Mönsterås, Sweden

Valmet will deliver the world’s first two electrical folding machines for pulp bales to Södra Cell Mönsterås pulp mill in Sweden. The machines’ start-up is planned for the last quarter of 2022.

The order was included in Valmet’s orders received of the first quarter 2022. The value of the order will not be disclosed.

“We are always looking forward to working with Valmet, and by being the first to try their latest hi-tech bale handling equipment, we hope to be one step ahead of our competitors. We have had similar projects before, and we are confident that Valmet will do a fantastic job this time too,” says Daniel Sjöberg, Project Manager, Södra Cell Mönsterås.

“We are very pleased to have gained the trust of Södra Cell Mönsterås for the delivery and start-up of the world’s first electrical folding machine for pulp bales. We have had successful new baling technology development projects with Mönsterås before and are now taking the collaboration to the next level,” says Philip Reiz, Global Technology Manager, Bale Handling, Services Business Line, Valmet.

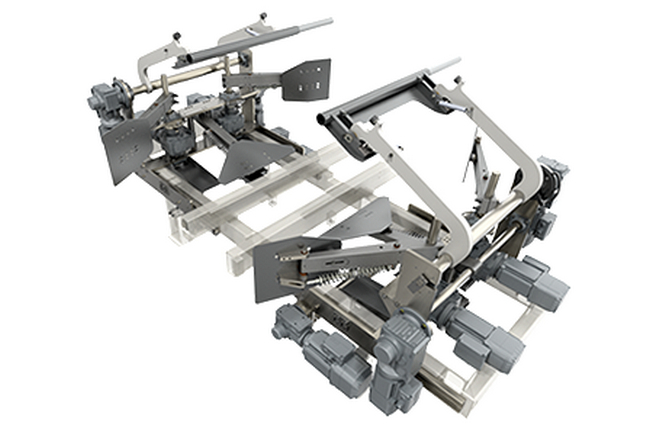

Valmet Electrical Folding Machine

Valmet Electrical Folding Machine

Information about Valmet’s delivery

Valmet’s scope of supply includes the release of the world’s first electrical folding machine for bale handling systems. The new Valmet Electrical Folding Machine is a further refinement of the Valmet Folding Machine VKC.

By removing the hydraulics and using only electrical drives, Valmet is improving the performance of the machine as well as the maintenance personnel’s and operators’ working environment. In addition, electricity consumption is reduced.

Information about Södra Cell Mönsterås

The mill in Mönsterås is one of the world’s most modern and hi-tech pulp mills, with a production capacity of 750,000 tonnes of softwood and hardwood pulp per year. The mill’s core business is pulp production, but it is also an important producer of green electricity. In 2020, the world’s first commercial biomethanol plant commenced operations in Mönsterås, strengthening the mill’s position as a growing supplier of biofuels.

Read more: Valmet’s services for pulp production

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Toscotec launches breakthrough in Steel Yankee Dryers for sustainable papermaking

Toscotec, the global market leader of Steel Yankee Dryers, introduces TT Induction SYD, a carbon-reduction breakthrough that redefines Yankee dryer technology entirely. TT Induction SYD uses electrical induction instead of steam energy to dry the paper web, thereby cutting direct greenhouse gas emissions to zero.

In 2000, Toscotec pioneered a major technological innovation, TT SYD, the first Yankee dryer entirely made of steel. Steel Yankees have since surpassed their cast-iron equivalent to become the benchmark for drying efficiency and safety in the paper industry. TT Induction SYD is now set to be the new game changer in tissue for its capability to use clean energy and slash direct carbon emissions associated with the drying process.

A disruptive innovation for dry crepe and TAD tissue machines

With TT Induction SYD, the internal steam distribution and steam/condensate removal systems are entirely replaced by an induction system composed of static coils installed inside the shell and electrical controls and instrumentation located outside for easy maintenance and monitoring. As a result of precise coil geometry, the induction system delivers a very fast and accurate heating effect exactly on the areas of the shell where it is required, while preventing residual circulating currents in other areas.

Steam-heated Yankees use steam energy typically generated by burning fossil fuels. TT Induction SYD uses electrical energy that can be derived from renewable energy sources while delivering the same result, i.e. uniformly heating up the Yankee’s shell in contact with the paper web to achieve dryness. TT Induction SYD is suitable for installation on dry crepe as well as Through-Air-Drying (TAD) tissue lines.

Luca Ghelli, Toscotec R&D Director, says, “Sustainability is the guiding idea of TT Induction SYD’s design. As a proven industrial technology, an induction system offers multiple advantages when applied to the most energy-intensive section of the tissue machine. The efficiency of this cutting-edge technology will dramatically reduce the carbon footprint of papermaking. Based on our expertise in steam-heated TT SYD and induction systems, we succeeded in developing a more efficient and sustainable steel Yankee dryer.”

Substantial carbon reduction with unchanged productivity and paper quality

Normally, approximately half of the carbon dioxide emissions produced by a tissue machine originate from the operation of the Yankee dryer. By using clean energy, TT Induction SYD achieves zero direct emissions, while maintaining productivity unchanged and reducing energy consumptions because of the higher efficiency of the induction system. Due to the precise heating of the shell, it also eliminates possible moisture profile issues related to uneven condensate removal, thereby ensuring an improvement in moisture uniformity in both cross direction (CD) and machine direction (MD).

Maximum safety, easier operation, and maintenance

TT Induction SYD was designed without any electrical, mechanical, and radiation risk to ensure maximum safety. Besides offering safe operations, it also clears all issues related to the maintenance of steam-heated Yankees, including pressure vessel’s mandatory and planned controls, maintenance of condensate straw pipes against potential plugging and of special heads for steam and condensate inlet and outlet. The entire Yankee system is simplified in the absence of steam: the heads, the internal surface which is groove-less, and the steam and condensate auxiliary system disappears entirely, including the steam generator with related maintenance and controls and delicate controls for steam quality. TT Induction SYD simply requires relatively easy maintenance on the electromagnetic induction system.

For further information, please contact:

Marco Dalle Piagge, Sales Director, Toscotec Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

ANDRITZ to supply two PMA systems and LC refining to Dongfang Smart Energy, China

International technology group ANDRITZ has received an order from Dongfang Smart Energy Co., Ltd. of Shaanxi Power Generation Group to supply two paper machine approach flow systems and LC (low consistency) refiners to its mill in Wugong County, Xianyang City, Shaanxi Province, China.

Start-up is scheduled for the second quarter of 2023.

The highly efficient PMA systems will have an aggregate design capacity of 1,850 t/d and will be part of lines PM1 and PM2 producing kraft board and testliner. Installation and supervision of start-up are also part of the scope of supply.

Zhao Shengli, General Manager, Dongfang Smart Energy says: “ANDRITZ’s impressive reference projects convinced us to trust in its well proven technology. We are looking forward to seeing the benefits we are expecting – excellent performance and significant energy savings.”

ANDRITZ ModuScreen HB © ANDRITZ

ANDRITZ ModuScreen HB © ANDRITZ

Dongfang Smart Energy Co., Ltd., of Shaanxi Power Generation Group, was established in 2020 and is active in various business segments, such as pulp and paper production, thermal power production and supply, sewage treatment and recycling, and the recovery of renewable resources.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ABB’s spare parts analytics to optimize operations for Vietnam’s leading paper manufacturer

ABB has successfully devised a spare parts and maintenance program for Saigon Paper, Vietnam’s leading paper manufacturer, enabling the company to drive productivity in their mills.

- ABB leverages its proprietary spare parts analysis tool to help enhance Saigon Paper Corporation’s mill parts inventory

- Accurate spare parts inventory reduces breakdown incidents, improves machine availability and optimizes productivity

- A solid inventory of spare parts offers a competitive advantage, allowing mills to avoid production losses

The ABB team created a recommended spares and gap analysis using mySpareParts Manager, an ABB-facing tool that built a custom report with required distributed control system (DCS) spare parts for Saigon Paper’s operations. Not only did it show how to optimize the cost of inventory and the exact lifecycle of the DCS equipment for advance planning of upgrading and replacing, but it also helped identify the minimum necessary spare parts, expanding initial scope from seven items to fifteen.

With proactive spare parts becoming more important to avoid production losses, having a solid inventory of spare parts is a clear competitive advantage. Saigon Paper will now be able to benefit from reduced breakdown incidents, improved machine availability and optimized productivity with low maintenance costs, while focusing on energy efficiency, further boosting profit margins.

“Our investment in ABB’s service is paying off already by giving us a better overview of the DCS spare parts needed in order to optimize the cost of inventory and improve productivity in our mills,” said Mr Quy Luu Tu, Maintenance Manager of Saigon Paper. “We expect to have the same service from ABB for all other equipment and software as well.”

“Strong collaboration has always been key to our long-standing relationship with Saigon Paper, and this really helped us to better understand their existing spare parts inventory for the entire ABB installed base, while driving towards a sustainable production process,” said Duong TranDai, Business Director, ABB Vietnam.

“Strong collaboration has always been key to our long-standing relationship with Saigon Paper, and this really helped us to better understand their existing spare parts inventory for the entire ABB installed base, while driving towards a sustainable production process,” said Duong TranDai, Business Director, ABB Vietnam.

Saigon Paper Corporation is the leading supplier of quality tissue and industrial paper and owns one of the country’s largest paper mills. Their paper mills collectively have an annual production capacity of 43,680 tons of tissue paper and 224,640 tons of industrial paper.

Both of their mills rely on ABB Ability™ System 800xA DCS to keep production running, and ABB is their long-term partner and preferred supplier for QCS, automation, drives, motors and electrification.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our # 1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations. go.abb/processautomation

How to reduce human intervention in the warehouse with robot AGV

The robot AGV has knocked on the door of the warehouse, and not as a passing guest, but as a new and welcome tenant. Automated Guided Vehicles - self-driving vehicles that perform handling tasks - represent a groundbreaking innovation for the world of intralogistics.

The innovation forms part of the wider one of Industry 4.0, which consists of connectivity and the Internet of Things, temperature, presence and movement sensors, RFID readers, and software that collects and analyses data to improve processes and perform predictive maintenance. These technologies are transforming production, but also other aspects of the supply chain.

There are various types of AGVs suitable for handling different quantities and types of goods, all of which share some abilities that translate into advantages.

Autonomy guaranteed by software and sensors

The ability to move independently (thanks to a range of technologies: electrical, optical, magnetic, GPS, etc.) makes the presence of a driver superfluous. Vehicles equipped with software can be programmed to perform precise operations, while cameras and sensors allow machines to perceive the surrounding environment.

The strength of machines

In intralogistics, as in many other fields (such as construction), the strength of machines far exceeds that of humans. The weight-bearing capacity of robot AGVs can vary greatly, but is in all cases superior to that of a team of people and often also to that of the classic forklift truck. The most powerful models can handle loads weighing several tons.

Constant energy

Lithium batteries, which can be charged quickly, increase the productivity of AGVs and reduce downtime. It can be said, then, that the level of performance of a machine does not improve or suffer according to physical condition, tiredness, hunger or commitment, but remains constant.

Safety for workers and goods

Intrinsically safe design, bumpers, brakes, and sensors that detect the presence of obstacles all help to reduce the risk of accidents (collisions with other vehicles or people, falling of goods, etc.).

Precision without distraction

Mechanical arms designed according to the goods to be handled (bales of raw material, pallets, paper rolls, etc.) and sensors allow for precise and repeatable movements, not subject to variability or human error.

The speed of a tireless robot

It is certainly easier for a vehicle to travel long distances, from one warehouse to another or between very large warehouse departments, or to shuttle between the picking area and the logistics delivery area. The performance of a robot AGV does not depend on subjective factors, on tiredness, or on the bulk of the shifted goods.

Benefits of a flexible fleet

If a company wishes to expand its production department or warehouse, it can increase the fleet of Automated Guided Vehicles in a gradual and flexible manner without risk of interference or the need to train new personnel.

Taken individually and of course as a whole, these features demonstrate why robot AGVs are a powerful tool in terms of productivity, efficiency and savings. A single self-driving vehicle can do the work of one or more people in less time. Programming makes it possible to precisely define routes and actions for the robot, but the advantages of AGVs are maximised in the case of use for repetitive processes in the warehouse and/or on a large scale.

The future of human-robot collaboration

Will we be saying goodbye to workers in the warehouse, then? Not exactly. Robots can improve and transform intralogistics processes, as well as cost and productivity models. But they don't have to be seen as earth-shattering. Their technology is scalable: you can start with one or two, and then increase the fleet when you best see fit.

Moreover, since AGVs are essentially "workers", it is them that have to adapt to existing workflows, and not the other way around. Rather than disappear, warehouse staff will be able to devote themselves to activities of greater added value: supervision, management, planning, maintenance and shipment control (thereby increasing the precision of operations and the correctness of deliveries).

Relieved of heavy work, the staff can dedicate more time and energy to tasks of responsibility. It is therefore true that there will be "less human intervention", but not from a purely numerical point of view: the more the warehouse is automated and managed by software, the more its processes interact without the need for a person to solve problems, perform maintenance, move objects or assign tasks to colleagues. Human intervention is reduced because the problems are reduced.

Industry 4.0 therefore allows robots and people to coexist by sharing tasks and responsibilities. But there is no doubt, in any case, that a 4.0 warehouse requires fewer new staff, since if the load increases it is possible to assign more hours of work to an AGV or add to the fleet.

There is a faster return on investment in machines due to cutting of personnel costs, not to mention better productivity and efficiency. In short, AGVs must not be seen as something of which to be afraid: they can be used in warehouses without causing confusion or threatening the existing dynamics, and indeed with the promise of numerous benefits.

In this article we focused on one aspect - reduced human intervention - but we will also talk about the other advantages in our eBook "Forklifts VS AGV systems: what is best for the warehouse?". Download it now for free!

Sunset Converting expands business and AFH private label offerings thanks to Kӧrber’s Perini MyLine and service

Sunset Converting Corp is the premier AFH private label tissue converting source for redistributors in Canada and the United States. Their industry experience, reputation for quality products, and commitment to innovation prompted the construction of a new mill in Quebec to better serve these markets.

The 2020 expansion also provided an opportunity to install two Perini MyLine on the Sunset production floor.

“Automation is in our DNA,” said Sunset Converting vice president and partner Mathieu Laferriere. “Our goal for the mill was keeping things clean, automated, well done, and functional. Kӧrber was a natural choice.”

Collaborating with Kӧrber also fueled Sunset innovation. The advanced technologies and capabilities enabled the supplier to run bath tissue and kitchen towels — products previously not available to the AFH private label market. “The flexibility of Perini MyLine is amazing. The machine does exactly what it says it can do in the specs, and more,” commented Laferriere.

“We pursued equipment purchases when the pandemic made it tricky. Perini MyLine was readily available, which was key. Also, Kӧrber could demonstrate it for us in their facility in Italy.”

“Seeing MyLine in action and experiencing the excellent product quality and features like AquaBond water lamination first hand confirmed what we needed to know. Plus the legendary reputation of the Perini converting technology from Kӧrber gave us confidence in our purchase.”

However, gaining competitive advantage with new product introductions is only the beginning of the benefits Sunset is receiving from the Perini MyLine. Laferriere sees the equipment’s ease of use and maintenance simplicity as foundational to success.

Like the majority of companies across industries, Sunset struggles with filling the skilled labor gap. “MyLine helps us empower less experienced team members. They have the right automation, production versatility, and streamlined processes to achieve their goals,” said Laferriere. “Our employees can be proud of their contributions. In turn, Sunset is able to serve the market well and efficiently provide high-quality private label AFH products to our customers.”

Service is a top priority for Sunset, both in providing it and receiving it from their key supplier relationships. “Kӧrber aligns with the Sunset philosophy of always being transparent and proactive with customers,” explained Laferriere. “It’s important for us to live that promise, and we couldn’t do it without suppliers who are on the same page. [Account Manager] Matt Kowalski’s professionalism and knowledge reflect Kӧrber’s commitment to their customers’ success before, during, and after the sale.”

From Perini MyLine versatility to Kӧrber service dependability, Sunset Converting Corp values every aspect of Kӧrber solutions. “When you feel good about a doing a deal, it validates your business decision,” concluded Laferriere. “Perini MyLine and our trust in the entire Kӧrber team continue to prove Sunset made the right choice.”

About Sunset Converting Corp

Sunset Converting Corp.’s is the inspiring story of three renowned and respected industry experts combining their assets to build and operate ultra-automated manufacturing facilities. Our mission is to offer a variety of cost-effective private label tissue products to customers in the North American redistribution market through a highly automated manufacturing process.

Get in touch

Körber Business Area Tissue

At Körber, our ultimate goal is to empower our customers’ ongoing success. We are the only truly integrated and global provider of advanced solutions for the tissue business. We offer the industry’s most comprehensive portfolio of tissue technology to support customers across the entire value chain — from roll to fold, from converting to packaging. Our advanced, automated, and easy-to-use integrated solutions are a fundamental asset to shape the success in tissue, take our customers operations to the next level, and strengthen their overall financial performance while optimizing their total cost of ownership.

About Körber

We are Körber – an international technology group with about 10,000 employees, more than 100 locations worldwide and a common goal: We turn entrepreneurial thinking into customer success and shape the technological change. In the Business Areas Digital, Pharma, Supply Chain, Tissue and Tobacco, we offer products, solutions and services that inspire. We act fast to customer needs, we execute ideas seamlessly, and with our innovations we create added value for our customers. In doing so, we are increasingly building on ecosystems that solve the challenges of today and tomorrow. Körber AG is the holding company of the Körber Group.

Valmet to deliver two chip washing and defibrator systems to Siempelkamp

Valmet will deliver two chip washing and defibrator systems to Siempelkamp Maschinen- und Anlagenbau GmbH as part of Siempelkamp’s panelboard plant deliveries to two different end customers, one in Europe, one in Asia. The start-ups of the systems are planned for 2023 and the beginning of 2024.

The orders were included in Valmet’s orders received of the first quarter 2022. The value of the orders will not be disclosed.

Valmet EVO 64 Defibrator System“Siempelkamp is well known as a supplier to the panelboard industry, and we are pleased to once again deliver defibrator systems to them. Together with Valmet’s market leading defibrator systems, Siempelkamp can offer high performing complete fiberboard plants to their end customers,” says Jonas Franzén, Sales Manager, Fiber Processing Business Unit, Pulp and Energy business line, Valmet.

Valmet EVO 64 Defibrator System“Siempelkamp is well known as a supplier to the panelboard industry, and we are pleased to once again deliver defibrator systems to them. Together with Valmet’s market leading defibrator systems, Siempelkamp can offer high performing complete fiberboard plants to their end customers,” says Jonas Franzén, Sales Manager, Fiber Processing Business Unit, Pulp and Energy business line, Valmet.

Technical information about the delivery

Valmet’s delivery will include all main machinery of the second-generation EVO 64 Defibrator system and chip washing, related motors, a control system as well as installation and start-up advisory.

Valmet’s defibrators are equipped with a patented grinding house that is unique in the industry. This feature enables both energy and resin savings, providing low operating costs and resulting in an environmentally friendly defibrator system for the production of high-quality wood fibers to MDF and HDF boards.

Information about the customer Siempelkamp Maschinen- und Anlagenbau GmbH

Siempelkamp is the leading global technology supplier for the panelboard industry with focus on machine and plant engineering, foundry technology, and engineering and services. Siempelkamp machine and plant engineering is a systems supplier of press lines and complete plants for the wood-based panel industry, the metal forming industry as well as the composite and rubber industry.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Change in Stora Enso’s Group Leadership Team

Kati ter Horst, Executive Vice President, Paper Division and a member of the Group Leadership Team, has decided to leave Stora Enso as of 1 July 2022. After more than 25 years with the Company, she will now pursue career opportunities outside of Stora Enso.

Kati ter Horst joined Stora Enso in 1996 and has been leading the Company’s Paper division since 2014.

“As a highly valued member of our Group Leadership Team, Kati has been instrumental in driving Stora Enso’s transformation journey into a renewable materials company by contributing to strategy development. She has showed strong leadership and has played a key role in the extensive restructuring process of our paper business. I want to express my gratitude to Kati for her significant contributions to Stora Enso, while wishing her all the best in her future endeavours,” says Annica Bresky, President and CEO at Stora Enso.

“As a highly valued member of our Group Leadership Team, Kati has been instrumental in driving Stora Enso’s transformation journey into a renewable materials company by contributing to strategy development. She has showed strong leadership and has played a key role in the extensive restructuring process of our paper business. I want to express my gratitude to Kati for her significant contributions to Stora Enso, while wishing her all the best in her future endeavours,” says Annica Bresky, President and CEO at Stora Enso.

"I have had a fantastic international career at Stora Enso, and I am very thankful for all that I have learned and for the opportunity to work with great people. This is a good moment for me to leave and start something new,” says Kati ter Horst.

In addition to his other duties, Seppo Parvi, CFO, will assume acting responsibility for the Paper division.

Stora Enso announced in March this year that it was initiating a sales process for possible divestment of four of its five paper production sites. The process is ongoing. Stora Enso has started a feasibility study at its paper production site in Langerbrugge, Belgium, for the conversion of one of the two paper lines into a high-volume recycled containerboard line. The feasibility study is expected to be finalised in the first half of 2023.

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 22,000 employees and our sales in 2021 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com/investors

Valmet to supply two tissue making lines to Liaoning Yusen Sanitary Products Co., Ltd. in China

Valmet will supply two Valmet IntelliTissue 1600 tissue machines for the Liaoning Yusen tissue mill located in the county of Tai’an, Liaoning province, China.

The order is included in Valmet’s orders received for the second quarter of 2022. The value of the order will not be disclosed. The total value of an order of this type and delivery scope is typically around EUR 6–8 million.

Valmet IntelliTissue machines belong to the small and medium-size tissue machines that were integrated into Valmet’s offering through an acquisition in 2020.

The two tissue lines are scheduled to be in production in the middle of 2023. The cooperation is a continuation of the successful supply of two Valmet IntelliTissue machines to Liaoning Yusen’s mill in 2020. The two new machines will increase the customer’s annual tissue production capacity by 60,000 tons.

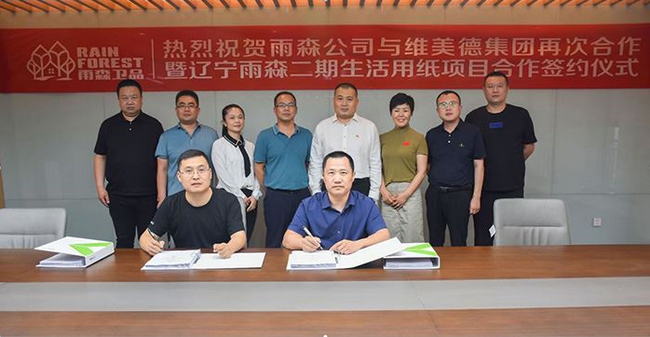

Harrison Zhang, Senior Manager of Valmet Changzhou factory (front left), signed a cooperation agreement with Zhao Zhancheng, General Manager of Liaoning Yusen mill (front right)

Harrison Zhang, Senior Manager of Valmet Changzhou factory (front left), signed a cooperation agreement with Zhao Zhancheng, General Manager of Liaoning Yusen mill (front right)

"We are happy to cooperate with Valmet again. The Valmet IntelliTissue machines stand out with their high tissue quality and low energy and raw material consumption. Valmet’s solutions enabled us to achieve ideal operating speed and drying efficiency. We were impressed by the high professionalism of the Valmet team during the execution of our previous project and are looking forward to further development with them," says Zhao Zhancheng, General Manager of Yusen Mill.

“We are grateful for Liaoning Yusen's long-term trust and collaboration. The excellent performance of our IntelliTissue machines delivered to the Liaoning mill earlier has been highly appreciated by the customer, and after years of cooperation, the Valmet and Yusen teams know each other well and work seamlessly together,” says Harrison Zhang, Senior Manager, Sales, China, Paper business line, Valmet.

Technical information about the delivery

The two new Valmet IntelliTissue making lines will produce high-quality tissue with a basis weight range of 12,5 -31,3 g/m2, a design speed of 1600m/min and a reel trim of 3500mm. The scope of supply includes approach pipe and instrumentation mechanical drive system, lubrication system, steam system and other auxiliary systems.

About the customer

Liaoning Yusen Sanitary products Co., Ltd. is a large producer and service provider focusing on tissue, nursing and hygiene and medical products by the brands "Yusen (Rain Forest)", "Baili" and "Water Gentle". The company is located in the Liaoning province in China.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Cepi calls for more focus, impact assessment and consultation on EU Commission’s nature restoration proposal

A Regulation on nature restoration has now been tabled by the EU Commission, the first European legislation addressing biodiversity in three decades. Parts of the proposed regulation would be relevant to the management of forests. Cepi, the Confederation of European Pulp and Paper Industries, continues to support the health and resilience of ecosystems, although a renewed European effort would have to be focused, efficient and inclusive.

The Commission proposal includes sweeping targets, with all ecosystems in need of restoration being covered by 2050 and an “increasing trend” of key indicators to be achieved in all forest ecosystems. But it does not clarify which actors will ultimately bear the responsibility and cost for the implementation of restoration measures which will require considerable human and financial resources (up to 54 billion euros according to the Commission). Cepi considers that restoration should first be targeted at areas where its benefits for biodiversity are maximised in order to be efficient. For example, in those already designated in the Natura 2000 network, or in areas affected by natural disturbances such as fires and insects.

What restoration would mean in areas that are not currently protected also is not yet well defined in the Commission’s proposal and its impact on the economic functions of the forests would need to be thoroughly assessed. The Commission’s own preliminary assessment recognises that “opportunity costs could stem from decreased biomass harvests” but does not go further in integrating these costs into its models. The decision on criteria determining a habitat’s ‘satisfactory level’ of restoration will rest in the hands of Member States through National Restoration Plans. In this process, Cepi calls for the consultation of all forestry stakeholders, to allow Member States to draw from extensive knowledge safeguarded by local actors, including those who depend on forests for their livelihoods.

What restoration would mean in areas that are not currently protected also is not yet well defined in the Commission’s proposal and its impact on the economic functions of the forests would need to be thoroughly assessed. The Commission’s own preliminary assessment recognises that “opportunity costs could stem from decreased biomass harvests” but does not go further in integrating these costs into its models. The decision on criteria determining a habitat’s ‘satisfactory level’ of restoration will rest in the hands of Member States through National Restoration Plans. In this process, Cepi calls for the consultation of all forestry stakeholders, to allow Member States to draw from extensive knowledge safeguarded by local actors, including those who depend on forests for their livelihoods.

Sustainable forest management practices as supported by Cepi are changing to meet new challenges, including in developing existing measures to protect biodiversity. This is why these practices have already improved biodiversity in many forest areas which are now unprotected. Sustainable forest management is also an efficient mean of climate change mitigation, by increasing forests’ carbon sink through the management of their age structure. It also helps forests’ climate adaptation, sometimes by introducing new species that are more resilient to new conditions. Biodiversity and climate objectives are both enhanced by human intervention, but in a changing climate neither supposes keeping forests exactly as they are today.

Other initiatives addressing biodiversity already exist. The Forest Europe process, to which EU Member states are signatories, has developed criteria and indicators for sustainable forest management which include biodiversity indicators. The Forest Europe 2020 report shows that over the years, sustainable forest management, in both protected and non-protected areas, has led to improving trends for many indicators, such as forest area, growing stock, deadwood volumes, tree species diversity, forest area designated for biodiversity conservation and forest bird species.

Quote

“The word ‘sustainability’ is originally a forestry term, coined already 300 years ago. Practicing sustainable forest management for so long has also been a journey to increase our understanding and evolve forest management. Now the best practice is to aim at a net positive impact for biodiversity through active forest management, including harvesting. In the light of the climate challenge, even protected areas are likely to require active management.”

Jori Ringman, Director General – Cepi (Confederation of the European Paper Industries)