Super User

AFT supplying POM approach system to Papeles y Conversiones de Mexico containerboard mill

AFT will be supplying a new POM thin stock approach system to the Papeles y Conversiones de Mexico containerboard mill in Monterrey, Nuevo Leon, Mexico. PCM is a leading Mexican company in the manufacture, conversion and marketing of high quality printing and packaging products.

The project will consist of two POMp degassers, two POM Dynamix static mixers, two POMlock seal tanks, two POM headers, and two POM head tanks for PCM’s two-ply PM2, along with accompanying spare parts and system engineering.

The POMp degasser provides a compact and efficient solution at the beginning of the white water handling process, requiring fewer and smaller silos and tanks downstream. By removing air before the paper machine headbox, the short circulation system will promote better machine runnability with fewer sheet breaks, faster start-ups and grade changes, reduced chemical and water use, and greater system cleanliness.

“We appreciate our continued partnership with PCM and look forward to a successful start-up later this year”, Sven Girschner, Regional Manager – Americas, Process & Equipment Solutions.

About AFT

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application and the end product being produced in order to optimize their return on investment. For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

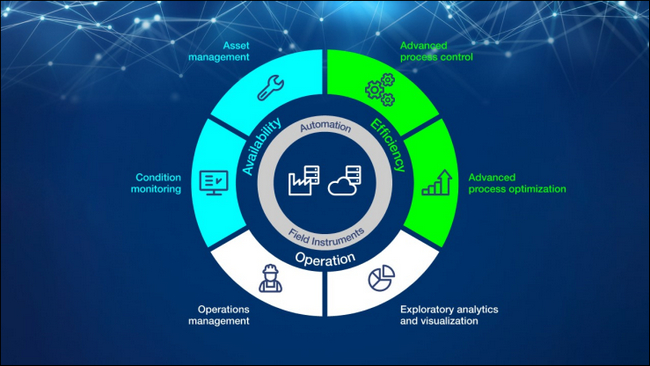

Voith and BTG present joint automation and digitalization portfolio

For maximum savings in pulp and paper production with the help of automation and digitalization, Voith and its wholly owned subsidiary BTG are merging their product portfolios. The two established data platforms, Voith’s OnCumulus and BTG’s dataPARC, will be merged into an integrated, hybrid system solution. OnCumulus will henceforth be offered under the name dataPARC cloud, while BTG’s MACS advanced process control solutions will join the OnEfficiency product family, thereby strengthening the Efficiency Solutions of the Voith’s Papermaking 4.0 portfolio. With the combined product portfolio, customers benefit from the best offerings of both companies – for the entire pulp and paper production.

- With extensive know-how and bundled experience, the leading full-line supplier Voith and its subsidiary BTG are optimizing their Papermaking 4.0 digitalization and automation portfolio to increase the overall customer experience

- OnCumulus becomes dataPARC cloud

- MACS solutions become part of OnEfficiency portfolio

“Many years of know-how, bundled experience and an excellent partnership between Voith and BTG are the basis for the optimized digitalization and automation portfolio Papermaking 4.0," says Peter Eisen, Vice President Digital Product Management at Voith Paper. "As the leading full-line supplier, our goal is to enable paper manufacturers worldwide to achieve significant productivity and cost advantages."

"The solutions offered by the OnEfficiency portfolio optimize the process in pulp and paper mills to significantly reduce variability and operating costs and increase productivity," says Dan Smith, Business Director Process Solutions at BTG. "This enables savings of between €2 and €10 per ton of paper produced. At the same time, the solutions ensure more sustainable production with lower resource consumption."

OnCumulus becomes dataPARC cloud

The combination of Voith's cloud solution OnCumulus and BTG's on-premise installation dataPARC combines the respective strengths of the platforms. In the cloud, for example, the almost unlimited computing power offers advantages for training AI models and simplifies cross-location solutions as well as location-independent access to data. The strengths of on-premise installations lie in processing high-frequency data or closed control loops. Thomas Greil, Vice President IIoT Technology & Advanced Applications at Voith, summarizes: "Our goal is to create a completely hybrid solution by 2025 that seamlessly combines on-premise and cloud, with a unified user interface, bridging the IT/OT gap. Hybrid and multi-cloud solutions permit all stakeholders to leverage data in a secure way that is efficient and most relevant to them. The user will no longer notice any difference between an application running locally or running in the cloud, and the benefits of both solutions can be optimally exploited."

MACS becomes OnEfficiency

With the integration of MACS into OnEfficiency, Voith is expanding its portfolio for cross-process controls and AI-supported process optimization, especially in the area of pulp production. Specifically, the following applications will be newly integrated and offered going forward under the name OnEfficiency.Pulp:

- Advanced process control combined with high-frequency single point kappa (SPK) measurements to improve kappa stability by 10 to 15 percent and optimize fiber yield (formerly MACScook).

- Improvement of the washing process in terms of carryover and black liquor solids (formerly MACSwash).

- Oxygen delignification optimization using SPK for high-frequency measurement of incoming and outgoing kappa (formerly MACSo2).

- Bleach optimization to minimize chemical consumption and stabilize distribution and brightness. The unique total kappa transmitter (BLT), brightness transmitters (BT) and pH management are also used for this purpose (formerly MACSbleach).

Optimized product portfolio from Voith and BTG

The addition of dataPARC and MACS to the Papermaking 4.0 portfolio completes the full-line offering from the global technology company Voith for digitalization in the pulp and paper industry. DataPARC cloud serves as the central platform and backbone of all applications in the Papermaking 4.0 portfolio. The proven automation solutions OnControl and OnQuality in the field of Automation, as well as the combined instrument portfolios of Voith and BTG – including control loops, sensors and actuators – form the basis for the solutions from the Availability, Efficiency and Operation areas. The solutions from the OnEfficiency portfolio optimize the production process for higher efficiency, lower costs and stable quality thanks to open or closed control loops using advanced process controls and AI. In the Availability arena, the OnCare family solutions help to improve maintenance processes and increase machine availability. In the area of Operations, Voith and BTG also offer intuitive applications for a wide range of functions. These can be used for analyzing and visualizing data; generating virtual sensors; displaying dashboards; and collecting and managing data, including generating reports and notifications. The experts of the OnPerformance.Lab (OPL) support with the installation and operation of the digitalization and automation solutions from the Papermaking 4.0 portfolio.

Further information can be found here: Voith.com/PaperIsOn.

About BTG

BTG Group is a multinational provider of integrated, highly specialized process solutions for the global pulp and paper industry. BTG's mission is to help its customers sustainably improve their business performance. https://www.linkedin.com/company/btggroupsa/

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Greycon Raises Funds for WasteAid by Completing Their Company-Wide Step Challenge

On Friday 1st October, members of the Greycon team began a collective companywide walk to raise money for WasteAid. The walk was split into three different parts with the first leg covering the distance between Greycon’s London office and the office located in Athens. During the first leg, the Greycon team walked a total of 3,466,000 steps covering 1,733 miles.

In the second leg, the Greycon team covered the distance from their Athens office to the Dusseldorf office of sister company WM Data. During this leg of the journey, a total of 3,064,000 steps were walked covering 1,532miles.

The final leg of the journey covered the distance from the WM Data office in Dusseldorf to the Greycon office in Montevideo, Uruguay. During this leg, a whopping 20,129,083 steps were walked covering 7,075 miles.

In total, 26,695,083 steps have been walked covering 10,340 miles!

Walking for a good cause

Greycon’s main aim with the Step Challenge incentive was to raise money for WasteAid. Upon completion of each leg, Greycon added £250 to the donation pot. A total of £852 has been raised so far. Donations for the incentive are still being taken. To donate, click here and visit the Step Challenge JustGiving page.

About WasteAid

WasteAid is an independent non-profit charity, set up by waste management professionals to share practical and low-cost waste management know-how with communities in low-income countries across the globe.

Around 1 in 3 people globally don’t have decent waste management.

Pollution caused by waste harms people’s health, the environment, and damages the local economy. In contrast, an affordable waste management system is relatively simple to implement, improving the environment, creating jobs and protecting public health – particularly for children.

Plastic pollution in the marine environment is of major global concern, and WasteAid is helping tackle this global problem. WasteAid work with upstream and coastal communities to set up small recycling centres and help keep plastic out of rivers and the oceans. They also share skills in managing organic waste, helping people make the most from the ‘waste’ materials they have.

WasteAid shares these skills with local trainers so that the knowledge can be passed on from community to community. They keep the cost of equipment as low as possible because $10 can make a big difference to the viability of a recycling start-up in a deprived community. WasteAid makes sure there are local markets for any products made from recycled materials, maximising the value to the local economy.

Thank You

Greycon extends a big thank you to all those who have made donations towards the incentive and to all of their staff members who took part in the incentive.

ANDRITZ to supply combi-pulping system to Sichuan Huaqiao Fenghuang Paper, China

International technology group ANDRITZ has received an order from Sichuan Huaqiao Fenghuang Paper Co. Ltd. to supply a patented combi-pulping system for its mill in Guanghan, Deyang City, Sichuan Province, China. Start-up is scheduled for the third quarter of 2023.

The technological solution provided by ANDRITZ will be the first of its kind in China and combines ANDRITZ FibreFlow drum pulping, LC (low consistency) pulping, and HD cleaning in one innovative system. The new combi-pulping system provides the advantages of both pulping technologies to enable an exceptional design capacity of 2,200 t/d at superior slushing performance, low energy consumption and fiber loss, as well as highest operational availability. It will be part of production line PM2 and process LOCC (Local Old Corrugated Containers) for production of liner board.

ANDRITZ FibreFlow drum pulper. Photo: ANDRITZ

ANDRITZ FibreFlow drum pulper. Photo: ANDRITZ

Liu Jinwei, Deputy General Manager, Sichuan Huaqiao Fenghuang Paper Company, says: “Our experiences with the ANDRITZ approach flow system at our PM1 have been very positive. At the same time, we are impressed by the combi-pulping innovation and its successfully operating references in Malaysia and Vietnam. We have set very challenging targets as to capacity, flexibility and final pulp quality and believe that the ANDRITZ technology is the best solution on the market to achieve these goals.”

Sichuan Huaqiao Fenghuang Paper Co. Ltd. is a subsidiary of the Huaqiao Fenghuang Group, a multinational enterprise focusing on various business areas, such as agriculture, industrial manufacturing, real estate, commerce, finance, international investment, and trade. The Sichuan Huaqiao Fenghuang Paper Company is active in various business segments, such as papermaking, plastic packaging, and recovery of renewable resources.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services, and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply SMART power boiler remote service using Metris BOA web platform to the Netherlands

International technology group ANDRITZ has received a five-year SMART service contract from BMC Moerdijk in the Netherlands to supply a Metris BOA platform including KPI dashboards and boiler operator advisor apps as well as automatically generated performance reports.

The SMART power boiler service uses the Metris BOA web platform – developed by ANDRITZ – to build KPI dashboards and operator advisor apps based on live as well as historical data to optimize and analyze power plant processes and monitor the equipment installed.

ANDRITZ Metris BOA digital advisor for power boilers

ANDRITZ Metris BOA digital advisor for power boilers

The tailored operation advisor apps will actively support the operator in increasing the efficiency of the boiler, detect opportunities to improve consumption values, and help start processes according to operational needs. Furthermore, automatically generated daily and bi-monthly performance reports comparing current data with data from previous periods will provide information at a glance for overall management of the power plant. The Metris BOA platform will be integrated into the control architecture as a third layer of automation and control together with the boiler protection and plant automation systems (DCS).

This is the third time that a Metris BOA platform will be installed in an existing plant and demonstrates the need for support tools to improve operations in the power plant market.

ANDRITZ is proud to provide another step from digital advisor to digital operator for power boilers. The order is an important part of ANDRITZ’s roadmap towards autonomous power boilers.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

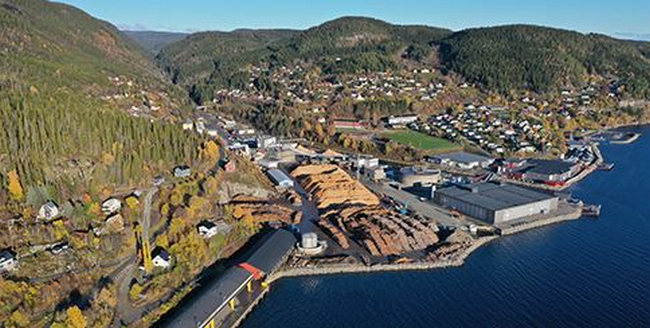

Valmet to supply new baling line and flash drying rebuild to MM FollaCell pulp mill in Norway

Valmet will deliver a new baling line and a flash drying rebuild to Mayr-Melnhof Group’s FollaCell pulp mill in Norway. It is the first phase in a larger rebuild project at the mill that aims to sustain the production capacity and to reduce the need for maintenance. The start-up is scheduled for the fourth quarter 2023.

The order is included in Valmet’s orders received of the second quarter 2022. The value of this kind of rebuild and scope of supply is typically around EUR 8–10 million.

“MM FollaCell AS chose Valmet as supplier after a thorough evaluation of several alternatives. The main reason why the choice fell on Valmet was the well-known and well-proven technology with good references,” says Odd Morten, Managing Director, MM FollaCell.

“We are happy that FollaCell has chosen to partner with us in this project. Valmet Slab Press is a proven bale forming machine that will ensure high availability and increase the reliability of the whole line,” says Per Jangdal, Sales Manager, Valmet.

MM FollaCell Mill

MM FollaCell Mill

Technical information about the delivery

Valmet’s delivery includes replacing an existing baling line with a new one. The new Slab press will increase the availability of the line and reduce the need for maintenance. The flash drying system will be rebuilt with a new cooling stage to prepare for the second phase of the project.

About the customer Folla Cell

The Norwegian MM FollaCell AS Pulp Mill produces high-quality mechanical pulp – BCTMP and CTMP – from round wood and sawmill chips. Depending on the type, the mill uses 100% softwood or a mixture of softwood and hardwood. The location in the North of Europe is an advantage not only because of the raw material growing near the mill. Its access to the Trondheimfjord also offers ideal infrastructure.

With its own ice-free harbour, the mill can deliver and receive reliably per ship all year round. MM FollaCell AS uses only materials from sustainable forestry. The required energy is primarily sourced from an environmentally friendly hydroelectric power station within close proximity.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Södra delivers robust result in uncertain times

Södra posted a robust result for the second quarter of 2022. The result reflects the sustained strong market for Södra’s core products in pulp and sawn timber, but the market outlook is highly uncertain.

In the second quarter of 2022, net sales for the Södra Group amounted to SEK 8,953 million (7,287), up 23 percent compared with the year-earlier period. Operating profit totalled SEK 2,325 million (1,326), the highest quarterly result for Södra to date.

Operating profit for the first half of 2022 totalled SEK 4,299 million (1,873). Return on capital employed was 39 percent (18), and the equity ratio was 61 percent at the end of the period.

Operating profit for the first half of 2022 totalled SEK 4,299 million (1,873). Return on capital employed was 39 percent (18), and the equity ratio was 61 percent at the end of the period.

The second-quarter result reflects the favourable market conditions, with strong demand and highly favourable prices for Södra’s core products, primarily pulp. In addition, Södra’s mills delivered high production volumes with stable quality and Södra Cell, for example, increased both production volumes and outbound deliveries during the period.

“The result is gratifying for us and for Södra’s 52,000 members. Price levels for our core products have been favourable for a long time and the production volumes of our mills have been high. Combined with the hard work of Södra’s members and employees, this led to a strong result for the second quarter of 2022,” said Lotta Lyrå, President and CEO.

“Market uncertainty has increased considerably due to global turmoil and negative economic growth. This could affect our core products moving forward, as slowing demand in Europe’s consumer-oriented building materials trade at the end of the quarter has already shown. We are monitoring the situation closely, continuing to focus on what we can influence and working hard every day to strengthen Södra’s long-term competitiveness,” said Lotta Lyrå.

Several investments during the quarter

In the second quarter, Södra made several decisions that will benefit the association’s 52,000 members and strengthen the profitability of their forest estates.

- During the quarter, Södra’s project for improving efficiency – World-class Efficiency – continued. The aim is to improve underlying profitability by an annual rate of SEK 1 billion, and the project strengthened the result during the quarter. Södra has now achieved efficiency gains corresponding to SEK 157 million on a 12-month basis. A decision to invest in the lime kiln at Värö was also made, which will improve stability and equip the mill for the future.

- A nature conservation premium was introduced. This means that members who set aside a higher percentage of forest land than is required by forest management certification – and contribute to the joint nature conservation activities – will be paid more for their wood. The aim of the nature conservation premium is to reward the benefits created by many of our family forest owners who have diverse objectives and management methods for their forest estates.

- Södra Ädla was formed. This new unit was formed to attract technologies and skills to family forestry. Södra Ädla will invest SEK 200 million in new companies that, in one way or another, can strengthen the profitability of Södra’s 52,000 members. This could be companies that are developing forest management methods, new forestry practices or alternative revenue models.

Serious accident in sawmill

There was a serious workplace accident in the second quarter. On 15 June, one of Södra’s employees was killed and another person was seriously injured at Södra Wood Orrefors.

“This is a horribly tragic event, and our thoughts are first and foremost with the families of those affected. The cause is being investigated by the authorities together with Södra, but whenever a tragedy like this occurs, it is obvious that our safety procedures should be – and must be – at the top of our agenda. Every workplace injury is one too many – no one should ever be exposed to risk at work,” said Lotta Lyrå.

Södra took immediate action in connection with the accident at all affected units and will continue working to improve safety. The cause of the accident is being investigated by the authorities in cooperation with Södra.

Business area results for the second quarter of 2022

In the Södra Skog business area, operating profit for the period totalled SEK 39 million (61). The change in earnings was primarily due to higher fuel costs.

In the Södra Wood business area, operating profit for the period totalled SEK 866 million (827) and reflects the sustained favourable prices for sawn timber. At the same time, demand for sawn timber decreased during the quarter.

In the Södra Cell business area, operating profit for the period totalled SEK 1,696 million (662). The earnings improvement was due to a considerably stronger price level for pulp and a favourable exchange rate for Södra, while both production volumes and outbound deliveries increased.

In the Södra Innovation business area, operating profit for the period totalled SEK 20 million (loss: 43). The positive trend was due to a favourable performance by SunPine and the fact that Södra’s holding in Silva Green Fuel is now recognised as profit from shares in partnerships and charged to net financial items.

Founded in 1938, Södra is Sweden’s largest forest-owner association, with 52,000 forest owners as its members. We conduct modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. In 2021, net sales amounted to SEK 27 billion and employees totalled 3,100. Through value-generating relationships and a long-term approach, Södra shows the way for the next generation of forestry.

DS Smith removes over 313m pieces of problem plastic in two years

Sustainable packaging firm leads plastic replacement fight

DS Smith has just announced that it has designed out over 313 million pieces of problem plastics in the last two years alone1 as part of its ambitious plastic replacement programme.

The significant figure equates to more than three million units per week, as customers and consumers demonstrate demand for fibre-based packaging as an alternative to hard-to-recycle plastics.

To meet this demand, DS Smith designers have worked with customers to create 1,000s of new innovations to replace plastic. Solutions have been created to remove everyday plastic items including ready-meal trays, plastic fruit and vegetable punnets and plastic six pack rings that pollute the planet. This all comes at a time when campaign groups are highlighting the amount of plastic that ends up as waste, making it more important than ever to remove them at the design phase.

Samantha Upham, Sustainability Business Partner – Sales, Marketing & Innovation commented: “With our help, customers are accelerating their ambitions to remove problem plastics from their products. By using our Circular Design Metrics, we can easily show not just where plastic can be replaced, but how circular their packaging is right now and where we can make improvements together.

“All 700 of our designers have been trained in our Circular Design Principles, which means we can design out problem plastics at inception stage and find alternative fibre-based solutions which deliver the required attributes.”

Over the next year, DS Smith will continue to drive adoption of fibre-based alternatives amongst customers in response to consumer demand for plastic alternatives. In a recent survey commissioned by DS Smith, 4 in 10 consumers (41 per cent)2a wanted packaging made from alternative renewable sources, whilst in a separate survey, 52 per cent of Brits said they would purchase products that contain less plastic to help improve recycling rates in the UK.2b

As part of DS Smith’s Now & Next sustainability targets, the company has an ambition to take one billion pieces of problem plastics off supermarket shelves, replacing them with corrugated alternatives. DS Smith’s plastic replacement work and wider sustainability progress can be found in its latest sustainability report which can be found here.

- Over a 2-year period from May 2020 to April 2022

- Market research conducted by OnePoll:

- Consumer research: 2,000 UK adults who have shopped online in the past six months. Conducted between 17th June and 23rd June 2022

- Consumer research: 2,000 UK adults who have shopped online in the past six months. Conducted between 17th June and 23rd June 2022

About DS Smith:

DS Smith is a leading provider of sustainable fibre-based packaging worldwide, which is supported by recycling and papermaking operations. It plays a central role in the value chain across sectors including e-commerce, fast moving consumer goods and industrials.

Through its purpose of ‘Redefining Packaging for a Changing World’ and its Now and Next sustainability strategy, DS Smith is committed to leading the transition to the circular economy, while delivering more circular solutions for its customers and wider society – replacing problem plastics, taking carbon out of supply chains and providing innovative recycling solutions. Its bespoke box-to-box in 14 days model, design capabilities and innovation strategy sit at the heart of this response.

Headquartered in London and a member of the FTSE 100, DS Smith operates in 34 countries employing around 30,000 people and is a Strategic Partner of the Ellen MacArthur Foundation. Its history can be traced back to the box-making businesses started in the 1940s by the Smith family.

Nordic Paper explores further improved barriers for packaging

Nordic Paper is world leading within natural greaseproof papers used in different food applications, for example as baking papers, for baking cups or for food containers. The paper has natural barrier properties achieved without the addition of fluorochemicals, so called PFAS. To further develop these natural barriers and to expand the markets for natural greaseproof papers, Nordic Paper has entered into a two-year cooperation with Centre Technique du Papier, CTP, in France.

Nordic Paper produces and develops natural greaseproof papers for the food industry without addition of fluorochemicals. Barrier properties are important characteristics for these paper grades in order that the grease of the packaged foodstuff does not go through the paper. The initiated cooperation project with CTP focuses on exploring and developing further improved natural grease barriers without addition of fluorochemicals.

Nordic Paper produces and develops natural greaseproof papers for the food industry without addition of fluorochemicals. Barrier properties are important characteristics for these paper grades in order that the grease of the packaged foodstuff does not go through the paper. The initiated cooperation project with CTP focuses on exploring and developing further improved natural grease barriers without addition of fluorochemicals.

- Our papers are equipped with good and natural barriers for many application areas, but we are eager to push the limits and to increase the grease resistance even further of our products, says Henrik Kjellgren, product manager Natural Greaseproof.

CTP is a leading research institute for the paper industry with a specific competence in treatment of fiber surfaces and in barrier properties. Several laboratory tests will be conducted in the project which is expected to result in valuable information for the continued development work of Nordic Paper regarding further improved barriers. The ambition is to expand the market for greaseproof papers so that the customers of Nordic Paper would be able to produce packaging solutions for food that is currently packaged in plastic or aluminum-based solutions.

- One example of an application we are looking into is food trays for frozen lasagna where the packaging requires very good barrier properties as the food and its packaging undergoes heating, explains Henrik Kjellgren.

Nordic Paper is already today, with its greaseproof papers, able to offer more sustainable alternatives to packaging manufacturers currently using packaging solutions based on plastics or on materials with added fluorochemicals.

- We can contribute to the ongoing phasing out of the use of PFAS and to reduce plastics consumption in society. It is important that we take further steps to develop us into neighboring application areas where our papers are currently not present to increase our contribution to a sustainable society, concludes Henrik Kjellgren.

Nordic Paper is a leading specialty paper producer with its base in Scandinavia. We have been manufacturing top-quality kraft papers and natural greaseproof papers since the 19th century. Our products are based on renewable raw material from local forests. From our five paper mills, four in Scandinavia and one in Canada, we supply customers in about 80 countries. Nordic Paper had in 2021 net sales of approximately SEK 3,100m, about 690 employees and is listed on Nasdaq Stockholm. www.nordic-paper.com

Toscotec’s turnkey tissue line starts up at Vajda-Papír in Hungary.

Vajda-Papír started up a double-width AHEAD 2.2L tissue machine supplied by Toscotec (PM2) at its Dunaföldvár facility in Hungary. The supply was full-on turnkey, including the entire tissue production line and all erection operations at the mill.

A complete turnkey supply

The turnkey scope included the entire stock preparation system and Toscotec’s patented TT SAF® (Short Approach Flow) fitted with a double dilution system to maximize energy savings. It comprised the electrification and controls, dust and mist removal systems, boiler plant, bridge cranes, air compressor station, roll handling and wrapping systems, and hall ventilation with conditioning system.

For the mill’s PM1, Toscotec also supplied an OPTIMA 2600 slitter rewinder equipped with automatic shaft puller and dust removal system that came online in February 2022.

Toscotec’s turnkey scope included a complete service package with detailed mill engineering, erection, training, commissioning, and start-up assistance. The installation of this double-width tissue line required a substantial erection team of more than 190 technicians over a period of approximately 200 days.

A tissue machine designed for superior energy efficiency

The AHEAD 2.2L machine features a net sheet width of 5,600 mm, a maximum operating speed of 2,200 m/min, and a production capacity of over 80,000 tons/year. It is equipped with Toscotec’s state-of-the-art technology, including a fully hydraulic TT Headbox-MLT, a shoe press of the upgraded design TT NextPress, a third-generation TT SYD Steel Yankee Dryer, and TT Hood system designed for maximum energy recovery.

Toscotec and Vajda-Papír’s teams at Vajda-Papír tissue mill in Hungary.

Toscotec and Vajda-Papír’s teams at Vajda-Papír tissue mill in Hungary.

Attila Vajda, Managing Director of Vajda-Papír, says, “This new Toscotec line constitutes our flagship investment at Dunaföldvár site. We have a vision for Vajda-Papír’s expansion to be in harmony with the environment, and that is why we chose the most energy efficient technology available on the market. Throughout the entire project, the whole Toscotec team demonstrated their extensive expertise and great passion for tissuemaking. The successful start-up of PM2 represents a key achievement and an important step forward for Vajda-Papír’s sustainable growth.”

Gabriele Barattini, Toscotec Project Manager, says: “Successfully completing a turnkey project of this magnitude is a great satisfaction indeed. The cooperation with Vajda-Papír’s team has been excellent all along and has allowed us to manage every phase in the best possible way. Toscotec’s flexibility is crucial for the success of any project, even more so for turnkey projects.”

About Vajda-Papír Ltd.

Founded in 1999, Vajda-Papír is headquartered in Budapest and operates 3 sites in Budapest, Székesfehérvár and Hungary’s biggest and most modern integrated tissue mill at Dunaföldvár, south of Budapest. It manufactures 115,000 tons/year of toilet tissue, handkerchiefs, towels, and napkins. Vajda-Papír owns the famous brands Ooops!, Sindy, Star and Lilla and distributes its products to the consumer and AfH markets in Hungary and over 30 countries worldwide.

For further information, please contact:

Matteo Giorgio Marrano, Sales Manager, Tissue Division: This email address is being protected from spambots. You need JavaScript enabled to view it.