Displaying items by tag: sulzer

Sulzer launches new CPE end-suction single-stage centrifugal pump

Sulzer has once again broken the conventions in the name of efficiency. The new CPE ANSI process pumps are specifically designed to exceed the strictest energy regulations for all industries as well as the requirements of ASME B73.1. With revolutionary hydraulics and high efficiency, they offer low life cycle costs.

The new CPE pumps meet the process requirements in a variety of industrial applications, and are suitable for use with clean or slightly contaminated liquids, viscous liquids of up to 3’000 cSt, and fibrous slurries with a consistency up to 6%.

When engineering the new range of CPE pumps, we at Sulzer considered numerous factors that can potentially influence the total cost of ownership of a process pump. The result is an innovative design that makes it possible for the user to achieve remarkable annual savings.

We improved the reliability of the CPE pump and reduced the risk for unplanned shutdowns by optimizing the shaft sealing. Heavy-duty rigid bearing units ensure a long bearing life and further protection against unexpected shutdowns. Learn more on sulzer.com.

The new pump design brings higher efficiency that translates into lower energy consumption. Coupled with this, the high standardization, easy installation and robust construction also equate to lower maintenance and operating costs.

“We are eager to offer our new CPE pump range to our customers, because it fits a wide range of industrial applications and will reduce operating costs.”

Joe Salah, Sales Manager, Sulzer Pump Solutions Inc.

Sulzer ─ world leader in pumping and mixing solutions for the pulp, paper and board industry

The knowledge accumulated through committed long-term research and development as well as through mergers and acquisitions, the most recent ones being Ahlström Pumps in 2000, Scanpump and ABS Pumps in 2011, and Ensival Moret in 2017, has strengthened Sulzer’s pump know-how and further enabled a full-scale research for the development of pumps, mixers, and agitators.

As the home of the following known trademarks, we serve the installed base also beyond Sulzer: Ahlström Pumps, Scanpump, ABS, Ensival Moret, Serlachius, Enso, API, Sonesson, Gothia, JMW, and Warren.

With our full-line product portfolio, we offer eco-efficient product solutions, including products for complete water and effluent treatment applications.

- The AHLSTAR pump series has proven performance with stocks and various types of suspensions and especially with high volume flows and liquids containing a high amount of gas.

- The MCE™ medium consistency pumping systems combine excellent performance with energy savings for the highest pulp mill production rates in the world.

- ZPP and Z22 low pulse feed pumps are designed specifically for paper and board machines.

- The MBN multistage pumps cover a range of high pressure and shower water applications.

- SALOMIXä, Scaba and AGISTARä agitators offer optimum tank and tower mixing results.

- The TMS tower management system prevents channeling in storage towers, providing unique process advantages.

We have full-scale test facilities in Kotka, Finland, and an expanding pump and agitator portfolio that provides unique applications coverage. Every year, we bring a new product series or a major upgrade of an existing range to the market. Sulzer is the trusted and proven partner when it comes to performance, reliability, safety, and sustainability.

Recent major deliveries for pulp mill projects by Sulzer

Sulzer is the key equipment supplier for many major recent pulp, paper, and board mill investments. Our products cover most of the processes, including water and wastewater applications. The ability to offer complete and high-efficient solutions for overall pumping and mixing needs in the pulp and paper industry together with the reliable services makes us a key partner for every new project in the industry.

Sulzer products equip the new greenfield pulp mill of Suzano Papel e Celulose S.A., one of the largest forestry-based companies in Latin America, in the state of Maranhão in northeastern Brazil. The package of around 400 Sulzer pumps contains double suction pumps type Z22, AHLSTAR and BE process pumps, submersible pumps types ABS XFP, ABS AFP and Scavenger, Salomix and Scaba agitators, as well as medium consistency pumps. The Imperatriz mill has a planned production capacity of 1.5 million tons of pulp per year.

In 2016, Sulzer was awarded a frame contract for process and medium consistency pumps to Fibria Celulose SA’s new production line in Três Lagoas, Brazil. The new production line has a planned annual capacity of 1.95 million tons of pulp. The pump package contains our efficient AHLSTAR process pumps, MBN multistage pumps and the latest generation of Sulzer MCE medium consistency pumps.

Also in 2016, Sulzer was granted an order for the delivery of an extensive process pump package to Metsä Group’s next-generation bio product mill in Äänekoski, Finland. The investment is the largest ever in the wood-processing industry in Finland. The mill’s planned annual pulp production is 1.3 million tons, of which 800’000 tons softwood pulp and 500’000 tons hardwood pulp. Besides pulp, the mill produces a broad range of bio products, such as tall oil, turpentine, lignin products, bioelectricity and wood fuel. We delivered efficient AHLSTAR process pumps, the latest generation of Sulzer MCE medium consistency pumps, as well as agitators and vacuum pumps to the bio product mill, altogether 400+ equipment.

The Sulzer equipment for these major projects is designed for high reliability and energy efficiency as well as for low operating costs, and will reduce the customers’ total costs of ownership (TCO).

Sulzer values strategic and committed partnerships

Partnerships with the key players in the pulp, paper and board industry set the baseline for our research and development work. Long-term development forums that include pilots and demos are imperative for dealing with the fascinating future potential of the industry.

Deep applications understanding is the key for clever and high-performance suspension transfer and treatment solutions. We are an independent equipment supplier and a trusted application solver. Our knowhow and product reliability are based on close cooperation with the world’s leading pulp, paper and board producers, machinery suppliers, engineering companies and research institutes.

For the time being, the growth rate in the tissue and packaging boards markets is high. The increase in pulp demand continues strong for board, tissue as well as other hygienic products, and it will accelerate for textiles. The time is right to strengthen the already close cooperation between the players in the industry, to the benefit of all.

Forest companies, research institutes and other industry partners are actively investigating and developing new processes for additional higher-value wood raw material based products. Such developments are, for example, to replace cotton and oil-based synthetic fibers like polyester, or to produce higher-value carbon products and modified cellulose materials for packaging barriers, coatings for medicines and nutrients.

The pulp, board, tissue and paper segments offer a very interesting and important scope together with new additional wood based future products. We are committed to this new development trend.

Digital enablers at Sulzer ─ smart and connected pumps

Sulzer is using digital technologies such as cloud platforms, digital connectivity and advanced analytic algorithms to create new business opportunities.

As digital sensors are becoming cheaper and more physical devices are connected to the Internet (Internet of Things, IoT), there is an enormous potential to convert data from the devices into actionable business insights. Often, this machine-generated data cannot be analyzed using traditional techniques because it is not standardized in format, the generated data volumes are huge, the data resides in multiple systems, or the data quality is volatile and messy. A different approach is required.

Today, the technology involved is becoming more affordable, and transforming our pumps into smart, connected devices is a viable business proposition. This is particularly attractive in general industry, such as pulp and paper factories, sugar, food, and fertilizer industries, where configured pumps have traditionally not been equipped with such options.

Sulzer is developing a smart sensor that can be attached to process pumps. It will measure parameters such as temperature and vibration of pumps in the field, then transfer this information wirelessly to our data lake. Our customers will then be able to receive information about the asset’s performance, reliability and efficiency.

The idea for such a device arose at Sulzer in Finland and in Switzerland at around the same time. The teams defined the specifications for the sensor by listening to customers and recognizing their needs for cost savings by increasing pump reliability.

In 2018, the sensor will be tested at customer facilities. Afterwards, it will be ready to use in the field. Soon, Sulzer’s goal is to deliver its new process pumps with the integrated sensor so customers can benefit from the entire package, and Sulzer can leverage the data captured from the field to improve our knowledge of the operations of our products.

Read more about turning pumps into smart devices in Sulzer’s annual report 2017

Sulzer Pumps PPI and new wood-based processes

Sulzer is a company with long and solid experience and proven expertise in several important customer segments. Pulp, board and paper processes and applications as well as new ones based on wood raw materials represent high-priority commitment and partnership areas for the business and product development organization of Sulzer Pumps Finland.

Sulzer is globally specialized in pumping and agitation solutions, rotating equipment maintenance and services as well as separation, reaction and mixing technology. The newest Sulzer division is Applicator Systems providing high-precision plastic molding, assembly, decoration and filling technologies for mixing and applicator solutions.

Sulzer is globally specialized in pumping and agitation solutions, rotating equipment maintenance and services as well as separation, reaction and mixing technology. The newest Sulzer division is Applicator Systems providing high-precision plastic molding, assembly, decoration and filling technologies for mixing and applicator solutions.

Sulzer serves clients worldwide through customer front-end experts, production sites, and a customer service network that provides qualified services for the entire product life cycle. The company also has a strong footprint in emerging markets. In 2017, the company achieved sales of CHF 3.0 billion with about 14’700 employees.

Pumps Equipment is the biggest Sulzer division by sales. Sulzer designs, develops and supplies pumping, mixing and agitation solutions and related equipment worldwide. Intensive research and development in fluid dynamics, process-oriented applications, products and special materials as well as reliable intelligent service and performance improvement solutions support the company to maintain its forerunner position in its focus market segments like oil and gas, power, pulp, paper, board, water and wastewater.

The main Sulzer competence center with the world’s biggest full-scale research facility for the pulp, paper and board segment and for new process applications based on wood raw materials is located in Kotka, Finland.

Thus, the main product platforms for these industries are developed in Finland where we have strong roots reaching back to the Ahlstrom Pumps era. The main manufacturing units for Sulzer products for these markets are also in Finland, but our global factory footprint covers all main regions

Strategic and committed partnerships and long-term development forums with pilots and demos are of crucial importance for coping with the fascinating future potential

Deep applications understanding is the key for clever and high-performance suspension transfer and treatment solutions. We are an independent equipment supplier and a trusted application solver, but you can never be strong if you try to work on your own. Our knowhow and product reliability are based on close cooperation with the world’s leading pulp, paper and board producers, machinery suppliers, engineering companies and research institutes.

Right now, today, is the time for even more active and committed partnerships. The growth rate in the tissue and packaging boards markets is high. The increase in pulp demand continues to be strong for board, tissue and other hygienic products, and it will accelerate for textiles.

Forest companies, research institutes and other players in the industry are actively investigating and developing new processes for additional products based on higher-value wood raw material. Such developments are, for example, to replace cotton and oil-based synthetic fibers like polyester or to produce higher-value carbon products and modified cellulose materials for packaging barriers, coatings for medicines, and nutrients. The pulp, board, tissue and paper segments offer a very interesting and important scope together with new additional wood-based future products. We are committed to this new development.

World leader in pumping and mixing solutions for the pulp, paper and board industry

The knowledge accumulated through committed long-term research and development as well as through mergers and acquisitions, the most recent ones being Ahlstrom Pumps in 2000, Scanpump and ABS Pumps in 2011, and Ensival Moret in 2017, has strengthened Sulzer’s pump know-how and further enabled full-scale research for the development of pumps, mixers and agitators. As the home of the following known trademarks, you can trust us to serve your installed base beyond Sulzer: Ahlstrom Pumps, Scanpump, ABS, Ensival Moret, Serlachius, Enso, API, Sonesson, Gothia, JMW and Warren.

- The AHLSTAR pump series has proven performance with stocks and various types of suspensions and especially with high-volume flows and liquids containing a high amount of gas.

- The MCE™ medium consistency pumping systems combine excellent performance with energy savings for the highest pulp mill production rates in the world.

- ZPP and Z22 low-pulse feed pumps are designed specifically for paper and board machines.

- The MBN multistage pumps cover a range of high-pressure and shower water applications.

- SALOMIXä, Scaba and AGISTARä agitators offer optimum tank and tower mixing results.

- The TMS tower management system prevents channeling in storage towers, providing unique process advantages.

With our full-line product portfolio, we offer you the most eco-efficient product solutions, including products for complete water and effluent treatment applications.

With full-scale testing facilities in Kotka, Finland and an expanding pump and agitator portfolio that provides unique applications coverage, Sulzer is the trusted and proven partner to achieve all your performance, reliability, safety and sustainability goals. Every year, we bring to the market a new product series or a major upgrade to an existing range.

Recent deliveries as proven examples

Sulzer is the key equipment supplier for many major recent pulp, paper and board mill investments in countries such as Finland, Sweden and Brazil. For example, Metsä Group’s new Äänekoski bioproduct mill has 400+ Sulzer equipment applications in key process positions throughout the main mill departments.

Please also note that the huge-capacity Sulzer MCE™ medium consistency pumping systems, developed and manufactured in Finland, manage all the pulp flows through the most modern pulp mill fiber lines in the world.

Maximizing pump efficiency through reduced corrosion and erosion

Industrial processes across the globe require pumps to operate reliably and efficiently. The latest pump designs and coating technologies offer significant improvements in the long term performance of industrial pumps. By minimizing the effects of corrosion and erosion, users can enhance productivity and reduce running costs.

Continued research into the processes that degrade pump performance is being matched by the development of better application techniques for protective coatings. By gaining a better understanding of both the pumping process and the factors that affect it, end users can make significant improvements in their maintenance strategies.

Coating technologies offer improved performance and durability

Affected applications

Almost every industrial process involving liquids will include a pump at some point. From deep sea oil and gas to DNA sequencing, pumps are required to perform a vast range of tasks. However, no matter what the design or the size of the pump, central to every application is reliability and efficiency – minimizing down time and running costs is essential to modern industry.

For those working with large industrial pumps, often operating in harsh environmental conditions, maintaining pump performance in the face of a continuous threat from corrosion and erosion can be a particular challenge. With increased knowledge of these processes and the techniques used to tackle them, it is possible to implement a more cost effective pump refurbishment program.

Corrosion:

Corrosion is commonly defined as a chemical reaction between the component surface and the reacting fluid passing through a pump. In general a distinction is drawn between general or uniform corrosion and localized corrosion like pitting and crevice corrosion. Non-stainless materials suffer mainly from uniform corrosion whereas metals forming oxide layers that adhere to and passivate the surface are prone to localized corrosion.

In situations where erosion-corrosion is evident, specialised coatings may be the best solution

Flow Accelerated Corrosion:

Flow accelerated corrosion (FAC) describes the removal of the protective oxide layer on a metal. The speed of this process is affected by the oxygen content, the flow velocity and, to some extent, the chloride content. The formation of a calcareous layer due to high carbonate hardness of the water reduces or even prevents FAC.

The influence of oxygen can be seen in the following example: Water with an oxygen content of less than 20 ppb (parts per billion) and a flow velocity around 15 m/s will typically see a corrosion rate around 0.01 mm/year. However, increased oxygen content can see the corrosion rate rise to several mm/year, which will present a significant challenge to the process.

Fortunately FAC only poses a real issue for low carbon steels and cast iron. Increasing the chromium content or using stainless steel will largely eliminate the vulnerability to flow accelerated corrosion.

Erosion:

Pumps that are used to transfer fluids containing abrasive substances, such as sand, can experience significant levels of erosion, especially in areas with high flow velocities. This can be seen in the oil and gas industry where injection pumps are employed to force water back into the oil field and thus maintain the pressure which is needed to lift the oil to the surface. The entrained sand particles act as an abrasive and the high working pressures only serve to compound the issue.

From a pure design standpoint, pump manufacturers in this field effectively have two options to minimize the erosion:

i) Reduce the flow velocities in every part of the pump

or

ii) Design the pump in such a way that the flow velocities through the close-running clearances are low.

However, in most cases the specifications required for the application will prevent either of these solutions from being implemented. Coatings with high erosion resistance in selected areas of the pump are a proven solution in these applications.

Where cavitation is unavoidable, a bespoke coating system should be used

Erosion-Corrosion:

In operating conditions where both erosion and corrosion are present, the degradation mechanism can become very complex and depends on the type of substrate and the fluid chemistry. Corrosion may create oxide layers with low adherence to the substrate which is prone to erosion, or erosion may damage the passive layer, leading to an activation of the surface which accelerates corrosion. In this case surface protection regimes are often the best and sole option.

Cavitation:

Most commonly seen on the pump impeller, cavitation is caused by a pressure difference, either on the pump body or the impeller. A sudden pressure drop in the fluid causes the liquid to flash to vapor when the local pressure falls below the saturation pressure for the fluid being pumped. Any vapor bubbles formed by the pressure drop are swept along the impeller vanes by the flow of the fluid. When the bubbles enter a region where the local pressure is greater than saturation pressure, the vapor bubbles abruptly collapse, creating a shockwave that, over time, can cause significant damage to the impeller and/or pump housing.

In most cases it is better to prevent cavitation rather than trying to reduce the effects on the pumping equipment. This is normally achieved by one of the three actions:

- Increase the suction head

- Lower the fluid temperature

- Decrease the Net Positive Suction Head Required (NPSHR)

For situations where cavitation is unavoidable or the pumping system suffers from internal recirculation or excessive turbulence, it may be necessary to review the pump design or minimize the potential for damage using a bespoke coating system.

Appropriate material selection

For pump manufacturers, the key is to mitigate the corrosion problems by using the most appropriate base material in the construction of the pump. For applications where the use of carbon steel or cast iron is preferred due to cost reasons, the corrosion rate can be estimated very accurately. Based on the mutually accepted corrosion rate per year, the service life of the pump can be anticipated and factored into the maintenance costs of the application.

If the expected corrosion rate is not acceptable the pump materials have to be upgraded to stainless steels which leads to higher costs. In cases where this cost increase is prohibitive, the alternative is to use advanced coatings that can be tailored to suit each application.

If stainless steel is selected for an application, the expected service life is much longer, in some cases infinite. However, this is only true as long as the appropriate stainless steel grade has been chosen for the specific application, it has been produced carefully and is used within the agreed fluid specifications. Special care is required as soon as particles are introduced into the fluid.

In this case even stainless steel becomes susceptible to corrosion due to the passive layer being damaged and the base material becoming activated, which then starts to corrode. Normally the passive layer can be re-established, but if the chloride content is too high or the pH level is too low, the material may remain in an active state and the corrosion continues. Another frequent cause of corrosion in stainless steel pumps are stagnant conditions caused by process interruptions or intermittent operation.

A further threat for stainless steel is chlorine, which is used to combat biological growth in the pump or the connected pipelines. Low level concentrations, around 2 ppm, will have little impact on stainless steel, but it is important to understand how and where the chlorine is introduced into the water flow, to avoid spot concentrations that will damage the protective layer.

Unexpected corrosion can easily negate the anticipated improvement in durability of stainless steel compared to the much cheaper carbon steel variant.

Protective coatings

It is important to determine if the application of coatings will actually improve the performance and the service life of the pump in the first instance and if the costs are really lower than a materials upgrade. In most cases pump manufacturers aim to meet the requirements of a process by using the most appropriate materials for the application and use coatings only as back-up solution.

Polymeric coatings like Fusion Bonded Epoxy can be applied to pump components using a fluidized bed or electrostatic coating. They provide a good level of corrosion protection as long as the coating isn’t damaged. As a polymer coating it is limited to low flow conditions and normally used in clean water applications where it may also improve the hydraulic performance by smoothening the pump surfaces.

However, coatings which are appropriate for pipelines may not be suitable for pump applications where the flow velocities are much higher, narrow passages concentrate the flow and moving parts can be difficult to protect. Again, some methods, such as galvanic protection, commonly used in pipework, are largely unsuitable for pumps.

In these cases coatings are applied to specific areas where increased flow rates are expected or at points where impact damage is expected, such as 90 degree bends. A hard layer is usually applied using a spray coating method such as Air Plasma Spraying (APS), or High Velocity Oxygen Fuel (HVOF) - which one will depend on the required coating thickness and composition.

Carbide coatings, which are deposited by using a high velocity oxy-flame, are extremely wear-resistant. Tungsten carbides in combination with cobalt, nickel or cobalt-chrome matrices are used preferably. Thanks to improvements in the powder and the thermal spray processes, the materials combine high wear-resistance and toughness with good corrosion resistance. Thermal spray coatings can be applied to most substrates, but it is a ‘line-of-sight’ process that makes the coating of complex shaped components, such as impellers, difficult.

CVD processes which are used for complex components that are difficult to coat with thermal spray create very hard surface layers, but are conducted at temperatures in excess of 850 °C. These high temperatures limit the selection of possible substrates, because structural changes and partial deformations can take place during the cooling stage.

Not all coatings are the same

The improvements in performance and durability afforded by coating systems have given rise to a large number of businesses offering a coating service. The raw materials and the basic equipment can be acquired relatively easily and used to apply coatings to a range of equipment.

However, the quality of an HVOF coating, for example, depends predominately on the spraying parameters, such as the material temperature, application velocity, application rate and the quality of the equipment used. Coatings such as these take time to apply correctly, which will inevitably impact on the final cost of the refurbishment. However, increasing the deposition rate will increase the stresses within the coating and over time this can cause the coating to degrade and fail prematurely.

The procedures and settings used by companies such as Sulzer and its coating suppliers have been developed over many years; applying extensive knowledge and experience to the process is the only way to improve it. The final procedure for each coating is closely guarded, proprietary information ensuring that every client will receive the same quality of coating across the world.

To illustrate the importance of these procedures, especially in pump applications, consider the process of installing and removing an impeller. In many situations, the impeller is heated to allow it to be installed or removed from the drive shaft. This shrink-fit procedure can cause inappropriate coatings to be damaged during a routine maintenance operation. Sulzer has ensured that its coating technologies can withstand this thermal shock and continue to deliver long-lasting corrosion protection.

Maintaining legacy equipment

Modern coating technology can be applied to legacy equipment as part of a refurbishment program that will extend the service life of a pump. Implementing a new coating as part of a refurbishment project can significantly improve the performance and reliability of existing equipment.

Ultimately, the key to a successful corrosion prevention scheme is to fully understand the application and to use all the available information to determine the most appropriate action. Working closely with experienced materials engineers enables the end user to achieve the most appropriate solution.

For those looking to refurbish an existing asset there are a number of potential improvements that can extend the service life and improve the performance of a pump. If a new pump design is required, there is an opportunity to establish not only the most appropriate base material, but also the best coating system for extended durability.

The future

As coating technologies continue to advance so end users will be able to select bespoke coatings that can be applied during the manufacturing process. However, even with the most advanced coating, there is a need to develop an application process that can be used to apply the coating to the complex internal surfaces of a cast impeller and volutes. As such, this remains the ‘holy grail’ of pump design and once this challenge is overcome, the reliability and service life of industrial pumps will be further improved.

Improvements in service intervals means reduced maintenance costs and reduced costs attributed to lost production. Together with improved efficiency, these costs of ownership can be minimized through the appropriate use of base materials, protective coatings and the implementation of better pump design to deliver a comprehensive and cost effective pump solution.

About Sulzer:

Sulzer is the leading worldwide, independent service provider for the repair and maintenance of rotating machines including turbomachinery, pumps and electro-mechanical equipment. With a global network of over 150 technically advanced manufacturing and test facilities, Sulzer offers a collaborative advantage that delivers high-quality, cost-effective, customized and turnkey solutions, providing its customers with the peace of mind to focus on their core operations.

Sulzer Rotating Equipment Services, a division of Sulzer, can accommodate all brands of rotating equipment including turbines, compressors, generators, motors and pumps. With an enviable track record, dedicated teams of on-site engineers provide best-in-class solutions to ensure that the most effective service is delivered.

Sulzer is dedicated to providing superior service solutions to a range of industries including power generation, oil and gas, hydrocarbon and chemical processing, water and air separation. Every solution is customized to suit the business needs of each application – whenever or wherever that may be.

With a long history of providing engineering service support, Sulzer is headquartered in Winterthur, Switzerland where it began in 1834. Today, with sales over US$ 3 billion and with approximately 15,000 employees, the Sulzer footprint spans across the globe. The core aim is to deliver a flexible and cost-effective service that optimizes customer operational efficiency and minimizes downtime.

For more information on Sulzer, visit www.sulzer.com New steam turbine repair facility in Piedmont expands Sulzer’s network capability

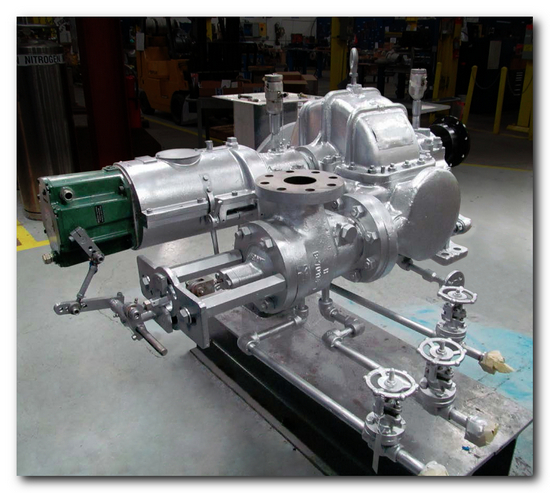

Sulzer’s extensive repair facilities have been further enhanced with the ability to refurbish small steam turbines in Piedmont, South Carolina. This additional service complements the existing range of repairs for electric motors, pumps, compressors and generators. In addition to mechanical repairs and welding services, the service center has an experienced field services team that delivers on-site repairs around the clock.

Sulzer’s extensive repair facilities have been further enhanced with the ability to refurbish small steam turbines in Piedmont, South Carolina.

As part of the investment made by Sulzer to improve local repair facilities, the service center in Piedmont has been equipped to carry out complete refurbishments of small steam turbine packages in addition to the services already delivered. The service center can now handle steam turbines up to 750 hp and repairs include balancing as well as overhaul of the governor and trip unit.

The service center in Piedmont has been equipped to carry out complete refurbishments of small steam turbine packages including overhauls of governor and trip units.

The experienced project team of engineers, designers and field service technicians is able to deliver repairs to small steam turbines and other turbomachinery for customers involved in power generation, paper, and petrochemical, steel as well as more general industries. This most recent addition in the Sulzer portfolio minimizes transport time for steam turbine repairs in the South East USA and ensures a cost effective repair.

Repairs to steam turbomachinery such as compressors and expanders up to 750 hp are delivered by the Service Center.

Sulzer service centers act as the local point of contact for a repair of any scale, even if the equipment has to be sent to another facility for the work to be completed. In this way every service center can offer the complete range of repair services to its customers. By delivering an efficient and reliable service, Sulzer is able to minimize downtime and increase productivity for each customer.

About Sulzer:

Sulzer is the leading worldwide, independent service provider for the repair and maintenance of rotating machines including turbomachinery, pumps and electro-mechanical equipment. With a global network of over 150 technically advanced manufacturing and test facilities, Sulzer offers a collaborative advantage that delivers high-quality, cost-effective, customized and turnkey solutions, providing its customers with the peace of mind to focus on their core operations.

Sulzer Rotating Equipment Services, a division of Sulzer, can accommodate all brands of rotating equipment including turbines, compressors, generators, motors and pumps. With an enviable track record, dedicated teams of on-site engineers provide best-in-class solutions to ensure that the most effective service is delivered.

Sulzer is dedicated to providing superior service solutions to a range of industries including power generation, oil and gas, hydrocarbon and chemical processing, water and air separation. Every solution is customized to suit the business needs of each application – whenever or wherever that may be.

With a long history of providing engineering service support, Sulzer is headquartered in Winterthur, Switzerland where it began in 1834. Today, with sales over US$ 3 billion and with approximately 15,000 employees, the Sulzer footprint spans across the globe. The core aim is to deliver a flexible and cost-effective service that optimizes customer operational efficiency and minimizes downtime.

For more information on Sulzer, visit www.sulzer.com

The image(s) posted with this press release may only be used to accompany this copy, and are subject to copyright. Please contact DMA Europa if you wish to license the image for further use.