Ianadmin

Xerium Announces Two Plant Expansion Projects in Roll Cover and Mechanical Services Business

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, announced two plant expansion projects to enhance its rolls products and mechanical services capabilities for the North American market.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, announced two plant expansion projects to enhance its rolls products and mechanical services capabilities for the North American market.

Xerium will expand and modernize its Griffin, Georgia plant. It will broaden its mechanical service offering, expand its capabilities for rubber roll recovering, and expand its capabilities for industrial roll recovering. These new investments will also lower lead times. This expansion is expected to generate increased sales volumes in the region. Completion is scheduled for Q4 2015.

Xerium will expand and modernize its Neenah, Wisconsin plant. It will broaden its product offering by installing a state-of the-art polyurethane roll cover production cell, and increase the size and breadth of its mechanical services department in order to more broadly serve customers in the region. These new investments will also improve lead times. This expansion is expected to generate increased sales volumes in the region. Completion is scheduled for Q4 2015.

Both facilities manufacture and repair large rolls used in the production of paper, containerboard, boxboard, tissue, pulp, nonwoven fabrics, fiber cement siding, steel, film production, and flexible packaging. Both facilities mechanically repair & service large sections of production machines that require regular and sophisticated maintenance.

"These expansions enhance Xerium's product and service offerings to customers in these areas of the North American market," said Mr. Harold Bevis, President and CEO of Xerium. "Both modernization projects enable these two plants to supply all of Xerium's roll product portfolio and mechanical service technologies to assist large machine owners in these regions to achieve optimized machine performance."

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 27 manufacturing facilities in 12 countries, 2 new plants under construction in 2 countries and employs approximately 3,200 employees.

Xerium Technologies, Inc.

Cliff Pietrafitta

Chief Financial Officer

This email address is being protected from spambots. You need JavaScript enabled to view it.

ZELLCHEMING-Expo 2015 – Keyplayers present again

Half a year before the event almost all keyplayers of the industry have applied for the exhibition. Valmet, Gebr. Bellmer, Kemira Oyj and Omya International present beside other important companies of this sector their products and solutions as well as innovations and services along the process chain of the pulp and paper industry.

Market place “Fibers in Process”

As in 2014 the market place “Fibers in Process” will be organized by the dfv Mediengruppe. The market place offers companies the opportunity of an easy exhibition participation with different “all-inclusive packages”. Moreover the integrated Trend Lounge will offer experts and users a forum for exchange of information and opinions regarding the topics “„Technology & Services“, „Materials & Processing“ and „Research & Development“.

At the concurrently held conference and 110th Annual General Meeting of the association ZELLCHEMING e.V. specialists of the industry will discuss “The transformation of the sector”. The official program will be released in spring.

Further information and the application form for ZELLCHEMING-Expo are available at www.zellcheming-expo.com.

About Mesago

Mesago Messe Frankfurt, founded in 1982 and located in Stuttgart, specializes in exhibitions and conferences on various topics of technology. The company belongs to the network of Messe Frankfurt. Mesago operates internationally and is not tied to a specific venue. With 110 members of staff Mesago organizes events for the benefit of more than 2,700 exhibitors and over 100,000 trade visitors, conference delegates and speakers from all over the world. Numerous trade associations, publishing houses, scientific institutes and universities work with Mesago closely as advisers, co-organizers and partners.

ZELLCHMING e. V. - The Association of Chemical Pulp and Paper Chemists and Engineers is an association which has dedicated itself fully to the various issues and topics surrounding chemical pulp production and paper making. We see ourselves as a technical-scientific professional association for the chemical pulp paper industry as well as its suppliers. Anybody who is involved with chemical pulp production and paper making in Europe will find that we offer a comprehensive range of information as well as strong representation of interests for the concerns and issues affecting our high-tech sector. We provide our members with an international network for the exchange of information and technical contacts in which topics discussed range from research and development concerning paper making through to ecology and the future of the chemical pulp industry and paper industry.

A Cut Above: Bar made from paper brings standalone style to fashion launch

A stylish bar, fit for a lavish cocktail party before being recycled, has been produced by British design studio, Flow Creation using luxury papers from British manufacturer, James Cropper

170 year-old paper innovators, James Cropper and heritage clothing brand, Thomas Pink joined forces to commission a stunning paper bar and set of paper drinking accessories, designed to stand as a centrepiece in the hallowed halls of London’s Institute of Contemporary Arts (ICA) during the London Collections fashion event.

170 year-old paper innovators, James Cropper and heritage clothing brand, Thomas Pink joined forces to commission a stunning paper bar and set of paper drinking accessories, designed to stand as a centrepiece in the hallowed halls of London’s Institute of Contemporary Arts (ICA) during the London Collections fashion event.

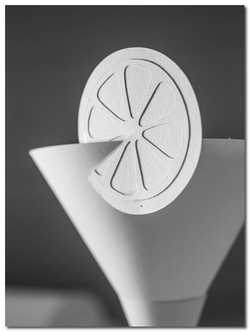

Developed and built by Sam Robins of design studio, Flow Creation, the free-standing bar, made from two different weights of James Cropper’s White Kendal Manilla stock came complete with paper glasses, lamps and fine architectural detail to complement the historic setting. Constructed to stand at the heart of Thomas Pink’s, London-inspired Autumn/Winter 2015 collection launch on Saturday 10 January 2015, the collaboration called on the designer to evoke the crisp freshness of a new, white shirt while testing the qualities of the versatile paper stock.

Following deliveries of 315gsm and 180gsm papers to his Blackpool studio, Robins combined manual hand-working and paper cut techniques with computerised design and cutting processes to develop the bar and drinking paraphernalia. As well as working with Thomas Pink’s commercial team and both event and lighting designers for his cues, he looked to the ICA itself for inspiration, noting detail from the Corinthian columns and ornate cornicing.

Sam says:“Initially I was shocked by the size of the venue; it’s a really grand, imposing space. The bar has grown to 8.5 metres long as a result. Thomas Pink really let me develop the design and specifications with little intervention, simply asking that it did the job of allowing models to interact with it as an alternative to your usual catwalk fashion show. The paper has stood up to every test I have thrown at it, with heavier stock taking the burden of structural support and the lighter weight allowing for decorative elements. Many of the props are really quite large, but can stand without additional support.”

As well as creating lemon slices, martini glasses and even a paper-framed, 3D artwork of the Thomas Pink logo, ‘cheeky fox’, Robins has incorporated LEDs and RGB lighting tape into hidden parts of the bar to ensure it responds to thematic changes during the show. The only structural concession required of the paper, to give models confidence in using the bar naturally, was an MDF sub-structure for surface strength and ballast. To close the event, gathered VIPs of the fashion industry and press were handed pink pens and invited to leave messages on the clean, white surface.

As well as creating lemon slices, martini glasses and even a paper-framed, 3D artwork of the Thomas Pink logo, ‘cheeky fox’, Robins has incorporated LEDs and RGB lighting tape into hidden parts of the bar to ensure it responds to thematic changes during the show. The only structural concession required of the paper, to give models confidence in using the bar naturally, was an MDF sub-structure for surface strength and ballast. To close the event, gathered VIPs of the fashion industry and press were handed pink pens and invited to leave messages on the clean, white surface.

Chris Brown, Commercial Director of James Cropper, said: “Our customers come to us for a product that is perfectly matched to their needs, and in this case our White Kendal Manilla was ideal for laser cutting as well as the purity of its colour. Kendal Manilla has become established as a benchmark in quality in the art, craft and stationery markets and has proved perfect for the intricate construction of this fun, visually stunning project.”

The paper bar will be recycled following the press launch alongside the PINK Drink/James Cropper branded paper drinks cups used to serve cocktails at the event. The Kendal Manilla stock contains up to 40% reclaimed fibres from single-use drinks cups. The reclaimed pulp originates from James Cropper’s own, pioneering recycling plant, which sees the formerly unrecyclable waste material given a new lease of life.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com

Record speed and successful start-up of ANDRITZ tissue machine at C&S Paper Yunfu, China

The PrimeLineST tissue machine started up by international technology Group ANDRITZ at C&S Paper Yunfu, China, at the beginning of 2014 achieved a production speed of 1,800 m/min, thus setting a world record for a tissue machine with steam-heated hood.

The PrimeLineST tissue machine started up by international technology Group ANDRITZ at C&S Paper Yunfu, China, at the beginning of 2014 achieved a production speed of 1,800 m/min, thus setting a world record for a tissue machine with steam-heated hood.

At the same time, the second tissue machine with steel Yankee supplied by ANDRITZ to C&S Paper Yunfu was started up successfully, with a design speed of 1,900 m/min and a width of 5.56 m.

The ANDRITZ PrimeLineST tissue machines were designed particularly to further reduce drying costs. The entire drying process uses steam only, and the high-precision steel Yankee – combined with a steam-heated hood – allows high output and runability as well as significant cost savings by operating with the comparatively cheap steam. Thanks to the steel Yankee and the fully integrated heat recovery system, the steam consumption is also well below the amount required by similar machines.

The ANDRITZ GROUP

The ANDRITZ GROUP is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and solid/liquid separation in the municipal and industrial sectors. The publicly listed, international technology Group is headquartered in Graz, Austria, and has a staff of around 24,500 employees. ANDRITZ operates over 250 production sites as well as service and sales companies all around the world. The ANDRITZ GROUP ranks among the global market leaders in all four of its business areas. One of the Group’s overall strategic goals is to strengthen and extend this position. At the same time, the company aims to secure the continuation of profitable growth in the long term.

ANDRITZ PULP & PAPER

The business area is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, gasification plants for energy production, flue gas cleaning plants, production equipment for biofuel (second generation) and biomass pelleting, biomass torrefaction, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

For further information please contact:

Oliver Pokorny

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

Amaco Group Honoring the president of Arab Federation of paper, printing and packaging Dr. Fadi Gemayel

In the occasion of honoring Dr. Fadi Gemayel, President of the Arab Federation of Industries and Paper, Printing and Packaging , AFPPPI, Mr. Ali Mahmoud El Abdallah, member of this Federation and the chairman of AMACO Group which is headquartered in Lebanon and specialized in the Tissue Paper Industries, especially the Converting Tissue Paper Machines and the Tissue Mill Machines over thirty years, held dinner ceremony in Phoenicia Hotel, Beirut – Lebanon, sponsored by the Ministry of Industry, Dr. Hussein El Hajj Hassan, gracing this Lebanese figure who played a very important role in the Paper Industry. Dr. Gemayel who is also the President of Association of Lebanese Industries was elected as President of AFPPPI, since he deserved this title for offering much for these industries (Paper, Printing and Packaging) and since this Federation is a Union of Arab countries active in developing these sectors from technical, scientific, and commercial wise and in raising the Arab Production Standards regionally and internationally.

In the occasion of the election of Dr. Fadi Gemayel, president of the Arab Federation for Paper, printing and packaging Industries- AFPPPI , the President of AMACO GROUP Mr. Ali Mahmoud Al - Abdallah honors Dr. Fadi Gemayel in Phoenicia Hotel Beirut - Lebanon

This Ceremony was attended by various Diplomatic, Political, Financial and Economic Public Figures as well as the CEOs of different industrial associations along with Presidents of various syndicates with the attendance many Industrial and businessmen.

Mr. Ali El Abdallah delivered a speech in this occasion, welcoming the attendees considering that the Industry is an important sector in building strong National Economy. Adding that having such strong industry will provide steady growth as well job opportunities. Then Mr. El Abdallah praised Dr. Fadi Gemayel for his major role as President of Syndicate of Paper in Lebanon and for his great efforts that brought Lebanon to the Presidency of the Arab Federation of Industries and Paper, Printing and Packaging, AFPPPI

As he said, since seniority Egyptians and the Chinese share in the creation of paper and industry throughout history: attributed to the ancient Egyptians who first use of paper in the human life through the papyrus and attributed to the Chinese the production of Modern Paper during thereign of Emperor (Ho-T) and the favor for this innovation is due to an employee in the imperial court.

Then Dr. Fadi Gemayel expressed his gratitude for this honor, thanking the support of his fellow members of the Arab Federation of Industries and Paper, Printing and Packaging, AFPPPI

He indicated that Lebanon is always in advance and the hostess forvarious industries and especially the Paper industry referred to hundreds of yearsback as the first factory for the production of paper was Tasco found on1923, the first carton factory was Gemayel Bros found on 1929, the first factory copybooks was OPP found on 1957 and the first factory for manufacturing of hygienic tissue Paper was Mimosa found on 1967. So, the Paper Industry nowadays is source of pride for the Lebanese all over the world from Africa to Nigeria and the United States where INDEVCO Group is.

Also Dr. Gemayel paid tribute to Saudi Arabia, Egypt, and mention of the volume and quality of this industry exported to the world and the European Region

Gemayel praised the role played by the Minister Hussein Hajj Hassan in contributing to find new industrial horizons and to communicate with the outside world to find new markets.

He focused on theimportantrole played byAMACO GROUPand its president, Mr. Ali Mahmoud El Abdallah in managing the group as well for the high quality, technology and high standards that specializes its machines, which witnessed wide spread to the Arab countries and most countries of the world.

Minister Hajj Hassan congratulates the Lebanese and the Arabs in the occasion of Christmas and the New Year and expressed pride in the national industry, asking the industrialist to form industrial lobby in order to protect and support the productive sectors. He stressed on the need to work in order to raise the Lebanese exports from3 billion US. Dollars annually to 5 billion US. Dollars, and then reduce the volume of imports from 20 to 16 billion dollars.

Then we do so we reduce the size of the debt, and reduce the trade deficit in the trade balance. Minister Hajj Hassan confirmed the existence of important industries in Lebanon to be proud of but he felt sorry for the lack of economic projects and national economic policy based on the industry as main sector helps to secure jobs opportunity and reduce unemployment and migration.

At the end of the ceremony, it was agreed to improve the general conditions of the paper industry and to lay the foundations for dealing with the countries of the world and expand the horizon of trade with these countries as the efficient project done which is purchasing Carton Factory – Gemdoubs – in France by Gemayel Company and considered as the first step to expand the interaction between Arab and foreign countries.

Valmet Advantage DCT tissue line successfully started up at Syktyvkar Tissue Group in Russia

A Valmet-supplied tissue line recently started up at Syktyvkar Tissue Group's new site in Semibratovo, Yaroslavl region, Russia. The new Advantage DCT 100HS machine adds 30,000 tons of tissue per year to the company's current production of bathroom tissue, napkin and towel grades.

A Valmet-supplied tissue line recently started up at Syktyvkar Tissue Group's new site in Semibratovo, Yaroslavl region, Russia. The new Advantage DCT 100HS machine adds 30,000 tons of tissue per year to the company's current production of bathroom tissue, napkin and towel grades.

Valmet has previously delivered an Advantage DCT 100 production line to Syktyvkar's mill in the republic of Komi, which started up in 2008, as well as a major rebuild of their PM1 at the same mill in 2011.

"Valmet and Syktyvkar Tissue Group have developed a strong relationship during our previous deliveries. Excellent teamwork and big efforts from both sides combined with our well proven technology made the start-up very smooth and efficient. We are looking forward to continuing our long-term partnership in future projects," says Björn Magnus, Sales Director EMEA, Tissue Mills Business Unit, Valmet.

Technical information about the delivery

The tissue machine has a width of 2.7 m and a design speed of 2,000 m/min and is optimized to save energy and to enhance final product quality.

Valmet's delivery included a complete tissue production line featuring an Advantage DCT 100HS tissue machine. The tissue machine is equipped with an OptiFlo headbox and a cast alloy Yankee cylinder and an AirCap hood. The project scope also included basic and detailed engineering, process equipment, as well as the supervision of the installation and training of the new tissue line. Metso delivered an automation package with a process control system.

Information about Syktyvkar Tissue Group

Syktyvkar Tissue Group is today one of the best known companies on the Russian market for tissue products with a market share of around 10%. Today the company employs 385 people and produces approximately 45,000 tonnes of tissue. Headquarters and existing production facilities of the company before this new site in Semibratovo are located in Syktyvkar, capital of the republic of Komi in the northwestern part of Russia.

For further information, please contact:

Björn Magnus, Sales Director, Tissue Mills business unit, Valmet, tel. +46 703 17 79 83

Hans Englund, Project Manager, Tissue Mills business unit, Valmet, tel. +46 705 17 40 00

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Changes to Pöyry's Group Executive Committee

Anja Silvennoinen, 54, MSc in Energy technology, MBA, has been appointed Executive Vice President of Pöyry PLC and President of the Energy Business Group and member of the Group Executive Committee of Pöyry PLC. She will assume these positions on 1 March 2015 and will report to Alexis Fries, President and CEO of Pöyry PLC.

Anja Silvennoinen, 54, MSc in Energy technology, MBA, has been appointed Executive Vice President of Pöyry PLC and President of the Energy Business Group and member of the Group Executive Committee of Pöyry PLC. She will assume these positions on 1 March 2015 and will report to Alexis Fries, President and CEO of Pöyry PLC.

Anja Silvennoinen is currently Vice President, Head of Energy, Nordics, in the Management Consulting Business Group of Pöyry.

Anja Silvennoinen will succeed Sergio Guimaraes in these positions. Reporting to Alexis Fries, Sergio Guimaraes will assume a Senior Vice President, Business Development position at Pöyry with a specific focus on Latin America and including tasks related to operations and process optimisation at Group level.He will leave his position at the Group Executive Committee.

"I want to warmly welcome Anja to the Group Executive Committee and wish her every success in developing our energy business further. At the same time, I want to thank Sergio for an outstanding job done in the Energy Business Group and as a member of the Group Executive Committee. I am particularly pleased that we had an excellent internal candidate to succeed Sergio in his positions", says Alexis Fries, President and CEO of Pöyry PLC.

PÖYRY PLC

Additional information:

Alexis Fries, President and CEO

tel. +41 44 355 5525

Pöyry is an international consulting and engineering company. We serve clients globally across the energy and industrial sectors and locally in our core markets. We deliver strategic advisory and engineering services, underpinned by strong project implementation capability and expertise. Our focus sectors are power generation, transmission & distribution, forest industry, chemicals & biorefining, mining & metals, transportation and water. Pöyry has an extensive local office network employing about 6,000 experts. Pöyry's net sales in 2013 were EUR 650 million and the company's shares are quoted on NASDAQ OMX Helsinki (Pöyry PLC: POY1V).

Kemira Oyj: Change in the management of Paper segment

![]() Petri Helsky, President of Paper segment and Asia Pacific region will leave Kemira to take up the position of CEO of Metsä Tissue Corporation.

Petri Helsky, President of Paper segment and Asia Pacific region will leave Kemira to take up the position of CEO of Metsä Tissue Corporation.

Petri Helsky will continuein his current position and as a member of Kemira's Management Board latest until the end of June 2015. Kemira has started the process of finding a successor to lead the Paper segment and the Asia Pacific region.

"I want to thank Petri for his achievements in a number of leadership positions in Kemira since 2007. I wish him best of success with his new challenges", said Jari Rosendal, Kemira's President and CEO.

For more information, please contact

Kemira Oyj

Jari Rosendal, President and CEO

Tel. +358 10 862 1801

Leena Lie, SVP, Communications and Corporate Responsibility

Tel. +358 10 862 1153

Tero Huovinen, VP, Investor Relations

Tel. +358 10 862 1980

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2013, Kemira had annual revenue of EUR 2.2 billion and around 4,500 employees. Kemira shares are listed on the NASDAQ OMX Helsinki Ltd.

www.kemira.com

Pankaboard delivers more value for customers in 2015 through product development

Pankaboard is set to deliver a significantly improved yield for PankaMax, PankaDisc and PankaSeal from January 2015, thanks to recent investments in the uncoated specialty paperboard machinery.

As part of ongoing product development activities, a new dilution headbox installed on the BM3 machine in June 2014, can deliver the required paperboard thickness by using up to 10% less substance depending on grade. With the new bulk improvements, customers can be confident that PankaMax, PankaDisc and PankaSeal products will retain the same high standards and quality characteristics, while further reducing the ecological footprint.

This means that from January 2015, Pankaboard customers will get more square meters per ordered ton, a real cost-saving.

The BM3 machine produces a wide range of high quality uncoated paperboards suitable for a variety of end-uses.

• PankaMax is used in various laminates for food and display applications

• PankaDisc is used for coasters and food underlay’s

• PankaSeal is used for cap seal applications

All products are made of 100% natural virgin fibres, certified by ISEGA for direct food contact and available from a mill with PEFC & FSC certified chain of custody accreditation.

Christer Nordman, Vice President Sales & Marketing, comments, “We are proud to offer our customers more value from our product development investments by providing new cost saving opportunities. We will be introducing the new specifications for the production of PankaDisc and PankaMax in January 2015 and will extend these to PankaSeal in February.”

For further information please contact:

Lauri Junnila, CEO

Tel: +358 104 804 601

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Christer Nordman, Vice President Sales & Marketing

Tel: +358 40 839 6900

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

About Pankaboard:

Pankaboard is a world leader in virgin-fibre, high substance, coated folding boxboards and uncoated speciality boards. The business provides material solutions for food packaging, luxury beverage packaging, food service and displays & laminates. Pankaboard is a Finnish privately owned paperboard producer, with annual net sales of over 80 million Euros and 160 employees.

Caption 1, 2: Christer Nordman, Vice President Sales & Marketing, comments, “We are proud to offer our customers more value from our product development investments by providing new cost saving opportunities. © Pankaboard

Södra surveys the aftermath of the storm Egon

The damage caused to forests by the storm Egon, which swept over Southern Sweden on 10-11 January, is currently considered to be less than anticipated, despite the high wind speeds recorded. Intensive efforts to survey the extent of the damage to Södra's members' properties are currently under way.

The damage caused to forests by the storm Egon, which swept over Southern Sweden on 10-11 January, is currently considered to be less than anticipated, despite the high wind speeds recorded. Intensive efforts to survey the extent of the damage to Södra's members' properties are currently under way.

According to initial estimates, the extent of the damage in the aftermath of Egon is significantly less than, for example, the storms Gudrun and Per, which occurred in 2005 and 2007, respectively, damaging 75 and 16 million cubic metres, respectively, in Götaland.

Intensive efforts to carefully assess the extent of the storm Egon are currently under way. To estimate the damaged wood volume, a large number of reference properties that are geographically dispersed across Södra's forestry operations areas are being analysed. Södra will present information regarding the damaged wood volume when these figures have been compiled.

The damage that has been identified to date is primarily dispersed windfalls and small concentrations of windthrown trees in exposed locations, for example, on the edge of forests. Damage to forests has been noted throughout much of Södra's forestry operations areas, albeit mainly concentrated to Västra Götaland and Jönköping counties around the Vänern and Vättern lakes.

Södra recommends members affected by the storm to first take an inventory of the damage to their properties and contact their forestry inspector. Södra urges all forest owners to always prioritise safety and to be extremely careful when processing storm-felled wood.

To find out more, please Contact:

Håkan Larsson, President of the Södra Skog business area, tfn: +46 705 894 510

Göran Örlander, Head of Forest Management, Södra Skog, tel: +46 470 893 62

Annica Gerentz, Director of Communications, Södra, tel: +46 703 984 209