Ianadmin

Valmet received a repeat order for Advantage THRU-AIR tissue line from First Quality Tissue, USA

Valmet will supply a complete Advantage ThruAir tissue line to First Quality Tissue (FQT) in USA. The new production line is planned to be started-up in the second quarter of 2018 and it will add 70,000 tons of ultra-premium quality tissue to the company's annual production.

The order was included in Valmet's fourth quarter of 2016 orders received. The value of the order will not be disclosed.

The order was included in Valmet's fourth quarter of 2016 orders received. The value of the order will not be disclosed.

Valmet has previously delivered three Advantage ThruAir lines to FQT's Anderson mill. They were started up in 2011, 2012 and 2016.

"Once again we have been awarded with the opportunity to continue to support FQT on their expansion plans in the ultra-premium tissue category. The fact that this is the fourth machine shows that we can deliver according to very high expectations and we are excited to continue the very good partnership with FQT ", says Jan Larsson, Director of Tissue Technology Sales, North America at Valmet.

Information about the customer First Quality Tissue

First Quality Tissue is a member company of the privately held First Quality group of companies, headquartered in Great Neck, New York, a leading manufacturer of nondiscretionary consumer products. The company is a market leader that offers a very diversified and full product offering of high quality private label and branded products. FQT is currently operating five tissue machines in Lock Haven, Pennsylvania and in Anderson, South Carolina.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply an Advantage ThruAir tissue production line to Irving Consumer Products

Valmet will supply a new Advantage ThruAir (TAD) machine for Irving Consumer Products. The new machine increases Irving's capacity for premium household paper products. The machine will be delivered in 2018, and will support Irving's ambition to provide premium products to the North American market.

The order was included in Valmet's first quarter of 2017 orders received. The value of the order will not be disclosed.

Valmet and Irving share a long history of partnership and this will be their fifth project together. Valmet has previously delivered ThruAir machines to Irving in Fort Edward, New York, and Toronto, Ontario, as well as major rebuilds of TM1 and TM2 tissue machines in Saint John, New Brunswick.

"The new TAD machine will help Irving Consumer Products continue to grow and deliver premium quality tissue paper products to our customers," said Robert K. Irving, President of Irving Consumer Products.

"We are happy to continue our relationship with Irving Consumer Products, working together to continuously improve their operations and performance. This new Advantage ThruAir Drying machine will increase Irving's production capacity for bath tissue with superior bulk and softness, and for towel products with excellent performance strength and absorbency," says Jan Erikson, VP for Sales, Tissue mills business unit, Valmet.

Technical information about the delivery

Valmet's delivery will comprise a complete tissue production line with stock preparation equipment. The new line will include an Advantage ThruAir tissue machine, including an OptiFlo II TIS headbox, ThruAir Dryers and Air system and an Advantage SoftReel reel. The delivery also includes mist and dust systems, automation systems, basic mill engineering, and advisory services.

Valmet Advantage ThruAir tissue machine

Valmet Advantage ThruAir tissue machine

Information about the customer Irving Consumer Products

Irving Consumer Products is one of North America's leading manufacturers of household paper and baby diaper products. Irving Consumer Product companies include Irving Tissue and Irving Personal Care. Irving Tissue produces premium household store brand paper products for many of North America's top retailers, in addition to some of the top-selling tissue brands in the marketplace. Irving Personal Care is the only manufacturer of baby diapers and training pants in Canada. Using state-of-the-art equipment and technology, they produce premium quality private label products for major North American customers. Read more at www.irvingconsumerproducts.com.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Tissue World Milan: Efficient production with Voith XcelLine tissue machines

XcelLine: In the last few months, Voith has sold 15 XcelLine tissue machines to customers from all over the world.

XcelLine: In the last few months, Voith has sold 15 XcelLine tissue machines to customers from all over the world.

Tissue World in Milan will be the ideal place to see Voith’s XcelLine tissue machines, new solutions to increase the efficiency and quality of the entire tissue production process supply chain. In addition, Voith will be showcasing Papermaking 4.0 solutions, the new InfiltraDiscfilter – the latest generation in dewatering without filter bags. Furthermore Voith presents the new SkySoft ceramic coated creping blades, the ProTect for safe press fabric measurements and new Yankee service options. The show is taking place in Milan, Italy from April 10 to 12, trade visitors will find Voith at stand F 500 in Hall 3 and have the chance to listen to Voith presentations during the conference.

OnCare: Voith is presenting its networked solutions like OnCare to increase the efficiency, productivity and quality of the entire paper production process supply chain.As a strong partner, Voith helps Tissue producers to set the right course and offers the ideal solutions for raising profitability and efficiency to the next level. In October 2016 the new generation of XcelLine tissue machines was launched. XcelLine paper machines enable Voith customers to reach the next level of tissue production. All technologies, components, and services are perfectly coordinated and integrated with each other. This interplay guarantees excellent performance over the entire lifecycle of the paper machine. The excellent design, coordination and reliability of all secondary systems also form part of Voith’s scope of supply. In the last few months Voith has sold 15 XcelLine tissue machines to customers from all over the world.

OnCare: Voith is presenting its networked solutions like OnCare to increase the efficiency, productivity and quality of the entire paper production process supply chain.As a strong partner, Voith helps Tissue producers to set the right course and offers the ideal solutions for raising profitability and efficiency to the next level. In October 2016 the new generation of XcelLine tissue machines was launched. XcelLine paper machines enable Voith customers to reach the next level of tissue production. All technologies, components, and services are perfectly coordinated and integrated with each other. This interplay guarantees excellent performance over the entire lifecycle of the paper machine. The excellent design, coordination and reliability of all secondary systems also form part of Voith’s scope of supply. In the last few months Voith has sold 15 XcelLine tissue machines to customers from all over the world.

Papermaking 4.0 for higher productivity and quality

The Voith XcelLine tissue machines and working environments are going digital. Fast and highly available internet connections are the prerequisite for systematic integration of digital process tools into the supply chain.

Voith is presenting its networked solutions to increase the efficiency, productivity and quality of the entire paper production process supply chain. Systems like OnCare and OnEfficiency are solutions that stem from the Papermaking 4.0 concept. As a general expert on the entire paper manufacturing process, Voith ensures that its customers benefit from practical experience in papermaking process management.

New technologies for higher efficiency and safety

New tissue machines can be equipped with the new InfiltraDiscfilter. The InfiltraDiscfilter has been built since more than 30 years. Due to the BaglessPlus technology holes in filter bags are history. Likewise the InfiltraDiscfilter reliably produces excellent filtrate quality which allows to maintain water consumption at a minimum. No additional cost for process chemicals needs to be spend. Very low solids content are a prerequisite to achieve long lifetimes of felts and fabrics. This is why leading tissue makers rely on Voith save all technology.

Another breakthrough technology is behind CFRP (Carbon Fiber Reinforced Plastic) lightweight rolls. Unlike steel, the strength and rigidity of CFRP rolls can be adapted to the specific requirements without altering the installation space required. Moreover, the much lower density ensures a significant weight reduction. CFRP components also offer a range of other benefits, like low thermal expansion or stable running properties and higher operating speeds for a given roll geometry.

The new SkySoft ceramic coated creping blades offer state-of-the-art technology for tissue production and contribute to increase productivity through more consistent tissue quality over the blade lifetime. The highly wear resistant material contributes to longer overall blade lifetime and higher machine uptime. Additionally, SkySoft reduces friction with the Yankee cylinder surface and infinitely adjustable, customizable bevel angles are possible to deliver.

Press felt measurements are essential to guarantee efficient paper production. The operator has to ensure the safety of the personnel. The ProTect system is designed to take reliable press felt measurements at various positions in the press section of the paper machine. ProTect consists of carriage, fixture and any number of traverse beams and can be operated with all available standard portable measurement devices for all kinds of press felt measurements.

OnSite Yankee Service

With OTR Precise and MiniGrinder, Voith extends its OnSite Yankee Service portfolio. With its OTR Precise system, Voith is offering tissue manufacturers a technology for reliably identifying deformations on the surface of a Yankee cylinder. The system uses a precise measurement of tensile force and a 3D measuring process to eliminate the influences of vibration producing a topographical map of the Yankee cylinder surface, at a precision that sets a new benchmark for the industry.

This data forms the basis for precise planning of maintenance cycles, to initiate countermeasures and in this way extend the service life of the cylinder. The MiniGrinder developed by Voith's OnSite Yankee Service enables easy, accurate removal of irregularities and thus restores the Yankee cylinder's ideal crown curve. What is special about the MiniGrinder is its size. It is so compact that it can be used on any tissue machine.

OTR: With OTR Precise and MiniGrinder, Voith extends its OnSite Yankee Service portfolio.

OTR: With OTR Precise and MiniGrinder, Voith extends its OnSite Yankee Service portfolio.

Voith Paper conference presentations

Laslo Monte, Director Sales Tissue EMEA, Voith Paper Rolls GmbH & Co. KG, will provide further insights into “New Yankee Metallizing Technology” and will explain how to reduce the amount of thermal energy consumed for a given production rate, alternatively realizing higher production rates. April 11, session “Yankee Operations and Energy Optimization“ from 8:40 a.m. to 11:40 a.m.

Magnus Bengtsson, Development Manager at Duni AB, Bernhard Kohl, Vice President Project Sales at Voith Paper, and Jan Achterman, Global Grade Owner Tissue at Voith Paper, will give a presentation together about “The next level of environmental friendly tissue production” and give some details on the co-operation agreement made to develop quality, productivity and operating cost. April 12, from 8:50 a.m. to 9:20 a.m. session “Improvements & Innovations: Efficiency Enhancing and Energy Saving Technologies”.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

For 150 years, Voith’s technologies have been inspiring customers, business partners and employees around the world. Founded in 1867, Voith today has around 19,000 employees, sales of €4.3 billion and locations in more than 60 countries worldwide and is thus one of the largest family-owned companies in Europe. Being a technology leader, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive.

Valmet's investor website awarded the best in Finland

Valmet's investor website won the 'Best investor website' contest, arranged by the Finnish Foundation for Share Promotion and the Finnish Society of Financial Analysts, in the category of Large Cap companies. In the contest, the Finnish websites of all the companies listed in Nasdaq Helsinki were evaluated. Valmet was ranked the best in the Large Cap category for the second time.

There were four categories in the contest: Large Cap, Mid Cap and Small Cap companies based on market value, and the companies listed in First North. All the main target groups for investor websites - analysts, institutional investors, private investors and brokers - were represented in the jury, which was led by Professor Jarmo Leppiniemi. In their evaluation, the jury concentrated on seven criteria: usability and visual appearance; strategy, growth and profitability; presentation of net sales and financial result; financial targets and historical performance; description of risks; Corporate Governance and sustainable operations, and responsiveness on mobile devices. Compared to the previous years, this time more emphasis was put on usability on mobile devices.

There were four categories in the contest: Large Cap, Mid Cap and Small Cap companies based on market value, and the companies listed in First North. All the main target groups for investor websites - analysts, institutional investors, private investors and brokers - were represented in the jury, which was led by Professor Jarmo Leppiniemi. In their evaluation, the jury concentrated on seven criteria: usability and visual appearance; strategy, growth and profitability; presentation of net sales and financial result; financial targets and historical performance; description of risks; Corporate Governance and sustainable operations, and responsiveness on mobile devices. Compared to the previous years, this time more emphasis was put on usability on mobile devices.

The jury acknowledged Valmet especially for the clear structure of the website and illustrative graphics. "The prize is a great recognition for the persistent work we have done. We continuously strive to further develop Valmet's investor website, and have also had the courage to put effort into new communication channels, like the video gallery and our IR blog", says Calle Loikkanen, Director, Investor Relations.

Valmet's investor website can be visited at the following address: http://www.valmet.com/investors.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Harmac Pacific Selects FITNIR to Supply Online Analyzer

FITNIR Analyzers Inc. has been awarded with supplying its state-of-the-art FT-NIR online analyzer system to Harmac Pacific. A single analyzer and field sampling station system will analyze seven recovery and recaust streams at the Nanaimo, BC mill.

“Harmac’s primary intention for installing FITNIR Online is to stabilize the TTA (Total Titratable Alkali) for more consistent slaker operations and a higher CE (Causticizing Efficiency),” stated Doug Barbour, Production Engineer. “With that, Harmac will see an improvement in white liquor strength and stability, potentially translating to an increase in digester yield.”

“Harmac’s primary intention for installing FITNIR Online is to stabilize the TTA (Total Titratable Alkali) for more consistent slaker operations and a higher CE (Causticizing Efficiency),” stated Doug Barbour, Production Engineer. “With that, Harmac will see an improvement in white liquor strength and stability, potentially translating to an increase in digester yield.”

Harmac Pacific considered other available liquor analyzer technologies, but a number or key attributes elevated FITNIR’s position to the top, including the technology’s broad acceptance within the pulping industry as well as overall life cycle cost.

“With a slight delay in initiating this project due to market downturn, we are pleased to finally be proceeding with the installation of FITNIR Online at Harmac Pacific,” said Ryan Prontack, Engineering Superintendent. “We are looking forward to improved operations from having an online liquor analyzer and expect to see a very quick return on investment on the project.”

“We are excited to add Harmac Pacific to our growing list of Canadian pulp and paper installations,” stated Thanh Trung, VP of Technology for FITNIR Analyzers. “We are pleased to contribute to the reinvestment of yet another locally owned and operated mill.”

Equipment delivery to Harmac Pacific is being planned for June 2017 in preparation for a target start-up date of July 31, 2017.

About Harmac Pacific

Harmac Pacific operates a Northern Bleached Softwood Kraft (NBSK) pulp mill located on the east coast of Vancouver Island near Nanaimo, British Columbia. Nanaimo Forest Products Ltd., the owner of the Harmac Pacific trademark, restarted the mill with a single production line on October 3, 2008, producing NBSK at the rate of 226,000 tonnes per year. In 2009, a second production line was restarted and capital upgrades in 2010 and 2011 brought the mill's production capacity up to 365,000 tonnes of pulp per year.

The Harmac mill produces high quality kraft pulps made from custom blends of Douglas fir, western hemlock, balsam fir, interior SPF and western red cedar. The pulp is sold in Asia, Europe, North America, and Latin America. With its strategic location on a deep water port, the mill is well situated for cost effective export of pulp and receipt of raw materials such as wood fiber. http://www.harmacpacific.com/

About FITNIR Analyzers Inc.

FITNIR’s automated online and benchtop analyzers reliably measure complete pulp liquor compositions. Fast, frequent and accurate measurements drive control strategies that decrease process variability and environmental impact for improved efficiencies and profitability. Proven applications for the digester, recausticizer, recovery boiler, ClO2 generator, brownstock washer, and now kappa measurements for wet and dry pulp, FITNIR is the next generation of process analyzers. www.fitnir.com

First Valmet Advantage NTT machine in Europe successfully started at Renova in Portugal

In late January Portuguese tissue manufacturer Renova produced its first jumbo roll on the first Valmet Advantage NTT tissue line in Europe. The Renova 2 mill, near Torres Novas, Portugal, will utilize the flexibility of the hybrid machine to produce both plain and textured tissue for their typical tissue products in bold colors.

"We are welcoming the production of a new generation of appealing paper at our new PM 7. Now we are eager to discover what we can achieve with the combination of Renova's proactive approach to innovation and Valmet's sustainable Advantage NTT technology. We believe its flexibility can provide us with endless possibilities to produce specially designed textured tissue products," says Mr. Paulo Pereira da Silva, Renova, CEO.

Valmet Advantage NTT tissue machine

Valmet Advantage NTT tissue machine

"It's been an exciting project and we are happy to support Renova in taking their tissue products to the next level. Advantage NTT technology is recognized as providing great opportunities to develop premium products with very high softness. We are excited to follow Renova's journey forward," says Jan Erikson, VP Tissue Sales, Valmet.

Technical information about the delivery

The new tissue machine has a design speed of 1,800 m/min in textured mode and 2,000 m/min in plain mode. The production line is optimized to save energy and fiber, as well as to add the possibility for product differentiation and increase the capacity for premium-quality products.

Valmet's scope of delivery comprised a complete tissue production line, including an Advantage NTT tissue machine, with an OptiFlo headbox and a cast alloy Yankee cylinder. It also features Advantage tissue technology, including an AirCap hood with a WetDust system. The delivery also included basic and detailed mill engineering, complete stock preparation, process and a Valmet DNA Automation system.

Information about the customer Renova

Renova is a European brand of high quality and innovative products. Available in more than 60 countries it offers colorful designs and new functional solutions through stylish and environmental friendly tissue consumer products.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

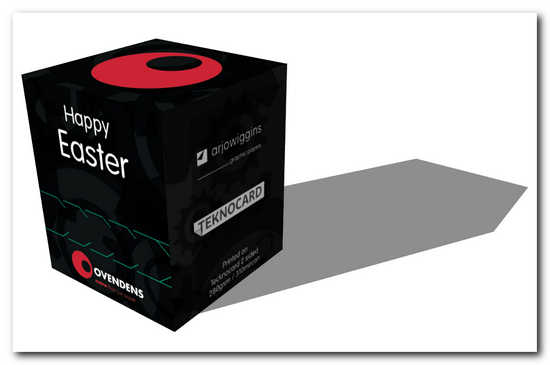

Arjowiggins graphic and Ovendens deliver ‘eggsellent’ Easter campaign to showcase the capabilities of teknocard

Arjowiggins Graphic, the leading manufacturer of environmental paper solutions, and independent paper merchant Ovendens has just launched a playful Easter campaign to showcase the versatility and technical attributes of the Teknocard board range.

The campaign will see printers receive an e-mail call to action to receive a mini chocolate Easter egg, showcased in a customised Teknocard box. Printed on Teknocard 2 sided 280gsm/310 micron, the box is in a striking red and black design with a serrated tear-out band mid-height, showcasing the exceptional surface smoothness for superb printability of Teknocard.

The lucky recipients of the Teknocard Easter egg will also have the opportunity to enter into a prize draw to win an Apple watch – a playful reference to the signature watch motif of Teknocard’s branding. Entrants have until Good Friday to enter the exclusive prize draw.

The Teknocard board range, available from Ovendens, offers a new direction in premium SBS boards in response to recent market trends. Teknocard is engineered to provide superior bulk, stiffness and outstanding converting performance for graphical and packaging applications and a vivid blue-white shade for stunning print contrast and product impact.

Ovendens is a UK stockist of Teknocard 1 (one-side coated) and Teknocard 2 (two-side coated), both FSC certified virgin fibre grades and also available on demand in 100% recycled FSC certified versions.

The range offers a broad, contemporary choice in premium boards to meet the growing demand for environmentally sensitive solutions, yet still delivers an outstanding look and performance with the option of a tactile feel in cards, covers and luxury packaging. Teknocard is also an extremely strong and versatile performer in digital print across the full range.

As part of the campaign, Ovendens will share a selection of swatches and provide customers with the opportunity to receive samples and trial sheets of SRA2.

Charles Eaton, Marketing Manager, Ovendens, said “We are delighted to launch this playful Easter campaign with Arjowiggins Graphic. It not only gives us the opportunity to reward our customers with an Easter treat and chance to win a state of the art Apple watch, but also showcase the exciting versatility and capability of the Teknocard range, which we are proud to stock.”

John MacDonald, Operations Director at Diversified Global Graphics Group (DG3), a leading provider of global print, technology, and visual communication services, said: “Teknocard is a superb sheet which provides us with the versatility to produce items of quality and innovation for our clients, across digital and Litho presses. Used on applications such as light packaging and greeting cards, it surpasses the incumbent as its ready and available in a wide range of sizes and weights on a same day service from our suppliers Ovendens.”

About Arjowiggins Graphic

Arjowiggins Graphic is a leader in the development of innovative environmental paper solutions, offering consistently high quality coated and uncoated recycled papers. The branch is part of Arjowiggins, the world's leading manufacturer of creative high-tech materials and papers. With over 3,500 employees and 16 paper mills around the world, Arjowiggins generates sales of around €905 million. Arjowiggins is the manufacturing arm of Sequana.

About Ovendens

Ovenden Papers is the leading independent paper merchant in the South East of England supplying a wide range of paper, board and envelope products to the commercial print sector. A family run business for over 70 years, Ovendens was built on solid foundations and provided the highest levels of customer service to local customers, fondly referred to as ‘The Ovenden Way’. Now in its fourth generation and with offices in Harlow, Ipswich and Croydon, the company has seen continued growth through consistently providing printers with an exceptional choice of materials at competitive prices, backed-up with locally held stocks available for same day or next day delivery. This is supported by a personable, reliable and responsive service from the dedicated sales team who understand their customers and work tirelessly to ensure their requirements are met.

MTORRES has acquired UTT, an experienced Italian Company in the tissue industry for complete automatic converting lines

MTORRES DISEÑOS INDUSTRIALES, S.A.U. and UNIVERSAL TISSUE TECHNOLOGY, Srl, have just announced the acquisition by MTORRES of Universal Tissue Technology (UTT). The company will operate under the name of MTORRES TISSUE.

This new MTORRES TISSUE brand will be able to supply and serve customers worldwide with a full range of highly flexible and productive complete automatic tissue converting lines, both for Consumer and Away‐from‐Home segments.

The merger of two experienced teams becoming one leverages innovative technology from different sectors and enables MTORRES TISSUE to provide exceptional value to our customers.

Founded in 1975, with 800 employees, more than 700 customers and thousands of machines worldwide, MTORRES specializes in Splicers, Unwinders and Rewinders for all industry sectors that involve web handling such as Tissue, Corrugated, Flexible Packaging, Liquid Packaging, etc.

UNIVERSAL TISSUE TECHNOLOGIES, was created in 2013, and is a young and growing Italian Company with a highly‐experienced team in the design, manufacturing and service of complete automatic tissue lines.

See more at www.mtorrestissue.com or www.mtorres.com

CEN/TC 172/WG 3 Group. FCMs Experts in FCMs at working in Lucca at Ecol Studio

The group of experts of CEN / TC 172 / WG 3: Analytical methods for the evaluation of paper and paperboard in contact with food, met on April 6 at the Ecol Studio headquarters in Lucca.

The group of experts of CEN / TC 172 / WG 3: Analytical methods for the evaluation of paper and paperboard in contact with food, met on April 6 at the Ecol Studio headquarters in Lucca.

The Working Group deals with the standardization of analytical methods for the evaluation of paper and paperboard intended for contact with foodstuffs, with the aim of assist companies in the development of their brand, and to protect the final consumer ensuring, that the products placed on the market are safe for human health.

The group is composed of 15/20 experts on Food Contact Materials (FCMs) coming from different country of Europe. The Group members belong to companies operating in the FCMs sector, research institutes, laboratories, consultancy and two of them are a part of Ecol Studio professional team. Although heterogeneous provenance of the participants, they have one common thing: a deep knowledge of materials in contact with food and a great skill about the matter, in a very particular market which is strongly subjected to a constantly evolving regulatory environment.

Ecol Studio offers innovative solutions and reliable tests to manufacture products and implement processes that conform to the increasingly complex standards required and to the continually evolving norms in force. The Tuscany company, with 8 different locations in Italy, supporting companies in the attainment of the desired, binding quality so that they are facilitated in answering the demands of their sphere of business and capable of consolidating their brand in relation to the stakeholders, bringing about improvements in terms of time, costs and effectiveness. Because brand growth passes through corporate quality standards.

Italian producer Ariete S.r.l. – Futura Line S.p.a. Group – chooses Toscotec for the installation of a new tissue machine.

Ariete S.r.l., Italian company producing high quality tissue paper, has ordered a new MODULO-PLUS machine from Toscotec for its paper mill in Cava dei Tirreni (Salerno), Italy.

The new tissue machine replaces the exiting one and startup is scheduled for July 2017.

All the dismantling and assembly operations will be performed and synchronized in order to minimize the mill’s downtime. The scope of the supply includes a

MODULO-PLUS in Crescent Former configuration with single-layer headbox.

Approach flow, electrical and control systems together with dismantling of the existing machine and installation of the new one, supervision and assistance for startup will all be performed by Toscotec.

Ariete S.r.l. has been working in the field of tissue paper since 1965, manufacturing qualitatively high standard products capable of meeting the different and changing demands of the market.

The paper mill, headquartered in Italy in Cava dei Tirreni (Salerno), spans along a property of 14,000 m2 and has a production capacity of 22,000 tons/year. The company offers its customer a wide range of semi-finished products for hygienic use and for use in the food industry, with productions that vary from 15 gr/m2 to 38 gr/m2 and from 1 to 4 plies of pure cellulose. Traditionally oriented towards innovation and quality in full respect of people and of the environment, Ariete has decided to make this investment pursuant to a new strategy focused on maximizing efficiency.

“Toscotec’s offer turned out to be the best on a technological level and the most suitable to our needs. To be competitive on the market, we must have the proper instruments: we are convinced that the new MODULO-PLUS is the technical solution that we were looking for and that will allow us to increment quantity and quality”, states Nicola Salsano, Chairman of the Board of Directors at Ariete S.r.l.

Toscotec S.p.A.

Leader in innovative solutions, Toscotec is the ideal partner for the tissue and paper industry. Since 1948 it designs and manufactures technological solutions for the world’s major paper industries: from complete production lines to rebuilds and upgrades, to individual components. With a global presence and a strong service offer, the company aspires to be a reference for its customers, distinguishing itself for quality and reliability.

Center of excellence in the production of TT SYD, the company stands for tradition of innovation, manufacturing quality and energy savings. Toscotec is market leader in the sale of tissue machines.