Ian Melin-Jones

Orient Paper Announces Production Line Updates

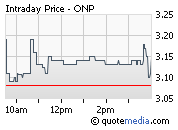

Orient Paper, Inc. (AMEX: ONP) ("Orient Paper" or the "Company"), a leading manufacturer and distributor of diversified paper products in northern China, today announced that the Company has successfully completed the  construction and installation of the paper manufacturing equipments at its new 360,000 tons corrugating medium paper production facility.

construction and installation of the paper manufacturing equipments at its new 360,000 tons corrugating medium paper production facility.

Following the completion of construction and installation of equipments, the Company is currently engaged in carrying out limited testing procedures with its current power supply system on separate sections of its new production line, and in recruiting and training new employees. Meanwhile, Orient Paper is coordinating with the local government and electricity department to activate the Company's new power station, which will be the primary source of power supply for the new corrugating paper production line. The Company expects the new power station to be activated and the commercial production of the production line to be officially launched in the near term.

Recent pictures of the new 360,000 tons corrugating medium paper line can be viewed at the below link: http://www.orientpaperinc.com/Picture.html

"With the completion of construction and installation of the paper manufacturing equipments, we are now making progress on testing procedures. We also expect to conduct complete trial runs after our new power station is activated," commented Mr. Zhenyong Liu, Chairman and Chief Executive Officer of Orient Paper. "We have been working towards expanding our capacity over the past few years. We believe at our new facility, we will produce high-quality products that will further strengthen our market reputation and increase our market share."

SOURCE Orient Paper, Inc.

NewPage Corporation and Certain U.S. Subsidiaries Receive Approval of First Day Motions To Enable Business Continuity Throughout Restructuring

NewPage Corporation announced today that its corporate parent, NewPage Group Inc., and certain of its U.S. subsidiaries (collectively, the "Company") have received approval from the United States Bankruptcy Court for the District of Delaware on all of the First Day Motions related to its voluntary Chapter 11 restructuring that were scheduled to be heard today. The remaining motions (dealing with certain professionals) will be scheduled for a hearing at a later date. These approvals give the Company the authority to continue to conduct its business as usual without interruption in U.S. employee wages and benefits programs or customer programs, among other stakeholder protections.

Among the First Day Motions granted, the Company received interim approval of its $600 million Debtor in Possession (DIP) financing committed by JPMorgan Chase Bank, N.A., Barclays Bank PLC and Wells Fargo Capital Finance, LLC. These facilities help ensure the Company has adequate liquidity to continue to operate and compete successfully while it works with its creditors and other stakeholders to complete a Chapter 11 plan for its U.S. operations.

Additionally, the Company emphasized that, following approval of the motions:

- It has authority to continue its pre-existing customer programs without interruption. The Company fully intends to deliver the same high level of quality and service its customers expect both during and after the restructuring.

- It has authority to continue its existing employee wage and benefit programs, including expense reimbursement, vacation, sick leave and holiday pay, as well as retirement and savings plans in the normal course. The Company believes that protecting employees is integral to its future success.

- It has received approval to use cash collateral and to continue its current cash management system for operations.

The Company previously stated that it fully intends to pay suppliers for all goods and services delivered on or after the September 7, 2011 filing date. Supplier claims for goods and services provided before the filings are typically dealt with as part of the Chapter 11 plan. The Company values and looks forward to continuing its relationships with its suppliers.

"Securing Court approval of our First Day Motions was a critical first step in our Court-supervised restructuring process," said George F. Martin, president and chief executive officer of NewPage Corporation. "We believe the intended balance sheet restructuring will enable us to fully realize the benefits of our prior operational improvements and make continued investments in the business. Building upon the consistency and exceptional service for which NewPage has been known, we will continue to create quality paper that is in high demand from our customers."

NewPage Group Inc. and certain of its U.S. subsidiaries filed voluntary petitions under Chapter 11 of the United States Bankruptcy Code on September 7, 2011. Separately, the company's Canadian subsidiary, NewPage Port Hawkesbury Corp., commenced proceedings before the Supreme Court of Nova Scotia under the Companies' Creditors Arrangement Act of Canada ("CCAA").

NewPage has established a dedicated website, www.NewPageRestructuring.com, through which its stakeholders can access current information about the restructuring and the related legal filings.

Court documents pertaining to the U.S. proceedings can also be accessed directly through the Claims Agent's website, www.kccllc.net/newpage.

Suppliers can receive answers to additional questions they may have by contacting the NewPage supplier call center at (877) 226-7107 or This email address is being protected from spambots. You need JavaScript enabled to view it..

Stora Enso the only European forestry and paper company listed in the Dow Jones Sustainability Indexes

Stora Enso has been listed in the Dow Jones Sustainability Index (DJSI) for the 11th year running. The Group is the only European company from the forestry and paper sector listed in the DJSI for 2011−2012. Stora Enso received top industry scores for sustainable forest management, product stewardship and environmental management. The members of the DJSI for 2011−2012 were announced today.

“We are constantly improving in our Global Responsibility efforts, and being listed in the Dow Jones Sustainability Index for 11th year in a row and still improving our performance in the Index are signs that we are on the right path,” says Stora Enso CEO Jouko Karvinen.

“We have been rethinking our responsibility approach and made new initiatives such as improving sustainability standards in our supply chain and enhancing engagement with local communities. I’m glad to see that the work we have done is also reflected in the DJSI results. The only way our company can become even more responsible than today is by rethinking − questioning old ways of working and finding new ways and solutions. The key is to listen to our stakeholders and learn from them.”

The Dow Jones Sustainability Indexes are the first global indexes to track the financial performance of leading sustainability-driven companies. Companies are included in or deleted from the indexes based on their economic, environmental and social performance. The indexes provide investors with reliable and objective benchmarks to help them manage their sustainability portfolios.

The European Paper Industry - Delivering Bio-value

European Paper Week 2011 will take place from 15 till 17 November included at the Crowne Plaza, Le Palace, Rogier, Brussels.

European Paper Week is the European paper and pulp industry’s biggest annual event gathering some 300 participants, from all areas and levels in the industry. The event extends over 3 days, includes a series of meetings involving a range of industry sectors and creates a high level forum for discussion.

Register before 30 September for the early bird rate and download the draft programme here.

Please note the change of date for the Annual Meeting. It is now on the Wednesday afternoon, 16 November. The online registration system will be open beginning September.

Invitation: 2011 European Paper Recycling Awards

The European Recovered Paper Council is pleased to invite you to attend the 2011 European Paper Recycling Awards on Wednesday 21 September 2011 at 18h00 at the European Parliament, rue Wiertz 60, 1047 Brussels, Batiment Spaak, 1st floor, Espace Menuhin

This year, awards will be given in two categories:

- Information & Education

- Technology Improvement & R&D

After the recycling awards, live music and a reception will provide an opportunity to meet and greet key individuals in the European Parliament.

To faciliate the organisation please register online at http://paperrecovery.org/online-registration before 12 September.

Start of consultation for Product Footprint Rules for paper

The Confederation of European Paper Industry (CEPI) and the European Commission DG Environment are launching a consultation for Product Footprint Category Rules (PFCR) for paper and paper products. The paper PFCR is linked to the forthcoming European methodology for the calculation of environmental footprint of products, currently being developed by the Commission services. This is a pilot project testing a new way of adopting PFCR for an industry sector using crowdsourcing and online tools

The PFCR development process will be transparent and open allowing all stakeholders to participate in the process. All interested organizations and experts are invited to register themselves now and start commenting on a consultation paper via the online collaboration platform www.paperpfcr.eu as of Monday, 12 September

A final PFCR for paper should provide clear guidance for paper companies to conduct environmental footprint studies. In addition, it might represent an important reference document for possible future policy actions both at EU and Member States level.

The European Product Footprint Category Rules (EPFCR) for paper will be divided into three sections; after each section there will be an open consultation (crowdsourcing). Stakeholders can comment on the draft PFCR during the crowdsourcing stages and at the stakeholder meeting which will be held in Brussels 14 and 15 November 2011. The comments received through the open consultation are visible for registered participants via the online platform. At the end of the process, in December 2011, an e-vote will be organised in order to measure the level of support of the document among the stakeholders who contributed to its drafting.

The EFPCR development work includes the following stages:

1. Preparatory stage July-August 2011

2. PFCR consulting stage:

a. 1st crowdsourcing 12/09 > 02/10/2011

b. 2nd crowdsourcing 10/10 > 30/10/2011

c. 3rd crowdsourcing 09/11 > 30/11/2011

3. E-vote: 12/12 > 19/12/2011

Stakeholders that are registered will be reminded of the start for each consultation stage by email.

Role of PFCR

Product Footprint Category Rules (PFCRs) aim at providing detailed technical guidance on how to conduct a product environmental footprint study. PFCR is linked to the forthcoming European methodology for the calculation of environmental footprint, currently being developed by the Commission services.

PFCR complement general methodological guidance for environmental footprint by providing further specification at the product level. PFCR will thus make important contributions to increased reproducibility and consistency in product environmental footprint studies. As defined in ISO 14025(2006), PCRs (Product Category Rules) include sets of specific rules, guidelines and requirements that are aimed at developing “Type III environmental declarations” for any product category. “Type III environmental declarations” are quantitative, LCA-based claims of the environmental aspects of a certain good or service.

30 years of formic acid production at Kemira

Kemira Oyj has produced formic acid for 30 years now. The production of formic acid has been expanded gradually, and the current production volume is over 100,000 tons per year.

Kemira actively develops new applications for formic acid, especially for the feed, chemical, and leather industries. "The main target of the development work is either to replace more harmful products with a formic acid based product, or to improve the customer process," tells Marjo Luoma, Director, Formate product line.

"A good example of our newest products is Tanfor A which improves the efficiency of the soy bean oil epoxidation process. Lowering the environmental load of the formic acid production is crucial for Kemira. We are developing processes which use renewable biomass based raw materials for formic acid production," says Luoma. "Formic acid is a simple organic acid which is chemically the same naturally degradable acid that red ants have produced in the nature for already millions of years."

When Kemira started the formic acid production in cooperation with Valio in Oulu in fall 1981, most of the production was sold to Finnish farms as a silage additive. "Still today the preservation of silage is an important application for formic acid, even though the acid today is sold for numerous applications all over the world," says Luoma.

The prospect of formic acid applications and customers is still developing. The bulk of the product is exported from Finland either unprocessed or as a further processed solution for the leather and textile, chemical, pharmaceutical, and feed industries in about 60 countries. The salts of formic acid, formates, are used in several applications, for example, as de-icers at airports and as oil drilling fluids.

Vaahto Group to rebuild Södra Cell Mönsterås Pulp Drying Machine

Vaahto Pulp & Paper Machinery has received an important order from Sörda Cell Mönsterås mill in Sweden. The pulp dryer TM5 of the chemical pulp mill will be revamped for higher production output and better runability. The machine produces both softwood pulp and hardwood pulp.

Vaahto Pulp & Paper Machinery has received an important order from Sörda Cell Mönsterås mill in Sweden. The pulp dryer TM5 of the chemical pulp mill will be revamped for higher production output and better runability. The machine produces both softwood pulp and hardwood pulp.

Vaahto´s supplies include water removal elements, steam-box, lead rolls and suction roll technology as well a major extension of the vacuum systems of the line. Installation, start-up and training services are essential parts of the delivery.

The wire width of the machine is 4650 mm and design speed 250 m/min. The maximum daily output of the dryer can reach 950 tons.

Equipment will be manufactured in Vaahto´s workshops in Hollola and Tampere in Finland. The start-up is scheduled for October 2012. The value of this kind of order amounts usually between 5 and 7 million euros.

Vaahto Pulp & Paper Machinery is part of Vaahto Group, which is a globally operating high technology company serving process industry in the fields of pulp and paper machinery and process machinery.

Xerium Technologies Unveils Advanced Rolls Product Technology

Xerium Technologies, Inc., a leading global manufacturer of industrial textiles and rolls used primarily in the paper production process, today announced full commercial availability of a technologically advanced new series of roll cover products designed for improved machine performance, better wear and longer, more efficient product life. The latest range of roll cover products are designed to reduce operational costs and maximize the output of existing equipment, while enhancing product customization capabilities for each individual customer. Roll covers, which are used to coat the large machine cylinders that transport raw paper along the lengthy belts while the paper is formed, pressed, and dried, are critical to the quality of paper as it is produced.

"We continue to work very closely with our customers to advance the technology of paper manufacturing by enabling greater efficiency, leaner inventories, and lower costs," said Stephen R. Light, President, Chief Executive Officer and Chairman. "The high-ROI class of products that we're developing is in direct response to manufacturers' demands for higher quality at lower costs."

Developed by Stowe Woodward's global research and product engineering team, the latest family of roll cover products from Xerium include:

Hypercoat and Multicoat HCX - Coater Backing Roll Technology

Hypercoat and Multicoat HCX covers are high strength, extremely tough rubber materials ideal for the most demanding coating applications. Their superior mark resistance and smooth uniform surface finish enable a high quality, uniform coating application. With increased wear resistance and higher material strength, Hypercoat and Multicoat HCX covers improve reliability and extend operating life.

Multicoat HCX improves machine reliability and coater backing roll cover performance. Its improved mark resistance and outstanding tolerance to impacts and wraps help maintain high coater efficiency and coating quality. In addition to minimizing scoring and edge wear, its outstanding abrasion resistance enables Multicoat HCX to maintain profile longer than standard covers and to deliver extended run times.

Hypercoat delivers superior overall performance, combining outstanding mark, dent and scoring resistance with superior wear resistance. Hypercoat has already set multiple operating records and has reset the bar defining maximum performance. Hypercoat's superior properties allow deckling, and minor coating build-up can be sanded off by hand with minimal effect on profile. When maximum run time is required, Hypercoat delivers.

Aquarius Armor

Aquarius Armor roll covers deliver long, constant, superior performance in the super-soft cylinder couch, extractor couch, and lumpbreaker applications.

With Aquarius Armor, machine superintendents will now have a consistent nip pressure and performance throughout the life of the cover. The durable polyurethane shell of Aquarius Armor does not experience the wear seen by other soft polyurethane or rubber materials. Chemical attack is greatly minimized to prevent significant changes in hardness and nip pressure. CD uniformity is greatly improved due to the excellent abrasion resistance.

Aquarius Armor is engineered to stay in the machine for an extremely long time at a constant diameter and constant hardness, giving the operator the most reliable and predictable machine operation.

SOURCE: Xerium Technologies, Inc.

FM Global Announces New Policy Enhancements to Meet Clients’ Evolving Needs

Just when insurers may be scrambling for ways to restrict coverage and reduce capacity to stave off the fallout from the next major disaster, FM Global, one of the world’s largest commercial property insurers, today announced that a new and improved FM Global Advantage® policy is now available to clients at renewal. Policy enhancements include the addition of four new coverages (Accidental Interruption of Services, Attraction Property, Crisis Management, and Machinery or Equipment Startup Option) and one dozen expansions to existing coverage to keep pace with clients’ exposure to emerging property risks. Additionally, the policy’s terms and conditions have been simplified to make it easier to read and understand.

“As the world becomes an increasingly risky place, it’s important that companies protect themselves with a comprehensive insurance policy that keeps pace with the evolution of that risk,” said Carol Barton, senior vice president, underwriting and reinsurance, FM Global. “As we continue to serve our mutual policyholders’ best interests, we’re committed to providing them the broadest coverage in the marketplace, backed by stable capacity and with the highest level of contract certainty.”