Ian Melin-Jones

Sonoco's Hartselle, Alabama, Reel Operations Undamaged by Violent Weather

Sonoco (NYSE: SON), one of the largest diversified global packaging companies, announced today that neither its Hartselle steel reels plant or nailwood/plywood reel producing plant received any damage as a result of last week's violent weather in Alabama. Although the Hartselle area remains impacted by storm-related power outages, both plants are currently operating using power produced by backup generators.

"Fortunately, none of our associates in Hartselle were physically injured by the dangerous storms," said James Harrell, vice president, Industrial Carriers, N.A. "Both plants suffered temporary disruptions in service due to the power outages, so our Jefferson, Texas, Sonoco Reels plant operated throughout the weekend to handle any unexpected customer emergencies.

"Both our steel reels plant and the nailwood/plywood reels plant were switched to back-up generators over the weekend and are currently operating," added Harrell. "Because it's unclear how long both facilities will be on temporary power, we are asking our customers to work closely with their normal customer service contacts to distinguish between forecast and more immediate demand requirements."

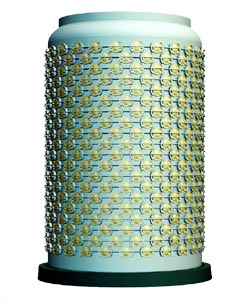

Sonoco Reels is the most comprehensive provider of reels produced from nailed wood, plywood, poly-fibers, molded plastic and steel materials. Reels produced by Sonoco are used by the wire and cable industry to serve the power transmission and distribution; telecommunications; commercial and industrial building; oil and gas; mining and marine industries.

USW and International Paper Ratify New Contract

The United Steelworkers (USW) and International Paper announced today that they have ratified a four-year Master Agreement contract that covers some 6,000 workers.

"The USW is extremely proud of the progress made by our members in the paper sector," said USW International President Leo W. Gerard. "Strong leadership and solidarity at each of the locations was vital to reaching this agreement at IP. The success of our local unions here sets a precedent for bargaining in rest of the industry."

"We are pleased that we have reached an agreement that accomplishes International Paper's bargaining objectives and continues to reinforce and build on the positive working relationship we have established over the past several years," said Paul Karre, Senior Vice President, Human Resources and Communications, International Paper.

The new contract includes wage increases in each year of the agreement, improvements to the pension and 401(k), cost stabilization for health care costs and employment security.

USW members covered by this contact include those represented by local unions in Augusta, Ga.; Campti, La.; Pensacola, Fla.; Courtland, Ala.; Georgetown, S.C.; Pine Hill, Ala.; Port Hueneme, Calif.; Prattville, Ala; Riegelwood, N.C.; Savannah, Ga.; Selma, Ala.; Texarkana, Texas; Ticonderoga, N.Y.; Valliant, Okla.; and, Vicksburg Miss. The USW represents 850,000 workers in the U.S. and Canada employed in the industries of metals, rubber, chemicals, paper, oil refining and the service sector. Some 100,000 are employed in the paper and pulp sector. For more information: www.usw.org/.

International Paper (NYSE: IP) is a global paper and packaging company with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include uncoated papers and industrial and consumer packaging, complemented by xpedx, the company's North American distribution company. Headquartered in Memphis, Tenn., the company employs about 59,500 people in more than 24 countries and serves customers worldwide. 2010 net sales were more than $25 billion. For more information about International Paper, its products and stewardship efforts, visit www.internationalpaper.com.

SOURCE International Paper; United Steelworkers

Stora Enso Fine Paper plans to increase competitiveness by restructuring operations

Stora Enso’s Fine Paper Business Area is re-evaluating its working methods and building a new business model to increase cost competitiveness. According to the plans, Stora Enso would restructure operations at Nymölla Mill in Sweden. At Uetersen Mill in Germany the plan is to restructure operations more towards Speciality Papers and at Oulu Mill in Finland, together with the sheeting plants in Belgium and the United Kingdom, find the most efficient way to utilise the converting capacity and streamline operations.

Stora Enso’s Fine Paper Business Area is re-evaluating its working methods and building a new business model to increase cost competitiveness. According to the plans, Stora Enso would restructure operations at Nymölla Mill in Sweden. At Uetersen Mill in Germany the plan is to restructure operations more towards Speciality Papers and at Oulu Mill in Finland, together with the sheeting plants in Belgium and the United Kingdom, find the most efficient way to utilise the converting capacity and streamline operations.

“The plans announced today would make Stora Enso Fine Paper more flexible and cost efficient, and so better able to meet customer and market expectations. Fine paper demand is still clearly below pre-crisis levels, and there are no signs of sustained recovery. We have been successfully remodelling our operations during the past few years, and now we plan to continue on the chosen path of improving our existing businesses. We are comparing the best practices at all our mills so we can continuously adopt the most efficient ways of working. Similarly, we need to question our way of running the operations. These plans are part of rethinking in Stora Enso, but of course rethink means much more for us, such as new products and services, new solutions with our customers – better solutions for the future,” says Hannu Alalauri, EVP, Fine Paper Business Area.

Stora Enso Fine Paper plans to reduce annual costs by approximately EUR 20 million, starting during 2011 with all actions to be completed by the end of the second quarter of 2012. The proposed restructuring measures would affect altogether up to 285 employees in Finland, Sweden, Germany, Belgium and the United Kingdom. Stora Enso will record a cash provision of approximately EUR 16 million as a non-recurring item in its second quarter of 2011 operating profit. The plans would not affect the Business Area’s paper production capacities.

The outcome of the plans will depend on the result of the local co-determination procedures. As before, Stora Enso would make every effort in co-operation with local communities to help the affected personnel find new employment opportunities, and all job openings in other Stora Enso units would be available to those affected.

AkzoNobel announces intention to restructure and split ICI Pakistan

Akzo Nobel N.V. (“AkzoNobel”) has today announced its intention to seek agreement from the Board and shareholders of ICI Pakistan Limited (“ICI Pakistan”) to separate the organization’s paints and chemicals businesses.

Under the terms of the proposal, AkzoNobel would retain direct majority control of the paints business by separating it into a new legal entity (AkzoNobel Pakistan Limited) through a de-merger process approved by the Pakistani courts. Subsequently, AkzoNobel would dispose of its entire shareholding in the remainder of ICI Pakistan.

The entire ICI Pakistan business has been a subsidiary of AkzoNobel since 2008, when the company acquired Imperial Chemical Industries PLC. It is listed on the Karachi, Lahore and Islamabad Stock Exchanges, with AkzoNobel currently holding 75.8 percent of the total shares. Focusing primarily on the Pakistan market, ICI Pakistan’s main businesses are polyester fiber, soda ash, life sciences, chemicals and decorative paints. In 2010, ICI Pakistan’s revenue amounted to €305 million.

During the last few months, AkzoNobel has been conducting a strategic review of the businesses and it became evident that ICI Pakistan’s paints business would be of clear commercial benefit for the company. Although the remainder of the ICI Pakistan portfolio is made up of strong and promising businesses, they do not offer sufficient opportunity to create value within AkzoNobel’s transformed portfolio and future strategic ambitions.

AkzoNobel believes that in order to provide the best growth opportunities for the activities carried out by ICI Pakistan (apart from paints), it would be most beneficial for all concerned if the company was transferred to a new owner who could commit to investing and help to realize its full potential. Accordingly, AkzoNobel’s intention would be to seek a new owner for its shareholding in ICI Pakistan through a formal sale process once the paints business is separated.

The procedure for achieving this strategic change would involve a two-stage process. Initially, two companies would be created through a de-merger process approved by the shareholders of ICI Pakistan and sanctioned by the Pakistani courts. Both would be listed and AkzoNobel would own 75.8 percent of each. The business, assets and liabilities of the paint business would be called AkzoNobel Pakistan Limited. ICI Pakistan would comprise all of the remaining businesses, assets and liabilities.

Once the de-merger is completed, AkzoNobel would undertake the formal process of identifying an appropriate buyer for its shareholding in ICI Pakistan.

ANDRITZ to supply two new pressurized refining systems to MDF producers in Asia

International technology Group ANDRITZ received two orders to supply new pressurized refining systems for leading MDF producers in South Korea and China, once again confirming its strong market position in this product segment in Asia.

ANDRITZ will supply a 54” 1CP pressurized refining system (capacity: 480 t/d) to Dongwha Enterprise Co., Ltd. in Asan, South Korea. Start-up of this seventh ANDRITZ pressurized refining system in South Korea is scheduled for the second quarter of 2012. Dongwha Enterprise is South Korea’s leading MDF producer.

Hebei Kaiyue Group, China, ordered its fourth ANDRITZ fiber preparation system in the past seven months: a pressurized refining system (with a 60” 1CP refiner and a capacity of 600 t/d) will be delivered to Hebei Kaiyue Wen An County Tianhua Density Board Co., Ltd., Hebei Province. Start-up is scheduled for the second quarter of 2012.

SCA is investing in expanded capacity for tissue and solid wood products

SCA is investing in expanded tissue capacity in Russia and Germany, and in solid-wood products in Sweden. The investments will total approximately SEK 2.6bn (approx. EUR 290m).

There is favourable growth in the Russian tissue market and SCA is the leading player, with such strong brands as Tork and Zewa. To further reinforce and strengthen the market position, a decision has been made to invest approximately SEK 1.2bn (approx. EUR 130m) in a second tissue machine in Sovetsk, Russia. The new tissue machine has a capacity of 60,000 tons annually and production is based on virgin fibre. Production is scheduled to commence in 2013.

SCA is also investing approximately SEK 1.1bn (approx. EUR 120m) in a new tissue machine in Kostheim, Germany. This investment is being made to meet increased demand, primarily for AFH tissue products. The new tissue machine will have a capacity of 60,000 tons annually and production is scheduled to commence in 2013.

To increase production capacity and reduce costs, a decision has been made to invest approximately SEK 300m (approx. EUR 30m) in the Bollsta sawmill, Sweden. The investment comprises two new biofuel boilers, increased drying capacity and an upgrade of the saw line. Through these investments, production capacity will increase from 450,000 cubic metres to 525,000 cubic metres of sawn pine products per year. The investment enables energy production exclusively from the company’s own biofuel, meaning that a large amount of oil can be phased out of production. The biofuel boiler is scheduled for commissioning at the end of 2012, while other parts will be successively commissioned during 2012 and 2013.

“Through these investments, we will enhance our capacity, efficiency and profitability in markets that are important to us,” says SCA President Jan Johansson.

CMPC Tissue S.A. signed a major service contract with PMT

Pinerolo, May 2nd, 2011, during Tissue World in Nice, CMPC Tissue S.A. signed a major service contract with PMT Italia S.p.A. for improving the energy efficiency and performance of nearly all of their Latin American Tissue Machines.

In short, PMT Industries (a subsidiary of PMT Italia S.p.A.) will retrofit at least ten (10) Yankees of varying sizes in CMPC’s tissue mills in Argentina, Chile, Uruguay, Colombia, Mexico and Brazil with new head insulation in order to optimise the drying and energy efficiency throughout their tissue production organization.

With this order, PMT solidifies its status as the premier supplier of Yankee technology worldwide – for retrofit, service as well as new Yankees. The development was driven by the rapidly increasing price of energy supplies as well as environmental and safety concerns. Addressing all those needs was accomplished by focusing the attention on the need for greater efficiency by reducing energy consumption, but without detriment to output.

CMPC will in the future benefit from a design which was developed to ensure that the increase in efficiency does not come at the expense of the machine operation, and the smooth external finish helps with cleanliness on the dryer end, and improves safety in the event that water sprays onto the end face of the Yankee. By retrofitting these Yankees, CMPC is improving their production cost structure, while at the same time further focusing on the environment by ensuring a more efficient and energy saving production process throughout their whole tissue production organization.

The total cost of the project cannot be disclosed, but it is expected that payback is in less than a year for each Yankee retrofit.

Noss : Dissolving Pulp System to Zhanjiang Chenming Pulp and Paper, China

Noss will supply an approach system to Zhanjiang Chenming Pulp and Paper Co., Ltd. for its dissolving pulp production in Zhanjiang City, Guangdong Province, China. The start-up after the re-build is estimated in January, 2012.

The original fiber line will be started up in May, 2011 and will produce standard bleached chemical market pulp. After rebuilding the fiber line will also be able to produce 1850 ADMTPD bleached chemical dissolving pulp.

The Noss delivery will include a RADISCREEN coarse screening system, a 6-stage RADICLONE AM80 forward cleaner system and a RADICLONE BM80 reverse cleaner system.

HIGHEST PULP CLEANLINESS

There are very strict requirements on dissolving pulp cleanliness. The highly efficient Noss RADICLONE systems are particularly suitable for this application. The professional knowledge and long time experience have made Noss AB a leading company within the high-end market with highest demands on pulp cleanliness.

SPCI Stockholm 2011 - News

Seminar on the Russian pulp and paper industry trends Focus on Russia: Innovation way

Within SPCI 2011

MAY 18, 2011 · 13.30–16.00 · Room: to be confirmed

Stockholm International Fairs

Moderated by Eduard L. Akim, Professor, member of the Advisory committee on paper and wood products of FAO UN

Speakers:

Eduard Akim

Professor, member of the Advisory committee on paper and wood products of FAO UN «Forest technology platform as a way to innovation development of the Russian pulp and paper industry»

Natalia Lukina

Russian Forest Technology Platform Director «Ways of interaction between Russian and European Forest Technology platforms»

Sergey Pondar

Managing Director of Technology and Manufacturing Services 97 Ilim Group «Ilim Group: Development, investments and innovations»

Sergey Malkov D.Sc.(Tech)

Director on Technical Development Investlesprom company «Innovation way of the Russian pulp and paper industry development as a key for competitive advantages. Investlesprom company experience»

Andrey Malkov

Technical Director KWI International Company «Innovative technology of optimize water recycling of companies in the pulp and paper industry of the Russian Federation. Experience of KWI»

Buckeye Evaluates Expanding High-Purity Specialty Wood Pulp Capacity

Growing customer demand exceeds supply

Focus on technically demanding high-end niches

Returns above cost of capital

Buckeye Technologies Inc. announced that its Board of Directors has approved funding for a comprehensive evaluation of our Florida mill's potential to further increase its high-purity specialty wood pulp capacity. Buckeye's high-end specialty wood pulp grades include ethers, high strength viscose, filtration and acetate, which are used in the production of food and pharmaceutical products, food casings, tire cord, filtration media and acetate tow. The global demand for these products is growing and Buckeye has a proven history of producing these technically demanding grades. Buckeye's specialty wood pulp production continues to be sold out and this potential expansion would help meet growing customer demand in these high-end applications.

Buckeye's Chairman and Chief Executive Officer John Crowe said, "Currently the lead option in this evaluation is to increase our Florida mill's high-end specialty capacity by 30,000 metric tons with a target startup date at the end of 2012. The overall capacity of the mill would remain at its current 465,000 ton per year level, but the mix of high-end specialty production would increase. In addition to the mix improvements, we plan to further enhance the performance attributes of the fluff pulp produced at our mill. We expect this project would generate returns significantly above our cost of capital. We believe this option could provide excellent value to our customers and our shareholders. We intend to complete our evaluation and make a final decision on the potential expansion in August 2011."

SOURCE: Buckeye Technologies Inc.