Displaying items by tag: metso

Metso-supplied Zhanjiang Chenming PM 1 sets another world speed record for woodfree uncoated paper

On November 16, 2012, the Metso-supplied PM 1 fine paper machine at Zhanjiang Chenming Pulp & Paper Co., Ltd. in Zhanjiang City in China set a woodfree uncoated machine 24-hour world speed record of 1,808 m/min. During the record run, the 11.15-m-wide PM 1 produced woodfree uncoated printing paper at a basis weight of 70 g/m2.

Zhanjiang Chenming PM 1 also held the previous world speed record for woodfree uncoated paper. The PM 1 was started up on September 1, 2011.

The PM 1 features Metso’s paper making and automation technology from headbox to reel, air and chemical systems and two WinDrum Pro winders. The annual dimensional production capacity of PM 1 is close to 600,000 tonnes of woodfree uncoated printing paper.

Zhanjiang Chenming is part of Shandong Chenming Paper Holdings Limited, one of the biggest paper producers in China. In 2011, the company’s paper production capacity was over 4 million tonnes, turnover over EUR 2 billion and the number of employees approx. 17,000.

First Metso Advantage NTT tissue line to be started up at Fabrica De Papel San Francisco in Mexico

The Mexican tissue producer Fabrica De Papel San Francisco is preparing to start up their third Metso tissue production line. It will be the world’s first tissue line based on the Advantage NTT concept, which enables high bulk and softness properties at the same time as it provides energy savings compared to conventional or structured tissue grades.

“After operating two Metso Advantage DCT tissue machines with good experience, we are now prepared to take the next step for quality to produce tissue products with higher bulk and softness, aiming towards the top end products. The Advantage NTT concept will also bring us a higher production capacity compared to the dry crepe tissue concept,” says Dario Palma y Meza Espinoza, Director of Operations, Fabrica De Papel San Francisco.

“We have a very long and fruitful relation with Fabrica De Papel San Francisco and we are of course very excited to supply the first Advantage NTT technology and support their ambition to supply high-quality products produced with less energy and fiber. Fabrica De Papel San Francisco has a very strong and knowledgeable team,” says Jan Erikson, Vice President, Sales, Metso.

The project is proceeding according to plan and the new tissue production line will start up in Mexicali, Mexico, in the end of the second quarter of 2013.

Metso’s scope of supply comprises a complete 2.6-m-wide Advantage NTT tissue machine equipped with an OptiFlo II TIS headbox, a Metso Yankee cylinder, an Advantage AirCap yankee hood, sheet control, tail threading equipment, an Advantage WetDust dust management system and an Advantage SoftReel reel.

The new tissue line will add another 30,000 tonnes per year of bathroom tissue, napkin and towel grades to Fabrica De Papel San Francisco’s existing production.

Fabrica De Papel San Francisco already operates two Advantage tissue machines at their Mexicali facility, one of which started up in 2006 and the other in 2009. The company’s PM 4 set a then world speed record of 2,160 m/min in 2009 and their PM 5 achieved a record-breaking rapid start-up in 2009, reaching a production speed of 2,100 m/min only 12 days after start-up.

Fabrica De Papel San Francisco now operates four tissue production lines and converting facilities, delivering tissue products for the Mexican and US market.

Metso to divest Metso Husum AB to Pichano Holding AB

Metso has divested all its shares of Metso Husum AB to Pichano Holding AB, as a result of a restructing plan of its service workshop network in Sweden. The business was transferred on January 1, 2013. The value of the agreement will not be disclosed.

Metso has divested all its shares of Metso Husum AB to Pichano Holding AB, as a result of a restructing plan of its service workshop network in Sweden. The business was transferred on January 1, 2013. The value of the agreement will not be disclosed.

Metso Husum AB is specialized in repair and maintenance work to the pulp and paper industry as well as to the construction industry. They provide services at the customer site as well as manufacture in their own workshop. The company has a turnover of 1.5 MEUR and 12 employees. All employees will remain with the company. The company is located close to Örnsköldsvik, Sweden.

”We will integrate the Husum company into Pichano without major changes, and then continue to develop the business in the areas we focus on; i.e. bioenergy, hydroelectric power, wind power, and steel work within the construction industry”, says Kent Modin, VD, Pichano Holding AB.

The Pichano group is a full service company serving customers within the construction, transport and maintenance area. The turnover in the group is 21 MEUR and they have 150 employees.

Metso strengthens its plant optimization services by acquiring U.S. software company ExperTune Inc.

Metso has acquired U.S. software company ExperTune Inc. ExperTune's products are widely used as software tools to analyze and monitor the performance of industrial processes and to identify the associated maintenance and improvement opportunities.

Metso has acquired U.S. software company ExperTune Inc. ExperTune's products are widely used as software tools to analyze and monitor the performance of industrial processes and to identify the associated maintenance and improvement opportunities.

ExperTune's acquisition is in line with Metso's strategy to deliver customer value solutions and grow the scope of the services business globally. The acquisition expands and strengthens Metso's ability to globally provide business-enhancing services to customers. ExperTune's products will be sold as stand-alone solutions that can be used in any automation system environment and as part of Metso's performance business solutions, targeted to optimize plant performance.

''The combination of ExperTune's products and Metso's services portfolio extends our capability to offer solutions targeted to improving process and business performance,'' says Mikko Keto, President, Services, Metso Automation.

''With ExperTune we can provide more versatile and more cost effective customer value solutions to our customers so that they can meet their most pressing business challenges, such as reducing raw material consumption, energy usage, product variability and environmental impact. ExperTune's products help our customers to find areas of improvement in their processes to which Metso has customer value solutions,'' Keto summarizes.

Metso's services business has developed strongly over the last decade. In 2011, the services share of the company's turnover was 45 per cent. ExperTune will be integrated into Metso's Automation segment's Services business.

ExperTune Inc.

Founded in 1986, ExperTune designs pre-packaged industrial software which help maximizing productivity and efficiency and reduces waste in the process industries worldwide. Its net sales are less than MEUR 10. ExperTune is headquartered in the United States in Milwaukee, Wisconsin. It has an extensive sales representative network on all continents. ExperTune's products include PlantTriage, ProcessApex and PID Loop Optimizer.

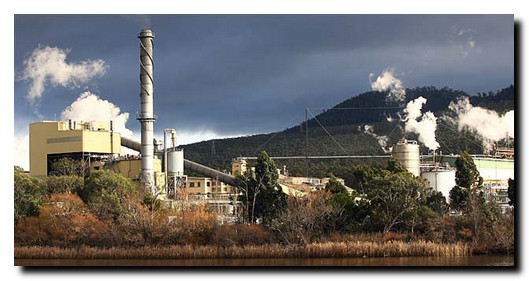

Metso to supply grade conversion rebuild from newsprint to lightweight coated grades for Norske Skog in Australia

Metso will supply Norske Skog with a grade conversion rebuild from newsprint to lightweight coated (LWC) grades of their PM 2 machine at their Boyer mill in Tasmania, Australia. The rebuilt production line will be fully operational after several phases of rebuild during the first quarter of 2014. The value of the order will not be disclosed.

The main target of the rebuild is to convert the newsprint machine into a competitive lightweight coated paper (LWC) production line. The delivery also includes a cooperation agreement aimed at achieving key objectives of the conversion.

Technical information

The future capacity of the PM 2 machine after the rebuild will be 140,000 tonnes per year of lightweight coated grades.

Metso’s delivery will include a rebuild of the existing machine calender and a new ValSizer sizing section, a coating preparation and supply system, a TurnDry Compact air dryer, an OptiLoad calender, a ValReel reeler, a WinBelt C winder and parent roll handling equipment.

The order is included in Metso’s Pulp, Paper and Power fourth quarter 2012 orders received.

Norske Skog has 11 wholly and partly-owned mills in 9 countries and is one of the world’s largest producers of publication papers like newspapers, magazines and periodicals as well as grades for advertising purposes. Norske Skog is listed on the Oslo Stock Exchange and had 5,100 employees at year-end 2011.

Metso supplies the Best Bioenergy Project of the Year

The Nacogdoches Generating Facility in Sacul, Texas was awarded the 2012 Project of the Year in the Biomass category by Power Engineering Magazine at the Power-Gen international conference on December 10,2012 in Orlando, FL.

The Nacogdoches Generating Facility in Sacul, Texas was awarded the 2012 Project of the Year in the Biomass category by Power Engineering Magazine at the Power-Gen international conference on December 10,2012 in Orlando, FL.

The Nacogdoches Project represents a Metso-supplied boiler island with the world's largest BFB Boiler. The project also included Metso Automation Flow Control Devices and a Metso DNA plant-wide distributed control system.

The boiler features efficient energy conversion of a wide range of biomass. Thanks to the advanced technology of the boiler island the Nacogdoches Generating Facility is prepared to deliver electricity whenever needed.

Dave King, Area President, North America, Power business line, Metso, explains that "the Nacogdoches project is a success since it plays a key role in preparing the City of Austin to meet its goals for sustainable power generation. Furthermore, this project would never have been possible if not for the excellent track record of Metso's existing global BFB base, and the ability to design a utility-grade biomass boiler capable of low emissions and high availability.

Tight with fuel consumption, generous with energy

This boiler is the largest HYBEX boiler in service, designed to produce 930,000 lbs/hr (117 kg/s) of steam and generate 100 megawatts of renewable electrical power. The entire boiler island, including air pollution control equipment and the plant-wide controls, was provided and erected by Metso under an EPC contract.

Clean and environmentally responsible power

The 100 MW capacity of the largest BFB biomass power plant in the United States can generate enough power to supply approximately 60,000 homes with electricity. The plant was built to serve a 20-year contract with Austin Energy to help meet the state's renewable portfolio standard, with the output serving the City of Austin.

The plant is fuelled entirely by non-merchantable wood biomass materials, with a base load renewable energy option that helps strengthen the nation's energy security. Abundant fuel supply in the proximity of the plant enables wood waste recycling from the local timber operations, manufacturing facilities, and municipalities. All of the fuel needed can be procured within a 75-mile radius.

During construction, extreme drought put the water supply for the facility, the Angelina River, in jeopardy - the river became completely dry and was deemed unreliable to supply the facility. Developers constructed a 10-mile water line to a nearby lake that now provides ample water to supply plant operations.

Nacogdoches has made a significant impact in the surrounding towns. During construction, more than 100 vendor contracts for services and maintenance were established, as well as 25 fuel supply contracts. The facility allowed for more than 1,000 construction jobs, which was a boost for the local economy in the 200-resident town of Sacul. The facility is also set to employ 40 full-time workers.

Each year, projects from around the world are honoured during POWER-GEN International's Projects of the Year awards gala, with many different award categories. Nacogdoches Generating Facility won the best biomass project of the year, and chosen as runner-up project was an anaerobic digester facility at the Nocton Fen Farm in the UK, developed by Cummins Power Generation.

Metso-supplied evaporation plant and recovery boiler started up at Eldorado’s Três Lagoas site in Brazil

The evaporation plant, with a capacity of 1,600 tonnes/hour evaporated water, is the largest single line evaporation plant in the world with the purpose of concentrating black liquor up to 80% dry solids content for efficient and low-emission combustion in the recovery boiler.

The recovery boiler is also among the largest in the world in operation and has a 6,800 tonnes of dry solids/day black liquor burning capacity and steam generation of 1,109 tonnes of steam/hour. The steam will be used in the pulp manufacturing process and in power generation to supply the entire mill and produce a significant amount of power surplus. Additionally, the recovery boiler has high chemical recovery efficiency making the mill economically and environmentally sustainable.

Celso Tacla, Area President, South America, Metso’s Pulp, Paper and Power segment, explains that “the Eldorado project is a success since it overcomes major challenges, such as the large-size equipment that came from different parts of the world, requiring extremely well executed logistics.”

Eldorado Celulose e Papel is a Brazilian company operating the world’s largest single-line pulp mill with a capacity to produce 1.5 million tonnes a year of bleached eucalyptus pulp. The company, controlled by J&F Holding, has plans to build three parallel pulp lines by year 2020. These lines would produce a total of 5 million tonnes per year.

Metso-supplied boardmaking line starts up at Liansheng Paper Industry in China

On October 28, 2012, Liansheng Paper Industry (Longhai) Co., Ltd started up their new Metso-supplied containerboard production line, PM 5, at their Longhai site in Fujian province in China.

On October 28, 2012, Liansheng Paper Industry (Longhai) Co., Ltd started up their new Metso-supplied containerboard production line, PM 5, at their Longhai site in Fujian province in China.

"The PM 5 start-up was successful with a stable operating process. The desired targets were achieved. I hope that we can continue a very good cooperation with Metso also in the future,” says Rongjun Xue, Project Manager of Liansheng Paper.

The new 7.25-m-wide PM 5 has an annual production capacity of approximately 350,000 tonnes of recycled testliner in the basis weight range of 100 to 140 g/m2. The design speed is 1,200 m/min.

Metso’s delivery included a complete boardmaking line from headbox to reel with air systems, a size supply system, a quality control system and a winder.

The PM 5 testliner production line features a novel two-layer forming process with only one hybrid forming unit equipped with the new OptiFlo layering headbox. With this innovative technology a two-layer web can be produced with only one headbox providing excellent profiles due to a unique dilution system and good formation due to new type of hydraulics.

Liansheng Paper Industry (Longhai) Co., Ltd. is a subsidiary of Fujian Liansheng Paper Co., Ltd. The company was founded in 1999 and is based in Zhangzhou, China. A third Metso-supplied production line for Fujian Liansheng, PM 6, is to start up at the Longhai site in December this year. The PM 6 boardmaking line will produce recycled fluting grades and it has the same width and design speed as the PM 5.

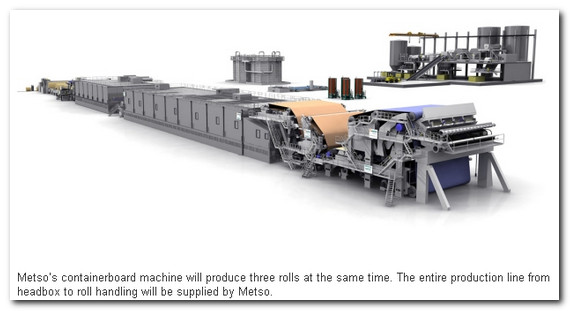

Metso to provide multi-year mill maintenance to Greenpac Mill in the USA

Metso and Norampac have reached an agreement in principle for Metso to supply the mill maintenance services for Greenpac Mill in Niagara Falls, NY, in the United States. With this mill maintenance agreement Metso will establish and manage all maintenance systems and procedures at the mill. The value of the agreement will not be disclosed.

The new linerboard machine at the Greenpac Mill will be supplied by Metso; the order was announced in 2011. The machine is scheduled to start up in the third quarter of 2013. The agreement includes recruitment of all maintenance personnel prior to start-up. Upon start-up, Metso will assume full responsibility of the mill maintenance operations for the entire production facilities at the Greenpac Mill.

“We are pleased to collaborate with Metso in creating a unique world-class operation at our Greenpac site. The outsourcing of maintenance is a first of its kind for Norampac and its partners in North America – after visiting a similar world-class site in Europe we were convinced of the benefits, performance and customer satisfaction of Metso maintenance operations, which will further contribute to the project’s success,” commented Marc-André Dépin, President and Chief Executive Officer of Norampac.

The Metso mill maintenance model optimizes the use of Total Productive Maintenance (TPM), Metso's streamlined reliability centered maintenance (Applied RCM) and condition-based maintenance. The model ensures the highest possible equipment efficiency and cost optimization.

Greenpac Mill LLC is a partnership controlled by Cascades and managed by Norampac. Created in 1997, Norampac, a Division of Cascades Canada ULC, is the largest containerboard producer in Canada and the 6th largest in North America, with 4,239 employees. Today, Norampac operates several containerboard and boxboard mills, corrugated product plants, folding carton plants and a graphic center in Canada and the United States.

Metso-supplied cartonboard line starts up at Shandong IP & Sun Food Packaging in China

The Metso-supplied complete cartonboard production line, PM 26, for Shandong IP & Sun Food Packaging Co. Ltd., successfully came on stream on September 19, 2012 in Yanzhou City, Shandong Province in China. The grade produced during the start-up was base paper for 300-g/m2 folding boxboard. Coated A grade was achieved in less than a week’s time from the start-up. In three weeks’ time from the start-up the machine exceeded the dimensioning capacity over a period of 24 h. In five weeks, another milestone, speed over design speed for 24 h, was reached.

The new 6.85-m-wide (wire) PM 26 has an annual production capacity of approximately 550,000 tonnes of folding boxboard and art board grades in the basis weight range of 170 to 350 g/m2. The design speed is 950 m/min.

Metso’s delivery included a complete coated board making line from three headboxes to reel with stock preparation and approach flow systems, air systems, a coating color preparation system and two winders. A comprehensive Metso automation package comprised process, machine and quality controls.

Shandong IP & Sun Food Packaging Co. Ltd. is part of a joint venture established by International Paper and Sun Paper Group in 2006. The joint venture includes International Paper & Sun Cartonboard Co., Ltd., Shandong International Paper & Sun Coated Paperboard Co., Ltd., Shandong IP & Sun Packaging Co., Ltd. and International Paper & Sun (Hong Kong) Trading Lirnited. Today the company operates a total of four paper machines supplied by Metso (PM 17, PM 18, PM 22, PM 26). Net sales in 2011 were about EUR 650 million.