Ianadmin

Pöyry awarded detailed engineering assignment for Kruger's paper machine rebuild project in Quebec

Kruger Trois-Rivières L.P. has awarded Pöyry (Montreal) Inc. detailed engineering services assignment for the rebuild of the Trois-Rivières No. 10 newsprint machine into a state-of-the-art lightweight and high-strength recycled linerboard production facility. The assignment covers the recycled old corrugated container plant (OCC), paper machine inter-connections, balance-of-plant, upgrade engineering to the mill control systems, extensive migration engineering of the existing control system, and engineering for dismantling of replaced systems.

Kruger Trois-Rivières L.P. has awarded Pöyry (Montreal) Inc. detailed engineering services assignment for the rebuild of the Trois-Rivières No. 10 newsprint machine into a state-of-the-art lightweight and high-strength recycled linerboard production facility. The assignment covers the recycled old corrugated container plant (OCC), paper machine inter-connections, balance-of-plant, upgrade engineering to the mill control systems, extensive migration engineering of the existing control system, and engineering for dismantling of replaced systems.

Kruger is a leading paper producer in North America. The Trois-Rivières project is one of their most important capital expenditures in recent years. The modernisation project includes the installation of a modern OCC production facility and a comprehensive rebuild of the existing PM 10 newsprint machine to a high-quality and high-performance lightweight linerboard machine. Pöyry's assignment includes services for the installation of a new starch system, chemical systems, heat recovery and modifications to the existing stock approach system.

During the 20-month conversion project, the existing newsprint machine will be extensively modernised to incorporate advanced containerboard manufacturing technology. The new production line will produce 360,000 metric tons per year of lightweight and high-strength linerboard using 100% recycled corrugated containerbaord as raw material.

"Thanks to Pöyry's proven track record, we trust that this production line rebuild will be highly successful and that PM10 will rank among the very best lightweight and high-strength containerboard production lines in North America," says Christian Lemay, Project Manager at Kruger Trois-Rivières L.P.

"The assignment is an important continuation for this key client relationship, and previous studies carried out by Pöyry will be a significant reference strengthening Pöyry's strong position as a leading engineering consultant for pulp & paper industry in the North American market," says Vilho Salovaara, President of Pöyry's Regional Operations North America.

The value of the order is not disclosed. The order was recognised within the Regional Operations order stock in Q4/2015.

Additional information by:

Vilho Salovaara

President, Regional Operations North America

Tel: +1 514 341 3221

Robert Baril

Senior Project Manager

Tel.: +1 514 341 3221

Pöyry is an international consulting and engineering company. We serve clients globally across the energy and industrial sectors and provide local services in our core markets. We deliver management consulting and engineering services, underpinned by strong project implementation capability and expertise. Our focus sectors are power generation, transmission & distribution, forest industry, chemicals & biorefining, mining & metals, transportation and water. Pöyry has an extensive local office network employing about 6,000 experts. Pöyry's net sales in 2014 were EUR 571 million and the company's shares are quoted on Nasdaq Helsinki (Pöyry PLC: POY1V).

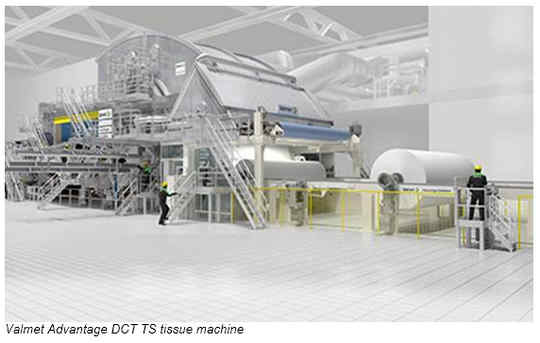

Valmet to supply fourth tissue production line to Fine Hygienic

Valmet has been awarded a repeat order of an Advantage DCT 200TS tissue production line to Fine Hygienic Holding (FHH), one of Nuqul Group's companies. The new line, including a complete delivery package from stock preparation equipment to rewinder, will be installed at FHH premises at Al Nakheel mill in Abu Dhabi and is planned to commence operation on the first quarter of 2017.

The order is included in Valmet's fourth quarter 2015 orders received. The value of the order is not disclosed.

The long partnership between FHH and Valmet goes back to 1988. Three Valmet tissue machines have already been installed at the FHH mills - Al Bardi Paper Mill and Al Sindian Paper Mill in Egypt and Al Snobar Paper Mill in Jordan.

"We at Fine Hygienic Holding, do not only look for technology when choosing our suppliers, but for forging strong long-term partnership that will enable us to grow together. Our long-term relationship with Valmet and their Advantage tissue technology convinced us that we will have the best conditions to meet the market's challenging requirements for high quality facial tissue produced with lowest possible energy consumption," says Hani Nuqul, the Chief Officer of Strategic Industries at FHH.

"We are proud to work in partnership with FHH and fulfill their demand of a complete package of tissue making equipment from stock preparation to rewinder. We are excited to be part of their expansion plans and together we will make this project a benchmark in the tissue market," says Jan Erikson, VP Tissue Sales at Valmet.

Technical information of the delivery

The new tissue machine will have a width of 5.6 meters and a design speed of 2,200 m/min. The new line will add 60,000 tons of high quality tissue per year to the company's current production of bath, facial, napkin and towel tissue for consumers in the Middle East.

Valmet's scope of delivery will comprise a complete tissue production line featuring stock preparation systems, an Advantage DCT 200TS tissue machine and a Focus Rewinder line. The tissue machine is equipped with an OptiFlo II TIS headbox and a cast alloy Yankee cylinder. It will also feature the well proven Advantage tissue technology including a ViscoNip press, and AirCap hood and a SoftReel reel. Services as installation advisory, training, start-up and commissioning are also included in the delivery.

Information about the customer Fine Hygienic Holding

Fine Hygienic Holding is a leading company in the hygiene industry and one of Nuqul Group's companies, founded in 1952 and has grown over the years to become a leading group embracing a number of ventures in the Middle East and North Africa. Fine Hygienic Holding is the sole company that uses SteriPro sterilizing technology, a unique sterilization process that eliminates germs. The company is keen on introducing high quality products in local and international markets.

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Metsä Board’s new folding boxboard production line has started up in Husum

Metsä Board, part of Metsä Group, has started up a new folding boxboard production line at its Husum mill in Sweden. The company is aiming the 400,000 t/a volume of the production line at the Americas, as well as at food service end-uses such as cups, plates and trays globally.

“Metsä Board is well known for its high-quality, lightweight folding boxboards, used widely in packaging globally. Thanks to the new production line and our recent product development, we are now able to respond to food service packaging requirements and demand better than ever before,” comments CEO Mika Joukio.

Several suppliers have brought their best expertise to the production line project from planning to start-up. During the actual installation phase of the folding boxboard machine, spanning from mid-October until January, over a thousand external workers were employed at Husum. After the start-up, the target is to assure smooth running and high product quality as soon as possible.

The folding boxboard machine BM1, supplied by Valmet, is the most significant part of the EUR 170 million investment programme carried out at Metsä Board’s Husum mill site. As part of the programme, enhancements have also been made at the pulp mill and the mill site’s own port. As a whole this investment programme completes the company’s transformation process to a pure paperboard company.

Last November, Metsä Board also announced it is investing an additional EUR 38 million in a new extrusion coating line and related infrastructure in Husum. This line will be taken into use at the beginning of 2017.

Metsä Board is a leading European producer of folding boxboards and white linerboards made from fresh forest fibres. Its lightweight paperboards are developed as the perfect fit for consumer goods, retail-ready and food service packaging. The pure fresh forest fibres Metsä Board uses are a renewable resource, traceable to origin in northern forests. The global sales network of Metsä Board supports customers worldwide, including brand owners, converters and merchants. In 2015, the company’s sales totalled EUR 2.0 billion, and it has approximately 2,600 employees. Metsä Board, part of Metsä Group, is listed on the NASDAQ OMX Helsinki.

Winfried Schaur appointed Executive Vice President, UPM Paper ENA

Winfried Schaur has been appointed Executive Vice President responsible for UPM Paper ENA (Europe and North America) and member of the Group Executive Team as of 8 February 2016.

Winfried Schaur is currently Senior Vice President responsible for Newspaper publishing business unit within UPM Paper ENA. He has been in his current role since 2013 and in UPM since 2001 holding several leadership positions in the paper business.

Winfried Schaur is currently Senior Vice President responsible for Newspaper publishing business unit within UPM Paper ENA. He has been in his current role since 2013 and in UPM since 2001 holding several leadership positions in the paper business.

He will be based in Augsburg and reports to Jussi Pesonen, President and CEO.

"The UPM Paper ENA management team has done excellent work and with Winfried's appointment I'm sure the solid implementation of the current strategy continues," says Pesonen.

"Paper ENA has been developing very well since the new business structure was decided in 2013. Clear targets, fast decision making and motivated teams are in place at all levels. I will build on this strong fundament together with the team," says Schaur.

Winfried Schaur is 50 years old and has a Master's degree in Mechanical Engineering.

UPM

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 19,600 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM - The Biofore Company - www.upm.com

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 19,600 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM - The Biofore Company - www.upm.com

Iggesund : Precision embossing

When a book of paper samples arrives in the post, the recipient is often most interested in the samples themselves. When Iggesund Paperboard begins to distribute its new swatch book of Invercote G, Invercote Creato and Invercote Duo this winter, recipients have good reason to study the embossings which heighten the effect of the book’s photos.

“Our main task was to emboss the details in the photos. In doing so, it’s important not to change or distort the basic concept behind the image,” says Alex Guglielmi of Iggesund Paperboard. © Iggesund

“Invercote has a dimensional stability and flexibility which make it a fantastic choice for people who want to use embossing to give their brochure or other printed material a third dimension,” explains Alex Guglielmi, one of Iggesund’s market technicians. He supervised the book’s production with a special focus on the embossing. “It can heighten the tactile experience, attract more attention and, not least, reinforce the experience of quality.”

Good tools are needed to achieve good-quality embossing. For this production Iggesund worked with the Swiss toolmaker SMR Stanztechnik.

“In the swatch book our main task was to emboss the details in the photos,” Alex says. “In doing so, it’s important not to change or distort the basic concept of the image.”

One example is the large embossing of an island on the cover. The embossing runs across the front cover, spine and back cover. The first test embossing of the image made a stone, which had been in the background, appear to have moved closer to the viewer.

“We had to remake the tool to avoid creating this effect and now we’ve achieved the right balance between the image and the embossing,” he says.

In another photo the embossing of an eye had to be redone. The effect was not clear enough so the tool had to be adjusted to create a more obvious visual impression.

Another effect Alex likes to mention is how the printing and embossing of the name Invercote work together on the first page of the sample book.

“It’s really easy to go wrong doing this. I usually recommend that people really think about and understand what they are going to highlight with embossing and printing. As it is a symbiosis between the paperboard, embossing tools and printing, it’s far easier to detect the smallest misregister when you emboss along straight lines. Often output and quality are misunderstood. So when you have these demanding elements coming together, I often recommend reducing the number of single positions per sheet to achieve the best registration between printed and embossed images.” When a project calls for finishing processes that require multiple press passes, Invercote’s dimensional stability provides exceptional registration. Normally, printers find themselves trying to convince their clients to limit the number of press passes in order to avoid registration issues. But Invercote’s dimensional stability allows you to take on heretofore unimaginable challenges. To demonstrate Invercote’s superior performance in this are

a, Iggesund has produced printed projects with more than 20 press passes with outstanding results. Of course, print costs normally discourage such undertakings, but for those who are prepared to spend money in finishing, consider Invercote as insurance on the finished product’s exquisite result.

Iggesund’s sample book was printed by VR Print in the UK and the embossing tools were produced by SMR Stanztechnik in Switzerland.

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Further information:

Staffan Sjöberg

Public Relations Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

Iggesund Paperboard

SE-825 80 Sweden

Tel: +4665028256

Mobile: +46703064800

www.iggesund.com

Wausau Paper Corp. Shareholders Approve the Sale of Wausau, a leading North American Away-from-Home Tissue Company, to SCA

SCA (NASDAQ OMX Stockholm: SCA) a leading global hygiene and forest products company, has just announced that the shareholders of Wausau Paper Corp. (NYSE: WPP), a North American Away-from-Home tissue company, have approved the acquisition by SCA. The transaction is scheduled to occur on Thursday, January 21, 2016 for total consideration of USD 513 million in cash.

SCA (NASDAQ OMX Stockholm: SCA) a leading global hygiene and forest products company, has just announced that the shareholders of Wausau Paper Corp. (NYSE: WPP), a North American Away-from-Home tissue company, have approved the acquisition by SCA. The transaction is scheduled to occur on Thursday, January 21, 2016 for total consideration of USD 513 million in cash.

“SCA is the world’s leading supplier of Away-from-Home tissue with the global brand Tork®. This acquisition is an excellent strategic fit and makes us a stronger supplier in North America. The acquisition will generate benefits for SCA and our customers,” said Magnus Groth, President and CEO, SCA.

Don Lewis, President, AfH Professional Hygiene, SCA, “On behalf of all SCA employees, I am excited to welcome Wausau Paper into the SCA family. The Wausau Paper product portfolio complements SCA’s offerings in North America, and the combined brands will provide customers with superior sales, service, innovation and logistics.”

"With the closing of this transaction, the Wausau team joins an organization that shares our vision and values," said Michael C. Burandt, Chairman and CEO of Wausau Paper. “We believe this provides an opportunity to capitalize on new resources and opportunities that will benefit our customers."

The transaction expands SCA’s North America footprint and production capacity, and the combined businesses will provide customers with a comprehensive portfolio of products. The acquisition is expected to generate annual synergies amounting to approximately USD 40 million with full effect three years after closing. Synergies are expected in sourcing, production, logistics, reduced imports, increased volumes of premium products and reduced SG&A costs. The restructuring costs are expected to amount to approximately USD 50 million.

NB: This information is such that SCA must disclose in accordance with the Swedish Securities Markets Act or the Financial Instruments Trading Act. Submitted for publication on January 20, 2016, at 23:00 CET.

About SCA

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. More information at www.sca.com.

About Wausau Paper

Wausau Paper produces a complete line of Away-from-Home towel and tissue products that are marketed along with soap and dispensing system products under a number of brands including Artisan™, DublSoft®, DublNature®, EcoSoft®, and related custom brands. To learn more about Wausau Paper, visit www.wausaupaper.com

VTT, Cannon EMEA, Nestlé, FiberLean and More Headline Specialty Papers Europe

Smithers Pira and TAPPI are pleased to announce the Specialty Papers 2016 programme. The 2016 edition of the conference, taking place 4-6 April at the Hilton Deansgate in Manchester, will feature more than 20 presentations from the world’s leading specialty papers organisations.

“We’re excited to announce the programming for the 2016 event. We’ve built the conference with two full days of entertaining and technical presentations focused on innovation and new technologies in the Specialty Papers space”

“We’re excited to announce the programming for the 2016 event. We’ve built the conference with two full days of entertaining and technical presentations focused on innovation and new technologies in the Specialty Papers space,” said Kimberlee Rohrer, Conference Producer at Smithers Pira. “In addition to dynamic content, we’ve included attendee benefits like numerous dedicated networking opportunities and an exclusive tour, including one of the James Cropper Paper Mill.”

“We’re excited to announce the programming for the 2016 event. We’ve built the conference with two full days of entertaining and technical presentations focused on innovation and new technologies in the Specialty Papers space,” said Kimberlee Rohrer, Conference Producer at Smithers Pira. “In addition to dynamic content, we’ve included attendee benefits like numerous dedicated networking opportunities and an exclusive tour, including one of the James Cropper Paper Mill.”

Specialty Papers will include presentations highlighting the latest developments in the industry, with a focus on commercialization and adoption of new technology, like “Application of Microfibrillated Cellulose in Specialty Papers” by Per Svending, the Commercial Director of FiberLean, Imerys. Also included in the programme will be a presentation highlighting foam technologies by Dr. Ulla Forsstrom, Principal Scientist at VTT.

The Specialty Papers Europe programme will also include presentations from Inca Digital, Nestle, McDonald’s Corporation, Canon EMEA, Fraunhofer Institute for Process Engineering and Packaging, Steptoe & Johnson LLP, EcoSynthetix Inc and more.

For more information about Specialty Papers Europe 2016 visit www.specialtypaperconference.com/europe.

Limited sponsorship and exhibition opportunities remain. Contact Stephen Frier on This email address is being protected from spambots. You need JavaScript enabled to view it. or +44-0-1372-802006.

About Smithers Pira

Smithers Pira is the worldwide authority on packaging, paper and print industry supply chains. Established in 1930, the company provides strategic and technical consulting, testing, intelligence and events to help clients gain market insights, identify opportunities, evaluate product performance and manage compliance. For more information, visit www.smitherspira.com.

About TAPPI

TAPPI is the leading association for the worldwide pulp, paper, packaging, and converting industries and publisher of Paper360° and TAPPI JOURNAL. Through information exchange, trusted content, and networking opportunities, TAPPI helps members elevate their performance by providing solutions that lead to better, faster, and more cost-effective ways of doing business. Visit www.tappi.org

Contacts

Smithers Pira

Katie Oster, +1-330-762-7441

This email address is being protected from spambots. You need JavaScript enabled to view it.

Verso Unveils New Sterling® Premium Promotion: Sterling® Premium. Paper, Elevated

Verso Corporation (OTCPink: VRSZQ) have just announced a new printed promotion for its premium coated paper, Sterling® Premium, titled Sterling® Premium. Paper, Elevated.

"This new printed brochure showcases the exceptional print quality of Sterling® Premium through detailed imagery of beautiful, mouthwatering chocolates made by Chicago chocolatier Katrina Markoff, founder of Vosges Haut-Chocolat®," said Verso Senior Vice President of Sales, Marketing and Product Development Mike Weinhold. "The promotion features many parallels between premium chocolates and premium papers, from sourcing ingredients to manufacturing to experiencing the end product, including their high quality, craftsmanship, artistry, beauty, sensory stimulation and sustainability."

Paper, Elevated. Verso uses sustainably sourced natural resources to manufacture its coated printing papers and reaches a new level in the art of papermaking to make the best of the best - Sterling® Premium. With an unparalleled combination of optics, surface quality, print performance, product breadth, sustainability, and service for the price, this great sheet made in the U.S.A. elevates the definition of premium papers to a new standard of excellence.

Chocolate, Elevated. Vosges Haut-Chocolat® uses the world's purest, highest quality ingredients in the most inspired, surprising, convention-challenging combinations. Vosges Haut-Chocolat® creations are an art form, a visual expression that uses the deep, rich neutrals of white, milk and dark chocolates as a canvas for brilliant color accents that your eyes taste before your fingers touch.

"Everything I make is a story, the result of inspiration and craft, rethinking and refining—a process that, for me, has no end," said Markoff.

Sterling® Premium has the widest and deepest offering of any premium grade, with a full line of sizes, finishes and weights to meet any need. Sterling® Premium offers true premium selection, with the industry's broadest range of basis weights — 60 lb. text through 130 lb. cover, including 7 pt. and 9 pt. caliper guaranteed products for direct mail. The product line also includes two matching digital companion products, Sterling® Premium Digital™ and Sterling® Premium Digital™ for HP Indigo, guaranteed on all digital offset, toner and HP Indigo print equipment. Sterling® Premium contains 10 percent post-consumer recycled fiber and it's Forest Stewardship Council® (FSC®), Programme for the Endorsement of Forest Certification™ (PEFC™) and Sustainable Forestry Initiative® (SFI®) tri-certified.

To learn more about Sterling® Premium, please visit our website versoco.com.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso’s long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso’s passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. The FSC® trademark license code for Verso Corporation is FSC® C014984. For more information, visit us online at versoco.com.

Vosges Haut-Chocolat®

Vosges Haut-Chocolat® makes its intriguing chocolate creations with the finest ingredients from around the world, sourced by founder and chocolatier Katrina Markoff. The purple house of Vosges Haut-Chocolat® and the concept of Travel the World through Chocolate™ were inspired by Katrina's journeys, which have included moving to Paris to pursue her dream of studying the culinary arts at Le Cordon Bleu, an apprenticeship in Spain under the direction of Ferran Adrià and an ongoing world tour in which she has followed her palate to Southeast Asia, Australia and other exotic, interesting destinations through the years. Katrina's fusion of indigenous spices, flowers, roots, herbs and liqueurs with premium chocolate creates a sensory experience that nurtures awareness of and appreciation for the world's diverse cultures. Vosges Haut-Chocolat®'s commitment to sustainable practices, processes and packaging is another dimension of Katrina's mission of spreading Peace, Love and Chocolate®. vosgeschocolate.com

Mondi launches NAUTILUS® ProCycle - a bright white recycled paper with Blue Angel certification

Full range of recycled papers with extensive certification at Drupa 2016

New “Yes, we plant” Green Range campaign for office papers

Mondi is expanding its portfolio of recycled papers with NAUTILUS® ProCycle, a bright white 100% recycled paper with Blue Angel and EU Ecolabel certification. As a special extra, the NAUTILUS® range offers ColorLok technology for more intense inkjet colours and faster drying ink. “The expanded NAUTILUS® portfolio offers customers a full range of recycled papers and certifications to satisfy everyone’s needs”, stated Johannes Klumpp, Marketing and Sales Director, Mondi Uncoated Fine Paper, Europe & International. “Market demand for bright white recycled paper with Blue Angel environmental certification has been rising for some time, and our new NAUTILUS® ProCycle paper meets this customer need. Our customers are our priority – each and every day,” continued Mr Klumpp.

Sustainable paper – every day Blue Angel is one of the oldest, most prestigious environmental certification in Germany. Consumers can have confidence that certified products and services meet high environmental, health and performance standards. Products and services bearing the Blue Angel label must satisfy criteria that have been developed for each product group. “To satisfy the strict Blue Angel certification standards and our own high quality standards for recycled paper production, we looked for a reliable partner to supply us with recovered paper. After a thorough search, we found a competent partner we could work with over the long term”, explained Mr Klumpp. The use of high quality recovered paper allows Mondi to achieve a target whiteness of 140 CIE (ISO 100) with no optical brighteners, thereby satisfying the Blue Angel requirements. “This is an important step in our product development that allows us to meet customer needs as a leading producer offering a complete portfolio of recycled papers under the NAUTILUS® brand”, stated Mr Klumpp. “The paper provides a pleasing bright white with no tint”, he continued.

Blue Angel is one of the oldest, most prestigious environmental certification in Germany. Consumers can have confidence that certified products and services meet high environmental, health and performance standards. Products and services bearing the Blue Angel label must satisfy criteria that have been developed for each product group. “To satisfy the strict Blue Angel certification standards and our own high quality standards for recycled paper production, we looked for a reliable partner to supply us with recovered paper. After a thorough search, we found a competent partner we could work with over the long term”, explained Mr Klumpp. The use of high quality recovered paper allows Mondi to achieve a target whiteness of 140 CIE (ISO 100) with no optical brighteners, thereby satisfying the Blue Angel requirements. “This is an important step in our product development that allows us to meet customer needs as a leading producer offering a complete portfolio of recycled papers under the NAUTILUS® brand”, stated Mr Klumpp. “The paper provides a pleasing bright white with no tint”, he continued.

Presentation at Drupa 2016

Drupa 2016, the leading global trade fair for graphic and industrial printing, takes place in Düsseldorf from 31 May to 10 June. NAUTILUS® ProCycle will be presented as part of Mondi's recycled paper portfolio at this event, together with its full range of uncoated fine paper. As a special highlight, visitors can watch a live demonstration of the high performance provided, as a version of NAUTILUS® ProCycle optimised for high-speed inkjet printing is printed on-site. Mondi's booth is located in hall 4, booth number C21.

Mondi launches new Green Range campaign

Mondi launches a new campaign for its Green Range office paper under the motto “Yes, we plant!”. The campaign deals with the topics of sustainable forestry and responsible paper production, but maintains an easy-going attitude. The Green Range online game plays a central role, because it skilfully combines entertainment with information. Participants can win attractive prizes each month, such as a “fair phone” or “paper trophy”. Participation is even worthwhile without prizes, as Mondi donates one euro for each registered user to NGO OroVerde, which makes concrete, sustainable contributions to the protection of rainforests and biodiversity every day. “We would like to invite all of our customers and consumers to plant, play and win in our new online game. Learning about sustainability has never been so entertaining”, encouraged Johannes Klumpp.

We are Mondi. IN TOUCH EVERY DAY.

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are in central Europe, Russia, North America and South Africa. We offer over 100 packaging and paper products, customised into more than 100,000 different solutions for customers and end consumers. In 2014 Mondi had revenues of €6.4 billion and a return on capital employed of 17.2%.

The Mondi Group is fully integrated across the packaging and paper value chain – from managing forests and producing pulp, paper and compound plastics to developing effective and innovative industrial and consumer packaging solutions. Our innovative technologies and products can be found in a variety of applications including hygiene components, stand-up pouches, super-strong cement bags, clever retail boxes and office paper. Our key customers are in industries such as automotive; building and construction; chemicals; food and beverage; home and personal care; medical and pharmaceutical; packaging and paper converting; pet care; and office and professional printing.

Mondi has a dual-listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc under the ticker code MNDI.

For us, sustainable development makes good business sense. We don’t just talk about sustainability; we make it part of the way we work every day. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is a business unit of Mondi’s Europe & International Division. In 4 paper mills in Austria, Slovakia, and Russia Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

ANDRITZ successfully starts up semi-chemical pulp line with green liquor pulping technology at JSC Arkhangelsk Pulp and Paper Mill, Russia

International technology Group ANDRITZ has successfully started up the pulp line delivered to JSC Arkhangelsk Pulp and Paper Mill (APPM) at the Novodvinsk mill, Russia. The new line features ANDRITZ green liquor technology for efficient pulp cooking, refining, and washing and produces 1,000 t/day of semi-chemical pulp for the production of corrugated board from birch and aspen.

The ANDRITZ semi-chemical pulp line with green liquor technology at Arkhangelsk Pulp and Paper Mill’s Novodvinsk mill, Russia: Fiber quality and production capacity significantly increased, production costs and waste water volume substantially reduced. Photo: ANDRITZ

Semi-chemical pulp is produced in a combination of mild chemical treatment and subsequent mechanical treatment in which the fibers are liberated from the wood matrix. This delignification process step is interrupted at an early stage in order to increase the yield and produce stiff fibers – an important quality criterion in the production of corrugated medium. A major advantage of the ANDRITZ green liquor technology, which is mainly applied for hardwoods and enhances the fiber quality substantially, is the efficient and easy recovery of cooking chemicals in the adjacent kraft mill. Thus, no additional process steps are needed for chemical recovery.

With this new line, the production capacity of APPM has doubled, while productions costs and waste water volume have been substantially reduced.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of almost 25,000 employees worldwide. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), and recycling plants are also allocated to the business area.

For further information, please contact:

Michael Buchbauer

Head of Corporate Communications

Phone: +43 (316) 6902 2979

This email address is being protected from spambots. You need JavaScript enabled to view it.