Ianadmin

Obsolete technology becomes an industry of the future

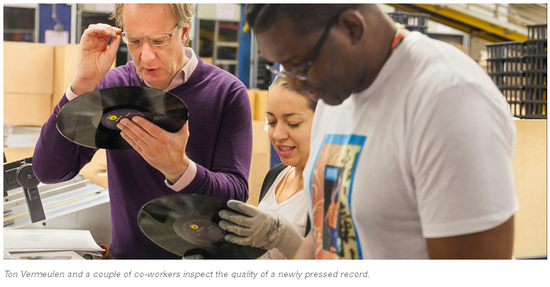

When Ton Vermeulen bought a pressing plant for vinyl records in Haarlem outside Amsterdam at the end of the 1990s neither he nor anyone else believed he was investing in tomorrow’s technology. The seller, one of the big players in the global music market (Sony Music Entertainment), had watched sales gradually decline since the 1980s and then basically disappear as CDs took over. Today the previously low-valued machines are working at full capacity and the company, now called Record Industry, has laid on an extra shift to meet demand.

As Vermeulen needed sleeves and labels for his records he approached Wil Pfeiffer of StyleMathôt, a printer based on the same industrial area, to help him out. A few years ago StyleMathôt moved into the same building so Record Industry is now a complete facility for the production of vinyl records, both LPs and singles.

“Since we switched to using Invercote from Iggesund for our record covers, we’ve been able to increase the productivity of our printing process by about 35 percent.”

The vinyl pressing plant is led by Vermeulen and his partner Wil Pfeiffer is in charge of the printing presses that uses 70 percent of their capacity to print record covers, sleeves and labels. In the past few years they have seen a powerful upswing in the market. Between 2013 and 2014 alone, global sales of vinyl records rose from 6.1 million records to 9.2 million.

“Within a fairly short time period we’ve quadrupled our production, leading to extra high demands on efficiency and the smooth functioning of everything we do,” Pfeiffer says. “Since we switched to using Invercote from Iggesund for our record covers, we’ve been able to increase the productivity of our printing process by about 35 percent.”

He is careful to emphasise the importance of the cover’s quality, a view that is supported by Ton Vermeulen’s analysis of the dramatic increase in vinyl record sales.

“The changeover from CDs to streamed music means that a large proportion of music consumers feel no need to own the music in physical form. Nor do I believe that the audiophiles’ view that vinyl records produce a better sound is very significant,” explains Vermeulen, who as a former DJ knows about music’s technical quality. “I’m convinced there is a group of music lovers who want to own their music and the traditional LP format just feels right to them.”

Most of the records produced (on behalf of their customers) are reissues of classic albums by such big names as Elvis Presley, the Beatles, Jimi Hendrix and Miles Davis, though the company also offers and presses a lot of new releases like David Gilmore and Ed Sheeran. The problem with reissues is that very often it can be difficult to find a good source to reprint the cover. The music might be well preserved but the covers have not received the same degree of care.

“Sometimes we have to use a worn cover with the price sticker still on it as the basis of our cover,” Pfeiffer says. “This then places heavy demands on our prepress department, which has to do a combination of restoration and hunting for material. The graphic quality of the cover is an important part of the whole experience.”

Together with Record Industry, StyleMathôt now has 150 employees and the record production of 2014 was 5,4 million, which increased to 7,5 million in 2015. The company is predicting yet another increase this year up to a total of 10-11 million albums produced.

But then perhaps the future can only be bright for a company whose visitors no sooner step into the reception area than they are welcomed by “I Heard It Through the Grapevine” with Marvin Gaye. Played on a traditional turntable, of course.

Iggesund to invest 60M Euro's in a major project

During 2016 Iggesund Paperboard will be investing a total of 60m Euro's in its paperboard mill in Iggesund and also in Workington UK.

During 2016 Iggesund Paperboard will be investing a total of 60m Euro's in its paperboard mill in Iggesund and also in Workington UK.

Workington will have the oldest section of its board machine press section upgraded with the latest technology.

Bengt Löfroth Strategy manager at the mill is the man behind this major project.

For the full information regarding the above and the upcoming changes at Iggesund please watch the short video below.

Anu Ahola appointed Senior Vice President, Newspaper Publishing, UPM Paper ENA

Anu Ahola has been appointed Senior Vice President responsible for SBU Newspaper Publishing, UPM Paper ENA (Europe and North America) as of March 1, 2016.

Anu Ahola has been appointed Senior Vice President responsible for SBU Newspaper Publishing, UPM Paper ENA (Europe and North America) as of March 1, 2016.

Anu Ahola is currently Senior Vice President responsible for Strategy & Energy within UPM Paper ENA. She has been in her current role since 2013. Ahola joined UPM in 2007 being responsible for strategy creation and implementation processes and Paper Business Group's strategy development. Prior to joining UPM she worked for Nokia and Pöyry.

Anu Ahola has Master's degree in Technology from Helsinki University of Technology, and MBA from Helsinki School of Economics and Business Administration.

She will be based in Helsinki and Augsburg and reports to Winfried Schaur, Executive Vice President, UPM Paper ENA.

UPM Paper ENA

UPM Paper ENA (Europe & North America) is the world's leading producer of graphic papers, serving customers in Magazine Publishing & Advertising, Merchants, Home & Office, and Newspaper Publishing. A leader in sustainable and high performance papers, UPM Paper ENA's production is located in Finland, Germany, the United Kingdom, France, Austria, and the United States. With headquarters in Germany, UPM Paper ENA employs approximately 9,500 people. To learn more about UPM Paper ENA visit: www.upmpaper.com

UPM

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 19,600 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM - The Biofore Company - www.upm.com

Xerium Introduces Drysoft Through-Air-Drying Fabric Technology for Tissue Machine

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched Drysoft fabric technology for tissue machines that utilize the through-air-drying process.

“We are delighted to introduce Drysoft fabrics for the global tissue market”

The Drysoft T.A.D. fabric portfolio includes designs with the ideal topography options to optimize sheet softness, maximize sheet bulk, and improve machine efficiency. Drysoft is also engineered with an exceptionally strong seam design and enhanced edge reinforcements for dependability, stability, and long economic life. More information is available about Drysoft at http://www.xerium.com.

“We are delighted to introduce Drysoft fabrics for the global tissue market,” said Mr. Bill Butterfield, EVP and CTO of Xerium. “In direct response to our T.A.D. customers’ requests, our research team has delivered an outstanding product portfolio to help tissue makers overcome some historical challenges with T.A.D. fabrics. Unlike some conventional T.A.D. fabrics, Drysoft seams do not use glues, coatings, or welds which can negatively influence performance and sheet quality. And with successful trials and orders in process, we are excited to see its adoption rate grow.”

About Xerium (NYSE:XRM)

Xerium Technologies, Inc. is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to the production of paper, paperboard, tissue, pulp, building products, nonwoven fabrics, and variety of industrial applications. Xerium products are specifically designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Contacts

Xerium Technologies, Inc.

Steve Cole, Director, Global Marketing

This email address is being protected from spambots. You need JavaScript enabled to view it.

At Tissue World New Orleans, Voith offers solutions to increase efficiency, productivity and quality

With Papermaking 4.0, Voith is introducing its networked solutions to increase the efficiency, productivity and quality of the entire paper production process supply chain. In addition, Voith will be showcasing NipcoFlex T, a shoe press developed to reduce energy con-sumption and raw material in tissue production. At Tissue World, which is taking place in New Orleans from March 15 to 17, trade visitors will find Voith at stand E 240.

- Papermaking 4.0 increases productivity and quality

- NipcoFlex T lowers production costs

- Find Voith at exhibition stand E 240

![]() Systems like OnCare and OnEfficiency are solutions that stem from the new Papermaking 4.0 concept. OnCare facilitates the maintenance management of paper machines, from planning, servicing and documenta-tion through cost control to spare parts management. The permanent monitoring of the entire paper machine allows optimization potentials to be identified and preventive maintenance measures to be planned and implemented. Preventive maintenance reduces unscheduled downtimes and the paper machine’s availability will increase. Unlike conventional software solutions, OnCare represents a complete maintenance concept, with the distinctive feature being that data are already embedded in the software system. Likewise, it is possible to integrate OnCare in existing systems.

Systems like OnCare and OnEfficiency are solutions that stem from the new Papermaking 4.0 concept. OnCare facilitates the maintenance management of paper machines, from planning, servicing and documenta-tion through cost control to spare parts management. The permanent monitoring of the entire paper machine allows optimization potentials to be identified and preventive maintenance measures to be planned and implemented. Preventive maintenance reduces unscheduled downtimes and the paper machine’s availability will increase. Unlike conventional software solutions, OnCare represents a complete maintenance concept, with the distinctive feature being that data are already embedded in the software system. Likewise, it is possible to integrate OnCare in existing systems.

In addition, Voith also developed OnEfficiency to maximize the paper ma-chine’s potential. OnEfficiency Forming gets right to the process at the heart of papermaking: sheet formation. This is measured and analyzed with a package of sensors so that dewatering, retention and flocculation can be stabilized and at the same time coordinated. As a result of the sta-ble process, raw materials and chemicals can be saved and energy usage reduced. Voith is a specialist in the entire paper manufacturing process and ensures that its customers benefit from a dependable documentation of practical experience in papermaking process management.

The increase in machine efficiency and improvement of paper quality are also at the core of the NipcoFlex T. At various paper mills, the innovative shoe press from Voith has already demonstrated that it can increase productivity and reduce costs. NipcoFlex T offers the benefits of up to 5% higher dry content, representing up to 20% thermal energy savings or up to 20% higher production, while maintaining the same or better paper quality. The production parameters of the press can be monitored online and re-adjusted if necessary.

Alfredo Sarli, Sales Manager at Voith Paper Air Systems, will be providing further insights into the latest work on tissue papers in his presentation “Energy Optimization of the Yankee Dryer Hood” to be held at 9:10 am on March 16, 2016 at the conference running alongside Tissue World.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith industrial Services.

ANDRITZ successfully starts up new equipment for stock preparation upgrade at VPK Paper, Belgium

International technology Group ANDRITZ has successfully started up pulping and screening equipment delivered for VPK Paperʼs PM 6 at Oudegem, Belgium. The upgraded stock preparation line processes corrugated paper and board packaging grades, boxboard cuttings, as well as corrugated board and has a feed capacity to the existing low-consistency pulper of approximately 900 tons per day.

The modified pulping system improves contaminants removal in the pulping stage at reduced energy consumption. The additional coarse screening stage enhances fiber recovery and operating efficiency. The order comprised the supply of a new ANDRITZ TrashWell for the existing low-consistency pulper, a de-trashing pump, a FibreGuard de-trasher, a ModuScreen D as the new, third-stage coarse screen, a spare and wear parts package, as well as training. This start-up confirms ANDRITZ’s wide technological experience with more than 60 pulping and de-trashing systems for packaging grades installed around the world.

The modified pulping system improves contaminants removal in the pulping stage at reduced energy consumption. The additional coarse screening stage enhances fiber recovery and operating efficiency. The order comprised the supply of a new ANDRITZ TrashWell for the existing low-consistency pulper, a de-trashing pump, a FibreGuard de-trasher, a ModuScreen D as the new, third-stage coarse screen, a spare and wear parts package, as well as training. This start-up confirms ANDRITZ’s wide technological experience with more than 60 pulping and de-trashing systems for packaging grades installed around the world.

VPK Paper produces high-quality packaging grades, such as fluting, testliner, and gray board, out of 100 percent recycled paper and cardboard.

For further information, please contact:

Michael Buchbauer

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.andritz.com

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of about 24,500 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

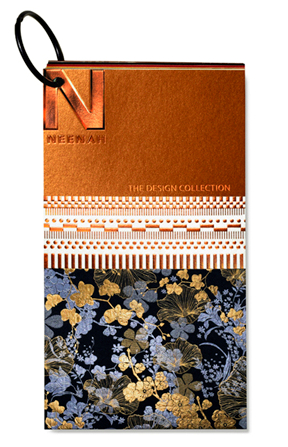

Neenah Releases Beautiful New Print Sampler Featuring Luxurious Papers from The Design Collection

Neenah continues to inspire creativity with the release of its second print sampler for the luxury grades found in The Design Collection. This beautiful, new promotion, known as The Design Collection 2.0 Sampler, holds 22 pages of idea-generating colors, textures, and specialty print techniques.

The Design Collection of papers offers 15 specialty grades with an extensive palette of colors and textures, inspired by Italy’s top fashion houses and America’s leading designers — including the new MONNALISA®, NATURAL EVOLUTION and SLIDE™ papers, and the soon to be released ASTROKING®. (A new all-encompassing swatchbook is due out this spring.)

The Design Collection of papers offers 15 specialty grades with an extensive palette of colors and textures, inspired by Italy’s top fashion houses and America’s leading designers — including the new MONNALISA®, NATURAL EVOLUTION and SLIDE™ papers, and the soon to be released ASTROKING®. (A new all-encompassing swatchbook is due out this spring.)

This new The Design Collection 2.0 Sampler features 27 different papers: from the glimmer of STARDREAM® to the letterpress-loving, textural surface of WILD®, and irresistible softness of STARWHITE®. Also showcased in this new sampler are the alluring new MONNALISA® and the authentic touch of new NATURAL EVOLUTION.

The Sampler is designed to inspire right from its SO…SILK® sleeve that reveals a thick cover constructed of three different papers laminated to a base sheet. Each of the three sheets shows a creative use of foil stamping and registered embossing.

The result is a beautiful introduction that makes you want to ask, “How’d they do that?”

Turn the cover to discover page after page of beautiful, trending colors and unique textures all with carefully considered artwork and production techniques, designed to spark ideas for creative use of paper and print.

You’ll want to examine every sheet, from the deckled edge sheet of TETON® with a blind sculptured emboss, to the eye-popping floral illustration digitally printed on STARDREAM®, to the traffic-stopping sheet of PLIKE®, Orange with dark blue foil artwork and white foil mouse type.

The Design Collection 2.0 Sampler is a feast for the eyes, the fingertips, and the creative juices. The ring closure lets designers take the sampler apart to further explore; visualize the idea of two paper colors together, view all the embossings at a glance, organize by texture, or show a client the possibilities of foil on paper.

Get a free copy of The Design Collection 2.0 Sampler through your Neenah rep or your local merchant. Find a Neenah distributor here: http://www.neenahpaper.com/resources/findadistributor

About Neenah

For more than 100 years, Neenah Paper (NYSE: NP) has been an innovative leader in the creation and manufacturing of papers for premium writing, text, cover, digital, packaging and specialty needs. The Neenah signature portfolio includes market leading brands such as CLASSIC®, ENVIRONMENT®, and ROYAL SUNDANCE® Papers. The company also offers envelopes in thousands of unique colors, finishes and styles. Neenah is committed to developing relevant mobile and online technologies including Neenah Cabinet™ for iPad, iPhone and Android. With multiple manufacturing facilities in Wisconsin, prime importance is also placed on recycled and alternative fiber products through the Neenah Green initiative. For more information on Neenah call (800) 558-5061. Follow Neenah on Twitter: @neenahpaper; subscribe to the Neenah Facebook page; or visit Against the Grain, Neenah’s blog for designers, printers and paper-lovers.

James Cropper helps fashion a sustainable future

British master papermaker James Cropper has teamed up with long-standing client Selfridges for a dramatic art installation to promote sustainability in the fashion industry.

The large-scale sculpture, unveiled in all its glory to shoppers on 27 February, depicts two hands made from thousands of coloured paper cubes and is on show at the Exchange Square Manchester store of the luxury retailer – for whose signature yellow shopping bags James Cropper provides the paper.

The ‘hands of industry’ installation is a tribute to the concept of artisan craft mastered over generations. It was created by Lancashire artist Sam Robins, of studio Flow Creation, in partnership with the Whitworth Art Gallery in Manchester and was crafted entirely from a selection of James Cropper papers, made using reclaimed fibre from disposable paper cups.

The reclaimed fibre facility at James Cropper, which was opened by HM The Queen in 2013, uses a method that separates the paper from the plastic coating and currently processes the equivalent of 10 million paper cups per week from the off-cuts of paper cup manufacturers. The company has invested significantly in its plant and technology, to both develop its range of recycled materials and to ensure its own production methods are as sustainable as possible.

Susan Wilson, luxury packaging director at James Cropper, said: “Fashions may come and go, but a sense of style is forever. Similarly, we believe sustainability is more than a passing trend. This installation is about championing creativity with longevity – supported by the right mix of innovative and authentic production methods that respect the environment.”

The project comes as part of Selfridges’ dedication to sustainability in the fashion industry, through which it is encouraging its employees, partners and customers to buy responsibly and advocate sustainable products. With this art installation, the store is taking inspiration from the idea of ‘northern heritage’, focusing on northern companies that have a long history of manufacturing, have sustainable credentials and create products made using time honoured skills and production methods.

James Cropper has been making distinct, custom-made paper products from its base in the English Lake District since 1845 – working with many of the world’s leading art galleries, designers and luxury brands – and is a proud sponsor of other artists and exhibitions, including events at NYCxDesign, YSL at The Bowes and the ‘Paper Bar’ at London’s ICA for Thomas Pink’s Autumn/Winter 2015 collection.

For more information about James Cropper, visit www.jamescropper.com.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

As well as paper products, James Cropper PLC also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors. For further information visit: www.jamescropper.com and www.tfpglobal.com.

Prize for Innventia's Ali Naderi for nanocellulose research

Ali Naderi at Innventia has been awarded this year's Kompetensutvecklingspris (Skills Prize) from the Gunnar Sundblad Research Foundation. The prize of SEK 500,000 is for development of methods for studies of nanocellulose-based materials.

Ali Naderi is a senior researcher within the Paper Chemistry and Nanocellulose group at Innventia. Nanocelluloses are exceptionally strong materials, putting them in the same class as Kevlar. However, in contrast to Kevlar and other materials based on fossil raw materials, nanocelluloses are produced from abundant renewable materials such as wood. The research and development into various nanocellulose-based applications took off in earnest five years ago when Innventia started the world's first pilot facility for production of nanofibrillated cellulose (NFC), a form of nanocellulose produced through the delamination of cellulose fibres. The use of NFC for the production of electrically conductive paper materials, barrier materials in packaging or as reinforcement in paper, cardboard and composite materials is now being studied.

This prize makes it possible for Ali Naderi to spend five months at Stony Brook University in New York. Along with Professor Benjamin S. Hsiao, an authority in employing X-ray scattering for the characterising of materials, develop methodologies for the study of NFC-based systems. It is envisaged that the methodologies will lead to a better understanding of the modes of interaction of NFC with varying materials.

"It's really exciting! I have been given the opportunity to learn an analysis method that may be of huge value to Innventia's research activities," says Ali Naderi.

"Advanced analysis is important in order to get the full potential of nanocellulose. This allows the new CNF-based materials to seriously compete by their unique properties, says Anna Wiberg, Research Manager in Paper Chemistry and Nanocellulose at Innventia.

The prize will be awarded by His Majesty King Carl XVI Gustaf of Sweden on 12 April during Skogsnäringsveckan (Forestry Week) in Stockholm. For more information, visit www.forestindustries.se/.

For more information, please contact:

Ali Naderi, telephone +46 (0)768-767321, This email address is being protected from spambots. You need JavaScript enabled to view it.

Anna Wiberg, telephone +46 (0)768-767361, This email address is being protected from spambots. You need JavaScript enabled to view it.

About the prize

The Gunnar Sundblad Research Foundation's Skills Prize has been awarded annually since 2007. The prize aims to promote the development of the Swedish pulp and paper industry towards new and improved products and services that can meet today's increasingly tough competition. The prize enables a researcher from the Swedish research and innovation system to work at a foreign research environment in order to develop, make contacts and bring home new knowledge. The Gunnar Sundblad Research Foundation Board is appointed by the Swedish Forest Industries Federation Board.

Valmet receives two new orders for automation technology from Kotkamills in Finland

Valmet has received two orders for automation technology from Kotkamills Oy in Finland to complement the paper machine technology and automation system orders received in April and July 2015 for a paper machine conversion project. Kotkamills is currently rebuilding its magazine paper production line PM 2 and converting it to produce high-quality barrier board and folding boxboard grades. The rebuilt machine will start up during the second quarter of 2016. Valmet's automation system deliveries will take place in April 2016.

Valmet has received two orders for automation technology from Kotkamills Oy in Finland to complement the paper machine technology and automation system orders received in April and July 2015 for a paper machine conversion project. Kotkamills is currently rebuilding its magazine paper production line PM 2 and converting it to produce high-quality barrier board and folding boxboard grades. The rebuilt machine will start up during the second quarter of 2016. Valmet's automation system deliveries will take place in April 2016.

The new orders are included in Valmet's first quarter 2016 orders received and the fourth quarter 2015 orders received. The value of the orders is not disclosed.

"Valmet has long experience and a lot of know-how in automation solutions for the paper industry. We are confident that we will be able to increase efficiency and make the most of the process with Valmet's solutions. The products now ordered match well with and complement the automation concept that we have chosen. We have been using Valmet's automation earlier, so our operators and maintenance staff know it well," says Jari Mäkelä, Manager, Automation and Electrification, Kotkamills.

"Our solutions will enable Kotkamills to improve board quality management as well as the management of the whole production process. Using this technology, the mill will be able to produce high-quality board and improve machine runnability," points out Harri Kohonen, Sales Manager, Automation business line, Valmet.

Technical information about the delivery

The orders include two automation systems, analyzers, measurements, consistency transmitters and optimizing process controls for various process stages in board production.

Valmet will supply Valmet DNA automation systems for the thermomechanical pulp (TMP) plant and the coating kitchen to replace Valmet's earlier-generation systems. For the TMP plant, Valmet will also deliver an online Valmet Pulp Analyzer (Valmet MAP) and optimizing process controls with which the plant can control low-consistency grinding and reach its desired board properties.

Additionally, the delivery includes over 20 consistency transmitters for the TMP plant and the board machine. The latter will be equipped with a Valmet Retention Measurement (Valmet RM3) and a Valmet Wet End Analyzer (Valmet WEM) to control whitewater consistency and chemistry. In connection with the delivery, Valmet will upgrade the mill's existing automatic Valmet Pulp Expert analyzer.

All the solutions will be integrated with the Valmet DNA automation and Valmet IQ quality management systems that are included in the orders announced earlier. One seamless automation system for the process and machine controls from a single supplier ensures that the solutions are a seamless match.

Kotkamills already has an automation service agreement with Valmet, including remote service support. In case of disruptions, Valmet's experts have access to the mill's automation systems through a remote connection.

For further information, please contact:

Harri Kohonen, Sales Manager, Pulp and Paper Mills, Nordic Countries, Automation, Valmet Tel. +358 40 748 3845

Jari Ehrling, Sales Manager, Pulp and Paper Mills, Finland, Automation, Valmet, Tel. + 358 400 765 012

Product pages: