Ianadmin

Alfa Laval wins SEK 50 million tall oil order in Russia

Alfa Laval – a world leader in heat transfer, centrifugal separation and fluid handling – has won an order to supply a complete process line to a pulp mill in Russia. The order, booked in the Energy & Process segment, has a value of approximately SEK 50 million and delivery is scheduled for 2015.

Alfa Laval – a world leader in heat transfer, centrifugal separation and fluid handling – has won an order to supply a complete process line to a pulp mill in Russia. The order, booked in the Energy & Process segment, has a value of approximately SEK 50 million and delivery is scheduled for 2015.

The order comprises decanters, separators, compact heat exchangers and fluid handling equipment for a plant, manufacturing high-quality tall oil in Russia. The plant, which will start up towards the end of 2015, is connected to a pulp mill – tall oil being an important byproduct of pulp manufacturing.

“This is an order for a unique solution, based on centrifugal separation. Compared to traditional methods using settling tanks, Alfa Laval’s unique offering is more efficient and it increases the quality of the oil,” says Lars Renström, President and CEO of the Alfa Laval Group.

Did you know that… tall oil is the major byproduct of pulp manufacturing and that it is used in a variety of products such as liquid soaps and printing inks?

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

Alfa Laval is listed on Nasdaq OMX, and, in 2013, posted annual sales of about SEK 29.8 billion (approx. 3.5 billion Euros). The company has today, after the acquisition of Frank Mohn AS about 17 500 employees.

For more information please contact:

Peter Torstensson

Senior Vice President, Communications

Alfa Laval

Tel: + 46 46 36 72 31

Mobile: +46 709 33 72 31

Gabriella Grotte

Investor Relations Manager

Alfa Laval

Tel: +46 46 36 74 82

Mobile: +46 709 78 74 82

Iggesund awarded for reducing environmental impact

Iggesund has embarked on a substantial initiative to reduce its environmental impact, which is now being recognized the world over. In October, the Pulp & Paper Industry (PPI) presented Iggesund with its “Bio Strategy of the Year” award based on an extensive investment program to reduce fossil carbon emissions.

“For several decades Iggesund has been systematically working to free itself from dependence on fossil fuel; switching the source of energy required to power our mills to bioenergy and, at the same time, increasing our energy efficiency,” says Arvid Sundblad, Vice President of Sales and Marketing for Iggesund. “We are satisfied with what we have achieved and pleased at the signs of recognition from the outside world.”

Strategic investment in a turbine-equipped recovery boiler have made the mill in Iggesund, Sweden fossil-fuel free to roughly 95% and nearly self-sufficient with respect to electricity; and in a biomass boiler at its mill in Workington, England, completely fossil-fuel free and a net supplier of green energy to the national electricity grid. The annual reduction in fossil carbon emissions from both mills is equivalent to taking more than 85,000 cars off the road.

But the story hardly ends there. Also in October, the Holmen Group, which includes Iggesund Paperboard, was elevated to the “A List” of the CDP Climate Performance Leadership Index 2014. The CDP (Carbon Disclosure Project) is an international not-for-profit organization that has the world’s only global system for measuring, reporting on, handling and sharing important environmental information.

But the story hardly ends there. Also in October, the Holmen Group, which includes Iggesund Paperboard, was elevated to the “A List” of the CDP Climate Performance Leadership Index 2014. The CDP (Carbon Disclosure Project) is an international not-for-profit organization that has the world’s only global system for measuring, reporting on, handling and sharing important environmental information.

Placement on the A List means that the Holmen Group is now one of 187 globally active companies that are regarded as being the most advanced for the actions they have taken to reduce carbon dioxide emissions and to manage the business risks associated with climate change.

“Our high placement in this evaluation proves that active energy and climate efforts plus clear communication about them reinforce both our brand and our credibility in the sustainability area,” says Lars Strömberg, Director of Sustainable and Environmental Affairs at Holmen.

Just over a year ago, the Holmen Group was added to the United Nations Global Compact Index, which lists the world’s 100 most sustainable companies. This year’s evaluation results have just been announced and Holmen remains on that list.

“In this context it is important to note that we are a heavy process industry competing with companies like banks and insurance companies, whose biggest environmental problem is the ozone emissions from their office laser printer. Yet our environmental work can easily hold its own against them,” Sundblad emphasises. He adds that this recognition of the group’s environmental efforts is part of everything that Iggesund supplies to its customers.

“Our service has many aspects, ranging from delivery service to knowledge transfer – and we include them all under the concept of Care by Iggesund. This includes having an environmental programme that reinforces our customers’ businesses.”

Care by Iggesund includes everything from customised delivery solutions to knowledge transfer, a sample service, technical support in local markets and transparent sustainability work.

Xerium Introduces ProSeam 3L Seam Felt Technology for Demanding Paper and Paperboard Machines

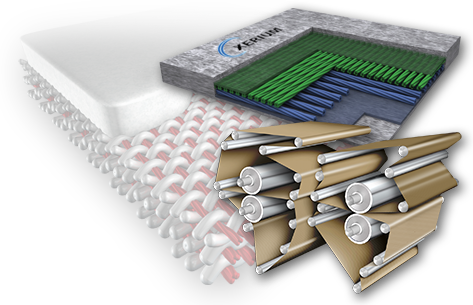

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched ProSeam 3L felt technology for paper and paperboard machines. ProSeam 3L is engineered for those demanding positions where handling high water volume and critical sheet properties are primary objectives. ProSeam 3L is a triple layer laminated construction providing up to 25% more void volume than conventional double layer designs. Its top layer and specially engineered batt fibre deliver exceptional pressing uniformity with outstanding compaction resistance for extended life potential. ProSeam 3L also enables rapid seaming for efficient installation. Learn more about ProSeam 3L technology at http://www.xerium.com/news/xerium-news.aspx.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched ProSeam 3L felt technology for paper and paperboard machines. ProSeam 3L is engineered for those demanding positions where handling high water volume and critical sheet properties are primary objectives. ProSeam 3L is a triple layer laminated construction providing up to 25% more void volume than conventional double layer designs. Its top layer and specially engineered batt fibre deliver exceptional pressing uniformity with outstanding compaction resistance for extended life potential. ProSeam 3L also enables rapid seaming for efficient installation. Learn more about ProSeam 3L technology at http://www.xerium.com/news/xerium-news.aspx.

"ProSeam 3L continues our long-standing commitment to providing our customers with innovative products that enable their machines to handle the increasing demands for enhanced productivity and improved sheet quality," said Mr. Bill Butterfield, EVP and CTO of Xerium. "As the global leader in seam felt technology, we are truly excited to introduce new high-performance machine clothing products that deliver measurable results for our customers."

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 27 manufacturing facilities in 12 countries around the world and employs approximately 3,200 employees.

Xerium Introduces Huyperm ES and ProSeam ES Enhanced Surface Felt Technology for High Quality Paper and Paperboard Machines

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched Huyperm ES and ProSeam ES felt technology which offer enhanced surface characteristics and reduced energy consumption for paper and paperboard machines. ES technology incorporates specially developed structures that are mechanically and thermally bonded forming a micro-fine felt surface delivering outstanding paper smoothness and improved drying efficiency for the most demanding press applications.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched Huyperm ES and ProSeam ES felt technology which offer enhanced surface characteristics and reduced energy consumption for paper and paperboard machines. ES technology incorporates specially developed structures that are mechanically and thermally bonded forming a micro-fine felt surface delivering outstanding paper smoothness and improved drying efficiency for the most demanding press applications.

And with ES technology's improved batt anchorage and surface resilience it is also ideal for press positions requiring high pressure cleaning showers. Learn more about Huyperm ES and ProSeam ES technology at http://www.xerium.com/news/xerium-news.aspx.

"Huyperm ES endless felts and ProSeam ES seam felts provide our customers with new options for improving both quality and energy efficiency on their paper and paperboard machines," said Mr. Bill Butterfield, EVP and CTO of Xerium. "These new felts continue Xerium's leadership in the field of super-smooth surface technology and enable all our customers to utilize this exciting technology regardless of machine size."

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 27 manufacturing facilities in 12 countries around the world and employs approximately 3,200 employees.

emtec Electronic banks on a new representation in France and the Benelux States

The company emtec Electronic GmbH from Leipzig in Germany expands its worldwide representation network by a cooperation with the company ODL Paper Service. As of now, Mr.Thierry Onder de Linden is the contact person for interests and questions concerning all products of the German producer of measuring devices.

The company emtec Electronic GmbH from Leipzig in Germany expands its worldwide representation network by a cooperation with the company ODL Paper Service. As of now, Mr.Thierry Onder de Linden is the contact person for interests and questions concerning all products of the German producer of measuring devices.

He took over the consulting and distribution activities for emtec Electronic in France, Belgium, Luxembourg and the Netherlands.

Further information at www.emtec-papertest.com

International Paper extends its support to Farmers

International Paper APPM Limited (IP-APPM) has announced the inauguration of the Check Dam at Tantikonda Village, 42 kms from Rajahmundry in East Godavari District in Andhra Pradesh. IP-APPM sponsored the development of the Check Dam as part of the company’s overarching sustainability efforts.

- Inaugurates 2nd Check Dam at Tantikonda Village, East Godavari

- 1st Check dam was constructed in Mamidilova, Vizag District in 2012

Mr. Rampraveen Swaminathan, President, IP India and CMD, IP-APPM, inaugurated the check dam at Tantikonda village amidst a gathering of officials, farmers and residents of the village. The length of the check dam is 10 meters and height is 3 meters with top width & bottom width at 0.6 meters & 2.5 meters respectively and a storage capacity of approx – 7.5 lakh liters. The source of water is from Pushkar canal. The check dam was constructed with an investment of INR 5 Lakhs. With proper irrigation system, the total cultivable area is set to increase from the current 68 acres to 200 acres.

Commenting on the initiative, Mr. Rampraveen Swaminathan said, “Sustainability has been one of the core objectives of International Paper and it has always been our endeavor to move it to the communities where we work and live. Watershed management initiatives, such as the Tantikonda Check Dam, help the local farmers in saving their crops from excess water flowing through the canal and contribute to their livelihood.”

The Need for a Check Dam

The water released from nearby Pushkar Canal, passes through Tantikonda village. Every year due to heavy flow, the farmers who cultivate paddy and other crops lose their produce as it washes away with the water. During the monsoon these problems increase many fold destroying the livelihood of farmers.

During a discussion with the villagers, IP-APPM identified this recurring problem of farmers losing their crops. It was then decided that construction of a check dam will help arrest the problem and result in multiple benefits including enhanced productivity, soil and water conservation, carbon sink creation, environment amelioration and socio-economic upliftment of farmers.

International Paper in India has been supporting tree farmers in costal Andhra Pradesh. The company provides them high yielding clonal sapling of Casurina which can be planted in marginal fallow, degraded land and wastelands. Earlier, the company had also constructed a check dam at Mamidilova Village in Vishakhapatnam district benefitting the local farmers.

About International Paper APPM Limited

International Paper APPM Limited (IPAPPM), a group company of International Paper in India, is a leading manufacturer of pulp and paper products and caters to both domestic and foreign markets. IPAPPM produces writing, printing and copier papers at its two manufacturing units in Andhra Pradesh, which have a total paper production capacity of 240,000 metric tons per year. The company is becoming a driving force in sustainability in the paper manufacturing arena in the world economy with sales of approximately US $182 million, focused social and community programs including its own pioneering work in raw material generation through social farm forestry and a very strong strategic growth focus. International Paper owns a majority shareholding interest in IPAPPM and the remaining shares are publicly traded on the Bombay Stock Exchange and National Stock Exchange in India. For more information on IPAPPM, please visit please visit ipappm.com.

About International Paper

International Paper (NYSE: IP) is a global leader in packaging and paper with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include industrial and consumer packaging and uncoated papers. Headquartered in Memphis, Tenn., the company employs approximately 65,000 people and is strategically located in more than 24 countries serving customers worldwide. International Paper net sales for 2013 were $29 billion (which included our now divested xpedx business). For more information about International Paper, its products and stewardship efforts, visit internationalpaper.com.

Xerium Introduces ProSeam CL Felt Technology for Cylinder Board Machines

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched ProSeam CL felt technology. ProSeam CL is specifically engineered to provide increased seam durability and felt life on demanding cylinder board machines. In addition, due to its unique base fabric structure, ProSeam CL is also designed to reduce installation time by speeding the on-machine seaming process required for new felts. ProSeam CL technology also incorporates improved batt fibre technology in the surface along with specially processed batt anchoring which combine for more resilient and steady-state performance over the life of the felt. Learn more about ProSeam CL technology at http://www.xerium.com/news/xerium-news.aspx.

"The Xerium R&D team is especially excited to unveil yet another step change in felt performance on these demanding cylinder board machines. ProSeam CL felt technology was developed with our customers' needs in mind: increased life and a significant reduction in seaming time. Through field trials these results have been verified with longer run life and faster seeming," said Mr. Bill Butterfield, EVP and CTO of Xerium. "It's always gratifying to help our global customers reach new levels of machine performance by applying our technology."

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 27 manufacturing facilities in 12 countries around the world and employs approximately 3,200 employees.

Production interruption at Tembec’s Temiscaming, Quebec industrial complex

In response to UNIFOR Union Local 233's decision to go on strike effective as of 26th Nov, Tembec ceases the operations at its Temiscaming, Quebec industrial complex, which comprises four main facilities manufacturing specialty pulp, high-yield pulp, multi-ply coated bleached board and powder and liquid phenolic resins. In addition to the production interruption, the strike will delay the commissioning activities now taking place on the high-pressure boiler and turbine.

In response to UNIFOR Union Local 233's decision to go on strike effective as of 26th Nov, Tembec ceases the operations at its Temiscaming, Quebec industrial complex, which comprises four main facilities manufacturing specialty pulp, high-yield pulp, multi-ply coated bleached board and powder and liquid phenolic resins. In addition to the production interruption, the strike will delay the commissioning activities now taking place on the high-pressure boiler and turbine.

The work stoppage involves approximately 650 unionized employees out of the 850 employees working at the Temiscaming complex. Negotiations between Tembec and the union began in August 2014. The four-year collective agreement expired on September 30, 2014.

The Company is monitoring the situation very closely and is putting into place measures to minimize the impact on its customers.

Tembec is a manufacturer of forest products – lumber, pulp, paper and specialty cellulose – and a global leader in sustainable forest management practices. Principal operations are in Canada and France. Tembec has approximately 3,500 employees and annual sales of approximately $1.6 billion. Tembec is listed on the Toronto Stock Exchange (TMB).

Information:

Michel Dumas

Executive Vice President, Finance and Chief Financial Officer

Tel.: 819 627-4268

This email address is being protected from spambots. You need JavaScript enabled to view it.

Linda Coates

Vice President, Human Resources and Corporate Affairs

Tel.: 416 775-2819

This email address is being protected from spambots. You need JavaScript enabled to view it.

Paper or Digital? The citizen’s right to choose

Launch of the European Keep Me Posted campaign website

Keep Me Posted EU is a campaign promoting the citizen’s right to choose how they receive important information – paper, digital or both, without being penalised. This information includes tax forms, election documents as well as bills and statements from service providers. It is not an anti-digital campaign but a pro-citizen-choice campaign promoting the inclusion of vulnerable consumers at European level.

Keep Me Posted EU is a campaign promoting the citizen’s right to choose how they receive important information – paper, digital or both, without being penalised. This information includes tax forms, election documents as well as bills and statements from service providers. It is not an anti-digital campaign but a pro-citizen-choice campaign promoting the inclusion of vulnerable consumers at European level.

Central to the campaign is the Keep Me Posted EU Pledge, which European organisations and Members of the European Parliament (MEPs) are called upon to adopt.1 The launch of this campaign could not be timelier as research shows that in 2013 a remarkable 21% of European households still had no internet access.

Since its creation in July of this year, the campaign has rapidly gathered momentum. It has secured the support of consumer groups and organisations representing citizens that may be disadvantaged by a lack of choice or simply do not agree with the fact that choice has been taken away from them.

The growing list of supporters includes European consumer organisations, European associations representing older citizens and the disabled as well as unions. The print value chain is represented by FEPE, PostEurop, CEPI, EuPIA and Intergraf.

Béatrice Klose, Secretary General of Intergraf is very encouraged by the progress made in such a short time: “The fact that we have gained so many enthusiastic partners since start-up shows that there is a genuine need and desire for this type of initiative. We are confident that more partners will join us as the campaign’s message spreads.”

Today marks the launch of the campaign’s website www.keepmepostedeu.org. It is regularly updated with news on developments in European countries regarding the trend to push citizens towards entirely paperless communication and efforts to support citizen choice. Users can subscribe to our newsletter to keep informed on the campaign’s progress, research concerning consumers’ preferences and developments across Europe. Supporters of the initiative are encouraged to get involved in a variety of ways including petitioning MEPs and service providers and sharing personal experiences.

The EU campaign is inspired by a similar initiative in the UK. Drawing on his experience from the Keep Me Posted UK campaign, David Gold, Head of Public Affairs at Royal Mail explains further how the campaign can even benefit the organisations that are being targeted: “Service providers are now starting to see the merit of being associated with this type of campaign. With 81% of adults wanting to choose how they receive information, giving consumers a choice in how they are communicated with, rather than pushing customers online by default, is not only the right thing to do, but better for their business.”

In 2015 the campaign will be launched publicly with an event at the European Parliament encouraging its members to sign the pledge.

For more information about the Keep Me Posted EU campaign please contact This email address is being protected from spambots. You need JavaScript enabled to view it.

______________________

1The Keep Me Posted pledge is available here: http://www.keepmepostedeu.org/the-campaign/

The next generation events for the global pulp, paper and biobased industries

Adforum, the world leading organizer of trade fairs for the pulp and paper industry and Mentor Communications AB, the leading media company in Sweden, are together launching two new events for the pulp, paper and biobased industries: International Pulp & Paper Week and Bioeconomy Innovation Forum. The events will be held at Stockholmsmässan on May 24-26th 2016.

The new events are designed by the exhibitors and the visitors themselves and are organized in order to match the needs of the rapidly changing forest industry. According to customer surveys done by Adforum, the companies wanted to combine the traditional exhibitions for the pulp and paper industry with a totally new forum focusing on innovations and products for the biobased industries, which has been missing from the market. The Bioeconomy Innovation Forum will focus on Bioenergy, Biorefinery, Nanotechnology, Biopolymers and other products and innovations of tomorrow.

“The new events will together with the traditional pulp and paper event offer a very strong platform for the entire forest industry”, says Marcus Bergström, CEO Adforum,and continues “There are a lot of synergies between the different product groups and it is time to integrate these into the existing event”.

“The new events will together with the traditional pulp and paper event offer a very strong platform for the entire forest industry”, says Marcus Bergström, CEO Adforum,and continues “There are a lot of synergies between the different product groups and it is time to integrate these into the existing event”.

The new events will not only focus on traditional exhibitors and visitors from the forest industry.

“Also other industry sectors will be invited to discuss and learn about the products andopportunities in the biobased industries. To guarantee a true mixture between different industry sectors, the leading media company in Sweden, Mentor Communications, is invited to be the co-organizer of the event. Through its different publications, Mentor is reaching over half a million decision makers within different industries on a monthly basis. According to the surveys done within companies in the forest industry, it is clear that the companies want to meet with professionals from different industry sectors. We can offer a lot of opportunities to make different industry sectors connect”, says Mikael Heinig, CEO of Mentor Communications.

The new events will feature the latest trends and tools in the meeting business, aiming to offer efficient business contacts between the participants. Apart from the exhibition there will be inspiring conferences, matchmaking, social events and company visits.

The last event held in Stockholm was organized in cooperation with a Swedish organization within the paper and pulp industry and was held in May 2011. The event gathered 650 exhibiting companies from 30 countries in 230 stands, and 9,064 visitors from 56 different countries. In 2016 the International Pulp & Paper Week and Bioeconomy Innovation will take place at Stockholmsmässan, May 24-26th.

For more information on International Pulp & Paper Week and Bioeconomy Innovation Forum, please contact Marcus Bergström on This email address is being protected from spambots. You need JavaScript enabled to view it. or telephone + 358 44 56 24 524

About Adforum

Founded in 1968, Adforum is the world's leading organizer of exhibitions for the pulp and paper industry. Through the years, the company has organized the world's largest pulp and paper events in Stockholm, Helsinki as well as in in China and India. Adforum is owned by Stockholmsmässan (Stockholm International Fairs) and the Finnish Fair Corporation.

About Mentor Communications

Founded in 1985, Mentor Communications is the leading media company in Sweden, offering 30 different publications especially for industry and trade, reaching ½ million decision makers on a daily basis. The channels used are magazines and newsletters. Mentor Communications is also an organizer of meetings and events. Mentor Communications is publisher of Nordic Paper Journal / Nordisk Papperstidning, the leading event magazine for the pulp, paper and biobased industries.