Ianadmin

Floor space 90% filled at Tissue World in Barcelona

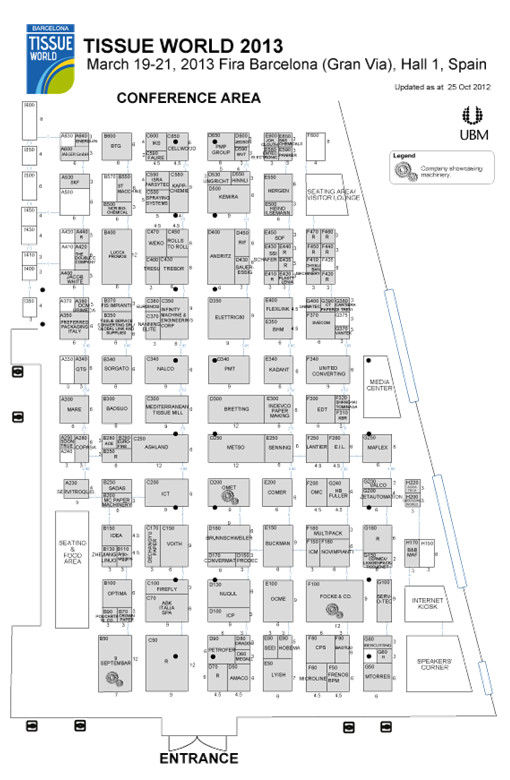

The floorspace at Tissue World 2013 in Barcelona is filling up fast. With five months still to go before the show opens next March, over 135 companies from all over the world have booked stand space at the event.

In terms of net space this means about 3,700 square meters have been booked, meaning it is already very close to the total size of the most recent Tissue World 2011 in Nice. The space is now over 90% allocated with only about 300-400 square meters remaining on the floor plan.

More suppliers are confirming their stand each week, so they can meet all the key people from the global tissue industry at the world’s top meeting for this business.

At all point through the supply chain, from raw materials to converting, packaging, wrapping and transport, Tissue World is the perfect place to pick up new ideas, new technology, new ways of doing things, and new approaches to improve operations and sustainability.

Don’t miss this chance to experience Tissue World 2013. The dates are 18-21 March for the conference meeting sessions, and 19-21 March for the trade show of vendors. The place is Fira Gran Via – Barcelona, Spain. For more information, please visit tissueworld.com.

To register to visit the Trade-show of Vendors click here.

To see the latest floorplan please click here or on the image below.

Clariant and Wilmar establish Joint Venture for amines and selected amines derivatives

Clariant Ltd, a world leader in specialty chemicals, and Wilmar International Limited, a leading Asian agribusiness group, have, through their respective subsidiaries, signed an agreement to establish a 50-50 joint venture as the global platform for production and sales of amines and selected amines derivatives. The joint venture will be headquartered in Singapore with global sales, distribution and production affiliates. Subject to receipt of regulatory approvals, including merger clearances, the joint venture is expected to be operational in spring of 2013. "Wilmar and Clariant will leverage on their companies' individual strengths to create a global platform with significant growth opportunities. With this first step, both partners are dedicated to creating a new leading player in the global amine and amine derivatives market. For Clariant it is also an important next move on our way to further optimizing our portfolio", said Clariant CEO Hariolf Kottmann. "This collaboration combines Wilmar's integrated agribusiness model and our large presence in basic and downstream oleochemicals with Clariant's technical expertise and established market presence in amines. The joint upstream and downstream strengths of our businesses make the merits of this venture very compelling", said Kuok Khoon Hong, Chairman & CEO of Wilmar.

Clariant will contribute its Industrial & Consumer Specialties (ICS) Business Unit's sales activities of relevant amines and defined derivatives to the joint venture as well as its amines plant in Germany and production output from its amines plant in Brazil. Headquartered in Muttenz, Switzerland, ICS has the highest sales volume in the Clariant Group and is one of the largest providers of specialty chemicals and application solutions for consumer care and industrial markets. Wilmar will contribute a new plant in China as well as its oleochemical expertise, including access to renewable raw materials. Wilmar is among the world's largest processors and merchandisers of palm and lauric oils. "Due to its strong roots in Asia combined with plans to expand the business globally, Wilmar is an excellent partner for Clariant to support our customer base in all parts of the world", said Michael Willome, Head of Business Unit ICS.

Metso concludes its evaluation of strategic alternatives for its Recycling business

Metso announced on September 1, 2011 that it intended reviewing strategic alternatives for its Recycling business. As part of this process, Metso evaluated both external and internal options. The review concluded that integrating Recycling into the Mining and Construction segment was the best possible alternative for creating value for Metso.

“We are committed to developing the Recycling business as part of our Mining and Construction segment,” says Matti Kähkönen, Metso Corporation’s President and CEO. “We believe that by integrating Recycling in this way we will add value to the Recycling business and for Metso generally in terms of volume growth, cost competitiveness, and developing our overall offering. We are a forerunner and global market leader in metal and waste recycling, and our goal is to further strengthen our position here.”

Recycling will be integrated into Mining and Construction as of December 1, 2012. Restated historical figures for Mining and Construction including the Recycling business will be published later this year.

Recycling had net sales of EUR 212 million in 2011 and the business currently employs approx. 660 people, mainly in Germany, the US and Denmark.

Walki to Demonstrate its Commitment toward Innovation at Moscow Forum

Walki Group is in the forefront of innovation and committed to being so also in the future. As one of the few companies in the field of intelligent packaging materials, Walki will showcase its cutting-edge technologies at the Moscow International Forum for Innovative Development “Open Innovations” scheduled to take place from 31st October to 3rd November.

The Open Innovations Forum is organized by leading Russian development institutes and Moscow Government under the support of the Government of the Russian Federation. It will bring together an estimated total of 6,000 representatives from business, government, and sciences, to share their experiences, create prosperous networks, and analyze fundamental global trends. Overall, about 50 events will take place in the framework of the Forum – including plenary sessions, panel and round-table discussions.

The Open Innovations Forum is organized by leading Russian development institutes and Moscow Government under the support of the Government of the Russian Federation. It will bring together an estimated total of 6,000 representatives from business, government, and sciences, to share their experiences, create prosperous networks, and analyze fundamental global trends. Overall, about 50 events will take place in the framework of the Forum – including plenary sessions, panel and round-table discussions.

Combining old and new technology

At the event, Walki will introduce the award-winning Walki 4E technology. This involves a dry process of laser patterning paper and aluminium laminate and drastically reduces the total cost of passive radio frequency identification (RFID) tagging. Such technology is environmentally friendly, as there are no chemicals used during the manufacturing process, and the process residue (metallic aluminium) is 100% recyclable.

- Participation gives us the opportunity to demonstrate how we have been able to create a totally new business out our traditional one by combining old technologies with new innovative ones, such as laser technology. Walki is proud to present at the event as Finnish company says Sami Liponkoski, Business Line Manager at Walki’s 4E Technology division.

Endless possibilities for the new technology

Endless possibilities for the new technology

Using the Walki 4E technology, Walki Group has developed the Walki Pantenna, which is the first UHF RFID antenna that offers extensive possibilities for converting. It can be made of paper or even fabric and printed directly on a label or a hang tag.

Liponkoski, who will hold a keynote speech and participate in a roundtable discussion related to RFID technology at the event, says that apart from RFID tag antennas, Walki’s newest innovation can benefit a wide number of other applications such as flexible batteries, photovoltaics, and mobile handset antennas. It also allows for high volumes delivering extremely efficiently and economically.

Innovation creates success

- Being innovative is extremely important for us – it is a matter of being successful. We are a global leader in producing sustainable packaging materials and in order to maintain that position we need to be innovative and always ahead of our competitors.

- At the event, we can show that we are still in the very frontline of packaging solution companies, and we have the honour to talk there about our newest innovations and how they can benefit the global packaging industry. /ins

Nippon Paper to Build Paper Recycling Plant in Australia

Australian Paper has announced that its parent company Nippon Paper has approved the construction of a $90 million paper recycling plant at its Maryvale Mill in Victoria, Australia. The plant will consume around 80,000 metric tons of recovered fiber per year to produce 50,000 metric tons of deinked pulp per year.

“Australian Paper is delighted to confirm this important investment in sustainable manufacturing following an extensive feasibility study. The Maryvale recycling plant will secure Australian Paper’s position as the market leader in premium recycled paper and is a positive initiative for our local environment, jobs and the community,” says Jim Henneberry, CEO of Australian Paper.

According to a release, the new plant will triple Australian Paper’s use of recycled fiber and will enable the development of a range of new Australian-made recycled office, printing, envelope and stationery papers. The $90 million recycling plant will begin construction shortly, with production to commence in early 2014.

“We are proud of this investment in sustainable Victorian manufacturing and would like to acknowledge the strong support we have received from a broad range of stakeholders including our customers, unions, the Latrobe City Council, environmental groups and a range of business and community stakeholders. In particular, we thank the State and Commonwealth Governments and Low Carbon Australia for their support and for sharing our vision to make this investment possible,” Henneberry adds.

Australian Paper notes that an economic impact report, prepared by Western Research Institute, calculates that the company’s total operations supported around 6,000 jobs and contributed more than $750 million to the Australian economy in 2011.

International Paper, Grupo Orsa to Form Joint Venture

International Paper (NYSE: IP) and Brazilian corrugated packaging producer Jari Celulose, Embalagens e Papel S/A, a Grupo Orsa company, have entered into an agreement to form a joint venture which will support IP's strategy of growing its global packaging presence and better serving its global customer base. Jari's industrial packaging assets, including three containerboard mills and four box plants, will be separated from its pulp and forestry businesses and transferred to a newly formed company in which IP will hold a 75 percent stake. IP's investment in the joint venture will be BRL 952 million, or approximately $470 million at today's exchange rate.

"This partnership fits well with International Paper's strategy to globally grow our corrugated packaging business in strategic regions of the world," said John Faraci, Chairman and Chief Executive Officer. "We are excited about Brazil's growing market and this investment provides us with an attractive position with a strong return on investment."

With an agreement now in place, the companies expect to finalize the transaction early in the first quarter of 2013, subject to various closing conditions and governmental approvals.

The company will discuss the agreement, during its third quarter earnings webcast on Thursday, October 25th.

SOURCE International Paper

ASCO Numatics introduces stainless steel pulse valve for dust collector systems

ATEX certified series 353 pulse valve is ideally suited to challenging environments in the agricultural, grain, food, pharmaceutical, chemical, wood, plastics and cement industries

ASCO Numatics has introduced a 316L stainless steel version of its series 353 pulse valve for use in dust collector systems. Certified to ATEX Category II 2G/D Zone 1 + 2 for explosive areas, it has been introduced to meet the growing demand for valves for challenging environments in the agricultural, grain, food, pharmaceutical, chemical, wood, plastics and cement industries.

ASCO Numatics has introduced a 316L stainless steel version of its series 353 pulse valve for use in dust collector systems. Certified to ATEX Category II 2G/D Zone 1 + 2 for explosive areas, it has been introduced to meet the growing demand for valves for challenging environments in the agricultural, grain, food, pharmaceutical, chemical, wood, plastics and cement industries.

The valve has the same features as the existing aluminium version and is suitable for control with either remote ASCO pilot valves or an integral solenoid. The diaphragm pulse valve combines high flow, long life and extremely fast opening and closing to provide a reliable and cost effective solution. The valves are available as ¾”, 1” and 1½” threaded versions and can be mounted in any position without affecting their operation.

The series 353 pulse valve is part of a complete range of dust collector products from ASCO Numatics that includes power pulse valves, pilot valves, pilot boxes, sequential controllers, pressure differential modules, tank systems and air preparation equipment.

ANDRITZ to supply biomass pre-treatment technology for commercial-scale Project LIBERTY in the USA

International technology Group ANDRITZ, through its U.S. subsidiary ANDRITZ Inc., received an order to supply its advanced continuous biomass pre-treatment technology for the Poet-DSM Advanced Biofuels commercial-scale biofuel facility being built in Emmetsburg, Iowa, USA.

International technology Group ANDRITZ, through its U.S. subsidiary ANDRITZ Inc., received an order to supply its advanced continuous biomass pre-treatment technology for the Poet-DSM Advanced Biofuels commercial-scale biofuel facility being built in Emmetsburg, Iowa, USA.

Project LIBERTY is POET-DSM’s first commercial scale 2nd generation cellulosic ethanol plant and is under construction in Emmetsburg, Iowa. The facility will produce 20 million-gallons per year by using corn cobs, leaves, husk, and some stalk to produce renewable fuel. Construction is scheduled to be complete in the fourth quarter of 2013.

ANDRITZ’s advanced steam explosion (SteamEx) technology is a two-stage process which includes a vertical reactor, interstage washing, and continuous steam explosion. The technology will be employed to help in the pre-treatment of biomass so that it can be converted into low-cost sugars which will be used in the production of ethanol. This technology is well-proven in other industrial processes and, through extensive R&D in liquid biofuels, has been optimized by ANDRITZ to satisfy the requirements for Project LIBERTY.

FutureMark Paper Group Names New Sales & Marketing Leader for 100% Recycled Uncoated Products

FutureMark® Paper Group, North America’s leading provider of responsibly made, high‐recycled paper, named respected paper industry veteran Paul E. Bradshaw Vice President of Sales and Marketing for the group’s uncoated paper products. FutureMark’s 100% recycled uncoated printing and packaging papers, made at the group’s plant in Manistique, Mich., are used by sustainability-minded companies such as Houghton Mifflin Harcourt, JPMorgan Chase, L.L. Bean and McDonald’s.

News Summary

- Paul E. Bradshaw joins FutureMark Paper Group as Vice President of Sales & Marketing for uncoated paper products, made at the group’s plant in Manistique, Mich.

- Bradshaw takes charge of expanding FutureMark’s footprint in uncoated publication papers—including book and digital papers—and in the growing market for brown kraft and packaging papers.

Mr. Bradshaw will direct all aspects of sales and marketing for FutureMark uncoated products, which include printing and writing grades such as Future Book™ UC, Future Mystique™ and Future Office™ and packaging papers such as Future Bag™ and Future Pack™. Mr. Bradshaw will also spearhead FutureMark’s continued expansion into high-end publication paper markets, including book and digital papers.

“Having Paul join the FutureMark team is a boon for our business,” said FutureMark Paper Group President and CEO Steve Silver. “Paul has proven experience building market-leading positions in high-end publication and digital papers. His deep expertise and relationships in our customer markets will generate many new opportunities for FutureMark with companies that value the environmental benefits of our 100% recycled uncoated papers.”

Mr. Bradshaw previously served as the senior vice president for publishing papers at Appleton Coated LLC, overseeing relationships with major publishing customers and leading the company’s entry into coated inkjet papers. He had held various sales and management positions at Appleton Coated and its predecessor companies since 1988.

FutureMark Paper Group Sets Course for Leadership in Environmental Paper

FutureMark® Paper Group launched as the umbrella group for two recycled paper producers previously operating as Manistique Papers and FutureMark Paper Company. Guided by an unwavering commitment to sustainability, FutureMark Paper Group is now the leading North American provider of responsibly made high-recycled paper for books, magazines, catalogs, retail inserts, business papers, commercial printing applications and packaging.

FutureMark Paper Group aligns the executive management, business development, marketing and operational functions of FutureMark Paper Company and Manistique Papers. FutureMark Paper Group’s uncoated recycled papers will be made at its FutureMark Manistique facility. The FutureMark Alsip facility will produce the group’s coated recycled papers. Industry veteran Steve Silver will serve as FutureMark Paper Group’s President and CEO, overseeing both manufacturing facilities.

“In addition to sharing a senior management team and board of advisors, our two recycled mills share a strong history of innovation,” says Silver. “Combining the unique production capabilities of these two mills creates a platform for faster growth and enables us to achieve operational synergies that otherwise wouldn’t be possible. We’re joining forces at a great time in the market to take advantage of the momentum behind environmental paper.”

Combining capabilities for improved performance

FutureMark Paper Group is strategically aligning the talents of its Manistique and Alsip teams to accelerate product development, spark innovation and enhance the business value it delivers to customers.

- Process innovation and product development – By cross-pollinating best practices in operations, predictive maintenance and new technology between the two mills, FutureMark Paper Group will accelerate development of high-quality products and lower the environmental impact of its manufacturing activities.

- Sales and marketing integration – Sales and marketing resources are now realigned to better serve the group’s green customer base with a unified brand and complementary products.

- Transportation optimization – The group is optimizing paper transportation routes between its two manufacturing facilities and their suppliers and customers to speed delivery and decrease its transportation footprint.

While FutureMark Paper Group’s Alsip and Manistique facilities will work closely in the marketplace to achieve synergies and bring new value to customers, each operation is financially and legally independent, owned by separate investment funds managed by The Watermill Group, a strategy-driven private investment firm.

New names, new products

FutureMark Paper Group’s 100% recycled uncoated papers, formerly sold under Manistique Papers’ product names, will now be sold under the brand Future Mystique™. Book papers will be marketed under the Future Book™ UC brand. Printing papers for the converter market will be bundled under the Future Office™ product family, and recycled packaging and bag papers will be sold as Future Pack™ and Future Bag™, respectively.

Product names for the group’s recycled coated publication papers, previously sold by FutureMark Paper Company, will remain unchanged: Future Book™, Future Choice® and Future Connection®. Future ReMark®, a C1S label paper, will now be renamed Future Label™.

Customers will continue to be served by their current sales representatives. Inquiries about all FutureMark Paper Group products should be sent to This email address is being protected from spambots. You need JavaScript enabled to view it..