Ianadmin

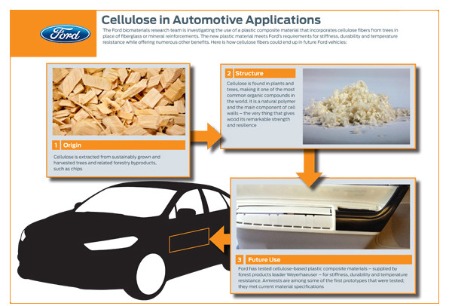

Ford and Weyerhaeuser Collaborate to Develop Automotive Applications Using Natural Fiber Materials

- Ford’s investigation into the use of tree fibers called cellulose in plastic composites has shown using the fiber in automotive applications could significantly reduce CO2 emissions and weight, while speeding processing time by as much as 40 percent

- Ford has worked with Weyerhaeuser – one of the largest forest products companies in the world – to prove out a more sustainable plastic composite material for future Ford vehicle components

- Ford already uses a variety of sustainable materials throughout its lineup, including soybean-based cushions and head restraints that save about 5 million pounds of petroleum annually

- The new Fusion uses the equivalent of about 42 recycled plastic bottles in its seat fabric and post-consumer recycled carpet in its cylinder head covers

- Ford’s entire North American lineup of vehicles contain soybean-based cushions and head restraints

- Flex has wheat straw in its plastic bins

- Kenaf fiber – derived from a plant related to cotton and okra – is used in the door bolsters of Escape

- Focus Electric uses a wood-fiber-based material in its doors and recycled plastic bottles in its seat fabric

- The new Fusion contains the equivalent of slightly more than two pairs of average-sized American blue jeans as sound-dampening material

- The equivalent of 25 recycled 20-ounce plastic bottles help make up the Escape’s carpet

High-tech Biopolymer Viscose Fibres from Kelheim Fibres

Man-made Fibres Congress, Dornbirn: new studies & our latest developments

Every year, we present our latest research results and our new fibre developments at the Man-made Fibers Congress at Dornbirn. This year, Kelheim Fibres made four presentations - as you see, our R&D team has been very busy! Here is a short summary of two of the presentations - more next time!

- Dr. Roland Scholz, R&D Kelheim Fibres and

- Ina Sigmund, Saxony Textile Research Institute (STFI): Viscose Fibers for Improved Dispersibility of Wet Wipes

Wipes for personal hygiene applications are frequently flushed into toilets - and risk blocking the waste water system. In the course of the study nonwovens based on 100% viscose fibres were tested for flushability according the demands of EDANA/-INDA’s “Guidance Document for Assessing the Flushability of Nonwoven Consumer Products”.

Wipes for personal hygiene applications are frequently flushed into toilets - and risk blocking the waste water system. In the course of the study nonwovens based on 100% viscose fibres were tested for flushability according the demands of EDANA/-INDA’s “Guidance Document for Assessing the Flushability of Nonwoven Consumer Products”.

The results: the two crucial factors for dispersability and transportability through sewer pumps are the fibre-length and the strength of the nonwoven web. Both factors have to be sensitively balanced to achieve sufficient web strength, easy break-up of the nonwoven and a complete dispersion of the fibres.

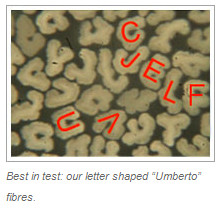

Nonwoven fabrics based on 20mm viscose fibres with round cross-sections and with the letter shaped cross section of our new “Umberto” fibres achieved the best test results for flushability.

Statement from : Matthew North, Commercial Director Kelheim Fibres

A Specialist specialises

We are proud to hold an excellent position in an increasingly competitive global market - what are the reasons for our success? First of all, we understand the challenges we face - and how to turn them into advantages.

As a medium-sized company in a high cost area we have skilled and reliable workforce and easy access to R&D resources. Our location on the banks of the Danube near a residential are means high environmental costs - yet at the same time it forces us to maintain the state-of-art technology of our plant. With eleven relatively small spinning lines our production capacity is limited - but we are highly flexible and can manufacture small lot sizes of speciality fibres competitively.

To guarantee our future success, our strategy focuses on four key elements: The effective and efficient use of available equipment and technology is the first important step. Based on that, we build leading positions in key markets and maintain them by continuous improvement of our products and production processes. To name just one example: We hold the number one position as supplier for short cut fibres for wet laid applications - 70% of viscose fibres used world wide in the manufacture of speciality papers are produced in Kelheim.

Forming strong partnerships with universities and research institutes and using the versatile viscose fibre process to our advantage, we adapt existing technologies for innovation. And last but not least, we establish new business in new applications, in the paper industry or filtration for example, where our speciality fibres offer benefits for an enhanced performance of the end product.

Our success is therefore not based on coincidence but solidy and strategically planned. With us, our customers have a reliable partner not just short-term, but also in the long run.

Orchids Paper Products Company Reports New Converted Product Business

Orchids Paper Products Company has reported that it has new understandings with several retailers for the supply of converted products and expects to begin receiving orders in the fourth quarter of 2012. The Company expects sales from this new business, when combined with sales from the new business announced in the Company's second quarter 2012 earnings press release, to be approximately 1.1 million cases on an annualized basis. This represents approximately 17% of the run rate for cases shipped in the second quarter of 2012. The expected new business was awarded by both existing and new customers.

Mr. Robert Snyder, President and Chief Executive Officer, stated, "We are pleased to announce that we have recently gained new business, primarily in the mid-tier and premium categories, with several new and existing customers. We expect the new business will begin shipping during the fourth quarter of this year and to be fully reflected in our first quarter 2013 results. The addition of this new business is primarily the result of continued success in our new product and market development efforts to further penetrate mid-tier market opportunities."

The Company will hold a teleconference to discuss its third quarter financial results at 10:00 a.m. (ET) on Thursday, October 25, 2012. All interested parties may participate in the teleconference by calling 800 860 2442 and requesting the Orchids teleconference. A question and answer session will be part of the teleconference's agenda. Those intending to access the teleconference should dial in fifteen minutes prior to the start. The call may also be accessed live via webcast through the Company's website at www.orchidspaper.com under "Investors". A replay of the teleconference will be available for 30 days on the Company's website.

Forward-Looking Statements

This release contains forward-looking statements that involve certain contingencies and uncertainties. The Company intends these forward-looking statements to be covered by the safe harbor provision for forward-looking statements contained in the Private Securities Litigation Reform Act of 1995. These statements relate to future events or future financial performance, and involve known and unknown risks, uncertainties and other factors that may cause its actual results, levels of activity, performance or achievements to be materially different from any future results, levels of activity, performance or achievements expressed or implied by such forward-looking statements. In some cases, forward-looking statements can be identified by terminology such as "may," "should," "could," "expects," "plans," "intends," "anticipates," "believes," "estimates," "predicts," "potential" or "continue" or the negative of such terms or other comparable terminology. Although the Company believes that the expectations reflected in the forward-looking statements are reasonable, it cannot guarantee future results, levels of activity, performance or achievements. These statements are only predictions.

Factors that could materially affect the Company's actual results, levels of activity, performance or achievements include, without limitation, those detailed under the caption "Risk Factors" in the Company's Annual Report on Form 10-K for the year ended December 31, 2011, as filed with the Securities and Exchange Commission on March 7, 2012.

The Company's actual results may be materially different from what it expects. The Company does not undertake any duty to update these forward-looking statements after the date hereof, even though the Company's situation may change in the future. All of the forward-looking statements herein are qualified by these cautionary statements.

SOURCE Orchids Paper Products Company

Ralf Spettmann becomes head of the business unit for Pigments & Resins Europe

On October 1, 2012, Ralf Spettmann (47) was appointed Senior Vice President of the Pigments & Resins Europe business unit of BASF. Beforehand, he was Senior Vice President of the Fuel and Lubricant Solutions unit. In his new function, he will be in charge of the product families of pigments, resins and additives for the coating, paint, printing and packaging industry. The Pigments & Resins Europe unit is part of the Dispersions & Pigments division of BASF.

Spettmann succeeds Jan-Peter Sander, who has become head of the Personal Care Europe unit.

About BASF’s Dispersions and Pigments Division

BASF is the leading global supplier of raw materials for the coating and paint industry. The division Dispersions & Pigments combines all BASF offerings towards this industry. The portfolio encompasses pigments, resins, dispersions and a broad range of additives like light stabilizers and photo initiators. Further end-use industries include construction materials, adhesives, printing and packaging. Our portfolio is focused on environmentally friendly systems, such as low-VOC water-based coatings. More details to be found on the Internet: www.dispersions-pigments.basf.com

MP Hygiene started-up a new Toscotec tissue line at Papeterie d’Annonay in France

On October 12, 2012, MP Hygiene started up their new Toscotec supplied complete tissue production line at their facility in Annonay, Ardeche Department on Rhone-Alps Region, France.

Due to the excellent cooperation between MP Hygiene and Toscotec the TM 1 machine started up smoothly on schedule, fifteen months after the order signature of the turn key contract.

The new Toscotec's line includes AHEAD-1.5S crescent former tissue machine with single-layer headbox, double press configuration and a Steel Yankee Dryer (TT SYD 12FT), machine auxiliaries, stock preparation plant for virgin pulp and electrification & control system.

The new Toscotec's line includes AHEAD-1.5S crescent former tissue machine with single-layer headbox, double press configuration and a Steel Yankee Dryer (TT SYD 12FT), machine auxiliaries, stock preparation plant for virgin pulp and electrification & control system.

The scope of supply includes also: a boiler plant, air compressors, turbo-blowers for vacuum production, steam generator and a cascade heat exchanger system for the hood heat recovery. A three unwind stands tissue slitter rewinder TT WIND-H and an automatic roll handling system complete the supply.

The machine design speed is 1900 mpm with a net web width of 2820 mm and with an average production of 100 tpd. The project has been fully managed by Toscotec on an EPC (Engineering Procurement and Construction) basis.

The AHEAD tissue plant concept has been developed with a great attention to the energy saving and low emission as well as to the environmental issues and the impact on the site. The new line will allow the French Company to guarantee its own requirements for the existing converting facilities.

Before the start up of the tissue machine MP Hygiene, settled in 1998, represented five industrial (AFH) divisions, with ten converting lines and three production sites over 34,000 m2. Its logistics hub of 18,000 m2 makes it possible to deliver all volumes of order, from one pallet to a whole truck, while continuous investment in research has opened the way for innovative products, such as DESL® technology, which adds resistance to paper wipes, or the Evadis® range of non-touch wiping systems.

“One of the major reasons for choosing Toscotec - said Marc Miribel President of MP Hygiene - was their flexibility in dealing with Customers and their references worldwide in turn key solutions and energy savings concept. The great ability in managing the whole project and the very smooth start up confirmed we have done the right choice that will give us opportunity to grow successfully in our business”.

Catalyst begins sales process for Snowflake mill and assets

Catalyst Paper announced today that it has begun a sale process for its Snowflake mill and associated assets in accordance with the US Court-approved sale and investor solicitation procedures (SISP).

The Snowflake facility is located in the foothills of the White Mountains in northeastern Arizona. The assets for sale under the sale process include the equipment and other assets associated with the paper mill, approximately 19,000 acres of land and The Apache Railway Company.

The steps and timeline for soliciting bids to purchase the Snowflake mill and associated assets will be implemented as follows:

(a) an initial offering summary and confidentiality agreement will be distributed to known potential bidders on September 17, 2012;

(b) potential bidders are to submit certain information and an executed confidentiality agreement not later than 5:00 p.m. (Vancouver time) on October 1, 2012;

(c) qualified bidders will be determined within three business days after such potential bidders have delivered their materials;

(d) qualified bidders are to submit a non-binding indication of interest not later than 5:00 p.m. (Vancouver time) on November 1, 2012 (the Phase 1 Bid Deadline);

(e) the non-binding indication of interest will be assessed within three business days after the Phase 1 Bid Deadline;

(f) once the non-binding indication of interest has been determined to likely be consummated, the bidder will submit a purchase bid or investment bid not later than 5:00 p.m. (Vancouver time) 30 calendar days from being advised by Catalyst to do so (the Phase 2 Bid Deadline);

(g) the purchase bid or investment bid will be assessed within the three business days following the Phase 2 Bid Deadline; and

(h) in the event that Catalyst determines there is more than one qualified purchase bid or investment bid, an auction will be conducted on a date and at a time and location to be advised by Catalyst to such qualified bidders.

Potential bidders who have questions about the recapitalization may contact Nancy Turner of Perella Weinberg Partners, the financial advisor for Catalyst Paper, at +1-415-671-4550.

Sofidel CEO to speak at Tissue World in Barcelona

Excitement is now building for Tissue World 2013, the world’s largest event targeted specifically at the soft hygienic tissue paper business.

Luigi Lazzareschi, CEO of the Sofidel Group based in Lucca, Italy, will be among the speakers at the opening management/markets session of the Tissue World Conference on Monday 18 March. Sofidel, which recently surpassed the milestone of one million tons per year of annual capacity, is Europe’s number two tissue producer and number six in the world.

Numerous other companies and organizations such as SCA, WWF, RISI and the European Tissue Symposium have also agreed to be on the Day One management and markets session. Other speakers will of course be joining this session as the program develops in the coming weeks.

The theme of the conference for 2013 is “Evolution or Revolution: The Next Steps in Sustainable Tissue Making.” Many tissue companies are today seeing that what is good for the environment is often good for profits as well. At the same time, many environmental groups, retailers and consumers are focusing on the tissue industry.

Increased efficiencies all through the supply chain can mean reduced environmental impact, as well as reduced costs. Therefore Tissue World is the perfect place to pick up new ideas, new technology, new ways of doing things, and new approaches to improve operations and sustainability.

The dates of the event are 18-21 March for the conference meeting sessions, and 19-21 March for the trade show of vendors. The place is Fira Gran Via, Barcelona, Spain. For more information, please visit tissueworld.com/world

To register to visit the Trade-show of Vendors click here

To see the latest floorplan please click here

Metso’s automation to boost green energy production in Reunion and Guadeloupe

Metso has signed an agreement on delivering state of the art automation for Séchilienne-Sidec, one of the market leaders in biomass and solar energy production in France and the French overseas territories. The new Metso DNA automation systems will be installed as retrofits in two of the Séchilienne-Sidec power plants in Reunion and additionally at a plant in Guadeloupe. The delivery for altogether six boiler units will take place between 2013 and 2015.

“We chose Metso’s automation systems because we believe that they provide the best technological and technical solution for a DCS retrofit to control industrial risks,” saysGilles Hassan, Project Manager at Séchilienne-Sidec. “Moreover, we have been satisfied with Metso’s solution that was commissioned in 2011 for our Caribbean energy plant which is located in Guadeloupe.”

Adding new technology to existing power plants is a demanding task that calls for expertise. Metso’s retrofit delivery scope consists of the Metso DNA automation systems with which the power plants will be controlled. A Metso Information Management System, a Metso DNA Control System Simulator, system installation and control system documentation updates are also included in the delivery. The simulator is a virtual learning environment that makes it possible for the operators to practice and learn the Metso DNA operator interface functions.

In Reunion, located in the Indian Ocean, Metso’s systems will be installed at the Compagnie Thermique Bois Rouge power plant with a capacity of 60 MW and the Compagnie Thermique du Gol plant with a capacity of 64 MW. Séchilienne-Sidec produces 57% of the island’s total electricity.

In Guadeloupe, Metso will retrofit the 64 MW Compagnie Thermique du Moulepower plant with new automation. Séchilienne-Sidec produces 31% of the electricity consumed on this island located in the Caribbean Sea. Both in Reunion and Guadeloupe, Séchilienne-Sidec’s power plants run on biomass, such as bagasse.

Séchilienne-Sidec has 20 years of experience in generating electricity from biomass resources. It is also a leading producer of energy from photovoltaic sources, always seeking to use locally available clean and renewable resources. The group’s installed thermal, wind power and solar capacity is 693 MW of which 624 MW is installed in the French overseas territories. The company is headquartered in Paris, France. In 2011, its net sales amounted to EUR 362 million. www.sechilienne-sidec.com

Metso to supply board machine rebuild for Obeikan Paper Industries in Saudi Arabia

Metso will rebuild the PM 1 cartonboard machine at the Riyadh mill of Obeikan Paper Industries in Saudi Arabia. The rebuilt production line will be fully operational in the middle of 2013. The value of the order will not be disclosed.

The main target of the rebuild is to improve end product quality, increase capacity and reduce production costs.

“This investment is aligned with Obeikan strategy to keep the mill up-to-date in technology in order to keep feet within the competitive environment of paper industries,” says Mohammed Al-Mowkley, General Manager of Obeikan Paper Industries.

The coater and air system rebuild order is included in Metso’s Pulp, Paper and Power third quarter 2012 orders received and the press section rebuild order is included in the second quarter 2012 orders received.

Technical information

The 3.4-m-wide (wire) PM 1 produces white lined chipboard in the basis weight range of 180-450 g/m2 at the design speed of 600 m/min. The current annual production level is 170,000 tonnes and capacity after the rebuild will be 220,000 tonnes per year.

Metso’s delivery will comprise a rebuild of the press section with a new SymBelt shoe press to increase dry content after the press section. The delivery will also include a new curtain coating station with a one-sided gas-heated air dryer. The new multilayer curtain coating unit adds two coating layers to the web at the same time in a non-contact operation with no speed restrictions. Metso will also take care of installation supervision, commissioning and start-up of the rebuilt machine.

Obeikan Paper Industries is a subsidiary of Obeikan Industrial Investment Group Ltd. It primarily involves in printing and packaging, education and publishing businesses. The company was incorporated in 1983. Obeikan Industrial Investment Group Ltd. is headquartered in Riyadh, Saudi Arabia.

Rottneros: Interim Report January-September 2012

Rottneros is reporting a positive 9-month result after net financial items of SEK 6 million for the year. Cash flow after investments and net financial income was also SEK 6 million. The customary four-week vacation shutdown at Rottneros Mill together with the annual maintenance shutdown at Vallvik Mill, which predominantly fell in September this year, had a significant effect on the result for the third quarter. The quarterly result was burdened with approx. SEK30million owing to these shutdowns.

-

Income after net financial items amounted to SEK 6 (-76) million for the period January to September 2012. The result for the previous year incurred total write-downs and one-off costs of SEK -148 million.

-

Income after net financial items amounted to SEK -26 million for the third quarter of 2012 compared to a profit of SEK 16 million for the same quarter of the previous year, excluding write-downs and one-off costs. There was a vacation and maintenance shutdown respectively at Rottneros Mill and Vallvik Mill during the third quarter of 2012. The maintenance shutdown at Vallvik, which in previous year took place during the fourth quarter, had a negative effect on the result of SEK 25 million.

-

Cash flow from current operations amounted to SEK 14 (27) million for the third quarter of 2012 and SEK 49 (57) million for the period January to September 2012.

The summer downturn was unusually severe this year for Swedish pulp producers such as Rottneros. There was a global fall in USD market prices, which had a major impact when added to the significant rise in the value of the Swedish kronor. The market price of our dominant product, NBSK (or chemical softwood pulp), is monitored via the PIX index, which is published weekly, and this price indicator was approx. SEK 5,000 per tonne for Europe at the end of September compared with approx. SEK 6,000 per tonne at the end of May and approx. SEK 5,700 per tonne at the beginning of the year. We now envisage an upward turn in price trends for the final quarter of this year. List prices in Asia have increased twice by USD 20 per tonne. In North America, which has the highest price level, the list prices increased by USD 20 per tonne and in Europe by approx. USD 30 per tonne. Nor was the Swedish krona as strong as it was in August, which means that revenues should now rise again.

The summer downturn was unusually severe this year for Swedish pulp producers such as Rottneros. There was a global fall in USD market prices, which had a major impact when added to the significant rise in the value of the Swedish kronor. The market price of our dominant product, NBSK (or chemical softwood pulp), is monitored via the PIX index, which is published weekly, and this price indicator was approx. SEK 5,000 per tonne for Europe at the end of September compared with approx. SEK 6,000 per tonne at the end of May and approx. SEK 5,700 per tonne at the beginning of the year. We now envisage an upward turn in price trends for the final quarter of this year. List prices in Asia have increased twice by USD 20 per tonne. In North America, which has the highest price level, the list prices increased by USD 20 per tonne and in Europe by approx. USD 30 per tonne. Nor was the Swedish krona as strong as it was in August, which means that revenues should now rise again.

Developments have been favourable for us on the cost side, with falling timber and electricity prices as well as fixed costs. We must learn to live with being a high-cost country in an extremely competitive world. Our only protection will be our own competitiveness, including continuous productivity improvements. The continuous rationalisations that have taken place in recent years, including staff reductions, mean that we are not planning any further downsizing or closures at the current time. However, our focus on efficiency and improved customer offerings is stronger than ever. We are obviously pleased in this connection about the permit allowing an increase in production at Vallvik Mill to 242,000 tonnes in three years. This in itself will facilitate a significant improvement in efficiency. The Swedish Environmental Protection Agency has however appealed against this decision.

During the quarter just ended, the world’s largest CTMP supplier shut down a major plant in Canada and in Europe Södra announced that they were withdrawing from the CTMP market. This will entail the disappearance of around 10% of global capacity and significantly more of the current CTMP supplies to the European market. Hopefully this reduction on the supply side of mechanical pulp will result in improved price formation. These pulps have unique quality characteristics that are of value to paper and board makers and over time must be priced so that manufacturers also continue in existence.