Ianadmin

New Metso Fiber Image Analyzer offers pulp and paper makers unparallel technology for optimizing process and product quality

The new Metso Fiber Image Analyzer (Metso FS5) expands the horizons of laboratory testing fiber samples, enabling pulp and paper mills to unlock the true value potential of their raw material for optimum end product quality. Enhanced accuracy, reliability and speed of fiber measurement offer a variety of possibilities for improved competitiveness thanks to better control of raw material treatment and quality.

"Metso FS5 incorporates the latest technology development in fiber imaging and image processing. The improved optical measurement capability allows pulp and paper makers to see more from the fibers, while the advances in the image processing creates the possibility to extract new features," says Jukka Nokelainen, Business Manager, Metso Automation.

"The Metso FS5 is the result of more than 30 years of experience with automated fiber property measurements and fully meets the requirements of the ISO 16065-2 standard. It is suitable for a broad variety of pulp types and fibers and is designed for routine pulp and paper mill laboratory testing as well as laboratory research use," adds Tuomo Kälkäjä, Product Manager, Metso Automation.

Metso FS5 offers several features for more efficient laboratory testing at pulp and paper mills:

* Easy to use, no lengthy training needed.

* Up to 100 samples easily per 8-hour shift. The increased analysis speed is enhanced by automatic consistency adjustment, allowing samples to be inserted without any special preparation, effectively eliminating operator error.

* The analyzer is individually customizable, equipped with only the selected measurements and easily programmable for customized analysis and reporting.

* The fiber dimension results from the analysis are traceable all the way back to the most used standardized length unit in the world - the SI unit.

* Testing on the spot in the laboratory or control room is fast, accurate, reliable and easy with an intuitive touch-screen display.

* Maintenance requirements are minimal, and automatic self-cleaning ensures maximum availability at all times.

* FS5 requires no on-site calibration. Every high definition module is calibrated at Metso's Kajaani production center with an accredited calibration tool.

Metso's comprehensive tissue machine automation solution is geared towards optimum productivity, energy efficiency and product quality

New online measurements and analyses for more stable, productive tissue machine operation

Metso's comprehensive tissue machine automation solution is complemented with newly updated products: furnish analysis and control, machinery condition and process stability diagnosis and high speed web break analysis capabilities.

These newly updated products, together with Metso's integrated quality control, process control and machinery control help tissue makers to achieve high speed process operation and the much sought after stability required for optimum productivity, energy efficiency and product quality. Since Metso's offering is flexible and scalable, cost-effective and grade-specific configurations can be made for each customer's needs

The new capabilities include:

* Metso Pulp Analyzer (Metso MAP) includes a new online microscopic scale fiber fibrillation measurement. With the additional online measurement of freeness and other fiber properties, the analyzer is invaluable for achieving optimum drainage and sheet quality properties. More precise furnish preparation and low consistency refining management provides better sheet runnability and higher machine efficiency. Both Metso MAP and a brand new off-line Metso Fiber Image Analyzer (Metso FS5) use the same HD technology for imaging analysis, thus these two products fullfill nicely Metso's portfolio for fiber furnish measurement solutions.

* Metso DNA Machine Monitoring, embedded within the Metso DNA control system platform, continuously measures and analyzes the mechanical condition of tissue making machinery and processes. Mechanical vibrations, process pulsations and creping blade chatter are detected promptly so corrective action can be taken to ensure stable sheet quality and runnability. In addition, maintenance actions can be made proactively and cost-effectively.

* Metso Process and Quality Vision (Metso PQV), with its new high speed and high resolution cameras, can isolate and define the causes of sheet flaws and breaks, thereby allowing machine operators to avoid their re-occurrence. With the system's high resolution capability, very small flaws and sheet instabilities can be resolved at a web speeds over 2000 m/min.

These new analytical products complement responsive online sheet quality measurements and controls by the Metso IQ quality control system. MD and CD controls of fiber weight and moisture are based on Metso IQ Fiber Weight Measurement - a single infrared sensor which replaces traditional nuclear sensors. Metso was the first automation supplier to introduce this single sensor to the tissue market. In the past year alone 33 have been sold and delivered, joining many others commissioned on new and previously installed quality control systems. The system's measurement and control capabilities include online tissue shade using IQ Web Color Measurement, specially developed for tissue applications.

Metso IQ Dilution Profiler and Metso IQ Steam Profiler provide uniform CD sheet quality. In addition to reducing Yankee air cap drying energy requirements the high heat steam profiler allows significant production increases. To date 30 of these profilers have been installed on tissue machines

Also, as part of a comprehensive automation solution Metso's consistency, retention and furnish charge analyzers and controls stabilize the wet end operation. The charge analyzer, Metso Wet End Analyzer, is particularly valuable for precisely controlling wet end functional additives and ensuring retention and white water fines levels are in balance.

Metso receives repeat order for two complete tissue lines from Hayat Kimya of Turkey

Metso has received a repeat order for two complete tissue production lines for the Turkish Hayat Kimya A.S. Each production line will include an Advantage DCT 200 TS tissue machine, and they will be installed at the company’s new mill sites near the city of Alabuga, Tatarstan, in Russia, and in the city of Mersin in southern Turkey. The start-up of the tissue machine to be installed in Russia is planned for the second half of 2014, and the second tissue machine will start up in Turkey at the end of 2015. The value of the order will not be disclosed.  The order follows the successful start-ups of two similar tissue lines supplied by Metso in 2010 and 2011.The tissue machine located at the mill in Yeniköy near the city of Izmit, Turkey, holds the world record in speed for tissue machines at 2,210 m/min.

The order follows the successful start-ups of two similar tissue lines supplied by Metso in 2010 and 2011.The tissue machine located at the mill in Yeniköy near the city of Izmit, Turkey, holds the world record in speed for tissue machines at 2,210 m/min.

"Metso has been a reliable and trustworthy partner for our previous installations and we are pleased to continue our good cooperation also in this new project," says Lütfi Aydin, Director, Paper Group, Hayat Kimya.

“We at Metso are very impressed with how Hayat has developed. Only seven years ago they were a newcomer in the tissue industry. Today Hayat is a global player in the tissue market and is also the current holder of the world speed record for tissue machines. The world class results show the strength of our partnership,” says Jan Erikson,Vice President, Sales, Tissue Mills business unit, Metso.

The main part of the order is included in Metso’s Pulp, Paper and Power first quarter 2013 orders received. The automation package is included in Automation’s first quarter 2013 orders received.

Technical information

Metso’s scope of delivery will comprise two complete tissue production lines featuring stock preparation systems and an Advantage DCT 200 TS tissue machine. Each machine will be equipped with an OptiFlo headbox, a Metso Yankee cylinder, an Advantage ViscoNip press, an Advantage AirCap hood prepared for co-generation, an Advantage WetDust dust system, an Advantage Run sheet transfer system and an Advantage SoftReel L reel. The stock preparation lines will consist of OptiSlush pulpers, OptiFiner conical refiners and OptiScreen machine screens.

Furthermore, the delivery will include an extensive automation package with Metso DNA machine and process controls and Metso IQ quality controls. Complete engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

Both tissue machines will have a width of 5.6 m and a design speed of 2,200 m/min. The new lines will have a design capacity of 70,000 tonnes a year of high-quality facial, toilet and towel grades. The raw material for the new lines will be virgin fiber. The production lines are optimized to save energy and to enhance final product quality.

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 140,000 tonnes and a converting capacity of 100,000 tonnes per year. Through the new investment and ongoing projects the total production capacity of Hayat Kimya will reach 350,000 tonnes.

ANDRITZ delivers world’s largest welded Steel Yankee for new paper machine in Pöls, Austria

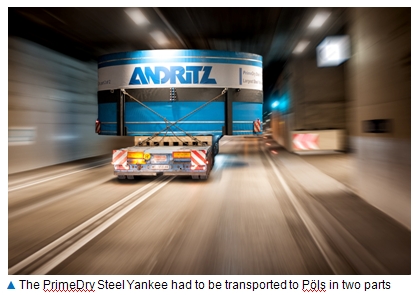

International technology Group ANDRITZ reached an important milestone with the supply of equipment for Europe’s largest kraft paper machine: the PrimeDry Steel Yankee (diameter 6.7 meters, weight 150 t) was successfully delivered to the Zellstoff Pöls AG mill in Austria.

The largest high-precision Steel Yankee in the world was manufactured in two parts for the transport purposes. The Yankee is made entirely of steel, providing higher performance and enhanced safety compared to a cast iron Yankee. It is currently being assembled and welded, and will be lifted into the machine room in June 2013 with a 600 t crane.

ANDRITZ is supplying a PrimeLine paper machine to Zellstoff Pöls for the production of special paper. The new 5.4 m wide machine, with capacity of 80,000 t/a and design speed of up to 1,000 m/min, will produce very high-strength paper grades used for shopping bags, high-grade medical packaging, and food packaging. ANDRITZ’s scope of supply includes the stock preparation plant, an approach flow system, the complete Fourdrinier paper machine, a calender, and the automation systems. Start-up is scheduled for the end of 2013.

With this investment, Zellstoff Pöls – the largest manufacturer of high-quality Elemental Chlorine-Free (ECF) sulfate pulp from bleached softwood in Central and Southeast Europe – is extending its existing paper production capacity. The total investment volume amounts to 115 million euros.

Kemira FennoClean PFA biocide program for efficient and safe microbiological control – conclusions from test trials to be presented at Tissue World 2013

Kemira has developed a new, completely biodegradable biocide concept FennoClean PFA. The novel program is based on a new active performic acid (PFA) which is the fastest and strongest halogen-free oxidizing biocide on the market today. The biocide program is highly effective and corrosion safe, and it leaves no biocidal residuals in the final product, making the product safe for the employees and the environment.

FennoClean PFA has been used in several virgin-fiber based tissue mills across Europe, and the results have been impressive, with excellent and rapid success in microbiological control. In addition, extra benefits have been observed that were not previously reported with other oxidizing-biocide programs.

“Poor felt performance, corrosion on the machine and toxic remains in the end product cause problems to many tissue mills.” says Jaakko Ekman, Sr. Research Scientist, Kemira R&D and Technology. “Kemira has developed FennoClean PFA to overcome these challenges. The trial results make it clear that this technology has the potential to revolutionize microbiological control in tissue mills due to efficacy and cost, as well as environmental, safety and corrosion advantages.”

Conclusions from FennoClean PFA test trials will be presented at the Tissue World Conference 2013 organized in Barcelona, Spain on March 18-21, 2013.

The conference runs with the theme: "Evolution or Revolution: The next steps in sustainable tissue making", and the conference sessions will cover the most important areas of the tissue business. Kemira will be participating in the forum with two interesting and topical presentations:

- "Squeezing more profits out of your sheet using novel and conventional strength technologies" by Vladimir Grigoriev & Roberto Zulian

- "Added Value for Tissue makers via Efficient Chlorine-Free Microbe Control Program" by Jaakko Ekman and James Atkinson

Metso receives repeat order for tissue production line from Syktyvkar Tissue Group, Russia

Metso has once again received an order for a complete tissue production line for Syktyvkar Tissue Group in Russia. The new tissue machine will be installed at the company’s new site in Semibratovo, located some 220 km from Moscow. The start-up of the machine is scheduled for mid 2014. The value of the order will not be disclosed.

The order follows the previous Metso installation of an Advantage DCT 100 tissue machine in 2007 and a major tissue machine rebuild during 2012.

”We consider Metso not only to be a supplier of first-class equipment. Over the years friendly relations have been established and we are happy that our cooperation is going on,” says Mark Reznik, Managing Partner, Syktyvkar Tissue Group.

”We are very pleased that Syktyvkar has ordered their third consecutive major project from us. This is proof that our way of working as partners with our customers is rewarding for both sides,” says Leif Forsberg, Senior Vice President, Sales, Tissue Mills business unit, Metso.

The main part of the order is included in Metso’s Pulp, Paper and Power first quarter 2013 orders received. The automation package is included in Automation’s first quarter 2013 orders received.

Technical information

Metso’s delivery will comprise a complete high-speed tissue production line featuring an Advantage DCT 100 HS tissue machine equipped with an OptiFlo headbox, a Metso cast iron Yankee cylinder and an Advantage AirCap Yankee hood. Metso will also supply stock preparation equipment including an OptiFiner conical refiner, OptiScreen cleaning and screening technology and converting broke equipment.

In addition, Metso’s scope of supply will comprise an electrification package, pumps, agitators, instruments, a vacuum system and white water handling. The delivery will include basic and detail engineering for the new tissue machine and services for installation and start-up of the machine. Furthermore, Metso will supply Metso DNA automation for process, machine and drive controls and Metso IQ quality controls.

The new line will have a width of 2.7 m and an operating speed of 2,000 m/min and it will add another 30,000 tonnes per year of bathroom tissue, napkin and towel grades to the company's existing production.

Syktyvkar Tissue Group is today one of the best known companies on the Russian market for tissue products with a market share of around 10 %. Today the company employs 385 people and produces approximately 45,000 tonnes of tissue. Headquarters and existing production facilities of the company are located in Syktyvkar, capital of the republic of Komi in the northwestern part of Russia.

SCA presents Annual Report and updated logotype

SCA presents its 2012 Annual Report and Sustainability Report on www.sca.com. In recent years, SCA has transformed into a leading, global hygiene and forest products company with a strong and award-winning sustainability profile. In conjunction with this, SCA has decided to modernize its logotype and unveil its look in connection with the publication of the Annual Report.

SCA presents its 2012 Annual Report and Sustainability Report on www.sca.com. In recent years, SCA has transformed into a leading, global hygiene and forest products company with a strong and award-winning sustainability profile. In conjunction with this, SCA has decided to modernize its logotype and unveil its look in connection with the publication of the Annual Report.

For SCA, 2012 was an eventful year marked by change. During the year, SCA carried out some of the largest business transactions in its history, accelerating the Group’s transformation into a leading, global hygiene and forest products company. The acquisition of Georgia-Pacific’s European tissue operations and the sale of the packaging operations were finalized.

“The sale of the packaging operations represented a further step in our journey of change and ensures reduced sensitivity to economic fluctuations and financial opportunities to grow in the hygiene business. In 2012, we continued to prioritize efficiency, innovation and growth and, despite a turbulent global economy, we increased our sales and profits in 2012,” says Jan Johansson, President and CEO, SCA.

In conjunction with the publication of the Annual Report and Sustainability Report, SCA is launching an updated logotype featuring stronger, more distinct colors and softer lines. The communication concept Care of life has been written out to clarify and strengthen the message of how SCA as a company can make a difference for people, nature and society.

“We have chosen to update the SCA logotype to include it in the transformation of our company and to better reflect our business operations,” says Jan Johansson.

The following files are available for download:

At SXSW, Domtar Unveils New, Cutting Edge 'Paper Hotspot'

Say Hello (Again) to Paper - the Original, Wireless, Interactive Communications Platform;

It Offered an Unplugged, Interactive Respite at One of the World's Largest Interactive Festivals

The SXSW Interactive Festival describes itself as "an incubator of cutting-edge technologies and digital creativity," and at the 20th annual show, Domtar Corporation unveiled a wireless venue that made people halt, spurred them to step inside and quickly became one of the most popular features: the Paper Hotspot.

Here's how it worked: In the middle of a tradeshow with flashing lights and loud music to promote new websites, video games and startup ideas, Domtar set up the Paper Hotspot as an oasis. It had comfy couches, a rug, a fireplace and bookshelves filled with books, magazines and sketchpads. People were encouraged to unplug for a moment, to sit down and interact with paper, which some of them did for as long as 30 minutes.

You can see a video of what the Paper Hotspot looked like as well people's interactions with the space here.

"We wanted to be at South by Southwest, because that's where you always see some of the most creative ideas from some of the sharpest minds, and it was interesting to see how people responded to the Paper Hotspot," said Paige Goff, Domtar's Vice President of Sustainable Business & Brand Management. "No matter what people were working on, and no matter how fast they were working, this reinforced the studies that show whether you're an executive or a millennial, people prefer to read on paper and it's faster to read on paper."

The Paper Hotspot comes as part of Domtar's award-winning PAPERbecause campaign (www.paperbecause.com) that showcases the effectiveness and sustainability of paper. The effort has featured a series of satirical videos about the exaggerated pressures to go paperless at the office as well as in our day-to-day lives. The New York Times recently wrote this article about the campaign's latest batch of videos.

"We thought the Paper Hotspot would be a fun, new way to highlight a key message," Goff said. "Even after 2,000 years, paper has a place, even more so in a digital age - it remains a purposeful, personal and environmentally responsible communication medium."

SOURCE DOMTAR CORPORATION

Employees’ ideas save BASF more than €50 million

Making good things even better – that is the recipe for success for both BASF and its employees. Last year, the company implemented nearly 20,000 suggestions for improvement from employees worldwide and as a result saved more than €50 million. BASF rewarded the inventive spirit and innovative power of the people behind the ideas with bonuses totaling more than €4.2 million. “Successful idea management enables us to increase our competitiveness and optimize our work processes. The improvements also often make an important contribution to promoting occupational safety and protecting health and the environment. These achievements are a credit to our employees, and we would like to extend our heartfelt thanks for their dedication,” said Margret Suckale, Member of the Board of BASF SE.

With a total of 7,000 ideas put into practice, employees of BASF SE at the Verbund site of Ludwigshafen saved the company just under €30 million in 2012. Thanks to just one idea from three employees who work at a solvent production plant, namely August Sadowski, Udo Storck, and Willi Haag, BASF saves more than €2.5 million per year. Their proposal was to rebuild the air cooler in the plant in such a way that the production capacity can be fully utilized even under high outside temperature conditions. This had previously not been possible due to insufficient levels of cooling and condensing. Now, BASF can meet the high demand for solvents in summer as well, and these employees are pleased to receive a record bonus totaling €170,000.

Idea management has become an integral part of the culture of innovation at BASF. The inventiveness of the company’s employees is clear from the numbers: In 2012 they submitted nearly 38,000 new suggestions for improvement.

UPM wins Sustainable Biofuels Award in Rotterdam

UPM has received the Sustainability Award 2013 for Breakthrough Innovation in Technology in Rotterdam, the Netherlands. The award which recognises the innovation that is taking place in the development of truly sustainable and renewable fuels is presented by the World Biofuels Markets Congress & Exhibition.

UPM Biofuels received the Sustainable Biofuels Award due to its success in developing an innovative production process for an advanced renewable diesel, UPM BioVerno. So even before it goes live, UPM’s renewable diesel production process has won a major international prize.

The award was judged by an elite panel of independent industry experts. According to reasoning, UPM was the winner of the Breakthrough Innovation in Technology Award because of the UPM BioVerno product characteristics corresponding to traditional fuel with the greenhouse gas emissions being reduced by up to 80%.

Event Director Claire Poole commented: “The Sustainable Biofuels Awards recognise the tremendous innovation that is taking place in the development of truly sustainable and renewable fuels, and the key success factor of this novel drop-in fuel is sustainability. The feedstock is wood-based, non-food origin with no indirect land use change. A truly sustainable achievement.”

“During the last few years we have made progress with remarkable R&D work and important investments for developing wood-based biofuels. UPM aims to become a major player in advanced biofuels so this recognition confirms that we have managed to make significant progress in this field,” says Petri Kukkonen, Vice President of UPM Biofuels Business.

Driving lower emissions with UPM BioVerno

UPM BioVerno is a high quality transport fuel that works well in modern vehicles and is fully compatible with existing fuel distribution systems. UPM BioVerno has been tested for its properties, functionality, and emissions in various laboratories including VTT (Technical Research Centre of Finland) and FEV (Forschungsgesellschaft für Energietechnik und Verbrennungsmotoren GmbH) in Germany.

Furthermore, UPM BioVerno decreases greenhouse gas emissions significantly. The greenhouse gas reduction of approximately 80% is calculated for the whole lifecycle taking into account all energy used in the plant and utilities used in production.

UPM BioVerno is produced from crude tall oil (CTO), which is a residue from the chemical pulping process. The main phases of the process are pretreatment of crude tall oil, hydrotreatment, recycle gas purification, and fractionation. Converting CTO to biofuel is an innovative way to use that residue without changing the main process, which is pulp production. This method makes additional use of an existing UPM residue, and also avoids any raw materials that could be used for food production.

“Coming from the forest industry we benefit from our profound experience in forest biomass and extensive resources that can be used effectively for developing biofuels business and executing large scale biofuel projects,” says Heikki Vappula, President of the Energy and Pulp Business Group in UPM.

Currently, UPM is building a hydrogenation biorefinery on its Kaukas paper and pulp mill site in Lappeenranta, Finland. The biorefinery will produce 100,000 tonnes of renewable diesel for transport, equating to 120 million litres annually. The investment of EUR 150 million is the first industrial scale investment in this field globally. Site construction will be completed in 2014.

The World Biofuels Markets Congress & Exhibition 2013 is Europe's largest congress and exhibition focused on biofuels. The annual Sustainable Biofuels Awards were yesterday presented to winners at a special ceremony during the annual World Biofuels Markets in Rotterdam, The Netherlands.