Ianadmin

Pro-Gest awards Kemira with a start-up contract at a green field board machine in Mantova, Italy

Kemira has been awarded a start-up contract at Pro-Gest Mantova in Italy, the only green field containerboard machine in Europe in recent years. Kemira will supply the start-up with all water treatment and wet end chemistries in line with its Total Chemistry Management (TCM) concept. The contract is signed for three years. The start-up of the machine is scheduled for the second half of 2017, and the production capacity will be 550,000 tons of high-quality lightweight recycled board.

"Kemira is proud to have the opportunity to participate in the new Pro-Gest Mantova board machine start-up", says Kimmo Strengell, Marketing Manager, Strength Products, Export Manager, Kemira Pulp & Paper EMEA. "Our TCM model makes chemistry management carefree in all different phases of the mill lifecycle – from start-ups and conversions to day-to-day operations. With our expertise, service capability and broad portfolio of board making chemistries, we are able to support Pro-Gest in reaching the desired quality and productivity targets of the new board grade.”

"Kemira is proud to have the opportunity to participate in the new Pro-Gest Mantova board machine start-up", says Kimmo Strengell, Marketing Manager, Strength Products, Export Manager, Kemira Pulp & Paper EMEA. "Our TCM model makes chemistry management carefree in all different phases of the mill lifecycle – from start-ups and conversions to day-to-day operations. With our expertise, service capability and broad portfolio of board making chemistries, we are able to support Pro-Gest in reaching the desired quality and productivity targets of the new board grade.”

“We are convinced that Kemira is the most capable partner for Pro-Gest to handle the chemistry on the board machine during the start-up period”, says Francesco Zago, General Manager and shareholder of Pro-Gest. “The whole team is very excited about the close cooperation in this high capacity and high quality board machine start-up.”

Pro-Gest is Italy’s leading vertically integrated producer of packaging in corrugated board, active in all fields, from the collection of raw materials to packaging production. It operates in 8 Italian regions with 22 production sites, employing over 1,100 people. In 2016 Pro-Gest generated a consolidated annual turnover of EUR 435 million.

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' product quality, process and resource efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2016, Kemira had annual revenue of around EUR 2.4 billion and 4,800 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd. www.kemira.com

A Valmet supplied demonstration scale plant for second generation sugar extraction officially opened at Sappi Ngodwana Mill in South Africa

In 2016 Sappi and Valmet agreed on a joint development project to deliver a demonstration plant to Sappi Ngodwana Mill in South Africa in order to explore and optimize the extraction of biorenewable chemicals.

The demonstration plant was officially opened on April 5, 2017. Guests from all over the world participated in the opening ceremony which included speeches from Sappi and Valmet management representatives.

The event was opened by Alex Thiel, Chief Executive Officer of Sappi Southern Africa and followed by SW Engelbrecht, General Manager Sappi Ngodwana Mill, who gave a mill perspective. Bertel Karlstedt, Business Line President Pulp and Energy, Valmet, highlighted the good cooperation between Sappi and Valmet and finally Luis Kruyshaar, leader of Sappi Biotech division, introduced the biotechnology concept.

"The plant continues Sappi's strategic move into the biomaterials and bio-energy business fields to extract more value from the production processes and in response to the global demand for renewable materials with a lower carbon footprint," commented Andrea Rossi, Group Head Technology from Sappi.

"The development of solutions to replace fossil materials with renewable ones and to produce new high-value end products is one of Valmet's research and development focus areas. This project is a concrete example of new opportunities. By working together, we have been able to combine Valmet's leading technology knowledge with Sappi's process and market insight," said Bertel Karlstedt, Business Line President, Pulp and Energy from Valmet.

"New revenue opportunities include possibilities to extract biobased materials from the cooking plant such as hemicellulose sugars and lignin for beneficiation to higher value biochemicals. The products under development will expand Sappi's renewable biomaterials offering which include nanocellulose, biocomposites and lignosulphonate," said Louis Kruyshaar, leader of the new Sappi Biotech division.

The plant is close to industrial size and makes it possible to study the next generation dissolving cooking process and test new ideas in mill scale.

Information about the customer Sappi

South African headquartered Sappi is a leading global producer of dissolving wood pulp and graphics, speciality and packaging papers. The company uses research and development to drive product innovation and to develop new uses for wood fiber, biomass and other residues from its production processes. One such area of investigation is in the field of biomaterials (nanocellulose and lignins), biochemicals and bio-energy forest products materials.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

James Cropper brings tailor made to the big apple

British master papermaker James Cropper is ramping up its presence across the pond with the launch of its Tailor Made service at this year’s Luxe Pack New York exhibition.

Attendees at the event, which takes place on 10 and 11 May 2017, will be able to delve further into the company’s Tailor Made service, which has been launched to allow brands to develop unique, custom-made paper solutions for brand presentation and packaging.

Susan Wilson, group packaging director at James Cropper, said: “We’ve always focused on creating personalised solutions for brands but now, with Tailor Made, we’re taking our bespoke service to a new level – and we’re sure it will be well received in a city as stylish as New York. With a wealth of experience in the world of premium and luxury, we’re very aware of how important it is for luxury brands to stand out and express their individuality through their packaging, and we’re here to work closely with them to facilitate that.”

The Tailor Made service offers a wide range of bespoke solutions, with clients able to choose everything from the individual fibres used to make paper to the ways they’re engineered, coloured, embossed and converted. For example, beautiful shades of unusual and tactile paper finishes can be developed for a sophisticated impression.

Retailers looking to boost their environmental credentials are expected to be impressed with James Cropper’s policy of all fresh fibre being sourced from sustainably managed forests, as well as its use of ingredients such as coffee cup fibre or post-consumer waste.

James Cropper has been carefully stewarded and nurtured by six generations of the Cropper family from its historic home in the English Lake District, and is renowned globally for its expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

Ivan Iannetta, packaging industry expert and USA sales manager at James Cropper, said: “The Tailor Made service allows clients to focus on their vision and let their imaginations run wild, enabling them to tell their story through paper and packaging. We bring these ideas to life, using the experience, tools and expertise we’ve developed over almost two centuries.

“Our rich papermaking know-how and capability, combined with an innovative approach and superior craftsmanship, mean that the creative possibilities of such a versatile product are virtually endless. The result is a truly custom-made and sustainable paper that perfectly complements and elevates a brand’s offering.

“James Cropper takes great pride in producing papers with a difference, unique to each brand. Combining our world-leading skills in colour-matching and post-production capabilities – such as embossing, laminating and coating – enables us to create papers for an extensive range of retail applications across presentation boxes, retail display, luxurious packaging and beautiful bags.”

Vincent Villeger, a creative consultant for the luxury packaging sector, said: “Uncoated, coloured papers provide an understated, warm and tactile feel, also allowing for maximum contrast against metallic foils. I consider them an essential component of brand consistency, and an integral part of the luxury packaging experience, which is why I try to use them whenever the project allows.

“Throughout my career, I have had the opportunity to develop many bespoke shades – a real treat for any designer – and in order to justify the decision to develop a bespoke paper, the results must be nothing short of perfectly accurate and consistent. James Cropper understands this and, thanks to the dedication of their teams and their collaborative approach, they have always been able to deliver to my high standards.”

To find out more about the ‘Tailor Made’ service, visit James Cropper at Stand B116.

About James Cropper

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

About Technical Fibre Products (TFP)

As well as paper products, James Cropper plc also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

About James Cropper 3D Products

With James Cropper 3D Products, James Cropper plc has created the next generation of sustainable moulded paper packaging. Available in a wide variety of colours and with a naturally tactile finish, the product has a clear focus on quality and is design-engineered to suit all packaging needs. Features to improve product value and packaging integrity, such as personal embossing, natural hinges and cut-outs, enhance brand impact. All packaging products are recyclable and made from 100 per cent renewable natural fibres.

For further information visit: www.jamescropper.com , www.jc3dp.com and www.tfpglobal.com.

BillerudKorsnäs first quarter impacted by spillover from previous production problems during 2016

BillerudKorsnäs first quarter results are negatively impacted by quality costs emanating from production during the second half of 2016 and start-up costs for the Rockhammar re-build late 2016. Operating profit for the first quarter is estimated to amount to approximately SEK 550 million.

"It is both unexpected and frustrating that we have to take these one-off costs in an otherwise positive development. Production is delivering to expectations. Production volumes were the highest ever in a single quarter, and sales, especially for Consumer Board, is showing better than anticipated growth. The market trends for Packaging Paper and Corrugated Solutions are also very strong at the moment so looking beyond these two issues it actually looks pretty good”, says Per Lindberg, President & CEO.

"It is both unexpected and frustrating that we have to take these one-off costs in an otherwise positive development. Production is delivering to expectations. Production volumes were the highest ever in a single quarter, and sales, especially for Consumer Board, is showing better than anticipated growth. The market trends for Packaging Paper and Corrugated Solutions are also very strong at the moment so looking beyond these two issues it actually looks pretty good”, says Per Lindberg, President & CEO.

The extra costs for the quality problem and the re-build amount to approximately SEK 80 million. There is also a timing issue between Q1 and Q2 for costs related to the maintenance shutdown in Gruvön where approximately SEK 15 million more than previously guided is taken in Q1, this will reduce Q2 impact with SEK 10 million compared to previous guidance. Additional SEK 10 million impact the result negatively due to reassessment according to IAS16 and relates to costs for moving and education in the restructuring project in Skärblacka. This will impact the full-year results with approximately SEK 45 million and hence reduce the capex with the same amount.

The results are still preliminary and have not been reviewed by the auditors.

BillerudKorsnäs will publish its first quarter report for 2017, on April 20, 2017 at 07:00 CET.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4 300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

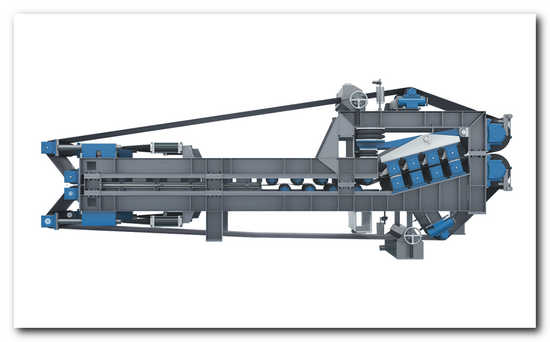

ANDRITZ to upgrade wet lap plant for Thai Paper

International technology Group ANDRITZ has received an order to upgrade the wet lap plant of Thai Paper Co., Ltd. at its Wangsala pulp mill in Kanchanaburi, Thailand. Start-up is scheduled for July 2017.

ANDRITZ will supply major components for an upgrade of the 2.4 m wide ANDRITZ twin wire press, installed in 1990 and used in a wet lap application. The scope of supply includes the following:

- Rebuild to floating wedge zone

- Grooved stainless steel pre-press rolls

- Newly designed split press roll system

- Pressure loading device for the drive rolls

- New drive system

ANDRITZ will upgrade the twin wire press at Thai Paper’s wet lap plant, Wangsala mill. Photo: Andritz

ANDRITZ will upgrade the twin wire press at Thai Paper’s wet lap plant, Wangsala mill. Photo: Andritz

The ANDRITZ delivery also comprises erection work supervision and start-up of the plant.

Thai Paper is part of the packaging business section of the Siam Cement Group (SCG). The company is a leading manufacturer of high-quality packaging papers in Thailand and the biggest manufacturer of these paper grades in Southeast Asia. SCG Packaging has manufacturing locations in Thailand, Vietnam, the Philippines, Singapore, and Indonesia and generates annual sales of around 1.9 bn. euros.

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

Hygienic Tissue successfully starts up a Toscotec-supplied tissue machine at its Pietermaritzburg plant, in South Africa.

On 4th April, the South African tissue producer Hygienic Tissue started up their new MODULO-PLUS tissue machine supplied by Toscotec.

With an annual production capacity of 27,000 tonnes, the unit will increase the total mill’s production capacity by threefold. Hygienic Tissue provides its customers with a wide range of products for hygienic use and AFH market, made from 100% virgin pulp as well as from recycled paper.

Based on an intensive energy-saving concept, Toscotec’s scope of supply included the approach flow system, featuring the ultimate TT SAF® technology, a MODULO-PLUS tissue machine with single-layer headbox, single press configuration and TT SYD-12FT with TT Milltech-MYH (Monosystem gas heated hood), Turbo Blower and Core Extraction unit. The supply also included an electrification and controls package and the steam & condensate system. Toscotec’s TT WIND-P tissue slitter rewinder completed the scope of supply.

Based on an intensive energy-saving concept, Toscotec’s scope of supply included the approach flow system, featuring the ultimate TT SAF® technology, a MODULO-PLUS tissue machine with single-layer headbox, single press configuration and TT SYD-12FT with TT Milltech-MYH (Monosystem gas heated hood), Turbo Blower and Core Extraction unit. The supply also included an electrification and controls package and the steam & condensate system. Toscotec’s TT WIND-P tissue slitter rewinder completed the scope of supply.

The excellent cooperation between Toscotec and Hygienic Tissue has allowed the South African tissue maker to achieve immediately high quality tissue paper, optimizing the production cycle, both in terms of performance and energy saving.

Hygienic Tissue Mill plays an important role in the South African tissue market, producing higher value disposable paper products, including toilet tissue, napkins, towels, facial and jumbo rolls. Since 2000 the company has been investing in state of the art manufacturing machinery. This is the first MODULO-PLUS tissue machine installed by Toscotec in South Africa and increases Hygienic Tissue Mill's capacity to make it the largest independent producer of Tissue in South Africa.

Toscotec S.p.A.

Leader in innovative solutions, Toscotec is the ideal partner for the tissue and paper industry. Since 1948 it designs and manufactures technological solutions for the world’s major paper industries: from complete production lines to rebuilds and upgrades, to individual components. With a global presence and a strong service offer, the company aspires to be a reference for its customers, distinguishing itself for quality and reliability.

Center of excellence in the production of TT SYD, the company stands for tradition of innovation, manufacturing quality and energy savings. Toscotec is market leader in the sale of tissue machines.

Valmet to supply process automation and quality control systems to Jiangxi Taison Paper's four tissue machines in China

Valmet will supply Valmet DNA automation systems and Valmet IQ quality control systems to Jiangxi Taison Paper's four new tissue machines, TM7, TM8, TM9 and TM10, at its greenfield mill in Jiujiang, Jiangxi Province, China. By installing Valmet's advanced automation technology in these tissue machines, the mill will be able to optimize machine performance and end-product quality.

The order is included in Valmet's first quarter 2017 orders received. The value of the order will not be disclosed. Typically, the order value of these kinds of automation system deliveries ranges from below one million to three million euros.

The order is included in Valmet's first quarter 2017 orders received. The value of the order will not be disclosed. Typically, the order value of these kinds of automation system deliveries ranges from below one million to three million euros.

"Valmet is one of the top suppliers for the Chinese pulp and paper industry. The company has very good tissue machine and automation technologies, wide experience and many successful references in China. It's also very important for us that Valmet has a professional local service team close to us. We trust in Valmet," says Wu Jianxiong, General Manager, Jiangxi Taison.

"Jiangxi Taison can count on highly efficient project management, on-time delivery and a successful startup when working with Valmet. Our proven technology for tissue making, such as non-nuclear measurements and the reliable Valmet DNA platform, will enable the mill to succeed and move its performance forward," says Andy Zhang, Area Sales Manager, Valmet.

Information about Valmet's delivery

Valmet's delivery will include Valmet DNA distributed control systems (DCS) to control the four tissue machines and Valmet IQ quality control systems (QCS) with scanning measurement sensors.

One of the QCS highlights is Valmet IQ Fiber Measurement, which simultaneously measures fiber weight and moisture. It was specially developed to replace traditional nuclear basis weight sensors. Today, close to 200 sensors are in use on the machines with a furnish that ranges from virgin pulp to 100% recycled fiber. The combination of the two measurements in one sensor - fiber weight and moisture - considerably reduces investment and life-cycle costs as well as eliminates the need for nuclear licenses, safety training and handling procedures.

About the customer Jiangxi Taison

Jiangxi Taison Paper Ltd., a subsidiary of Taison Group, is located in Jiujiang, Jiangxi Province. It will build a new plant with an annual production capacity of 480,000 tons of tissue paper. The new hygiene product lines will be capable of making 1.8 billion sanitary pads and diapers per year.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet and Solar Turbines establish cooperation agreement to share expertise and experience

Valmet and Solar Turbines Incorporated (a Caterpillar company) have agreed to cooperate with a view to further develop integrated gas turbine cogeneration systems for the tissue industry. The target of the joint development of the energy optimizing systems is to contribute to the reduction of tissue mills' production costs and improve the energy efficiency of the production process.

Valmet and Solar Turbines share a long history in the development of cogeneration systems for tissue customers. Ever since the 1990s, the companies have been jointly working on the integration between cogeneration gas turbines and hood air systems for the tissue drying process. In 2016, a cooperation was established with Solar Turbines' Power Generation business unit and its subsidiary Turbomach to further enhance these solutions.

Valmet and Solar Turbines share a long history in the development of cogeneration systems for tissue customers. Ever since the 1990s, the companies have been jointly working on the integration between cogeneration gas turbines and hood air systems for the tissue drying process. In 2016, a cooperation was established with Solar Turbines' Power Generation business unit and its subsidiary Turbomach to further enhance these solutions.

"The development cooperation between Valmet and Solar Turbines aims at providing the tissue producers with the ultimate integration of a cogeneration system to a tissue machine taking into account the different customer needs and the energy market where the tissue production is located" says Paolo DellaNegra, Sales Manager, Sales Department, Tissue Business Unit, Valmet.

"The target of the Valmet - Solar Turbines agreement is to introduce a game changer in the tissue mill energy management bringing together the best in class of tissue production and power generation" says Benoît Fécamp, Paper & Tissue Market, Global, Market Development, Power Generation, Solar Turbines.

Over the years, Valmet and Solar Turbines have been working on developing and optimizing integrated gas turbine cogeneration to tissue production and delivering the system worldwide. Integrated gas turbine cogeneration has been successfully applied to conventional and textured tissue production processes.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

www.valmet.com, www.twitter.com/valmetglobal

Headquartered in San Diego, California, USA, Solar Turbines Incorporated, a subsidiary of Caterpillar Inc., is one of the world's leading manufacturers of industrial gas turbines, with more than 15,000 units and over 2 billion operating hours in over 100 countries. Solar Turbines' products include gas turbine generator and compressor sets (ranging from 1 to 22 megawatts).

www.solarturbines.com/, http://www.linkedin.com/company/solar-turbines

Yokogawa delivers next-generation plant network solution to the Oji Group

–First plant-wide implementation of software-defined networking (SDN) technology in Japan–

Yokogawa Electric Corporation announces that its subsidiary, Yokogawa Solution Service Corporation, has completed the installation of a software-defined networking (SDN) solution at four paper plants in Japan that are operated by group companies of Oji Holdings Corporation (the Oji Group). This is the first-ever plant-wide implementation in Japan (based on a March 2017 Yokogawa market survey) of SDN, a software-based technology that enables the creation of virtual network environments. As part of this undertaking, Yokogawa assessed the company’s IT infrastructure, including its existing networks, and designed and deployed SDN-based networks at these facilities.

With conventional plant networks, network devices (i.e., routers, firewalls) must be installed and configured for each individual application, location, and facility. The software-based SDN technology enables flexible implementation of virtual networks for each individual application, linking network devices using the same physical network. This facilitates the integrated management, implementation, and reconfiguration of networks. Also, this helps to reduce the required number of network devices and the amount of wiring that needs to be performed, saving both operating and management costs. Furthermore, the visualisation of network status leads to enhanced security. Problems can be easily identified, and network operators can remotely shut down specific segments of the plant network in the event of an emergency.

With conventional plant networks, network devices (i.e., routers, firewalls) must be installed and configured for each individual application, location, and facility. The software-based SDN technology enables flexible implementation of virtual networks for each individual application, linking network devices using the same physical network. This facilitates the integrated management, implementation, and reconfiguration of networks. Also, this helps to reduce the required number of network devices and the amount of wiring that needs to be performed, saving both operating and management costs. Furthermore, the visualisation of network status leads to enhanced security. Problems can be easily identified, and network operators can remotely shut down specific segments of the plant network in the event of an emergency.

Yokogawa won this order because the customer highly valued its solid track record in delivering production control systems, wealth of production site knowledge, and experience in providing solutions that lead to enhanced productivity, safety, and product quality.

For this project, Yokogawa chose to use a proven SDN network device solution, NEC Corporation’s UNIVERGE PF series of controllers and switches. While minimising impact on plant operations is usually difficult when replacing IT infrastructure, Yokogawa was able to do this by leveraging its abundant experience and knowledge of production sites. At each of this customer’s plants, Yokogawa assessed their IT infrastructure, including existing networks, and based on this assessment then designed and deployed its SDN technology solution.

Yokogawa is also providing on a trial basis a security management service that monitors the status and health of the networks throughout these plants. While enabling timely preventive measures that help to maintain the health of the networks in these plants, this service also ensures that prompt actions can be taken in the event of an emergency.

In plants around the world, there is an increasing need to improve productivity, safety, and maintenance efficiency, and this is being achieved through the introduction of Industrial IoT (IIoT) technology. Networks help to create new value by connecting various types of devices, but it is essential to be able to flexibly change their configuration, quickly respond to surges in data volume, and ensure more secure operations. For the optimal implementation of IIoT technology, attention is now increasingly turning to the use of SDN technology in plant IT infrastructure. This also will help company IT departments manage the IT infrastructure at their plants in a more integrated manner.

Capitalising on its production site know-how, Yokogawa will continue in its endeavors to introduce SDN and other cutting-edge technologies that will enable the realisation of smarter plant IT infrastructure.

About Yokogawa

Yokogawa's global network of 114 companies spans 59 countries. Founded in 1915, the US$3.7 billion company engages in cutting-edge research and innovation. Yokogawa is active in the industrial automation and control (IA), test and measurement, and aviation and other businesses segments. The IA segment plays a vital role in a wide range of industries including oil, chemicals, natural gas, power, iron and steel, pulp and paper, pharmaceuticals, and food. For more information about Yokogawa, please visit http://www.yokogawa.com

About Yokogawa Europe B.V.

The European headquarters of Yokogawa were founded in Amersfoort in the Netherlands in 1982. Throughout Europe Yokogawa has its own sales, service and engineering operations. This dedicated network has been extended to Central and East Europe to further enhance the coverage and support associated with serving the process control and automation market place. Yokogawa develops and produces flowmeters at Rota Yokogawa in Germany and liquid analysers and industrial safety systems in the Netherlands. In addition to this dedicated network of Yokogawa subsidiaries, a select organisation of Test & Measurement (T&M) subsidiaries and distributors is established in certain areas to support the specific customer needs of this continuously developing and specific market of T&M instrumentation.

WEPA starts up the new AHEAD-2.0S PM21 tissue machine at its Piechowice plant in Poland.

WEPA group, based in the Westphalian city of Arnsberg, announces the successful start-up of the new Toscotec’s 32,000 tpy tissue line installed at Piechowice Mill, Poland. The machine went easily in operation on 9th February, eleven months after the beginning of the works and six days in advance of the official scheduled start-up.

Following the almost twenty-year partnership in supplying new tissue machines, equipment and services for several well-known WEPA’s projects, the Italian manufacturer Toscotec was chosen to be the right supplier for the new plant again. The Toscotec turn-key delivery includes a stock preparation system for virgin pulp and brokes, an AHEAD-2.0S tissue machine equipped with TT SYD-15FT and all auxiliaries, electrification & control system. Full engineering, erection, erection supervision, training, start-up and commissioning were also included in the scope of the supply.

The new machine has a width of 2.8 m and will run at a maximum speed of 2,000 m/min, producing, among the other grades, super soft toilet paper from virgin pulp as well as recycled fibre as a raw material.

The new paper machine is already working efficiently, in particular from an energy point of view, and contributes in reducing the ecological footprint of the WEPA Group by reducing CO2 emissions.

The new project will allow the WEPA to optimize the existing logistics structures of all European sites, thus enhancing the competitiveness of the entire group.

ABOUT WEPA _ The WEPA Group, which is based in Arnsberg (NRW), Germany, is a family business which manufactures high quality tissue paper. With 11 plants in Europe, WEPA produces toilet paper, kitchen roll, pocket tissues, cosmetics tissues, serviettes, industrial rolls and paper towels. www.wepa.de