Ianadmin

A.Celli Paper: A new rewinder for Sonoco Alcore.

Sonoco Alcore, a major player in terms of high quality, innovation and added value in the production of cardboard tubes and cores, has confirmed the supply of a paper rewinder from A.Celli Paper.

Sonoco Alcore is part of the international group Sonoco, retained among the most representative, dynamic and innovative global providers of consumer packaging, industrial products, protective packaging and supply chain services.

The choice of A.Celli Paper as supplier of this paper rewinder earmarked for the Ciriè facilities, a town in the province of Turin (Italy), is the latest of many professional satisfactions for the Lucca company, part of the Celli Group. A renewed trust that rewards A.Celli Paper’s work and commitment aimed at developing high performance technology, flexible at the same time, flanked by continuously available, excellent service.

Together with the rewinder model AC842 in a format of 2700 mm and a production speed of 1200 m/min, the order also includes a complete product handling system (overhead crane – wagon – conveyor belts). Start-up at Sonoco Alcore’s Ciriè Paper Mill is scheduled for September 2016.

Sonoco Alcore

Sonoco Alcore delivers tube and core solutions and services to customers in the paper, film, man-made fiber yarn, metal and construction industries. Understanding the importance of tube and core products in the production process and delivering solutions and services that meet customers’ needs is one of the company’s strongholds. With a sales and technology group dedicated to every specific market, Sonoco Alcore possesses the knowledge and capabilities to identify and solve any issues.

Sonoco Alcore is part of Sonoco, a global provider of consumer packaging, industrial products, protective packaging and supply chain services. Sonoco Alcore is the acknowledged leader in high-quality, innovative, value-creating tube and core solutions.

Improved performance for Voith press felts thanks to PeakElement technology

PeakElement, the elastomer component developed by Voith and available for all Voith press felt designs, improves the efficiency of machines for all paper grades. The new material reduces startup time and energy consumption.

- Shorter startup time

- Energy savings

- Improved machine efficiency

The elastomer component is integrated into the felt structure and ensures that the felt achieves the optimum saturation in the nip as quickly as possible. This is necessary to obtain the ideal hydraulic pressure in the press nip and enable appropriate dewatering. As press felts with PeakElement technology compress up to 15 % more than standard felts, the functional saturation is achieved within a much shorter period. As a result, the startup time for the paper machine is noticeably reduced and the actual production speed is reached sooner.

The rebound capacity of the press felt is also crucial for performance over the entire service life. The elastomer component prevents a lasting deformation of the material – even after over two million revolutions. This means that the flow of water is guaranteed and the machine efficiency is continuously maintained.

PeakElement technology has already proven effective in numerous paper machines producing all grades of paper. Along with the shorter startup times and lower energy consumption, paper manufacturers have also opted to switch to PeakElement technology because of the higher production volume it offers.

About Voith Paper

Voith Paper is a Group Division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

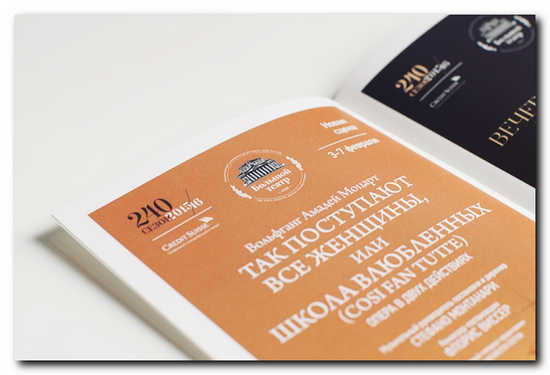

Mondi’s PERGRAPHICA® paper on centre stage with the Bolshoi Theatre

All promotional materials of Russia’s premier theatre now printed on PERGRAPHICA®

The Bolshoi Theatre of Russia has chosen Mondi’s PERGRAPHICA® design paper for all its printing needs. Launched in 2015, PERGRAPHICA® is the first collection of design papers offered by Mondi that is targeted specifically for the exacting needs of the creative and commercial print industries. The name, derived from Latin, means “the most exquisite.” PERGRAPHICA® is Mondi’s ‘Paper for Perfectionists’, combining unique printing properties and brilliant colour reproduction.

“The paper we have chosen for the Bolshoi programs reflects how we interact with the audience. Here, PERGRAPHICA® is a unique paper. It does not only share emotions, visualize images and promote creativity and inspiration, but enhances the status and highlights the best traditions of the theatre as well. The paper proves perfect in printing, aside from its splendid performance. This is truly the paper for perfectionists! With PERGRAPHICA® we never doubt the result,” said Yury Tikhonov, Director of the Bolshoi Theatre printing house.

“Mondi is greatly honoured to cooperate with the Bolshoi theatre. PERGRAPHICA® incorporates professionalism and sophistication, being a good match for offset and digital printing. We are really pleased that the number of customers being inspired by PERGRAPHICA® continues to grow. It speaks volumes about its high demand on the market,” said Johannes Klumpp, Marketing & Sales Director, Mondi Uncoated Fine Paper.

PERGRAPHICA® offers a variety of options: Two textures (Rough and Smooth), three shades (High White, Classic White and Natural) and six grammages between 90 and 300 g/m2. The paper can provide a soft, velvety feel for an elegant look and feel with PERGRAPHICA® Smooth, or a more open, coarse surface for a pure, natural effect with PERGRAPHICA® Rough.

PERGRAPHICA® is produced exclusively in Mondi Neusiedler, an ISO 14001-certified mill and is FSC® and EU Ecolabel certified, underlining its high eco-efficiency and low environmental impact when measured against other paper products. It is a part of our Green Range, the family of Mondi products with a strong environmental profile. PERGRAPHICA® is also the only design paper brand included in the WWF’s ‘Check Your Paper’ resource for third-party audited, environmentally friendly pulp and paper products (checkyourpaper.panda.org).

Double V, the largest distributor and a system integrator for the printing industry, represents PERGRAPHICA® in the Russian market. “PERGRAPHICA® is more than a high-quality designer paper. It has become a strategic collection, which offers the whole range of white shades coming in different weights and textures. We are greatly pleased that The State Academic Bolshoi Theatre of Russia has chosen this particular collection and look forward to further growing our cooperation,” said Ludmila Chekalkina, Marketing and Communications Director, Double V.

We are Mondi: IN TOUCH EVERY DAY

At Mondi, our products protect and preserve the things that matter.

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are located in central Europe, Russia, North America and South Africa. We offer over 100 packaging and paper products, customised into more than 100,000 different solutions for customers, end consumers and industrial end uses - touching the lives of millions of people every day. In 2015, Mondi had revenues of €6.8 billion and a return on capital employed of 20.5%.

The Mondi Group is fully integrated across the packaging and paper value chain - from managing forests and producing pulp, paper and compound plastics, to developing effective and innovative industrial and consumer packaging solutions. Our innovative technologies and products can be found in a variety of applications including hygiene components, stand-up pouches, super-strong cement bags, clever retail boxes and office paper. Our key customers are in industries such as automotive; building and construction; chemicals; food and beverage; home and personal care; medical and pharmaceutical; packaging and paper converting; pet care; and office and professional printing.

Mondi has a dual listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc, under the ticker code MNDI.

For us, acting sustainably makes good business sense and is part of the way we work every day. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is a business unit of Mondi’s Europe & International Division. In 4 paper mills in Austria, Slovakia, and Russia Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

Pankaboard continues to invest into product development

Following on from the recent investment in a new dilution headbox at BM3, Pankaboard’s investment programme has continued, with an upgrade on their BM2 machine, which produces Folding Boxboards, specializing in the heavier weight substances.

In early 2016 the company made a significant investment to up-grade the formation control on BM2 to meet the highest of quality standards. As a result of this new investment the fiber distribution was reengineered and optimized for enhanced smoothness and converting performance.

“Through this targeted investment and dedicated product development we have been able to reach a superior formation that results in several benefits for our customers” says, Petri Saastamoinen, mill manager at Pankaboard.

The result of the development can be seen as outstanding printing quality, an improved surface for lamination, and improved runnability at high speed packaging lines.

The new fiber technology will enable the company to continue the development work in FBB to further optimize the product offering for strategic end uses.

Pankaboard is a global leading producer of special cartonboards with a capacity of 110 000 t/a. The product portfolio consists of high thickness FBB as well as various uncoated speciality boards. The company serves a wide range of end uses, including luxury beverage and food packaging, picture framing, capseals and visual communication.

Further information:

Petri Saastamoinen

Mill manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

+358-40-526 2871

Christer Nordman

Head of product development

This email address is being protected from spambots. You need JavaScript enabled to view it.

+358-40-8396900

Xerium Announces the Promotion of Mr. Robert Burke to the Position of Xerium - President of Asia

Harold Bevis, the President and CEO of Xerium Technologies, Inc., a leading global provider of industrial consumable products and services, has just announced the promotion of Mr. Robert Burke to the position of Xerium - President of Asia.

Mr. Burke will be based in Xerium - Asia headquarters located in Kunshan, China. Mr. Burke will have full responsibility for the Asia region and be responsible for delivering Xerium-Asia’s long-term and short-term business plans while maintaining and strengthening customer relationships.

Mr. Burke will be based in Xerium - Asia headquarters located in Kunshan, China. Mr. Burke will have full responsibility for the Asia region and be responsible for delivering Xerium-Asia’s long-term and short-term business plans while maintaining and strengthening customer relationships.

Harold Bevis said “Xerium has a very successful and growing business in the Asia region and we have significantly increased our competitive position with our strategic initiatives over the past 3 years. We have even bigger plans over the next 3 years. We have a great team and are closely aligned with key customers throughout Asia. Bob will be taking over a great business for Xerium and taking it to the next level. He is a seasoned leader both within Xerium and in the industry with significant strengths and established relationships. He adds a lot to our Asian business and to our top executive team. Bob will shape the team under him, refine the company’s product offerings, expand our production capabilities, and deepen our go-to-market strategies.”

“Xerium is committed to leveraging its customer relationships, best practices and cost optimization across the globe and is an expert at creating value for our customers and we have an arsenal of patented solutions,” continued Mr. Bevis. “Asia is an extremely important market for Xerium and it is imperative that we continue to profitably grow, enhance our lead times and diversify our Asian business.”

Mr. Robert Burke said, “Xerium is a market leader in the region and we are committed to the continued growth of the business while further executing our strategic business plans. It is my goal to ensure alignment with the company’s long-term strategy, address future market demands and opportunities while further developing our strong relationships with critical regional customers.”

Mr. Robert Burke Background Highlights

- 30+ years of sales, operational, development, managerial and executive leadership experience within the industry.

- Seasoned international leader with 20+ years residing and operating in China and the USA.

- Joined Xerium as an Executive leader in 2009. Most recently held the position of Vice President of Sales and Marketing for Xerium – Asia.

- Many years of full P&L responsibility with functional leadership experiences including manufacturing, project management, business development, sales and marketing.

- Experience in establishing and maintain manufacturing and sales operations in China, Malaysia, India, Korea, Japan, Indonesia and Australia.

- Instrumental in the start-up and business development for our Kunshan, China Greenfield operation.

- BS in Industrial Engineering from the University of Massachusetts - Dartmouth

ABOUT XERIUM TECHNOLOGIES

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 30 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

ANDRITZ to supply wet lap plant rebuild to Kimberly-Clark, Germany

International technology Group ANDRITZ has received an order from Kimberly-Clark GmbH to supply components for rebuild of the wet lap plant at its Coblenz mill, Germany. Kimberly-Clark produces pulp from waste paper in Coblenz, which is used to make various sanitary papers. The aim of the rebuild, which is to be completed in December 2016, is to increase the plant capacity and enhance operating reliability.

Twin wire press for pulp dewatering PHOTO: Andritz

The scope of supply includes rebuild of the 1.2 m wide twin wire press and heavy-duty press. A floating wedge zone, a new filtrate drainage design, grooved stainless steel pre-press rolls, a pressure loading device for the drive rolls, and a new drive system are to be installed in the twin wire press. At the heavy-duty press, the frame will be replaced and a new drive system installed. The scope of supply also includes supervision of erection work and start-up.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 24,200 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

Successful start-up of ANDRITZ Papillon refiner at Sofidel, UK

International technology Group ANDRITZ has successfully started up a Papillon refiner for Sofidel in Lancaster, UK. The new LC-refiner is part of a major upgrade project of the stock preparation equipment and tissue machine at Sofidel’s mill in Lancaster.

ANDRITZ Papillon refiner installed at Sofidel in Lancaster, UK Photo : Andritz

The aim of Sofidel's upgrade project was to increase the production capacity of the tissue production line and to improve the final product quality. Both ANDRITZ’ many years of experience in LC-refining and the very short delivery time of just seven weeks were decisive for Sofidel in placing the order with ANDRITZ. The new machine is the fourth Papillon refiner installed in the Sofidel Group.

The ANDRITZ Papillon cylindrical refiner has been successful on the market for 15 years and has proven its fiber development capability in tissue production lines as well as in specialty paper applications. The proven advantages of the ANDRITZ Papillon refiner concept are:

- Improved fiber development when compared with conventional refiners

- Enhanced paper properties and reduced energy consumption for the papermaking process

- Reduction of over 40% in no-load power consumption compared to similar-sized conventional refiners

The Sofidel Group is one of the world market leaders in the production and conversion of tissue paper for hygienic and domestic use, such as toilet paper, napkins, kitchen paper, facials, and handkerchiefs. From its headquarters in Porcari (Lucca), Italy, Sofidel coordinates the activities of 20 companies located in 13 countries throughout Europe and the United States, which produce more than one million tons of paper per year.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 24,200 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

Kuban Papir (Russia) has signed a contract with PMP for TM#1 wet-end rebuild

In May 2016, Kuban Papir, Russia signed a contract with PMP for TM#1 wet-end rebuild. TM#1 will be supplied with state-of-the-art new technological items provided by PMP. The project driving force is a modern technology that ensures energy savings solutions following global trends. Additionally, excellent tissue quality is expected.

The TM of reel trim 2750 mm produces tissue with basis weight range at the reel from 15 to 30 gsm and maximum operating speed of 1000 mpm. As an existing headbox is not efficient enough, a main goal of the project is to ensure higher efficiency of production through applying a modern new Intelli-Jet V® hydraulic headbox. Generally, project goals are focused on TM speed-up to 1500 mpm, capacity increase and tissue quality improvement.

The TM of reel trim 2750 mm produces tissue with basis weight range at the reel from 15 to 30 gsm and maximum operating speed of 1000 mpm. As an existing headbox is not efficient enough, a main goal of the project is to ensure higher efficiency of production through applying a modern new Intelli-Jet V® hydraulic headbox. Generally, project goals are focused on TM speed-up to 1500 mpm, capacity increase and tissue quality improvement.

PMP has been supporting Kuban Papir development since 2009 through deliveries of core technological items. In 2009 Intelli-Reel® was implemented. This time PMP’s scope of delivery includes a single layer Intelli-Jet V® hydraulic headbox of 2850 mm ponside. To ensure proper TM operation PMP will deliver also design engineering for silo and flume reworks. PMP will support Kuban Papir during entire time of the project by executing mill assembly & start-up supervision and operator’s trainings. The start-up is scheduled for the beginning of 2017.

About PMP Intelli-Jet V® Technology:

PMP Intelli-Jet V® Hydraulic Headbox Technology has become iconic – it is today a leading solution in the Pulp & Paper industry. It is a part of PMP Intelli-Paper® platform for papermakers. There are over 140 units working successfully on 6 continents.

About Kuban Papir:

Kuban Papir – was founded in 2003. It one of the largest manufacturing and distributive holding of the paper and hygienic products in the South Russia. Its wide range of products varies from B2B to B2C markets.

About PMP:

PMP – a global provider of tissue, paper & board technology, has been supporting pulp and paper industry for over 160 years, executing projects on 6 continents, in 33 countries. Company with headquarters in Jelenia Góra, Poland, owns 6 facilities in 4 countries (Poland, USA, China, Italy). PMP is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching a new logo & visual identity. (learn more: www.pmpgroup.com)

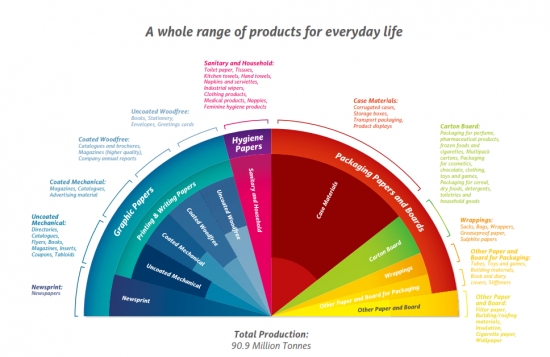

European paper industry: Structural change continues, overall positive performance

In 2015, the European paper industry’s performance in total was second best in the world after China, with a stable production and increased consumption compared to 2014. The packaging sector’s production continued to increase whilst graphic paper (newsprint, printing and writing paper) maintained its recent decline. This and other figures can be found in the Confederation of European Paper Industries (CEPI)’s recently-launched 2015 Key Statistics brochure, which gives a clear picture of the industry’s performance last year. The report includes data on production, consumption and the trade of pulp, paper and raw materials, as well as on energy and environment.

Here are the main highlights of the report:

- CEPI members produced 90.9 million tonnes of paper and board. This corresponds to a slight decrease of 0.2% in 2014 and relative stability over the last three years. The operating rate for 2015 was 91.2%, up from 89.7% in 2014.

- Graphic grades (newsprint, writing and printing paper) represented 38.8% of all paper and board produced in Europe in 2015, packaging grades 49.0%, sanitary and household papers 7.9% and speciality grades 4.3%.

- The overall output performance of CEPI countries in total was slightly better than in most other major traditional paper producing regions of the world, with a fall in production recorded in all regions except China. Paper and board production decreased in Brazil (-0.5%), South Korea (-0.9%), the USA (-1.0%), Japan (-1.0%) and Canada (-7.4%). Production in China rose by 2.3% compared to 2014.

- Consumption rose for the second year in a row by 0.5% compared to 2014, totalling 77.4 million tonnes. The economic recovery observed in the EU28 and the euro area in 2015 - annual GDP increase by 2.0% and 1.7% respectively (source: Eurostat) - had a positive impact on paper and board demand.

- CEPI countries maintained an overall positive paper and board trade balance (exports exceeding imports) of 13.5 million tonnes in 2015, compared to 14.0 million tonnes in 2014.

- Market pulp production fell by 0.7% compared to 2014, with an output of 13.1 million tonnes.

Ernst & Young issued a limited assurance statement on the data quality rating that CEPI carried out on its core indicators in the statistics report. You can download it as well as the Key Statistics report in PDF format from CEPI’s website at www.cepi.org/topics/statistics or request your own paper copy by sending an email to This email address is being protected from spambots. You need JavaScript enabled to view it..

KapStone Acquires Central Florida Box

KapStone Paper and Packaging Corporation (NYSE: KS) has just announced that it completed the acquisition of Central Florida Box (CFB) Corporation located in Lake Mary, Florida.

CFB provides design, graphics, manufacturing, assembly, fulfillment, warehousing and distribution services to over 400 customers ranging from small, family-owned companies to large, national corporations.

CFB provides design, graphics, manufacturing, assembly, fulfillment, warehousing and distribution services to over 400 customers ranging from small, family-owned companies to large, national corporations.

Chairman and Chief Executive Officer, Roger W. Stone, stated, "The acquisition of Central Florida Box enhances KapStone's footprint in the strategic Southeast market. In addition, this acquisition further strengthens our goal of increasing integration, providing additional internal opportunities for our Mill Division and Victory Packaging. We believe this business acquisition is a wonderful fit to our overall business strategy."

Jeff Ramsey, President of Central Florida Box Corporation, stated, "CFB is excited to become a part of the KapStone family. With their Think Big, Act Small philosophy, we believe their goals and values align perfectly with CFB. We will look to expand our footprint in the Florida market and leverage our relationships with existing national customers to grow national accounts for KapStone."

About KapStone

Headquartered in Northbrook, IL, KapStone Paper and Packaging Corporation is the fifth largest producer of containerboard and corrugated packaging products and is the largest kraft paper producer in the United States. The Company has four paper mills, 21 converting plants and 65 distribution centers. The business has approximately 6,300 employees.