Ianadmin

Two new Valmet-supplied tissue lines started up at Hayat Kimya in Turkey and Russia

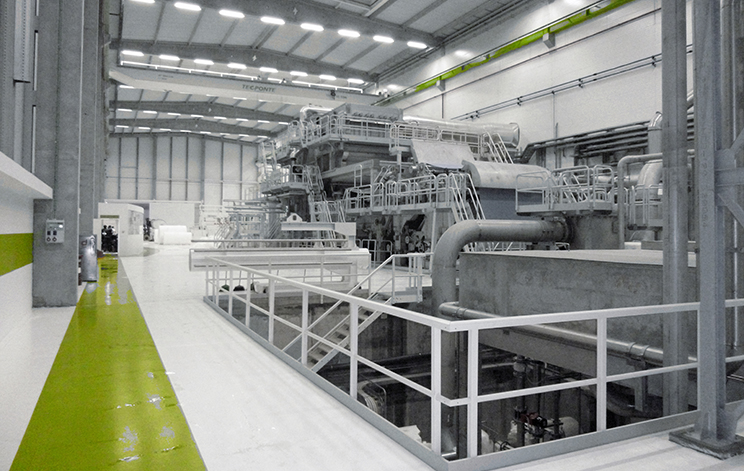

Hayat Kimya's new Advantage DCT 200TS tissue line, PM5, was started up in March 2015 by a joint Valmet and Hayat Kimya team. The new line, at the Mersin mill in Turkey, came smoothly on stream according to schedule and produced sellable paper from the very start.

This was the second start-up for the same team in three months, as Hayat Kimya's PM4 at the new Alabuga mill in Tartarstan, Russia was started up in December 2014. The time schedule was very tight but the paper was on reel as expected with good paper properties.

"This was for most of us, the third and fourth tissue line installation we have started together. During the years we have developed a mutual respect and high confidence in each other, which makes the coordination of the assembly and all commissioning activities very smooth and together we make things happen," says Rolf Tellack, Project Manager, Valmet.

"We share the same excitement with everyone who has contributed with patience and determination to make these projects successful. Even though the conditions were very different between the Russian and the Turkish installations both machines started up on time and are now producing top quality paper at high speed," says Lütfi Aydin, Director Paper Group, Hayat Kimya.

Hayat Kimya has now four tissue lines supplied by Valmet in their machine fleet and one more to start up in 2016. Recently the company announced the rebuild of their PM1 which means that all their tissue lines will be operating with the Advantage DCT technology from Valmet.

Hayat Kimya and Valmet team celebrating the PM5 start-up at the Mersin mill in Turkey

Hayat Kimya and Valmet team celebrating the PM4 start-up at the Alabuga mill in Tartarstan, Russia

Technical information

Both tissue machines have a width of 5.6 m and a design speed of 2,200 m/min. The design capacity for each machine is 70,000 tonnes a year. Both machines will produce high-quality facial, toilet and towel grades from virgin fiber and are optimized to save energy and enhance final product quality.

The two tissue production lines feature stock preparation systems and Advantage DCT 200TS tissue machines. The machines are equipped with OptiFlo headboxes and Valmet cast alloy Yankee cylinders as well as the Advantage technology including ViscoNip press, AirCap hood prepared for co-generation, WetDust sytem, sheet transfer system and SoftReel reel. The delivery also included an extensive automation package with Valmet DNA, process controls and Valmet IQ quality controls. Complete engineering, supervision, training, start-up and commissioning was also included in the delivery.

Information about the customer Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 350,000 tonnes and a converting capacity of 200,000 tonnes per year. Through new investment and ongoing projects the total production capacity of Hayat Kimya will reach 420,000 tonnes.

For further information, please contact:

Björn Magnus, Sales Director, Tissue Mills business unit, Valmet, tel. +46 703 17 79 83

Rolf Tellack, Project Manager, Tissue Mills business unit, Valmet, tel. +46 705 62 75 65

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

ANDRITZ and Metsä Fibre Oy finalized contract to supply key production technologies for the new bioproduct pulp mill in Finland

International technology Group ANDRITZ and Metsä Fibre have finalized the contract to deliver key production technologies for a new bioproduct pulp mill with an annual capacity of 1.3 million tons of pulp in Äänekoski, Finland. The respective letter of intent was signed in early February this year.

The order value for ANDRITZ is over 100 million euros. Start-up of the mill is scheduled for third quarter of 2017. The core equipment supplied by ANDRITZ will originate largely from Finland and thus will have a significant positive employment impact on ANDRITZ’s engineering staff located in Kotka, Lahti and Varkaus as well as on the ANDRITZ workshop located in Savonlinna where a big part of the core equipment for this contract will be fabricated.

“Photo: Metsä Fibre Oy”.

“The bioproduct mill in Äänekoski is the largest investment of the forest industry in Finland. Competence, reliability and successful cooperation in previous large investments were emphasized when we made a decision of the key technology suppliers”, says Ilkka Hämälä, CEO of Metsä Fibre Oy.

ANDRITZ’s scope of supplies includes the core equipment for:

- A complete wood processing plant with three debarking and chipping lines, three stacker-reclaimer chip handling systems, and bark handling. Each debarking line can process both softwood and hardwood and is designed for world record capacities (pine/spruce/birch: 470/350/270 m3 solid-over-bark per hour), and includes a de-icing conveyor, a debarking drum (5 x 48 meter), and the world’s biggest horizontally fed HHQ chipper, ensuring high capacity without compromising the chip quality.

- A softwood and hardwood fiberline comprising a chip feeding system, a two-vessel continuous cooking plant, a new evaporation system for liquor extraction, and seven DD (Drum Displacer) washers for brownstock washing and bleaching. The softwood capacity of this line will be the highest in the world (3,900 tons per day).

- The world’s most energy-efficient black liquor evaporation plant with the highest capacity in Europe (1,650 tons/hour). The plant is closely connected to the fiberline using ANDRITZ’s latest innovative and patented solutions, and thus creating the most energy efficient overall combination for the mill. The plant will have seven stages and concentrate black liquor to the very high dry solids content of 85% for efficient combustion in the recovery boiler. In addition, ANDRITZ will also deliver chloride removal systems to enhance the chemical recovery process and to produce liquid methanol, which will be used as a biofuel source.

- A recausticizing plant, which will be the largest in Europe (white liquor production of 16,000 m3/day), and world’s largest single-line recausticizing plant, with two centrifuges for dregs, slaker-classifier, white liquor disc filter, and lime mud disc filter.

The new mill will be a next-generation bio-product pulp mill which can convert wood raw material into biomaterials and bioenergy in addition to producing high-quality pulp. It will not use any fossil-based fuels as all of the energy required will be generated from wood.

For further information, please contact:

Oliver Pokorny

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

The ANDRITZ GROUP

The ANDRITZ GROUP is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and solid/liquid separation in the municipal and industrial sectors. The publicly listed, international technology Group is headquartered in Graz, Austria, and has a staff of around 24,500 employees. ANDRITZ operates over 250 production sites as well as service and sales companies all around the world. The ANDRITZ GROUP ranks among the global market leaders in all four of its business areas. One of the Group’s overall strategic goals is to strengthen and extend this position. At the same time, the company aims to secure the continuation of profitable growth in the long term.

ANDRITZ PULP & PAPER

The business area is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, gasification plants for energy production, flue gas cleaning plants, production equipment for biofuel (second generation) and biomass pelleting, biomass torrefaction, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

Metsä Group

Metsä Group is a responsible forest industry group whose products’ main raw material is renewable and sustainably grown northern wood. Metsä Group focuses on tissue and cooking papers, fresh forest fibre paperboards, pulp, wood products, and wood supply and forest services. Its high-quality products combine renewable raw materials, customer-orientation, sustainable development and innovation. Metsä Group’s sales totalled EUR 5 billion in 2014, and it employs approximately 10,500 people. The Group operates in some 30 countries. Metsäliitto Cooperative is the parent company of Metsä Group and is owned by approximately 122,000 Finnish forest owners

Metsä Fibre

Metsä Fibre is a world-leading producer of softwood pulp and its main brand is Botnia. Our products – sustainably and cost-efficiently produced softwood and birch pulp – are specially developed for the production of high-quality tissue and writing papers, speciality products, and board. With four pulp mills in Finland, we employ a total of about 850 people. Our sales in 2014 were approximately EUR 1.3 billion. Metsä Fibre is part of Metsä Group.

New screen element from Voith: SplitScreen substantially simplifies screw press maintenance

Voith has brought to market a new screen element for the screw press. SplitScreen is the first screen element consisting of a supporting structure and a screen plate, enabling maintenance and inspection time to be significantly reduced compared with conventional cylindrical screen baskets. In addition, investment costs over the lifetime of the screw press are much lower than for conventional screen elements.

SplitScreen comprises a split supporting body with two removable screen plates instead of one cylindrical basket. This design enables direct access to the individual screw press components without having to dismantle it completely. Whereas with previous technologies the entire press screw including screen baskets had to be lifted out using an indoor crane to get to the cylindrical screen elements, SplitScreen allows the top half of the SplitScreen to be disconnected after lifting the hood to check the condition of the plate. If the screen plate, which is a wearing part, does actually need to be replaced the lower half can also simply be turned to the top. This then gives easy access to exchange the upper and lower screen plates. At the same time this makes the press screw accessible for inspection.

With SplitScreen, the time necessary for replacing a screen element is only three to four hours instead of the average 24 to 48 hours that were previously needed. Moreover, procurement costs can be cut up to 40 percent per year after first installation, as in the event of wear only the screen plate and not the entire SplitScreen has to be changed. The large, open design of the screen area also helps improve the dewatering efficiency of the screw press.

SplitScreen is a standard feature of Voith's new InfiltraScrewpress. All conventional screen elements of Voith’s Thune screw press as well as screw presses from other manufacturers can be converted to SplitScreen.

The new screen element has already been successfully installed more than a dozen times worldwide and has also been retrofitted to conventional screw presses six times to date. The product is proving effective in the field and customers that have installed SplitScreen are very satisfied with its performance.

SplitScreen is a component of Voith’s BlueLine product range that has been developed for stock preparation. BlueLine products are known for their low consumption of energy, fibers and water.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

11 ‘DEFORESTATION FRONTS’ WILL ACCOUNT FOR 80% OF GLOBAL DESTRUCTION, SAYS WWF REPORT

Eleven global hotspots will account for over 80 per cent of forest loss by 2030, according to research released today by WWF.

Eleven global hotspots will account for over 80 per cent of forest loss by 2030, according to research released today by WWF.

Up to 170 million hectares of forest could be lost between 2010 and 2030 in these “deforestation fronts” if current trends continue, according to findings in the latest WWF’s Living Forests Report.

The fronts - the Amazon, the Atlantic Forest and Gran Chaco, Borneo, the Cerrado, Choco-Darien, the Congo Basin, East Africa, Eastern Australia, Greater Mekong, New Guinea and Sumatra - contain some of the richest wildlife in the world, including endangered species such as orangutans and tigers. All are home to indigenous communities.

Rod Taylor, Director of WWF’s global forest programme said:

“Imagine a forest stretching across Germany, France, Spain and Portugal wiped out in just 20 years.”

“We must tackle that risk to save the communities and cultures that depend on forests, and ensure forests continue to store carbon, filter our water, supply wood and provide habitat for millions of species.”

WWF analysis shows that more than 230 million hectares of forest will disappear by 2050 if no action is taken. Forest loss must be reduced to near zero by 2020 to avoid dangerous climate change and economic losses.

WWF-UK’s Chief Adviser on Forests, Will Ashley-Cantello said:

“Deforestation needs to stop if we are to reverse biodiversity loss and combat climate change – which, if unchecked, will affect our quality of life.

“Managing forests sustainably could underpin sustainable development, poverty alleviation and a stable climate around the world. 2015 should be a year of action locally, nationally and globally – and Britain can play a key role in driving change by shaping new UN Sustainable Development Goals and working for an ambitious global climate deal.”

Globally, the biggest cause of deforestation is expanding agriculture – including commercial livestock, palm oil and soy production, but also encroachment by small-scale farmers. Unsustainable logging and fuelwood collection - or “death by a thousand cuts” - contributes to forest degradation, while mining, hydroelectricity and other infrastructure projects bring new roads that open forests to settlers and agriculture.

WWF-UK is campaigning to close EU loopholes that mean Britain still contributes to the illegal trade in timber products, and calling on British businesses to buy wood only from sustainable sources.

Will Ashley-Cantello said:

“Here in the UK you can still buy furniture, books, cards and other products made from illegally or unsustainably sourced wood. EU rules to prevent the exploitation of forests only cover half of traded products. The next UK government should lobby hard to end this nonsense.”

The Living Forests Report will be published at the Tropical Landscapes Summit: A Global Investment Opportunity, an international gathering of political, business and civil society leaders in Jakarta, Indonesia.

Despite a recent slowdown, deforestation remains a major issue in Indonesia. Sumatra has lost more than half of its natural forests due to paper and palm oil plantations, and the remaining forest is severely fragmented. WWF projections show that another 5 million hectares of forest could be lost by 2030.

EU rules governing the trade in timber products are due for review in 2015. WWF is campaigning to close loopy loopholes that contribute to the destruction of the world’s forests, and is working with colleagues in Europe to ensure that the regulation is implemented and enforced effectively across all 28 Member States.

The Living Forests Report aims to catalyse debate on the future role and value of forests in a world where humanity is living within the Earth’s ecological limits and sharing its resources equitably.

The Living Forests Model, which WWF developedwith the International Institute for Applied Systems Analysis, forms the basis for the Living Forests Report. panda.org/livingforests

About WWF

WWF is one of the world's largest and most respected independent conservation organizations, with over 5 million supporters and a global network active in over 100 countries. WWF's mission is to stop the degradation of the Earth's natural environment and to build a future in which humans live in harmony with nature, by conserving the world's biological diversity, ensuring that the use of renewable natural resources is sustainable, and promoting the reduction of pollution and wasteful consumption.

Visit panda.org/news for latest news and media resources

HMR Auction Signs Exclusive Auction Partnership Agreement with Proxibid, Brings First Sale Online

Proxibid (www.proxibid.com), the most trusted online Marketplace for buying and selling highly valued items, today announced it has entered into an agreement with HMR Auction (www.hmrauctions.com.ph), the Philippines’ largest full-service auction and valuation company, whereby HMR Auction will bring its auctions online exclusively in the Proxibid Marketplace. HMR Auction, which specializes in the sale of industrial goods, listed its inaugural sale of a Yankee Dryer Pressure Vessel on Proxibid. The auction is now open for bidding until Friday, May 8 at 5:00 pm AUS (WST) by visiting www.proxibid.com/HMRauctions.

Designed for paper manufacturing facilities, this Yankee Dryer is brand new and has never been installed or used. Its current location at the port makes it the perfect option for paper and tissue manufacturing facilities as it can easily be shipped to any destination. With Proxibid, any buyer from anywhere in the world with an Internet connection can log on and bid in this auction. The online Marketplace boasts the most sophisticated risk management system in the industry, built to manage high dollar transactions like the sale of this Yankee Dryer. Buyers can rest assured that they are safe when purchasing on Proxibid.

Designed for paper manufacturing facilities, this Yankee Dryer is brand new and has never been installed or used. Its current location at the port makes it the perfect option for paper and tissue manufacturing facilities as it can easily be shipped to any destination. With Proxibid, any buyer from anywhere in the world with an Internet connection can log on and bid in this auction. The online Marketplace boasts the most sophisticated risk management system in the industry, built to manage high dollar transactions like the sale of this Yankee Dryer. Buyers can rest assured that they are safe when purchasing on Proxibid.

“We are excited to work with Proxibid to bring our auctions to a global online audience,” said Joseph Dela Cruz of HMR Auction. “We have chosen to work with Proxibid because of the company’s robust platform and global presence. Proxibid is able to provide us with a sophisticated technical solution with risk management capabilities that outpace anyone else in the industry. That, combined with its Marketplace reach makes it a logical partnership choice for our company.”

Proxibid’s online Marketplace connects buyers and sellers across 15 categories ranging from industrial machinery and equipment and heavy construction equipment to real estate and everything in between. More than 3,000 sellers and hundreds of thousands of buyers rely on the Proxibid Marketplace for secure transactions of highly valued items every day.

For more information about this auction or to place a bid, please visit www.proxibid.com/HMRAuctions.

Proxibid Social

Visit us online at www.proxibid.com

“Like” us on Facebook www.facebook.com/proxibid

Follow us on Twitter www.twitter.com/proxibid

About Proxibid

Proxibid provides asset owners of all sizes and buyers with access to the world’s most trusted online Marketplace and selling solutions for excess inventory. More than $3 billion in inventory passes through Proxibid’s marketplace annually in product categories that include heavy equipment; commercial and industrial equipment; real estate; fine art, antiques and collectibles and more.

Founded in 2001, Proxibid is headquartered in Omaha, NE with offices in New York and London. For more information about Proxibid, please visit www.proxibid.com.

Best Available Techniques and Associated Emission Levels (BAT AELs) guidelines for paper and pulp will test wastewater processing efficiency

![]() The origin of the EU’s best-available-technique (BAT) guidelines for pulp and paper installations go back over 10 years, but it is only recently that they have surfaced again for most mill operators, who now need to urgently consider emissions controls to improve anti-pollution measures.

The origin of the EU’s best-available-technique (BAT) guidelines for pulp and paper installations go back over 10 years, but it is only recently that they have surfaced again for most mill operators, who now need to urgently consider emissions controls to improve anti-pollution measures.

The guidelines form a reference for regulators to set permit conditions under the Industrial Emissions Directive and all regulated industries, including the pulp and paper sector, are expected to achieve compliance with BAT and their Associated Emission Levels (AEL) rules within strict timeframes. Permits for all installations will require updating by early 2018.

In particular, the BAT guidelines will have much tighter limits on pollutant levels and will cover by way of example, wastewater that is discharged into rivers. Current EU pulp production mostly uses the kraft process, and under the guidelines, the acceptable level of pollutants for the chemical oxygen demand of waste water per tonne of dry pulp has been halved. As such, the industry will need a mixture of end-of-pipe measures, better technology and improved management, if it is to meet the new rules.

The pulp and paper sector is a significant energy user and currently ranks fourth in the industrial sector for its energy use, according to the Industrial Efficiency Technology Database, consuming by some estimates up to 6% of global industrial energy use. Filtering and the removal of contaminants from the wastewater is known to be very energy demanding, with mechanical surface aeration and sub-surface jet aeration systems for biological treatment demanding high volumes of electricity. Consequently, the search is on for energy efficient wastewater treatment technologies which can now deliver against the specific challenges of pulp and paper manufacturing.

One such technology company which is well placed to deliver against this need is Mapal Green Energy, with its innovative Floating Fine Bubble Aeration technology (FFBA), currently used by Anglian Water, Thames Water and United Utilities in the UK. The same technology has also been deployed successfully in South Africa in the pulp and paper sector and again in factory farming installations in Israel, where the challenges of treating aggressive and hazardous liquids echo many of the issues faced in the pulp and paper industry.

A revolutionary solution, floating fine bubble aeration approaches the challenge of wastewater oxygenation by marrying the strengths of mechanical surface aeration technology – easy to install and accessible for maintenance - with the efficiency which is derived from sub surface fine bubble aeration systems. With no moving parts generating friction and driving high energy consumption, a key benefit for users of Mapal Green Energy’s floating fine bubble aeration system is its dramatically reduced energy bill. Tests around the world have shown that in some cases, compared to mechanical surface aeration, a plant’s energy consumption can be reduced by significant amounts. In the UK, Anglian Water reported a 22% drop in energy consumption using Mapal’s system, as compared to its previous mechanical aeration technology.

Mapal GE CEO Zeev Fisher comments, “We have a well proven technology in use at over 40 sites around the world, including in the pulp and paper sector and by leading Utility companies in the UK, where regulatory pressure has long been a feature of the industry. The technology is perfectly suited to the new challenges laid down in the latest EU BAT-AEL rules and our in house teams can advise on all aspects of systems design and installation.”

For details of Mapal Green Energy’s floating fine bubble aeration technology, please visit http://www.mapal-ge.com

Mapal Green Energy pioneered the concept of floating fine bubble aeration (FFBA)as a more efficient means of treating waste water for both utility companies and industry applications.

Floating fine bubble aeration approaches the challenge of waste water biological aeration by marrying the strengths of surface aeration technology – easy to install and accessible for maintenance - with the efficiency which is derived from sub surface fine bubble aeration systems. With no moving parts generating friction and driving high energy consumption, a key benefit for users of Mapal Green Energy’s floating fine bubble aeration system is its dramatically reduced energy bill.

Tests around the world have shown that in some cases, compared to surface aeration, a plant’s energy consumption can be reduced by up to 70% using the Mapal system,

With over 35 installations worldwide, Mapal's floating fine bubble aeration technology has been proved to meet and exceed stringent effluent quality parameters including the reduction of : BOD5, TSS, COD, Tkn and Ammonia.

In the UK, the system is being used by Anglian Water, Thames Water and United Utilities.

Mapal’s innovative equipment floats on the surface, so wet and live installation is the norm, which makes for a very fast changeover of plant and a minimal downtime. The units are made from robust stainless steel, so have a long life and as a modular system, the installation can be added to or reduced quickly and easily. Thus far, their largest UK installation is designed to handle a flow rate of up to 10,450m3/day in wet weather.

The Mapal technology can be adapted for aggressive and hazardous liquids and is therefore suitable for application across a wide range of industry sectors where a solution based on aeration is required. Liquid waste from the paper, food and beverages, petro chemicals and other industries can all be treated.

Tullis Russell Group announcement

It was with deep sadness that Tullis Russell Group announced today that its papermaking subsidiary Tullis Russell Papermakers Limited had been placed into Administration by its directors.

It was with deep sadness that Tullis Russell Group announced today that its papermaking subsidiary Tullis Russell Papermakers Limited had been placed into Administration by its directors.

The Employee Owned Tullis Russell Group’s two other operating subsidiaries Tullis Russell Security & Speciality Coating based in Bollington Cheshire and Tullis Russell Image Transfer based in Ansan, South Korea are totally unaffected by this move and continue to trade normally under the Tullis Russell Group.

Tullis Russell Papermakers Limited was founded in 1809 and since that date has operated from a 100 acre site in Markinch, Scotland. The company manufactures high quality board for use in the cards, covers and premium packaging sectors.

Group CEO Chris Parr said: “This is a terribly sad day for employees and their families, the local community and everyone else associated with the business and its proud 206 year history. Since the global recession in 2008 demand across the traditional markets for papermaker’s products has fallen by 40%, our primary raw material, wood pulp, is now trading at consistently higher price levels than ever before and exchange rates have moved structurally against the business. The company has been able to generate new business within luxury packaging and certain digital applications over this time, however annual volume is currently 14% lower than 2008 levels and the profit margin achieved is substantially weaker.

“In 2009 we successfully negotiated a pioneering scheme with RWE Npower who built and since 2014 have operated a biomass plant on our site initially reducing our annual energy costs by 50%. We have also continued to improve year on year efficiencies and remove cost from our business. Despite these efforts there remains over supply in the global paper market and demand continues to fall. It has become clear to the board that Papermakers is no longer a viable business.

“Recognising this situation the Group and Papermaking boards concluded that the best chance of protecting jobs would be through a trade sale of the papermaking company to a buyer capable of, and committed to developing the Markinch site. The Group engaged KPMG to run a comprehensive sales process and between October 2014 and March 2015 over 72 trade parties have considered and subsequently rejected the opportunity to acquire the business. This has unfortunately only confirmed that the business is no longer viable.

“This difficult position finally became untenable with the papermaking company’s third largest and most profitable customer entering into an insolvency process on Monday 1 April 2015. The directors of our Papermaking business were therefore faced with no other option than to place the business into Administration.”

Tullis Russell Papermakers Limited (in administration)

Blair Nimmo and Tony Friar of KPMG LLP were appointed Joint Administrators of Tullis Russell Papermakers Limited on 27th April 2015, at the request of the company’s directors.

Blair Nimmo and Tony Friar of KPMG LLP were appointed Joint Administrators of Tullis Russell Papermakers Limited on 27th April 2015, at the request of the company’s directors.

Based in Markinch, Fife the employee-owned company was founded in 1809 and produces high quality paper board for use in cards, covers and premium packaging.

The company has 474 employees, 471 of which are based at Markinch and three operating remotely throughout the UK.

In the year to 31 March 2014, the company sold 126,000 tonnes of paper and board. It recorded a turnover of £124.6 million, but suffered a pre-tax loss of £3.4 million. It has incurred cumulative losses of £18.5 million over the last five years, largely as a result of weakening demand and pressure on its margins.

The company’s market is in long term decline as media and other outlets move from paper to digitally-based products, resulting in worldwide oversupply and price competition. The company has also faced a number of specific challenges in recent years:

- A significant portion of the company’s sales are to Europe and the recent strengthening of Sterling against the Euro has had an impact on competitiveness

- The cost of the company’s main raw material, wood pulp, is trading at consistently higher levels than historically experienced

- The loss of a major customer due to insolvency proceedings

These factors have, in part, been offset by steps taken by the company to widen its product and customer base and improve the efficiency of its operations. In March 2014 a £200m biomass plant was opened on site in partnership with RWE Npower with the aim to reduce Tullis Russell’s energy costs.

Despite these efforts, the company remains significantly loss making and this is projected to continue, resulting in severe cashflow issues.

Recognising the structural changes in the industry and the need for consolidation, the directors took steps in October 2014 to seek a buyer for the business. This process continued until this month, but ultimately no party was found.

The directors therefore concluded that they must act in the best interests of the company’s creditors and take steps to appoint administrators.

Given the very difficult trading conditions and that a sale process to seek a buyer for the company had not been successful, the administrators have taken steps to significantly reduce the company’s cost base whilst all options are considered. Unfortunately, this has resulted in 325 employees being made redundant with immediate effect. The remaining 149 have been retained to complete some orders.

Blair Nimmo, Joint Administrator and Head of Restructuring for KPMG in Scotland, said: “This is a sad day for the employees of Tullis Russell Papermakers, who have worked hard against the significant headwinds facing the global papermaking sector. Whilst we will be exploring whether a sale of all or part of the business and asset of the company can be achieved, we have had to take steps to significantly reduce the company’s overheads. Unfortunately, with trading effectively ceasing, we have had no option but to reduce the size of the workforce. We will be working with government agencies to minimise the impact on employees. We would encourage any party with an interest in acquiring all, or parts, of the business to make contact with us as soon as possible.”

Tullis Russell Papermakers Limited is a wholly owned subsidiary of Tullis Russell Group Limited. The Group’s Coating business based in Bollington, Cheshire and its Image Transfer business based in Ansan, Korea are not affected by the administration and continue to trade as normal.

KPMG LLP, a UK limited liability partnership, operates from 22 offices across the UK with approximately 12,000 partners and staff. The UK firm recorded a turnover of £1.9 billion in the year ended September 2014. KPMG is a global network of professional firms providing Audit, Tax, and Advisory services. It operates in 155 countries and has 162,000 professionals working in member firms around the world. The independent member firms of the KPMG network are affiliated with KPMG International Cooperative ("KPMG International"), a Swiss entity. Each KPMG firm is a legally distinct and separate entity and describes itself as such.

Toscotec-supplied AHEAD-2.0 tissue machine started up at Fortissue S.A., Portugal.

The Toscotec-supplied AHEAD-2.0 tissue machine at Fortissue S.A., the new productive division of Suavecel S.A based in Viana do Castelo, in the coastal and delta region of Rio Lima about 75 km north of Porto, was successfully started up in early April 2015. The machine came easily on stream after the commissioning period and is now producing high quality tissue products according to the guaranteed technological parameters.

Due to the excellent cooperation between Fortissue and Toscotec the line started up smoothly on schedule, 18 months after the order signature of the turn key contract.

The new Toscotec's line, based on the best available technology, includes an AHEAD-2.0 crescent former tissue machine with TT Headbox-MLT double-layer, a Steel Yankee Dryer (TT SYD-16FT), Milltech hood, steam&condensate and dust removal system.

The supply also comprises stock preparation plant for virgin pulp, vacuum plant, boiler plant, air compressors and electrification & control system. A three unwind stands tissue slitter rewinder TT WIND-H and an automatic roll handling system complete the delivery.

The project has been fully managed by Toscotec on an EPC (Engineering Procurement and Construction) basis.

With a net web width of 2820 mm and a maximum drying capacity of 120 tpd, the new tissue line has a capacity of 35,000 tpa making Suavecel active on the entire tissue production process.

The combination of technical expertise with the right equipment and tools required to a superior productive performance, is the key to success of the company’s project, and it largely accounts for the increasing growth that Suavecel is experiencing since 1996, year of its foundation. Before the start-up of the new machine, the Portuguese company was engaged in the transformation of paper, namely producing toilet paper, paper towel, pocket tissues and paper napkins, but also offering some products for the AFH sector.

“Throughout the years - Nuno Ribeiro, CEO of Fortissue and Suavecel, said – our company has successfully met the challenges, based on its ability for a sustainable growth along with suitable development policies, as the notion of growth does not necessarily mean improvement. The company has made a considerable investment effort in capital and human resources in order to achieve the winning combination of these two concepts”.

Wood fiber costs for pulp mills in the Western US have increased substantially over the past year

Wood fiber costs for pulp mills in the Western US have increased substantially over the past year while other regions in the US have experienced only modest increases, according to the North American Wood Fiber Review

Pulp mills in the US South continued to have stable wood fiber prices in the 1Q/15 at levels lower than any other region in the country. The dramatic increase in chip prices in the Northwest during 2014 started to level off early in 2015, while tight fiber supply in both the Lake State region and in the Northeast resulted in upward price pressure, reports the North American Wood Fiber Review.

Pulp mills in the US South continued to have stable wood fiber prices in the 1Q/15 at levels lower than any other region in the country. The dramatic increase in chip prices in the Northwest during 2014 started to level off early in 2015, while tight fiber supply in both the Lake State region and in the Northeast resulted in upward price pressure, reports the North American Wood Fiber Review.

Wood fiber costs for pulp mills in the US South were substantially lower than the costs for pulp companies in the rest of the US in the 1Q/15. Prices for softwood residual chips in the Southern states were over 30 percent lower than in the Northeast, Lake States and the Northwest, according the latest issue of the North American Wood Fiber Review (NAWFR).

Pulplog and wood chip prices have held steady in the South for the past 12 months at prices nearing 10-year highs. Sufficient supply of pulplogs and residual chips and steady production levels at the region’s pulp mills have contributed to a healthy fiber supply and demand balance.

With pulpmills generally able to build healthy wood inventories in the 1Q/15 and with a number of maintenance outages scheduled for the second quarter, the stage is set for a possible reduction in pulpwood pricing in some southern states in the near future.

Heavy snowfalls across the Northeast, excluding the northern half of Maine, have created challenges for forest access and transportation during the 1Q/15. Fiber inventories, particularly those of hardwood, remained short resulting in concerns over having sufficient supplies on hand to carry through the spring, when road weight limitations and mud season greatly diminish harvest levels. Pulplog prices in this region were slightly higher in the 1Q/15 as compared the previous quarter.

Prices for both logs and chips in the Lake States were up to record high levels as obtaining adequate fiber supplies remained a serious challenge in the 1Q/15. Prices remained high despite the reasonable snow levels and standard temperatures.

In the 1Q/15, wood chip prices in the US Northwest continued their upward trend that started in late 2013, reaching their highest levels in almost three years. In only the past 12 months, softwood chips prices have gone up 21 percent. With the recent increases, this region had some of the highest wood chip prices in North America, reports the NAWFR (www.woodprices.com). With additional residual chips generated by increased lumber production in the coming months, it is likely that chip prices will decline later in 2015.

The North American Wood Fiber Review has tracked wood fiber markets in the US and Canada for over 20 years and it is the only publication that includes prices for sawlogs, pulpwood, wood chips and biomass in North America. The 36-page quarterly report includes wood market updates for 15 regions on the continent in addition to the latest export statistics for sawlogs, wood pellets and wood chips.

Contact Information

Wood Resources International LLC

Hakan Ekstrom

Seattle, USA

This email address is being protected from spambots. You need JavaScript enabled to view it.