Ianadmin

Neal McConnellogue Named President of BW Papersystems

Tim Sullivan, Barry‐Wehmiller Group President and ex‐interim President of BW Papersystems is pleased to announce the appointment of Neal McConnellogue as President of BW Papersystems. BW Papersystems is a leading global supplier of sheeting and sheet packaging machinery for the paper converting, manufacturing and packaging industries and the largest division of Barry‐Wehmiller. Companies within the BW Papersystems group include MarquipWardUnited, Will‐Pemco, Curioni and Kugler‐Womako.

Tim Sullivan, Barry‐Wehmiller Group President and ex‐interim President of BW Papersystems is pleased to announce the appointment of Neal McConnellogue as President of BW Papersystems. BW Papersystems is a leading global supplier of sheeting and sheet packaging machinery for the paper converting, manufacturing and packaging industries and the largest division of Barry‐Wehmiller. Companies within the BW Papersystems group include MarquipWardUnited, Will‐Pemco, Curioni and Kugler‐Womako.

“Neal is an extremely talented and experienced executive who has produced strong results in every position he’s held during his nineteen year career with the Barry‐ Wehmiller organization,” said Sullivan. “With his strategic vision, operating skills and leadership experience, BW Papersystems will continue to evolve into a global leader known for its exceptional people, outstanding products and service, and ability to offer enduring value in the marketplace.”

In his new role, McConnellogue will be responsible for all aspects of the business, including new equipment sales, aftermarket sales, customer service, field service, engineering and manufacturing at BW Papersystems’ operations worldwide. BW

Papersystems employs nearly 1,400 team members and generated in excess of $370 million in revenue in FY 2014.

“I am excited and honored to lead the BW Papersystems team in furthering the company’s growth and success through new levels of innovation, customer experience and value in the marketplace,” McConnellogue commented.

McConnellogue joined Barry‐Wehmiller in 1996 after serving in leadership roles for Conal, his family’s business. Throughout his tenure with the Barry‐Wehmiller organization, he has served in numerous capacities. He began as the Director of Aftermarket for its then Jetstream division. From there he was promoted to Director of Sales for Jetstream before moving to its newly‐acquired Fleetwood division and serving as VP of Sales. There he contributed significantly to the acquisitions of Goldco, Wyard and Ambec and integration of Barry‐Wehmiller’s historic brewery equipment business. When these companies were merged into FleetwoodGoldcoWyard (recently renamed BW Container Systems), McConnellogue served in a Global Sales capacity. He became Executive VP in 2011 and was named BW Container Systems President in 2013.

“BW Papersystems has experienced significant growth over the past several years as it has expanded its range of products, technologies and markets worldwide,” said Bob Chapman, Chairman and CEO of Barry‐Wehmiller. “With Neal’s skillful leadership, BW Papersystems will continue to grow as an important platform in the strong balance of industries served by Barry‐Wehmiller.”

ABOUT BW PAPERSYSTEMS

BW Papersystems incorporates five of the strongest brands in the industry: Will‐Pemco, MarquipWardUnited, SHM, Wrapmatic and Kugler Womako. Market leading technology is available for folio‐size, cut‐size and digital‐size sheeting and packaging of paper, board and other materials, plus stationery, passport production and specialized paper converting applications. For the corrugating industry, customers rely on the well‐known brands MarquipWardUnited, Curioni and VortX.

ABOUT BARRY‐WEHMILLER

Barry‐Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper converting industries. By blending people‐centric leadership with disciplined operational strategies and purpose‐driven growth, Barry‐Wehmiller has become a $2 billion organization with 8,500‐plus team members united by a common belief: to use the power of business to build a better world. To see how, go to www.barry‐wehmiller.com

Tissue World Barcelona: Voith presents the NipcoFlex T shoe press and state-of-the-art products

Voith will have its own stand again this year at Tissue World Barcelona, Spain, to be held from March 17 to 19, 2015. Trade fair visitors will find Voith at stand C 150.

Voith will introduce the current NipcoFlex T shoe press and illustrate examples of the system already installed worldwide, including the new PM 7 production line Fripa Papierfabrik Albert Friedrich KG in Miltenberg, Germany. The presentation will furthermore include ATMOS, the Voith technology for the manufacture of premium tissue, as well as more than 20 other state-of-the-art products for tissue production.

Marcus Schwier, Voith Vice President Sales Tissue EMEA, will give a presentation on Wednesday, March 18, 2015, on the topic: ‘Join the Future – the Most Energy Saving Tissue Production Line in the World.‘ Mr. Schwier will present the latest operating results from Miltenberg.

Laslo Monte, Voith Director Sales FRS Tissue & Replacement Rolls EMEA, will give a presentation on Thursday, March 19, 2015 focusing on ‘State-of-the-Art Conditions for Dewatering at the Suction Pressure Roll.’ Mr. Monte will report on the significant energy savings and performance increases that can be achieved for paper machines with the HydroSeal sealing strip system, the SolarSoft polyurethane roll cover and the Evolution press felt.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

SCA and CEO Magnus Groth inaugurate first production facility in India

SCA, a leading global hygiene and forest products company, has inaugurated its first manufacturing facility for personal care and tissue products in India. SCA has been active in the Indian market since late 2013.

SCA, a leading global hygiene and forest products company, has inaugurated its first manufacturing facility for personal care and tissue products in India. SCA has been active in the Indian market since late 2013.

The facility, which produces baby diapers and tissue for the Indian market, is located in Pune in the central Indian state of Maharastra. Baby diapers are sold under the Libero brand and tissue under the global leading Tork brand.

“The low penetration of hygiene products and the large population in India provide the potential for future growth. The plant in Pune will enable us to further leverage the growth potential in India. The investment is in line with our strategy of strengthening SCA’s presence in emerging markets. Meeting customers and employees and understanding the markets we operate in is very important to me, why this trip, my first as President and CEO of SCA, means a great deal to me,” says Magnus Groth, President and CEO of SCA.

As previously announced, SCA has invested SEK150m in the plant in India.

“The team in India has done a very good job and last year they launched our biggest information and educational campaign ever. In 2014, we reached 2,300 doctors, 5,000 hospitals and clinics and 1.2 million mothers and babies, providing them with parental guidance. We also communicated the importance of good hand hygiene to more than eight million people,” says Magnus Groth.

“SCA has shown deep commitment and has invested time and effort to understand the Indian market and consumer needs as we enter a new phase. With this new production facility, SCA underlines its long-term strategy for our business in India,” says Cecilia Edebo, Managing Director of SCA in India.

For additional information please contact:

Johan Karlsson, VP Investor Relations, 46 8 788 51 30

Karl Stoltz, Media Relations Manager, 46 8 788 51 55

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Valmet receives order from Holmen for softwood line rebuild at Iggesund mill

Valmet will deliver equipment and services for a rebuild of the soft wood pulp line at Holmen's Iggesund mill in Sweden. The rebuild will improve production stability, cut variable costs and increase pulp production capacity by 15 percent equally to 50,000 tonnes. The works will be implemented in two stages during 2015 and 2016.

Valmet will deliver equipment and services for a rebuild of the soft wood pulp line at Holmen's Iggesund mill in Sweden. The rebuild will improve production stability, cut variable costs and increase pulp production capacity by 15 percent equally to 50,000 tonnes. The works will be implemented in two stages during 2015 and 2016.

The order is included in Valmet's first quarter 2015 orders received.The value of the order will not be disclosed.

"We have a good experience since we have had Valmet presses in our mill for many years. This rebuild will eliminate bottle necks in the process and increase pulp capacity. We will also cut variable costs which will strengthen our competitiveness", says Olov Winblad von Walter, Mill Director, Iggesund.

"This rebuild is the first step towards a press based bleach plant. The high outlet consistency makes the process easier to control and the volume of effluent will be less than for washers with lower discharge consistencies. Also water and chemical consumption will be minimized. We are looking forward to a good co-operation in this project", says Mikael Gustafsson, Sales Manager, Valmet.

Technical information about Valmet's delivery

The scope of the Valmet delivery includes main machinery, basic engineering and erection. In the first stage, two pressure diffusers will be rebuilt, one in the cooking plant and one in the brown stock washing, where also a new TwinRoll press, will be installed. In the second stage, the oxygen delignification stage will be extended into a two-stage OxyTrac system, which will make it possible to still reach lower kappa numbers in case of a further production increase. In the bleach plant two new TwinRoll presses will be installed.

About Holmen and Iggesund mill

Holmen is a forest industry group that manufactures printing paper, paperboard and sawn timber and runs forestry and energy production operations.

Holmen's Iggesund mill is one of the most advanced, fully integrated pulp and paperboard mills in the world. The product family is called Invercote and is used for the highest quality graphics products and packaging. Exclusive packaging for perfume, chocolate, wine, spirits, cigarettes and CD covers are examples of applications. The mill has a production capacity of 340,000 tonnes per year and has 800 employees.

For further information, please contact:

Mikael Gustafsson, Sales Manager, Pulp and Energy Business Line, Valmet, Tel. +46 70 653 3809

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 10,500 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Valmet to supply OptiConcept M containerboard line for Yuen Foong Yu Packaging, Inc. in Taiwan

Valmet will supply an OptiConcept M containerboard production line for Yuen Foong Yu (YFY) Packaging Inc. for the company's Xin Wu site in Taoyuan County in Taiwan. The new production line will produce high-quality fluting grades out of 100 percent recycled raw materials. The start-up of the new machine is scheduled for the third quarter of 2016.

The order is included in Valmet's first quarter 2015 orders received. The value of the order will not be disclosed.

Energy efficient high quality production with Valmet's OptiConcept M

"We selected a machine concept that emphasizes environmental efficiency especially in terms of energy saving. Our target is to produce high quality containerboard. In order to be competitive, we want to operate with the latest proven technology. Valmet's OptiConcept M has the features which align well with our expectations," says Mr Chia-Feng Yeh, Project Director of Yuen Foong Yu Packaging.

"This high efficient containerboard making line ordered by YFY Packaging will be Valmet's seventh OptiConcept M production line to be supplied globally. The new production line will be able to reduce both carbon footprint as well as energy consumption significantly. The annual production capacity of the new machine will be approximately 300,000 tonnes of board and the design speed will be 1,200 m/min," says Jari Vähäpesola, President, Paper Business Line, Valmet.

The operating profitability of the OptiConcept M is based on the concept's overall efficiency covering energy- and resource-efficient processes and high speed. The production line ensures optimized productivity at minimal operational cost.

Valmet's delivery includes complete boardmaking line from headbox to reel. A new winder is also included in the delivery.

Information about Yuen Foong Yu Packaging

Yuen Foong Yu Packaging, Inc. is an independent subsidiary of Yuen Foong Yu Paper Mfg. Co., Ltd. It is one of the two largest manufacturers of industrial paper in Taiwan and one of the largest suppliers of paper containers in the Greater China.

Further information, please contact:

Hannu T Pietilä, Area President, Asia-Pacific, Valmet, tel. +66 (0)81 862 1122

Mika Ollikainen, Sales Director, Asia-Pacific, Valmet, tel. +358 45 271 1711

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 10,500 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Verso Project Uncovers Vernal Pools on Michigan State Forest Lands

Verso Corporation (NYSE: VRS) has announced the release of a report titled Identifying and Mapping Vernal Pools on State Forest Lands in Michigan's Upper Peninsula (UP). The report documents the results of a year-long collaboration between Verso, the Michigan Natural Features Inventory (MNFI, a program of Michigan State University Extension), the Michigan Forest Products Council (MFPC), and the Michigan Department of Natural Resources (MDNR), to identify and map vernal pools in the UP region, where Verso procures wood for its pulp and paper production. The goal of the project was to enhance the understanding of vernal pools' distribution and ecology in Michigan and how to effectively identify, manage and conserve them.

Verso Corporation (NYSE: VRS) has announced the release of a report titled Identifying and Mapping Vernal Pools on State Forest Lands in Michigan's Upper Peninsula (UP). The report documents the results of a year-long collaboration between Verso, the Michigan Natural Features Inventory (MNFI, a program of Michigan State University Extension), the Michigan Forest Products Council (MFPC), and the Michigan Department of Natural Resources (MDNR), to identify and map vernal pools in the UP region, where Verso procures wood for its pulp and paper production. The goal of the project was to enhance the understanding of vernal pools' distribution and ecology in Michigan and how to effectively identify, manage and conserve them.

"The results of this project will greatly assist Verso, the MDNR, the MFPC and other partners with forest planning and harvesting efforts, and help facilitate sustainable forest management practices," said Jim Contino, Verso senior director, fiber supply.

Vernal pools are small, temporary bodies of water that form in shallow depressions primarily in forested areas throughout Michigan and many other states. Because vernal pools are small, isolated and dry for part of the year, they can be difficult to identify in the field, easily overlooked and unintentionally damaged or destroyed. Vernal pools are important because they provide food, water and habitat for a number of animal and plant species, including several endangered, threatened or rare species in Michigan.

"We feel the project was a success in that we were able to identify and map a significant number of potential and verified vernal pools on state forest lands that had not been documented, mapped or compiled into a single, statewide database prior to this project," said Yu Man Lee, conservation scientist/zoologist, MNFI.

Project accomplishments include:

- Reviewing aerial imagery and mapping a total of 1,332 potential vernal pools across approximately 120,000 acres of state forest lands within two study areas located in the Baraga and Crystal Falls State Forest Areas in Houghton, Iron and Dickinson counties.

- Surveying a total of 207 potential and new vernal pools in the field, of which 173 were potential vernal pools that had been mapped from air photos and 34 were new pools encountered in the field.

- Verifying and mapping a total of 112 active vernal pools in the field, and identifying 22 additional potential/likely vernal pools for which more information is required to confirm their status.

"This project was possible and a success because of the partnership and combined resources of those who participated," said Debbie Begalle, assistant chief, Forest Resources Division, MDNR. "Michigan's vast natural resources -- from wildlife to plants -- will benefit from the results of this collaborative effort."

Information from this project will be provided to the MDNR to be incorporated into their forest planning and management efforts. This will help inform and facilitate vernal pool protection and management on state forest lands in Michigan's Upper Peninsula.

For a copy of the report, Identifying and Mapping Vernal Pools on State Forest Lands in Michigan's Upper Peninsula, please contact Yu Man Lee, MNFI, at This email address is being protected from spambots. You need JavaScript enabled to view it..

About Verso

Verso Corporation is a leading North American producer of printing papers, specialty papers and pulp. Our printing papers are used primarily in commercial printing, media and marketing applications, including magazines, catalogs, books, direct mail, corporate collateral and retail inserts. Our specialty papers are used primarily in label and release liner, flexible packaging and technical paper applications. Headquartered in Memphis, Tennessee, with a business center in Miamisburg, Ohio, Verso operates eight mills strategically located in Kentucky, Maine, Maryland, Michigan, Minnesota and Wisconsin with a total annual production capacity of approximately 3.6 million tons.

About MDNR

The Michigan Department of Natural Resources (MDNR) is committed to the conservation, protection, management, use and enjoyment of the state's natural and cultural resources for current and future generations. Michigan citizens own 4.6 million acres of state land that is managed by the MDNR. The land is managed to protect Michigan's natural and cultural resources, provide quality outdoor recreation opportunities, and foster regional economic prosperity.

About MFPC

The Michigan Forest Products Council (MFPC) is committed to protecting, promoting, and sustaining Michigan's forest products economy by representing and advocating for Michigan's entire forest product industry value chain. MFPC's advocacy activity focuses on three strategic areas: supporting Michigan's working forests, promoting business competitiveness, and ensuring sustainability. This includes working with municipal, state and federal leadership to shape science-based, economically sound policy; advocating for increased benefits to landowners; promoting family-sustaining employment and logger safety; and providing education on sustainable forest management practices. The Michigan Forest Products Council Foundation is a non-profit, 501c3 committed to the mission to educate and inform Michiganians about the benefits of sustainable management of Michigan's natural forest resources.

About MNFI

The Michigan Natural Features Inventory (MNFI) is a program of Michigan State University Extension. It maintains the most comprehensive database on the location and condition of threatened, endangered, and other rare species, and high-quality natural communities in the state of Michigan. MNFI also engages in applied research for the conservation of biodiversity and provides conservation planning information to decision makers.

Toscotec to supply two new tissue machines to Chinese producer Liuzhou Liangmianzhen Paper Product Co.,Ltd

Liuzhou Liangmianzhen Paper Product Co., Ltd. has placed an order with Toscotec for #2 MODULO-PLUS ES tissue lines, which will be installed at its production site in Liuzhou, Guangxi.

Originally established in 1941 as a group of private soap enterprises, the LMZ Group was listed on the Shanghai Stock Exchange in 2004. It currently operates in 5 different areas: cosmetics, paper, fine chemicals, medicine and real estate.

The two TMs are based on Toscotec ES concept. Especially interesting for Asian market, the Energy Saving solution is capable to guarantee, according to the configuration, a substantial reduction in energy consumption during the tissue drying process. The two MODULO-PLUS are designed for a design speed of 1500 m/min and will produce 65 tons/day of high-quality toilet and facial tissue from pre dried virgin pulp and Slush pulp produced by LMZ.

The order includes the two crescent former machines, each equipped with a TT SYD-15FT (4572mm) and a double press configuration, a Milltech Steam Heated Hood, Toscotec stock preparation high efficiency equipment and the electrical and control systems. A TT WIND-M Tissue Slitter Rewinder, spare parts for the entire plant and a full service package complete the scope of supply.

Start-up is scheduled for the second half of 2015.

Where have all the flowers gone? 18,000 art lovers walk into a room of poppy paper.

The launch exhibition for Manchester’s newly re-opened and revamped Whitworth art gallery caused a stampede of visitors, but few were to know that James Cropper’s paper lies at the heart of Cornelia Parker’s stunning War Room installation.

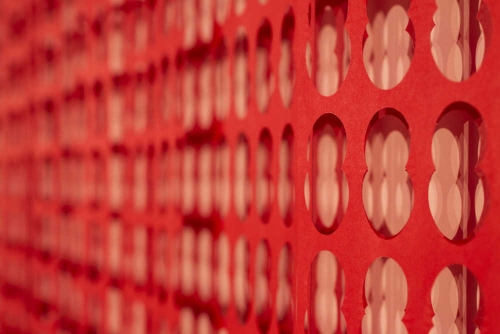

Thousands of punched sheets of James Cropper’s custom-made, red poppy paper now hangs in the most unusual of places - the newly reopened Whitworth art gallery in Manchester. Usually sent for recycling, the vast sheets of paper left with poppy-shaped holes now feature at the heart of internationally renowned artist, Cornelia Parker’s solo exhibition.

A reported 18,000 people passed through the gallery’s doors on its opening weekend, reacting to the international media attention gained by the opening. Many of these visitors took their time to walk into War Room, the immersive installation that sees an entire room bedecked with paper reclaimed from the Aylesford poppy factory. Simply left with the poignant outline of the missing poppy, hung from floor to ceiling and overhead, Parker’s exceptionally well-received, emotionally charged tribute to fallen soldiers asks a literal question: where have all the flowers gone?

The poppy paper is made to exacting standards by James Cropper Paper, especially made to match the colour of the real flower and made to be rub and run resistant to protect clothing. The manufacturer supplies 250km of the paper to the Poppy Factory every year.

The artist likens the intended experience of her installation to that of the op-artists of the 1960s, which saw the likes of Bridget Riley manipulate traditional art techniques to create optical illusions. A ‘walk-in’ piece, visitors are surrounded by with the industrial, rhythmic pattern pressed out of the paper. The breath-taking use of an otherwise wasted material has caused equal pride and intrigue amongst staff at the Cumbrian paper mill.

Phil Wild, CEO of James Cropper, comments: “James Cropper supplies the red poppy paper to the Royal British Legion, and support and respect the fantastic job that they do for past and present veterans and their families. It is really interesting to see thought provoking art and narrative illuminating the effects of war. In re-using the remnants from poppy production to create War Room, Cornelia Parker poignantly reminds us of all the holes in our lives left behind by those who have been lost in conflict.”

Cornelia Parker, famed for her use of found and overlooked materials, presents War Room as part of an exhibition of new commissions and retrospective installations at The Whitworth until Sunday 31 May 2015.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com Buckman Features Range of Innovative Tissuemaking Products at Tissue World Barcelona

Buckman, a global specialty chemical company with expertise in creping, is showcasing its portfolio of innovative tissue and toweling products at Tissue World in Barcelona, Spain, March 17-19 . Buckman offers tissue manufacturers worldwide an unmatched combination of new technology, application and technical expertise.

Buckman, a global specialty chemical company with expertise in creping, is showcasing its portfolio of innovative tissue and toweling products at Tissue World in Barcelona, Spain, March 17-19 . Buckman offers tissue manufacturers worldwide an unmatched combination of new technology, application and technical expertise.

Exciting new technologies include Buckman’s TAD+sm Yankee dryer adhesive system for the through air dried process. This package removes process limitations that have been associated with the TAD process since its inception. The TAD+ coating package provides high levels of wet tack which allow the tissue manufacturer to significantly increase the moisture transfer at the Yankee and this in turn results in reduced energy consumption and increased production rates.

The development and application of novel on-machine softeners, giving tissue manufacturers access to a lotion-like feel from a product applied on the tissue surface prior to the Yankee instead of in converting. This technology can be used in isolation or with the hugely successful Buckman® 691 softening technology applied in the wet end.

About Buckman

Buckman is a privately held, global specialty chemical company with headquarters in Memphis, Tenn., USA. Buckman works proactively and collaboratively with worldwide customers in pulp and paper, leather and water treatment to deliver exceptional service and innovative specialty chemical solutions. Buckman's goal is to help customers boost productivity, reduce risk, improve product quality and provide a measurable return on investment. Buckman is committed to safeguarding the environment, maintaining safety in the workplace and promoting sustainable development, for its associates, its customers and its communities in more than 90 countries around the world.

New Voith rotor for pulping recovered paper impresses industry

Voith has developed a new rotor, the IntensaRotor R, for pulpers used to process recovered paper. It has been operating successfully for months with industrial customers and has proven that its energy consumption is as much as 20 percent below the usual values. The IntensaRotor R is suitable for installation in existing Voith pulpers as well as in pulpers from other manufacturers.

During operation at both a Turkish paper mill, and at a paper manufacturer in China, the IntensaRotor R has proven that it has lower specific energy consumption at a higher throughput than its predecessors. In the first case, the daily output was increased from 260 metric tons to 300 tons, with an energy saving of eight percent per ton. In the second industrial example, the amount of stock after installation of the IntensaRotor R was increased from 510 metric tons to 630 tons per day, while energy consumption per ton dropped by 12 percent.

Both the better energy balance and the higher output are due to the new rotor design. The IntensaRotor R is especially suitable for pulpers of secondary fiber applications in low-consistency area and is delivered in various sizes.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.