Ianadmin

UPM to close and sell Pestovo mill site in Novgorod region

UPM announces a production curtailment at its Pestovo sawmill in Novgorod region and begins negotiations with employees. The negotiations will affect all of the approximately 180 sawmill employees. Starting today, production at the mill will be curtailed to the level necessary to fulfil the on-going contracts. At the same time UPM announces a search for a buyer for the Pestovo mill production area for restructuring or reorientation of production.

The measures taken in Pestovo follow UPM’s renewed Timber business strategy announced in April 2012. UPM concentrates on the development of sawmills closely integrated with the company’s pulp and paper mills. Sawmills have a central role in UPM’s wood sourcing supply chain as their by-products are used in the production of pulp, paper and energy.

“The profitability of the sawmills and further processing units located furthest from our integrated mills has been weak for a long time, and Pestovo sawmill is no exception”, says Anssi Klinga, Senior Vice President, UPM Timber.

UPM’s decision to curtail production and put the Pestovo sawmill on sale have no effect on current customer commitments or other valid contracts.

After completion of this sale, UPM will still own several capacities in Russia, namely a plywood mill in Chudovo (Novgorod region) and two UPM Raflatac terminals. “There are no plans to divest the plywood mill, as UPM’s restructuring strategy deals only with lumber business”, UPM Corporate Communications Russia director Natalia Malashenko told WhatWood.

The Pestovo mill was launched in 2004. Its rated capacity is 260,000 cu m of lumber annually.

Lenzing Partners with NanoCarbons LLC to Develop New Activated Carbons for Energy Storage Systems

Lenzing AG and NanoCarbons LLC, Fort Lauderdale (Florida, USA), will cooperate in the future to develop and explore the use of new activated carbons in electrode technology. This technology is based on a combination of Lenzing’s TENCEL® fibers and the technology provided by NanoCarbons LLC. After extensive research Lenzing constructed a new pilot production facility to take the technology forward.

Lenzing AG and NanoCarbons LLC, Fort Lauderdale (Florida, USA), will cooperate in the future to develop and explore the use of new activated carbons in electrode technology. This technology is based on a combination of Lenzing’s TENCEL® fibers and the technology provided by NanoCarbons LLC. After extensive research Lenzing constructed a new pilot production facility to take the technology forward.

The jointly developed carbons should deliver optimal performance in the area of energy storage. It is believed that these new carbons will accelerate the development of the already rapid growth in uses of electrical devices such as double layer capacitors (also known as ultra capacitors or super capacitors). These high performance capacitors are being increasingly used in hybrid vehicles as well as with stop-start systems, uninterruptable power supplies and wind turbine blade orientation.

“For Lenzing, the development of new, special applications in the technical segment comprises an important extension of the use of our fibers”, says Peter Untersperger, Chief Executive Officer of the Lenzing Group in commenting on the new partnership. “The strongly growing market for energy storage devices is a promising market niche for us. With our TENCEL® fibers we will certainly witness the development of a series of additional, highly interesting technical applications in the coming years.”

Friedrich Weninger, COO of the Lenzing Group with management responsibility for research and development, adds: “We are continuing to invest in new areas of research to increase the range and reach of our product portfolio, both in-house and through external cooperation. The new carbons optimally complement our existing business with separator materials for the energy storage devices. We strongly believe in the future growth of this market. We are offering our customers a sustainable product with consistent quality to allow the industry to develop further.”

Rud Istvan, CEO of NanoCarbons LLC, comments: “I strongly believe that this development will allow the double layer capacitor market to make a significant advancement. With the combination of Lenzing’s technical understanding and infrastructure and Nanocarbons’ technology, we can expect an acceleration in the market uses and exploitation of double layer capacitors, from new automotive stop-start systems to uninterruptable power supplies. This could be a breakthrough for electrode technology that will reap dividends for the designers of electrical components and the drivers of vehicles alike.”

Catalyst receives final TSX listing approval and initiates program to assist small shareholders

Catalyst Paper Corporation announced today that final approval has been received for listing on the Toronto Stock Exchange (TSX) of its new class of common shares (new Shares) created pursuant to its reorganization under the Companies’ Creditors Arrangement Act that completed on September 13, 2012. The new Shares will begin trading on the TSX on January 7, 2013 under the trading symbol “CYT”.

Catalyst Paper Corporation announced today that final approval has been received for listing on the Toronto Stock Exchange (TSX) of its new class of common shares (new Shares) created pursuant to its reorganization under the Companies’ Creditors Arrangement Act that completed on September 13, 2012. The new Shares will begin trading on the TSX on January 7, 2013 under the trading symbol “CYT”.

Catalyst also announced that it has initiated a Small Shareholder Selling Program (SSSP). The program gives shareholders of record as of January 3, 2013 holding 99 or fewer new Shares the opportunity to sell all of these Shares without incurring commission charges thereby minimizing their cost and inconvenience. While the SSSP does not include a mechanism to buy new Shares, the TSX listing will provide that opportunity for those who wish to purchase additional new Shares.

The SSSP will begin on January 7, 2013 and will expire on February 28, 2013, unless extended. Shareholders wishing to participate in the SSSP must sell all of their new Shares. Catalyst will arrange for orders received pursuant to the program to be sent to a participating organization of the TSX (the Broker) for execution after clearance of such orders for trading. Orders received and cleared for execution will be placed with the Broker no later than 12:00 p.m. on the next business day for execution by the TSX. Orders may be aggregated, but not netted, by Catalyst or the Broker. The price received by shareholders for their new Shares will be the average price received on all orders placed with the Broker for execution on a given day, regardless of when any individual orders are executed on that day.

Catalyst and its Board of Directors are making no recommendation as to whether any shareholder should sell their new Shares pursuant to the SSSP or purchase any additional new Shares. The SSSP is entirely voluntary and shareholders are advised to contact their broker or other financial adviser as to the suitability of participating.

As previously announced, all common shares of Catalyst that were outstanding prior to the reorganization on September 13, 2012 and that were formerly traded under the symbol “CTL” were cancelled pursuant to the reorganization for no consideration and will not be listed on the TSX.

Additional information concerning the SSSP can be obtained by contacting Catalyst’s program manager – Canadian Stock Transfer Company Inc. by telephone at (416) 682-3860 or toll-free at 1-800-387-0825, or through e-mail to This email address is being protected from spambots. You need JavaScript enabled to view it..

Metso to divest Metso Husum AB to Pichano Holding AB

Metso has divested all its shares of Metso Husum AB to Pichano Holding AB, as a result of a restructing plan of its service workshop network in Sweden. The business was transferred on January 1, 2013. The value of the agreement will not be disclosed.

Metso has divested all its shares of Metso Husum AB to Pichano Holding AB, as a result of a restructing plan of its service workshop network in Sweden. The business was transferred on January 1, 2013. The value of the agreement will not be disclosed.

Metso Husum AB is specialized in repair and maintenance work to the pulp and paper industry as well as to the construction industry. They provide services at the customer site as well as manufacture in their own workshop. The company has a turnover of 1.5 MEUR and 12 employees. All employees will remain with the company. The company is located close to Örnsköldsvik, Sweden.

”We will integrate the Husum company into Pichano without major changes, and then continue to develop the business in the areas we focus on; i.e. bioenergy, hydroelectric power, wind power, and steel work within the construction industry”, says Kent Modin, VD, Pichano Holding AB.

The Pichano group is a full service company serving customers within the construction, transport and maintenance area. The turnover in the group is 21 MEUR and they have 150 employees.

Rottneros: Successful product development results in continued production of groundwood pulp

The Rottneros Group has decided to continue to produce groundwood pulp at Rottneros Mill. The initiative to improve the groundwood mill's process has resulted in the mill producing and marketing a new grade with properties that are particularly attractive to board manufacturers.

The Rottneros Group has decided to continue to produce groundwood pulp at Rottneros Mill. The initiative to improve the groundwood mill's process has resulted in the mill producing and marketing a new grade with properties that are particularly attractive to board manufacturers.

There are plans to produce between 40,000 and 50,000 tonnes of groundwood pulp in 2013 and it will constitute the new board grade as well as current printing paper grades.

The Board of Rottneros announced in May 2012 that it had entered into negotiations concerning the termination of continuous groundwood pulp production at Rottneros Mill. Negotiations, which were concluded mid-year, resulted in the organisation having to reduce its staff by around 50 posts. Twenty or so employees are now being offered continued work.

Alfa Laval acquires leading provider of niche heat transfer products to the North American natural gas market

Alfa Laval – a world leader in heat transfer, centrifugal separation and fluid handling – has acquired the US-based company Air Cooled Exchangers, LLC (ACE), a leading manufacturer of custom-engineered air-cooled heat exchangers, used to cool air, natural gas, oil and water in the natural gas market as well as other energy-related end markets.

Alfa Laval – a world leader in heat transfer, centrifugal separation and fluid handling – has acquired the US-based company Air Cooled Exchangers, LLC (ACE), a leading manufacturer of custom-engineered air-cooled heat exchangers, used to cool air, natural gas, oil and water in the natural gas market as well as other energy-related end markets.

Lars Renström, President and CEO of the Alfa Laval Group, comments: “The acquisition of ACE brings a new product range into our heat transfer offering, at a time when demand for air-cooled heat exchangers is accelerating – especially in the natural gas industry. Together, Alfa Laval’s overall position is further strengthened, and we’re even better positioned to serve the energy-related industries.”

ACE is expected to generate sales of approximately SEK 350 million in 2012, with profitability well above the average for the Alfa Laval Group. The intention is to integrate Air Cooled Exchangers, LLC into Alfa Laval’s Energy & Environment segment, within the Process Technology division. The company was acquired on December 31st 2012.

Did you know that… Air Cooled Exchangers (ACE) was founded in 1964 and that the company currently has 230 employees at its location in Broken Arrow, Oklahoma, US?

International Paper Completes Acquisition of Sabanci Shares in Olmuksa Corrugated Packaging Joint Venture in Turkey

International Paper today announced it has completed the acquisition of the shares of its joint venture partner Sabanci Holding in the Turkish corrugated packaging company Olmuksa, for a purchase price of $56 million. International Paper had obtained regulatory approval for the deal in the fourth quarter of 2012. The deal sees International Paper become the majority shareholder, owning approximately 87.5 percent of Olmuksa's outstanding shares. The change of control triggers a mandatory call for tender of the remaining public shares (approximately 12.5 percent float) of Olmuksa, which will be conducted in line with the regulations of the Turkish Capital Markets Board.

International Paper today announced it has completed the acquisition of the shares of its joint venture partner Sabanci Holding in the Turkish corrugated packaging company Olmuksa, for a purchase price of $56 million. International Paper had obtained regulatory approval for the deal in the fourth quarter of 2012. The deal sees International Paper become the majority shareholder, owning approximately 87.5 percent of Olmuksa's outstanding shares. The change of control triggers a mandatory call for tender of the remaining public shares (approximately 12.5 percent float) of Olmuksa, which will be conducted in line with the regulations of the Turkish Capital Markets Board.

"Packaging is a core business for International Paper and this deal follows our commitment to expand profitably our strong global platform and regional presence," said Maximo Pacheco, President of International Paper Europe, Middle East & Africa. He added "It is an exciting opportunity to grow and serve our customers in a strategically important geography."

The Turkish corrugated market is currently the 7th largest in Europe with expected continued average growth rates of greater than 5% annually. The country is also strategically positioned to serve as potential growth platform to the Middle-East.

SOURCE International Paper

Nurseries in the forest industry adopt degradable paper pots

Companies like Montes Del Plata and Forestal Oriental replaced the plastic pots by degradable paper Ellepot

Companies like Montes Del Plata and Forestal Oriental replaced the plastic pots by degradable paper Ellepot

The production of young plants in South America has won a great ally: the Ellepot. The technology consolidated in Europe consists in production of degradable paper pots that ensures better quality of young plants and allows automation of nurseries more efficiently.

With customers over 60 countries the Danish Ellegaard landed in Brazil in 2004 believing in the great potential of the forestry sector. Since then it has conquered the market and the admiration of clients.

The beauty of the entire system is the simplicity. The Ellepot machine fills a degradable paper tube with substrate. Then the tube is cut into "Ellepots" which will be ready for propagation of seeds and cuttings.

The main advantages of the Ellepot System are faster and healthy root development, reduction of transplant shock, up to 40% faster transplanting, improved crop timing, streamlined and uniform production among others.

The main advantages of the Ellepot System are faster and healthy root development, reduction of transplant shock, up to 40% faster transplanting, improved crop timing, streamlined and uniform production among others.

Today more than 60% of the costs of growing young plants are labor costs. The Ellepot System is designed to reduce these costs and offer more competitiveness to forest nurseries.

CONSOLIDATED MARKET

Ellegaard’s solutions are definitely conquering the market and that is the result of more than 20 years tradition of the brand and the benefits for the forest nurseries.

Uruguay got the first forest nursery of the world 100% projected with degradable pots.

Montes Del Plata in Uruguay produces approximately 20 million eucalyptus young plants /year. The company which belongs to the groups Stora Enso and Arauco is a pioneer in the adoption of the Ellepot technology.

"We are preparing our nursery for the next 20 years. Therefore we have invested in an innovative system, which has long-term projection as the degradable pots, "says Francisco Ferreira, assistant manager of the company's research and nursery. “Before joining the product, the company tested other alternatives, but chose Ellepot for its quality and flexibility", he complements.

Another Uruguayan company Forestal Oriental (UPM) built up a nursery based on the automated Ellepot system and produces about 15 million young plants / year.

In Brazil forestry companies already working with the Ellepot technology are Tecnoplanta, Angicos, Camará, Eucapinus, Eucalipto do Brasil, Verde Novo Landebo among others. In Chile, Arauco Group has already adopted the Ellepot System.

AUTOMATION OF NURSERIES

AUTOMATION OF NURSERIES

Elleggard offers customized solutions for production and selection of young plants from small to large producers. Automatic and semi-automatic Ellepot machines can produce up to 40.000 degradable pots per hour in different heights and diameters.

FSC CERTIFICATION

The degradable paper used in Ellepots has FSC certification, Rainforest Alliance and Veriflora.

Click and watch the videos with the automation system of nurseries:

http://ellepot.dk/equipment/ellepot-machinery/fully-automatic-machines/flexline.html

For further information please contact:

Darcy Werneck

This email address is being protected from spambots. You need JavaScript enabled to view it.

+4521155570

Metso strengthens its plant optimization services by acquiring U.S. software company ExperTune Inc.

Metso has acquired U.S. software company ExperTune Inc. ExperTune's products are widely used as software tools to analyze and monitor the performance of industrial processes and to identify the associated maintenance and improvement opportunities.

Metso has acquired U.S. software company ExperTune Inc. ExperTune's products are widely used as software tools to analyze and monitor the performance of industrial processes and to identify the associated maintenance and improvement opportunities.

ExperTune's acquisition is in line with Metso's strategy to deliver customer value solutions and grow the scope of the services business globally. The acquisition expands and strengthens Metso's ability to globally provide business-enhancing services to customers. ExperTune's products will be sold as stand-alone solutions that can be used in any automation system environment and as part of Metso's performance business solutions, targeted to optimize plant performance.

''The combination of ExperTune's products and Metso's services portfolio extends our capability to offer solutions targeted to improving process and business performance,'' says Mikko Keto, President, Services, Metso Automation.

''With ExperTune we can provide more versatile and more cost effective customer value solutions to our customers so that they can meet their most pressing business challenges, such as reducing raw material consumption, energy usage, product variability and environmental impact. ExperTune's products help our customers to find areas of improvement in their processes to which Metso has customer value solutions,'' Keto summarizes.

Metso's services business has developed strongly over the last decade. In 2011, the services share of the company's turnover was 45 per cent. ExperTune will be integrated into Metso's Automation segment's Services business.

ExperTune Inc.

Founded in 1986, ExperTune designs pre-packaged industrial software which help maximizing productivity and efficiency and reduces waste in the process industries worldwide. Its net sales are less than MEUR 10. ExperTune is headquartered in the United States in Milwaukee, Wisconsin. It has an extensive sales representative network on all continents. ExperTune's products include PlantTriage, ProcessApex and PID Loop Optimizer.

The perfect design of viscose fibres for wetlaid nonwovens

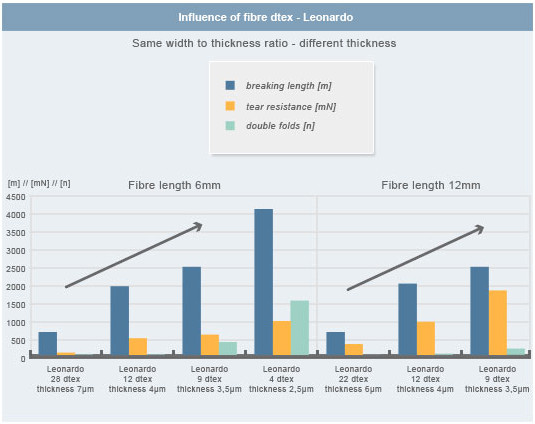

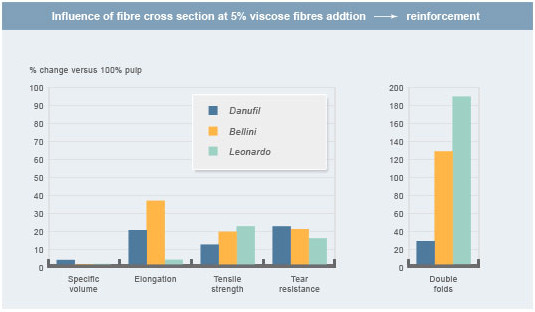

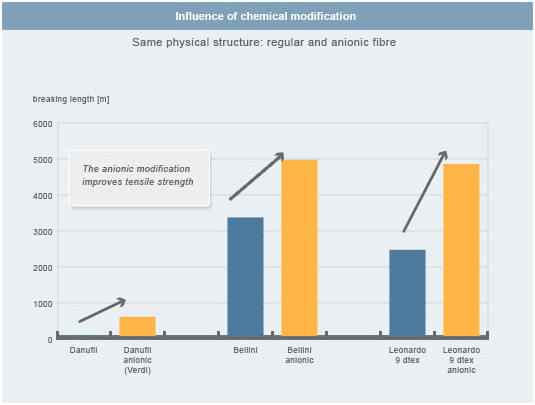

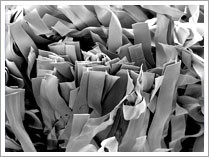

In wetlaid nonwovens or paper applications, good bonding properties of the fibres bring advantages for the strength of the web. Due to their large surface area and their high flexibility, fibres with flat cross-sections display very good bonding properties - our Bellini fibre is an excellent example.

The extremely flat and smooth structure of our Leonardo fibre with its width to thickness ratio of 40:1 and its extremely regular and flat fibre surface not only facilitates good fibre-fibre bonding; it also makes the fibre highly transparent, allowing for the production of wetlaid nonwovens and papers with improved transparency.

The extremely flat and smooth structure of our Leonardo fibre with its width to thickness ratio of 40:1 and its extremely regular and flat fibre surface not only facilitates good fibre-fibre bonding; it also makes the fibre highly transparent, allowing for the production of wetlaid nonwovens and papers with improved transparency.

By the choice of the appropriate fibre cross-section, by chemical modification and by the selection of the right cut-length, our customers can achieve improvements in tensile strength, folding properties and other nonwoven parameters - and by adding Leonardo to our range of products we made the choice even wider for you. Don't forget: only small amounts of viscose fibres can improve your product significantly!