Ianadmin

Packaging is not responsible for mineral oils found in chocolate from advent calendars

The German consumer organisation Stiftung Warentest published test results according to which most chocolates in 24 tested advent calendars in Germany contained mineral oil hydrocarbon residues. Stiftung Warentest also mentioned recycled cardboard packaging as the source of those residues. An analysis of the Technical University Darmstadt published today, shows that this conclusion is not appropriate.

The German consumer organisation Stiftung Warentest published test results according to which most chocolates in 24 tested advent calendars in Germany contained mineral oil hydrocarbon residues. Stiftung Warentest also mentioned recycled cardboard packaging as the source of those residues. An analysis of the Technical University Darmstadt published today, shows that this conclusion is not appropriate.

The Paper Technology and Mechanical Process Engineering Unit of the Technical University in Darmstadt obtained each of the 24 calendars tested by Stiftung Warentest to conduct an analysis on the fibre content of the calendars. This is a standard test that Darmstadt University conducts on a regular basis. The results show clearly that 23 out of the 24 calendars tested are made of virgin fibre, only one contained recycled fibre.

The broad statement from Stiftung Warentest that mineral oil hydrocarbons in the chocolate of their tested advent calendars originates most likely from the recycled cardboard packaging is questionable and cannot be correct. The source is not the cardboard used in the calendars.

There are several possibilities of how mineral oils can get into chocolate. The root cause for this still needs to be determined. As potential sources Darmstadt University listed additives and processing chemicals used during food production and other packaging materials (e.g. plastic trays) as well as potential contamination during transportation and storage.

As a precautionary measure the paper-based fibre chain has implemented several voluntary actions on this issue, taking a pro-active and innovative action to solve the case. The industry has also developed self-regulation: Industry Guideline for Food Contact Materials and a guidance on GMP (Good Manufacturing Practise) to ensure a consistent European production of safe food packaging.

Bellona and Norske Skog are working for a better environment

Norske Skog and the environmental foundation Bellona have signed a partnership agreement to create a more environmentally-friendly supply chain. During the last 20 years, Norske Skog has made significant investments to rationalise energy consumption and reduce greenhouse gas emissions. For many years, the company has received recognition from the international Carbon Disclosure Project (CDP) for social responsibility through its reporting of greenhouse gas emissions and targets for emission reductions.

Norske Skog and the environmental foundation Bellona have signed a partnership agreement to create a more environmentally-friendly supply chain. During the last 20 years, Norske Skog has made significant investments to rationalise energy consumption and reduce greenhouse gas emissions. For many years, the company has received recognition from the international Carbon Disclosure Project (CDP) for social responsibility through its reporting of greenhouse gas emissions and targets for emission reductions.

The collaboration aims to reduce the environmental impact of current production, utilising logs in a better way and finding the right commercial environmental solutions for production of bio-energy and bio-waste.

- Paper is environmentally friendly. It is based on a renewable resource, and paper is recycled to a large extent. Bark and other waste products are used for bio-energy. We want a partnership to examine possibilities for creating better commercial environmental solutions than we have today. A concrete example of the cooperation is that we hope to find good and environmentally friendly uses of ash that occurs as a by-product at Norske Skog's mills in Skogn and Halden, says President and CEO in Norske Skog, Sven Ombudstvedt.

Bellona acknowledges that environmental organisations can not drive forward environmental solutions on their own. Therefore, the environmental foundation has had a cooperation programme with industrial companies since 1998. The reason for this is that Bellona would like to team up with the players in the industry who take the environment seriously, so that we can develop tomorrow's environmental solutions together. To realise these environmental ambitions, great emphasis is placed on the long term. This partnership agreement gives the parties room to develop shared visions and strengthen each other's expertise. In addition, the company will contribute an agreed annual amount to Bellona.

- For a long time, we have been working intensively in Norske Skog to drive in an even more environmentally friendly manner, and we have defined and quantified targets for cuts in greenhouse gas emissions. To achieve these, we need to use energy more efficiently. For example, we are investing in a new and more energy efficient pulp plant at Norske Skog Saugbrugs in Halden. Furthermore, we see that we must do even more in the future, and we have great expectations for our cooperation with Bellona, says Ombudstvedt.

- Industry must take responsibility for environmental and climate-related matters. Bellona's vision is that we have a sustainable land-based industry in Norway. Together, Norske Skog and Bellona can find and implement solutions that are in line with our vision and simultaneously provide a viable industry, said Frederic Hauge, technical manager at the Bellona Foundation.

- We need manufacturing jobs, and the industry produces goods we depend on. At the same time, all manufacturing operations lead to increased use of energy and emissions to our environment. The goal must be to reduce these drawbacks as much as possible, and we in Bellona wish to contribute to Norske Skog being a pioneer in this area, says Frederic Hauge.

Metsä Board negotiates to divest the Alizay mill site

Metsä Board Corporation, part of Metsä Group, announced in March 2012 the start of a voluntary reindustrialization project in Alizay mill in France. The project is carried out jointly by Metsä Board, workers’ representatives and local authorities.

Metsä Board Corporation, part of Metsä Group, announced in March 2012 the start of a voluntary reindustrialization project in Alizay mill in France. The project is carried out jointly by Metsä Board, workers’ representatives and local authorities.

Negotiations regarding the divestment of the land, buildings and machinery of the Alizay mill have proceeded, but unlike discussed in certain public medias, an agreement on the divestment has not been signed. If the negotiations proceed well, it is possible that the arrangement will materialize by year end. This will be announced separately.

Metsä Board permanently closed down the Alizay site in early 2012 as part of the group’s strategic transformation from a fine paper company to a paperboard company.

Cellulose: from biogenic polymer to novel functions and innovative applications

This was the title of the paper given to approximately 280 attendees at the third Cooperation Forum Biopolymers in Straubing by Dr. Haio Harms, CEO of Kelheim Fibres GmbH. The paper illustrated impressively the versatility of viscose fibres made in Kelheim and presented future-oriented applications possibilities for their use.

This was the title of the paper given to approximately 280 attendees at the third Cooperation Forum Biopolymers in Straubing by Dr. Haio Harms, CEO of Kelheim Fibres GmbH. The paper illustrated impressively the versatility of viscose fibres made in Kelheim and presented future-oriented applications possibilities for their use.

“Cellulose- and lignocellulose-based materials and composites” was one of the main topics of the Forum organized by Bayern Innovativ in collaboration with the Centre of Excellence for Renewable Resources in Straubing – and Kelheim’s viscose fibres are a prime example of such materials.

Speciality fibres from Kelheim are high-performance materials which can substitute oil based synthetic materials in certain applications and deliver equal or even better performance; filters and speciality papers are examples of end products which can benefit from Kelheim’s fibres – and even carbon fibres are made from viscose fibre precursors. In addition to this, viscose fibres are made from 100% renewable cellulose as a raw material and are therefore completely biodegradable.

As a result, the field trip to the speciality fibre manufacturer’s headquarters at Kelheim, which was offered as part of the additional programme of the cooperation forum, was met with great interest. Around 50 visitors were given the opportunity to see the production plant and Kelheim’s R&D pilot plants.

Metso-supplied evaporation plant and recovery boiler started up at Eldorado’s Três Lagoas site in Brazil

The evaporation plant, with a capacity of 1,600 tonnes/hour evaporated water, is the largest single line evaporation plant in the world with the purpose of concentrating black liquor up to 80% dry solids content for efficient and low-emission combustion in the recovery boiler.

The recovery boiler is also among the largest in the world in operation and has a 6,800 tonnes of dry solids/day black liquor burning capacity and steam generation of 1,109 tonnes of steam/hour. The steam will be used in the pulp manufacturing process and in power generation to supply the entire mill and produce a significant amount of power surplus. Additionally, the recovery boiler has high chemical recovery efficiency making the mill economically and environmentally sustainable.

Celso Tacla, Area President, South America, Metso’s Pulp, Paper and Power segment, explains that “the Eldorado project is a success since it overcomes major challenges, such as the large-size equipment that came from different parts of the world, requiring extremely well executed logistics.”

Eldorado Celulose e Papel is a Brazilian company operating the world’s largest single-line pulp mill with a capacity to produce 1.5 million tonnes a year of bleached eucalyptus pulp. The company, controlled by J&F Holding, has plans to build three parallel pulp lines by year 2020. These lines would produce a total of 5 million tonnes per year.

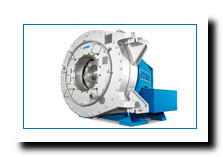

ANDRITZ to supply pressurized refining system for new MDF/HDF board plant in Turkey

International technology Group ANDRITZ has received an order to supply a pressurized refining system with a design capacity of approximately 1,200 t/d for a new MDF/HDF production plant being built by AGT Ltd., Turkey. The new MDF/HDF line will be erected next to an existing door production facility owned by AGT, a leading profile supplier and producer of doors and WPC elements. Start-up is scheduled for the fourth quarter of 2013.

International technology Group ANDRITZ has received an order to supply a pressurized refining system with a design capacity of approximately 1,200 t/d for a new MDF/HDF production plant being built by AGT Ltd., Turkey. The new MDF/HDF line will be erected next to an existing door production facility owned by AGT, a leading profile supplier and producer of doors and WPC elements. Start-up is scheduled for the fourth quarter of 2013.

This order confirms ANDRITZ’s position as one of the leading suppliers worldwide for tailor-made, complete front-end systems for the MDF industry. In 2012, ANDRITZ secured four important orders and conducted six successful start-ups in China, where a total of more than 125 ANDRITZ systems have already been sold. In Europe, the MDF industry ordered ANDRITZ machines for Russia, France, and Germany.

The ANDRITZ front-end systems include the woodyard (debarking, chipping, screening, and chip storage), as well as the chip washing and pressurized refining systems. Depending on the raw materials used, ANDRITZ delivers tailor-made solutions for processing chips, sawdust, and annual plants. To ensure continuous production with fast refiner plate changing and short downtimes, the ANDRITZ refiner has a “swing-door” design. Keeping a keen eye on energy costs, ANDRITZ systems have extremely low energy consumption. In total, ANDRITZ has already installed 250 pressurized refining systems worldwide.

ANDRITZ to supply biomass boiler island to Växjö Energi, Sweden

International technology Group ANDRITZ has received an order from the regional Swedish utility Växjö Energi AB to deliver a biomass power boiler island that will be part of a new combined heat and power plant. The plant will supply heat and power for the Växjö community in the province of Småland in southern Sweden and is scheduled to start up at the end of 2014.

International technology Group ANDRITZ has received an order from the regional Swedish utility Växjö Energi AB to deliver a biomass power boiler island that will be part of a new combined heat and power plant. The plant will supply heat and power for the Växjö community in the province of Småland in southern Sweden and is scheduled to start up at the end of 2014.

The scope of supply includes the boiler island from the inlet to the fuel silos to the boiler outlet, based on the well-proven bubbling fluidized bed design of ANDRITZ, which combines high efficiency with excellent environmental performance. The boiler will burn wood-based biomass (forest residue, bark, sawdust, and wood chips) to generate steam at the rate of 155 t/h, with steam parameters of 540 °C and 140 bar(a).

“ANDRITZ’s high level of technological competence and experience were decisive the in award of this order,” says Björn Wolgast, the business area manager for power and heat at Växjö Energi.

Lars Idermark named Södra's new Group President and CEO

Södra's executive committee has named Lars Idermark as the new Group President and CEO. Lars Idermark is currently the CEO of PostNord.

Södra's executive committee has named Lars Idermark as the new Group President and CEO. Lars Idermark is currently the CEO of PostNord.

"Lars Idermark is a person with outstanding experience of various elements of trade and industry, and he has a good insight into the cooperative form of business. He has many years of experience in senior positions, and he is well equipped to lead Södra," said Christer Segerstéen, Chairman of the Södra Board.

Lars Idermark is currently the President and CEO of PostNord, Chairman of Swedbank and a board member of the Chalmers University of Technology Foundation. Lars Idermark has previously held positions as Group President and CEO of Kooperativa Förbundet/Coop, President of the Second Swedish National Pension Fund, Acting Group President of the Capio healthcare group and Deputy CEO and acting CEO of Föreningssparbanken (Swedbank), and before that Föreningsbanken.

Lars Idermark is very familiar with Södra: he has been a member for many years and he also served on the Södra Board of Directors from 1999 to 2009. His experience of agricultural cooperative operations also goes back a long way: in addition to his duties at Södra, he was also the CEO of LRF Holding.

As Lars Idermark has a six-month notice period in his present job, when he will be able to take up his new position is unclear as yet. Gunilla Saltin will continue in her position as Acting Group President and CEO until then.

Lenzing Group: TENCEL® Celebrates 20th Anniversary

TENCEL® has turned 20. The first large production facility for lyocell fibers was put into operation in Mobile/Alabama (USA) in 1992. Today the Lenzing Group manufactures TENCEL® fibers at three sites located in Austria, Great Britain and the USA. Lenzing celebrated this anniversary by holding a commemorative ceremony and a customer symposium.

TENCEL® has turned 20. The first large production facility for lyocell fibers was put into operation in Mobile/Alabama (USA) in 1992. Today the Lenzing Group manufactures TENCEL® fibers at three sites located in Austria, Great Britain and the USA. Lenzing celebrated this anniversary by holding a commemorative ceremony and a customer symposium.

20 years ago the TENCEL® plant in Mobile was the first large-scale industrial production site in the world for the new lyocell fibers. The factory was originally built by the British company Courtaulds plc., a former Lenzing competitor. Lenzing also took over this facility within the context of the acquisition of the Tencel Group in the year 2004. In recent years it has been technologically upgraded, and annual production capacity was increased to the current level of about 50,000 tons of TENCEL® fibers. Today Lenzing manufactures TENCEL® fibers at three sites: Heiligenkreuz (Austria) with an annual capacity of 60,000 tons, Grimsby (Great Britain), featuring a capacity of approx. 40,000 tons each year, and the Mobile, Alabama plant. A fourth production plant is currently being constructed in Lenzing (Upper Austria). Total annual capacity will amount to 60,000 tons, and the facility will be the first second-generation TENCEL® plant from a technological perspective.

On the occasion of the special commemorative ceremony, Lenzing CEO Peter Untersperger emphasized the tremendous importance of the TENCEL® technology. “TENCEL® has been the biggest technological step forward in the man-made cellulose fiber industry since the invention of viscose fibers about 100 years ago. The development of the fiber over the last 20 years only marks the beginning of a success story which will continue for many decades to come. TENCEL® ideally combines the need for competitive production costs compared to other fibers with the requirement of ensuring sustainable, environmentally compatible production. TENCEL® is a breakthrough technology, and I am proud that the Lenzing Group is by far the world’s number one provider of TENCEL® fibers.“

On the occasion of the special commemorative ceremony, Lenzing CEO Peter Untersperger emphasized the tremendous importance of the TENCEL® technology. “TENCEL® has been the biggest technological step forward in the man-made cellulose fiber industry since the invention of viscose fibers about 100 years ago. The development of the fiber over the last 20 years only marks the beginning of a success story which will continue for many decades to come. TENCEL® ideally combines the need for competitive production costs compared to other fibers with the requirement of ensuring sustainable, environmentally compatible production. TENCEL® is a breakthrough technology, and I am proud that the Lenzing Group is by far the world’s number one provider of TENCEL® fibers.“

The beginnings: a competitive race between giants

The initial phase in the development of lyocell fibers (marketed by Lenzing today exclusively under the brand name TENCEL®) was characterized by a bitter rivalry between the Lenzing Group and Courtaulds. Both companies conducted research in competition with each other to become the first of the two firms to launch promising new fibers on the marketplace. At the production start in Mobile in 1992, Courtaulds had a competitive edge, but Lenzing’s first large-scale lyocell factory in Heiligenkreuz (Burgenland) was already in the pipeline. It was successfully put into operation in 1996. In 2004, Lenzing finally acquired the Tencel Group and all its production sites.

The initial phase in the development of lyocell fibers (marketed by Lenzing today exclusively under the brand name TENCEL®) was characterized by a bitter rivalry between the Lenzing Group and Courtaulds. Both companies conducted research in competition with each other to become the first of the two firms to launch promising new fibers on the marketplace. At the production start in Mobile in 1992, Courtaulds had a competitive edge, but Lenzing’s first large-scale lyocell factory in Heiligenkreuz (Burgenland) was already in the pipeline. It was successfully put into operation in 1996. In 2004, Lenzing finally acquired the Tencel Group and all its production sites.

Combining forces

The merger of Tencel and Lenzing led to a bundling of their collective strengths. The two-way know- how exchange and the decision to consolidate research and development on TENCEL® fibers at one site finally led to the sought-after breakthrough on the marketplace for the new generation of fibers. The range of applications was expanded, and the TENCEL® business subsequently developed very dynamically, spreading from the USA to Europe and Asia.

Diverse applications

At the present time TENCEL® fibers are used by the textile industry as well as for nonwovens. The production process is particularly environmentally compatible, and is characterized by the nearly complete recovery of the deployed solvent.

At the present time TENCEL® fibers are used by the textile industry as well as for nonwovens. The production process is particularly environmentally compatible, and is characterized by the nearly complete recovery of the deployed solvent.

Lenzing is continuously developing new applications in cooperation with customers and partners. The optimal moisture management of TENCEL® fibers makes them attractive for use in home textiles such as mattresses, quilts and bed linen as well sportswear and women’s outerwear. TENCEL® is also integrated into sensitive segments such as cosmetics, hygiene, and medicine, for example in wound dressings and baby wipes. In the technical segment, TENCEL® is used, for example, to strengthen plastics or to manufacture electrotechnical components.

The Lenzing Group

The Lenzing Group is a world market leader with headquarters in Austria, production sites in all major markets as well as a worldwide network of sales and marketing offices. Lenzing supplies the global textile and nonwovens industry with high-quality man-made cellulose fibers and is the leading supplier in many business-to-business markets. The portfolio ranges from dissolving pulp, standard and specialty cellulose fibers to high-quality plastic polymer products and engineering services.

Lenzing quality and innovative strength set global standards for man-made cellulose fibers. With more than 70 years of experience in fiber production, the Lenzing Group is the only company worldwide combining the manufacturing of all three man-made cellulose fiber generations on a large industrial scale under one roof – from the classic viscose to modal and lyocell (TENCEL®) fibers. The success of the Lenzing Group is based on a unique combination of consistent customer orientation together with its leadership in innovation, technology and quality. Our successful specialization strategy and an outstanding cost position are the basis for our economic strength.

Lenzing is committed to the principle of sustainable management and very high environmental standards. Lenzing's core business fibers is complemented by our activities in the business fields plastics and engineering.

Key Figures Lenzing Group 2011:

Sales: EUR 2.14 bn

Export share: 91.5%

Fiber production: 705,100 tons

Staff: 6,593

For more info please contact:

Angelika Guldt

Head of Corporate Communications

Phone: +43 (0) 7672 701-2713

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Ilim Group revealed details of the start of its coated paper production

Ilim Group held a meeting with representatives of Russia's largest printing offices and distributors of print media and paper products in order to familiarize them with the progress on construction of the first coated freesheet paper production in Russia. The meeting was attended by representatives of Russia's largest printing mills, including Bereg, Regent, Petrobumaga, Papirus, Double V, A.Brown, Eksmo and AST publishing houses.

Ilim Group held a meeting with representatives of Russia's largest printing offices and distributors of print media and paper products in order to familiarize them with the progress on construction of the first coated freesheet paper production in Russia. The meeting was attended by representatives of Russia's largest printing mills, including Bereg, Regent, Petrobumaga, Papirus, Double V, A.Brown, Eksmo and AST publishing houses.

At the meeting Ilim Group told the attendees about the implementation status of the investment project that will ultimately enable the Koryazhma Branch of OJSC Ilim Group in Arkhangelsk region to produce coated paper complying with European quality standards in Q2 2013. The company will produce up to 90,000 tons of double-coated paper per year, its basis weight ranging from 90 to 150 gsm (both matt and glossy), to be available in rolls and sheets.

The company was represented by Vera Bubelo, White Papers Business Director, and marketing and sales experts. Vera Bubelo spoke about quality of the future products, expected product range and the company's strategy for cooperation with customers, and answered the questions. Upon the company's invitation, the meeting was also attended by representatives of the St. Petersburg State Technical University of Plant Polymers who spoke about specific features associated with coated freesheet papers manufacturing.

‘’We consider it really important that our potential customers understand well what we plan to do and what we can do. We tried to describe our products, technology, and our cooperation strategy in as much detail as possible. We have been present at the Russia's pulp and paper market for over 20 years and have proven ourselves as a reliable supplier of board, pulp and offset paper. Now we aim at establishing long-term partnership relations with representatives of Russia's printing industry. We hope that this meeting will be the beginning of our cooperation. We have all prerequisites for that’’, Bubelo noted.