Ianadmin

Metso concludes the statutory employer-employee negotiations covering its Paper business

Metso has concluded the statutory employer-employee negotiations covering personnel in its units serving the paper industry. As a result of these discussions, 400 employees will be reduced and a further 136 positions will be outsourced in Finland.

The statutory employer-employee negotiations initiated in Metso units serving the paper industry in September this year and covering personnel reductions and layoffs have ended. Following the negotiations, which involved a total of approximately 4,100 employees, Metso has decided to reduce 400 jobs and outsource a further 136 positions. A total of 152 employees will take retirement and 15 will transfer to new positions in other Metso units. At the start of the negotiations on September 18, it was estimated that a maximum of 480 employees would be affected, and around 150 positions likely to be outsourced.

As a result of the negotiations temporary layoffs will only be implemented if they are required by the low production and order book in 2013. Temporary layoffs could affect jobs in units serving the paper industry in Juankoski, Jyväskylä, Järvenpää, Raisio, and Valkeakoski.

Metso will assist those affected through a comprehensive program aimed at helping them to set up their own company as well as retrain and find new jobs.

The redundancies and outsourcing that have been decided on are intended to achieve savings of approximately EUR 25 million in annual operational costs. Cost reductions in 2013 are expected to yield savings of approximately EUR 20 million.

“It’s very unfortunate that we have been forced to implement such large-scale measures affecting our personnel,” says Pasi Laine, President of Metso’s Pulp, Paper and Power segment. “By working closely and proactively with employee representatives, however, we will try to minimize the impact of the redundancies through a comprehensive program aimed at helping people find new employment.”

Metso’s decision to make these reductions in personnel is the result of the need to adjust the manufacturing capacity of the Group’s paper business unit to the permanent structural changes that have impacted the business and weakened its competitiveness and profitability.

As a result of restructuring, Metso will book non-recurring cost of around EUR 10 million in its fourth quarter results.

Enissey pulpmill expanded its investment program to build a bark-chip boiler

By June 2013, Enissey pulpmill (Krasnoyarsk, belongs to Continental Management holding) is planning to build a new bark-chip boiler which will generate 25 tons of steam per hour, as Continental Management press service reported.

Cost of the project is estimated at over 40 million Rubles (€1 million), while its construction will save 45 million Rubles annually.

The company is now carrying out another investment project, upgrade of paper corrugating equipment for 230 million Rubles which entails rebuild of the board-making machine No. 2 and installation of new wood pulp preparation equipment. The project is to be finished by 2014.

source: www.whatwood.ru

Amazar pulpmill project started with beam production

Another media confirmed that first stage of Amazar pulpmill project, ‘’Polyarnaya’’, is launched in Zabaikalskiy region. It is a joint Russian-Chinese project with total investment scope of $215 million, including the infrastructure.

‘’The neighboring regions are exporting roundwood, but we see there a new enterprise with state-of-the-art German equipment, and it will generate added value here, on the Russian territory’’, vice PM of regional government Evgeniy Vishnyakov said.

The mill, however, is now producing beams for the neighboring municipalities and for export. The investor says that by 2015 the mill will produce non-bleached sulfate pulp. The regional government assures that the mill complies with international environmental standards.

The logging site entails 500,000 ha of overmature forests close to Amazar.

Wood is of very poor quality, and final yield is quite low, as said by chief forester of Express LLC Aleksandr Kulusov.

The company plans to build 100 km of forest roads there. As long as the mill reaches rated capacity, municipal budget will get additional 122 million Rubles, while regional budget – around 2.5 billion Rubles.

Launch of the mill was first scheduled for 2007. Total investment scope of the project reached $500 million, while major investor was Sida, a Chinese company that planned to finance the construction with the help of Chinese banks. As regional minister for industry Oleg Polyakov said, as of 2010 the project cost was 13.5 billion Rubles (€335 million).

source: www.whatwood.ru

NewPage Strengthens Partnership with American Tree Farm System

NewPage Corporation (NewPage) has announced that it has increased its supply-chain preference for pulpwood procured from certified woodland owners, including those certified to the American Tree Farm System (ATFS).

NewPage, the leading producer of printing and specialty papers in North America, is the largest buyer of pulpwood in the Great Lakes States. In 2011, 48 percent of the fiber (wood and pulp) purchased by NewPage came from certified sources.

According to Gordy Mouw, NewPage Certification and Resource manager, the procurement preference reflects the company's commitment to forest stewardship as well as its efforts to meet the growing demand of its customers seeking paper sourced from certified timberlands. In addition to ATFS, NewPage has established preferences for wood certified by the Forest Stewardship Council and the Sustainable Forestry Initiative.

"Adding certified ATFS wood to our supply-chain addresses our customers' interests, our own commitment to sustainability, and helps family forest owners by expanding markets for their wood products," Mouw said. "This in turn helps them keep their forest land forested."

ATFS is a program of the American Forest Foundation (AFF) and Tom Martin, President and CEO of the American Forest Foundation, applauded the action by NewPage. "Buying preferences such as the one announced by NewPage contribute to the vitality of American woodlands by encouraging family forest owners to seek certification and manage their woodlands to higher environmental standards," Martin said. "Certification thereby promotes healthy forests and with that more sustainable pulpwood markets."

Mouw explained that the supply-chain preference will be imbedded in the company's continuing process of establishing and maintaining relationships with woodland owners and pulpwood suppliers.

The relationship between NewPage and ATFS has been a long and fruitful one. Through this partnership, thousands of woodland owners have had the market support to manage their land for optimal environmental and recreational use. NewPage has provided markets, assistance to landowners in conducting responsible management and volunteers to help ATFS operate their owner education and outreach programs to woodland owners.

ATFS is a network of 89,000 certified Tree Farmers sustainably managing 27 million acres of forestland. It is the largest and oldest sustainable woodland system in America, internationally recognized, and meeting strict third-party certification standards. Learn more at www.treefarmsystem.org.

SOURCE NewPage Corporation

BTG at Paper+ '12, Stall No. E07, Codissa Trade Fair Complex

With a paper market growth estimated at 6%, India is the place to be!

Visit our booth and

- Talk to us about your applications; we have solutions for your pulping process right from your stock preparation to fiber lines.

- See how we can optimize your fiber usage with the widest range of consistency transmitters and basis weight valves on the market.

- Or discuss about our cost-effective upgrades of your current BTG MEK consistency transmitters to simply improve its performance.

Our engineers will present a wide range of value-based solutions to increase the papermaker's profit by reducing operating costs and raising productivity, such as process automation packages.

We can also assist in delivering sustainable energy savings, waste reduction and stable paper quality supported with our latest instrumentation.

In November, our Instruments division opens a Service facility in Begumpet, Hyderabad to enhance support for its growing number of Indian customers, staffed by experienced BTG service engineers. At the new facility we provide full product repair, upgrade, service and training support to the growing number of local customers. Information on training programs planned will be available soon.

BTG is present throughout the papermaking process and is committed to helping clients achieve significant, sustainable gains in business performance, accomplished through our world-wide experts, market-leading technologies and a passion for results.

BTG - raising your productivity

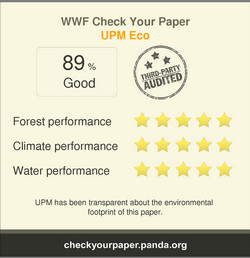

Transparency and environmental performance of UPM’s papers recognized in 2012 WWF Environmental Paper Awards

UPM is one of seven paper producers to receive an award from the WWF (World Wide Fund For Nature) in the category of ‘Transparency’ during the 2012 WWF Environmental Paper Awards. The award recognizes UPM’s efforts in providing public information on the environmental footprint of the majority of its paper products in ‘Check your paper’: a global benchmarking database of eco-rated papers that promotes the responsible supply chain of paper products.

UPM is one of seven paper producers to receive an award from the WWF (World Wide Fund For Nature) in the category of ‘Transparency’ during the 2012 WWF Environmental Paper Awards. The award recognizes UPM’s efforts in providing public information on the environmental footprint of the majority of its paper products in ‘Check your paper’: a global benchmarking database of eco-rated papers that promotes the responsible supply chain of paper products.

“Transparency is essential to driving environmental performance and ensuring customers have the necessary information to make responsible purchasing decisions”, commented John Sanderson, Director of Environmental Market Support for UPM.

In addition, two paper brands of UPM have received the WWF Environmental Paper Award 2012 in the category “Best Environmental Performance Paper Brands” reaching over 90% of achievable scores in WWF´s eco-rating and the maximum 5 stars in all performance categories: forest, water and climate. UPM has published 66% of coated paper, 22% of uncoated paper and 11% of its newsprint on WWF´s ‘Check Your Paper’ database where users can assess how papers rate against criteria such as management of forests, greenhouse gas emissions, water pollution and waste, all of which are also combined into a single measure to rate each paper grade overall.

In addition, two paper brands of UPM have received the WWF Environmental Paper Award 2012 in the category “Best Environmental Performance Paper Brands” reaching over 90% of achievable scores in WWF´s eco-rating and the maximum 5 stars in all performance categories: forest, water and climate. UPM has published 66% of coated paper, 22% of uncoated paper and 11% of its newsprint on WWF´s ‘Check Your Paper’ database where users can assess how papers rate against criteria such as management of forests, greenhouse gas emissions, water pollution and waste, all of which are also combined into a single measure to rate each paper grade overall.

“Increased transparency of value chains is a sign from companies that they want to improve their environmental and social responsibility. I’m delighted by this development and encourage companies to provide transparent information also in the future”, said Liisa Rohweder, CEO of WWF Finland.

UPM’s paper products are made of sustainable raw materials and with a minimal environmental impact. This exceptional performance is assured by certification, continuous monitoring and reporting. The world’s largest conservation organisation also recognized UPM’s outstanding environmental performance of other paper brands featured in WWF’s ‘Check your paper’: thirteen of UPM’s paper brands reached over 80% and four reached over 70% points.

UPM’s Biofore vision and consistent work on corporate responsibility has recently gained recognition from different parties. UPM was listed as the only forestry and paper company worldwide in the Dow Jones Sustainability Indexes, and also recognized as the ‘Most Innovative Company’ at the 2012 Ethical Corporation Awards. In the Nordic Carbon Disclosure Leadership Index, UPM was ranked in shared first place with top scores.

Foundation stone for UPM’s wood-based renewable diesel biorefinery laid in Lappeenranta

The construction of the world’s first biorefinery producing wood-based renewable diesel in Lappeenranta is running according to schedule. The foundation stone of UPM Lappeenranta Biorefinery will be encased today. Construction began last summer and the biorefinery will start producing renewable diesel made from tall oil in 2014.

The construction of the world’s first biorefinery producing wood-based renewable diesel in Lappeenranta is running according to schedule. The foundation stone of UPM Lappeenranta Biorefinery will be encased today. Construction began last summer and the biorefinery will start producing renewable diesel made from tall oil in 2014.

“The EUR 150 million investment to Lappeenranta is UPM’s spearhead project and the first step on our way to becoming a significant producer of advanced second generation biofuels. The Biorefinery is also a focal part in the realisation of our Biofore strategy, combining the bio and forest industries,” says UPM President and CEO Jussi Pesonen.

The UPM Lappeenranta Biorefinery is the first significant investment in a new and innovative production facility in Finland during the ongoing transformation of forest industry. It will be realised without public investment grants.

Lappeenranta Biorefinery project is important for the local economy and employment. The construction of the biorefinery will offer work for nearly 200 people for approximately two years. When production commences, the biorefinery will directly employ nearly 50 people and indirectly about 150 people. The Biorefinery will produce 120 million litres of advanced, renewable diesel fuel annually.

”UPM is executing the company’s renewal strategy persistently and expects that the operation possibilities and competitiveness of industry is maintained rather than hindered with short-sighted decisions. UPM is still the biggest and most versatile wood refiner in Finland. In the past 10 years, the company has invested nearly EUR 700 million in Eastern Finland.”

“One of the greatest features of Lappeenranta project is that it combines the know-how of many UPMers. By utilising our own development work, a sustainable wood-based raw material is converted into high quality transport fuel that truly decreases emissions and is suitable for modern cars. The quality of our end product and its environmental characteristics has gained significant interest among a wide range of customers. The seamless cooperation of UPMers is needed in the future, too, to enhance the growth of our biofuel business.”

The greetings of the Finnish Government will be presented by Esa Härmälä, Director-General, Energy Department in Ministry of Employment and the Economy.

Vacon has established regional center in Singapore

Global AC drives manufacturer Vacon has established a regional center in Singapore. The new center started operations in August 2012.

Vacon's regional center in Singapore ensures that Vacon's entire product portfolio and service network offering are available to customers in the region. The center is also in charge of effective sharing of best practices, know-how and the professional personnel that the company already has in the Middle East, India, South East Asia and Pacific region. This will open up new opportunities for Vacon to gain market share and increase volumes in this region with its huge population and great market potential.

"As a major world trade node with a business-friendly economy, Singapore was a logical location for Vacon to establish a regional center. We are at the heart of the region which is one of Vacon's major growth areas," says Olli Tevä, Vacon's Vice President for Middle East, India, SEA, Pacific.

"Singapore has also a rich supply of skilled and experienced workers, which will help us to continuously improve our customer service in the region. As many of Vacon's global customers have their regional offices in Singapore, it will help us in building seamless cooperation with them. This also reflects Vacon's values: keeping customers and partners at the heart of Vacon's operations," concludes Tevä.

DuraPulp won prize in the competition "Plastovationer"

Södra Cell and the composite - material DuraPulp won a prize this week in the category "Bio" in the competition "Plastovationer".

Södra Cell and the composite - material DuraPulp won a prize this week in the category "Bio" in the competition "Plastovationer".

The prize is awarded annually by the magazine Plastforum to a company or person who has used plastic, rubber or a composite material in a product or a detail in a way that replaces other materials and thereby making the product in question better, cheaper and more environmentally friendly.

"It is really nice that the material has gained recognition from the plastic industry", says Anna Altner, Project Manager DuraPulp.

Jan-Eric Hedberg, process engineer, received the prize on Södra's behalf.

The composite - material DuraPulp is based on fibre pulp in combination with a renewable biopolymer. Thus far the material has been used in the production of a designer lamp and a children's chair and has gained a great deal of attention for its properties in several different contexts.

You can read more about the price at www.plastovationer.se

Pulp Paper logistics magazine and Pulp-paperworld.com join forces.

Vince Maynard the publisher & editorial director of Pulp Paper Logistics magazine has quoted "it has been interesting to see the changes from within the industry over the past 12 months. Mergers, acquisitions and sadly some closures. Tissue and packaging continues however to inspire and the developments in this area have been innovative".

Vince Maynard the publisher & editorial director of Pulp Paper Logistics magazine has quoted "it has been interesting to see the changes from within the industry over the past 12 months. Mergers, acquisitions and sadly some closures. Tissue and packaging continues however to inspire and the developments in this area have been innovative".

Innovation and the ability to look forwards continue to drive our industry worldwide and this is something we have also taken part in.

Our forward looking attitude has again taken another step forwards and after months of discussions I can report that as of now we will work in co-operation with Ian Melin Jones of Pulp-paperworld to provide the much needed website platform that many you have asked for. This agreement will in return allow www.pulp-paperworld.com an avenue for print promotion and at the same time enable every reader of PPL access to a comprehensive and daily updated website.

PPL magazine will continue to be available in Print, on line digital and full issue PDF formats, this form of cooperation is nothing new in the pulp and paper industry but for the publishing sector it offers an innovative and mutually beneficial collaboration for both readers and subscribers alike.