Ianadmin

Stora Enso divests its ownership in Arapoti Mill in Brazil

Stora Enso plans to divest its ownership in the Arapoti Mill in Brazil to Papeles Bio Bio. The divestment supports Stora Enso's transformation into a renewable materials growth company.

Stora Enso has signed an agreement to divest its entire 80% shareholding in the Arapoti magazine paper mill in Paraná, Brazil, to Papeles Bio Bio, a Chilean paper producer. The consideration for the divestment of the shares is approximately EUR 21 million, subject to customary closing day adjustments. The loss on disposal amounts to approximately EUR 27 million and will be recorded as a non-recurring item in Stora Enso’s fourth quarter 2015 results. The transaction will reduce Stora Enso’s net debt by approximately EUR 18 million.

Stora Enso has signed an agreement to divest its entire 80% shareholding in the Arapoti magazine paper mill in Paraná, Brazil, to Papeles Bio Bio, a Chilean paper producer. The consideration for the divestment of the shares is approximately EUR 21 million, subject to customary closing day adjustments. The loss on disposal amounts to approximately EUR 27 million and will be recorded as a non-recurring item in Stora Enso’s fourth quarter 2015 results. The transaction will reduce Stora Enso’s net debt by approximately EUR 18 million.

The transaction is subject to regulatory approvals and is expected to be completed during the first quarter of 2016. At completion, the cumulative translation adjustment loss will be transferred from an equity reserve to the income statement. Based on the foreign exchange rate on 30 November 2015, the cumulative translation adjustment loss is estimated to be EUR 30 million.

Arapoti’s plantation company, which owns 30 000 hectares of plantations, and in which Stora Enso has a 20% shareholding, is not part of the transaction.

Based on 2015 annual figures, the transaction decreases Stora Enso’s sales by approximately EUR 100 million.

“Arapoti Mill is in good technical shape and has a loyal customer base. I believe that it will benefit from being part of a Chilean company with a newsprint production unit close to the mill,“ says Kati ter Horst, EVP Paper division at Stora Enso.

Arapoti Mill is the only producer of coated magazine paper (LWC) in South America. The majority of its production is sold to the domestic market and the rest to other Latin American countries. The mill has an annual production capacity of 185 000 tonnes of LWC, and it employs 320 people. Arauco, a Chilean forest products company, owns 20% of Arapoti Mill.

About the buyer

Papeles Bio Bio S.A. is a Chilean producer of newsprint and mechanical speciality papers, with one mill located in Chile and one in Brazil. Papeles Bio Bio’s annual paper production is approximately 300 000 tonnes and the company serves the major newsprint publishers and commercial printers of South America. It is owned by a consortium of Chilean and international investors.

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Our aim is to replace non-renewable materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 27 000 people in more than 35 countries, and our sales in 2014 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market.www.storaenso.com

Minerals Technologies Inc. Signs Commercial Agreement with European Paper Company to Deploy FulFill® Technology for High-Filler Loading

Signing Marks the Company's 24th Agreement for FulFill® Technology that Provides Significant Cost Savings in Reduced Fiber Consumption by Increasing PCC Filler Usage

Minerals Technologies Inc., (NYSE: MTX) has just announced that it has signed a commercial agreement with a prestigious European papermaker to provide Fulfill® E-325 high-filler technology at the paper company's mill in Europe. This is the second agreement for the deployment of the FulFill® technology at this paper mill.

Minerals Technologies Inc., (NYSE: MTX) has just announced that it has signed a commercial agreement with a prestigious European papermaker to provide Fulfill® E-325 high-filler technology at the paper company's mill in Europe. This is the second agreement for the deployment of the FulFill® technology at this paper mill.

Minerals Technologies now has 24 agreements with paper mills that have adopted the Fulfill® technology that the company introduced in late 2010. The company has nine agreements with paper companies in Asia; eight in North America; six in Europe; and one in South America.

"We are delighted that this highly respected European papermaker has signed a second agreement to use our technology, which will allow them to produce high quality paper at lower cost," said Joseph C. Muscari, chairman and chief executive officer.

These agreements confirm the commercial progress of the Fulfill® brand, a portfolio of high-filler technologies that offers papermakers a variety of efficient, flexible solutions that decreases dependency on natural fiber and reduces costs. The Fulfill® E-325 series allows papermakers to increase loading levels of precipitated calcium carbonate (PCC) by three to five points, which replaces higher cost pulp, and increases PCC usage between 20 to 30 percent.

"We are engaged with approximately 20 other paper mills to introduce our FulFill® technology, as well as our breakthrough NewYield(TM) Integrated Process Technology that converts a papermaking waste stream into a useable filler," said Rand Mendez, senior vice president & managing director, Paper PCC. "Through continued innovation, MTI is advancing our leadership in technology that can reduce costs and improve quality for the worldwide paper industry."

PCC is a specialty pigment for filling and coating high-quality paper. By substituting Minerals Technologies' PCC for more expensive wood fiber, customers are able to produce brighter, higher quality paper at lower cost. In 1986, Minerals Technologies originated the satellite concept for making and delivering PCC on-site at paper mills and the concept was a major factor in revolutionizing papermaking in North America. Today, the company has 60 satellite plants in operation or under construction around the world and continues to lead the industry with consistent quality and technical innovation.

Minerals Technologies Inc. is a resource- and technology-based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral-based and synthetic mineral products and related systems and services. The company recorded sales of $1.725 billion in 2014.

Xerium Technologies Announces the Appointment of New Board Member

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, today announced the appointment of Mr. Alexander Toeldte to the Company’s Board of Directors.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, today announced the appointment of Mr. Alexander Toeldte to the Company’s Board of Directors.

Mr. Toeldte is currently an Operating Director at Paine & Partners, LLC, a private equity firm. Prior to this, he served as the President, Chief Executive Officer and a Director of Boise Inc. and Executive Vice President at Boise Cascade LLC. Mr. Toeldte's previous experience includes Executive Vice President of Fonterra Co-operative Group and Chief Executive of Fonterra Enterprises; and Chief Executive Officer of Fletcher Challenge Building and Fletcher Challenge Paper. In addition, Mr. Toeldte was a Partner of McKinsey & Company serving in the Toronto, Brussels, Montreal, and Stockholm offices.

Currently, Mr. Toeldte is the Chairman of the Board of Jitasa, Inc., and is on the Board of Wevorce Inc., each of which are privately-held companies.

About Xerium (NYSE:XRM)

Xerium Technologies, Inc. is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to the production of paper, paperboard, tissue, pulp, building products, nonwoven fabrics, and variety of industrial applications. Xerium products are specifically designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Verso Sells Verso Androscoggin Power LLC to Eagle Creek Renewable Energy, LLC

Verso Corporation (OTCQB: VRSZ) has just announced that it has sold one of its subsidiaries, Verso Androscoggin Power LLC (VAP), to Eagle Creek Renewable Energy, LLC, for a purchase price of approximately $62 million in cash. VAP owns four hydroelectric generation facilities associated with Verso's Androscoggin pulp and paper mill located in Jay, Maine. The parties contemporaneously entered into a purchase agreement and consummated the transaction.

Verso Corporation (OTCQB: VRSZ) has just announced that it has sold one of its subsidiaries, Verso Androscoggin Power LLC (VAP), to Eagle Creek Renewable Energy, LLC, for a purchase price of approximately $62 million in cash. VAP owns four hydroelectric generation facilities associated with Verso's Androscoggin pulp and paper mill located in Jay, Maine. The parties contemporaneously entered into a purchase agreement and consummated the transaction.

The sale of VAP is part of Verso's efforts to raise funds to address its previously disclosed cash flow and liquidity concerns. Verso continues to evaluate other potential asset sales in connection with its exploration of various debt restructuring alternatives.

The sale of VAP is expected to have no impact on the operations of the Androscoggin mill. The mill purchased electricity from VAP before the transaction, and it will continue to do so with VAP now under Eagle Creek's ownership. Moreover, the mill operates its own energy cogeneration facilities - consisting of two recovery boilers, a biomass boiler, three steam turbines, and three gas turbines - and also purchases electricity from Central Maine Power Company. Most importantly, the sale will not affect the Androscoggin mill's ability to manufacture its high-quality products and will not cause any interruption in serving its customers.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.

About Eagle Creek

Eagle Creek Renewable Energy, LLC (www.eaglecreekre.com) is an owner, operator and developer of hydroelectric generation facilities and provides safe, clean, economic renewable energy to electricity consumers in the U.S. Eagle Creek currently owns and operates in excess of 130 MW from 47 facilities. Eagle Creek was founded in 2010, is privately owned and is headquartered in Morristown, New Jersey.

ANDRITZ successfully starts up the world’s first eucalyptus fluff pulp drying plant at the Suzano mill, Brazil

![]() International technology Group ANDRITZ has successfully started up the world’s first eucalyptus-based fluff pulp drying plant at Suzano Papel e Celuloseʼs Suzano mill, São Paulo, Brazil. The pulp produced is mainly used for production of sanitary papers.

International technology Group ANDRITZ has successfully started up the world’s first eucalyptus-based fluff pulp drying plant at Suzano Papel e Celuloseʼs Suzano mill, São Paulo, Brazil. The pulp produced is mainly used for production of sanitary papers.

ANDRITZ PULP & PAPER delivered several modifications to the existing PM5 production line including a new rewinder. Within a time frame of less than nine months, the complete line was engineered, rebuilt, and put into operation for the production of both fluff pulp and wood-free paper.

For further information, please contact:

Michael Buchbauer

Head of Corporate Communications

Phone: +43 (316) 6902 2979

f_to=This email address is being protected from spambots. You need JavaScript enabled to view it.&;g_cmsid=5222" title="Contact ANDRITZ about "ANDRITZ successfully starts up the world’s first eucalyptus fluff pulp drying plant at the Suzano mill, Brazil"">This email address is being protected from spambots. You need JavaScript enabled to view it.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of almost 25,000 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, production equipment for biofuel (second generation), biomass torrefaction equipment, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

Valmet-supplied OptiConcept M board making line started up at Pratt Industries in the USA

Pratt Industries' Valmet-supplied containerboard production line, PM 16, successfully came on stream on October 04, 2015 at their greenfield paper mill in Valparaiso, Indiana, USA. This is Valmet's first OptiConcept M installation in North America.

"PM 16 is one of the industry's most efficient paper mill, employing 120 people to make 370,000 tons a year - twice the productivity of many competitor mills. It is the world's most environmentally-friendly paper mill and a showcase for the latest in 21st Century paper-making technology," says Anthony Pratt, Global Chairman of Pratt Industries.

Valmet OptiConcept M board making line is designed to use less water, electricity and raw materials. "That's important not only for our environment but also for our customers who realize the importance of sustainable packaging." says Pratt.

The Valmet OptiConcept M containerboard production line started up on October 4, 2015 for Pratt Industries at the Valparaiso mill in Indiana, USA.

About Pratt Industries

Pratt is America's 5th Largest corrugated packaging company and the world's largest, privately-held 100% recycled paper and packaging company, with more than 5200 highly-skilled employees dedicated to the environment and sustainability. Pratt was founded in the USA some 25 years ago and, since then, has shown dramatic growth with sophisticated manufacturing facilities in more than 20 states.

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Further information, please contact:

Tuomo Rämö, Senior Project Manager, Paper Mills, Valmet, tel. +358 40 748 8513

Mike Gray, Area Vice President, North America, Valmet, tel. +1 920 738 8542

The Board of Directors of Valmet resolved on continuing the long term incentive plan for key employees

The Board of Directors of Valmet has decided to continue the share based incentive program for Valmet's key employees approved in December 2014. The aim of the program is to combine the objectives of the shareholders and the key employees in order to increase the value of the company, to commit the key employees to Valmet, and to offer them a competitive reward plan based on holding the company's shares.

The Board of Directors of Valmet has decided to continue the share based incentive program for Valmet's key employees approved in December 2014. The aim of the program is to combine the objectives of the shareholders and the key employees in order to increase the value of the company, to commit the key employees to Valmet, and to offer them a competitive reward plan based on holding the company's shares.

The program approved in 2014 includes three discretionary periods, which are the calendar years 2015, 2016 and 2017. The Board of Directors of Valmet shall decide on the performance criteria and targets in the beginning of each discretionary period. The potential reward of the program from the discretionary period 2016 is based on EBITA % improvement and orders received growth % of the stable business, that is, the Services and Automation business lines. The potential reward of the plan from the discretionary period 2016 will be paid partly as Valmet shares and partly in cash in 2017. The proportion to be paid in cash is intended to cover taxes and tax-related costs arising from the reward to the key employee. As a rule, no reward is paid, if the key employee's employment or service ends before the reward payment.

As part of the share based incentive program members of the Valmet Executive Team shall have a possibility to receive a matching share reward for the discretionary period 2016 provided that he or she owns or acquires Valmet shares up to a number determined by the Board of Directors by December 31, 2016. Reward receipt is tied to the continued employment or service of the Valmet Executive Team member upon reward payment.

The reward of the plan may not exceed 120 percent of the key employee's annual total base salary. The shares paid as reward may not be transferred during the restriction period, which will end two years from the end of the discretionary period. Should a key employee's employment or service end during the restriction period, as a rule, he or she must gratuitously return the shares given as reward to Valmet.

The plan is directed to approximately 80 people. The rewards to be paid on the basis of the plan are in total an approximate maximum of 850,000 shares in Valmet.

Further information, please contact:

Pasi Laine, President and CEO, Valmet, tel. +358 10 672 0001

Hanna-Maria Heikkinen, Vice President, Investor Relations, Valmet, tel. +358 10 672 0007

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Fibria included in the Corporate Sustainability Index (ISE) for the seventh straight year

For the seventh consecutive year, Fibria was selected as a component of the Corporate Sustainability Index (ISE) of the BM&FBovespa, which reflects its firm commitment to practices that balance financial performance, sustainability and corporate governance. Fibria was included in the ISE portfolio for 2016, which will be valid from January 4 to December 29, 2016.

For the seventh consecutive year, Fibria was selected as a component of the Corporate Sustainability Index (ISE) of the BM&FBovespa, which reflects its firm commitment to practices that balance financial performance, sustainability and corporate governance. Fibria was included in the ISE portfolio for 2016, which will be valid from January 4 to December 29, 2016.

Developed in partnership with the Center for Sustainability Studies (GVces) of the Getúlio Vargas Foundation (FGV), the ISE is formed by the 35 best companies from a corporate sustainability standpoint and assesses how effectively they balance economic growth, social responsibility and environmental performance. According to the BM&FBovespa, the new portfolio is formed by corporations from 16 industries with combined market capitalization of R$960.52 billion, which corresponds to 44.75% of the total market capitalization of companies with stock listed on the exchange at the close of trading on Nov. 24, 2015.

“For Fibria, sustainability is a business principle and we are very satisfied to have been selected as an ISE component stock for the seventh straight year. It represents the market's recognition of Fibria's good practices in finance, governance and sustainability. It also shows that we remain firmly on the path of developing our forestry business responsibly, while generating "admired profit" and sharing value with society,” said Guilherme Cavalcanti, Fibria's Chief Financial and Investor Relations Officer.

In addition to the ISE, Fibria was also selected as a component stock for 2015-2016 of the Dow Jones Sustainability™ Emerging Markets Index, which is a global reference in sustainability stock indexes.

“Fibria's commitment to using natural resources efficiently and social engagement is intrinsically linked to its strategy, which was born from the mission to develop the forestry business as a sustainable source of life and to create value in a way that is responsible, shared and inclusive,” said Maria Luiza de Oliveira Pinto e Paiva, director of Sustainability, Communication and Corporate Affairs at Fibria.

This year, Fibria also received the Sustainable Standard-Setter Award from the Rainforest Alliance, an independent non-governmental organization that defends a global system for forestry product certification and works to conserve biodiversity, ensure sustainable means of subsistence and transform land-use practices.

About Fibria

The world leader in eucalyptus pulp production, Fibria is a company that strives to meet the growing global demand for forestry products in a sustainable manner. With annual pulp production capacity of 5.3 million tons, the company has industrial units in the cities of Aracruz (Espírito Santo), Jacareí (São Paulo) and Três Lagoas (Mato Grosso do Sul), and in Eunápolis (Bahia), where it operates the Veracel plant through a joint-operation with Stora Enso. Fibria has 967,000 hectares of forests, with 563,000 hectares of planted forests and 343,000 hectares of environmental preservation and conservation areas. The pulp manufactured by Fibria is exported to more than 40 countries. In May 2015, Fibria announced the expansion of its Três Lagoas unit, which will receive a new line with the capacity to produce 1.75 million tons of pulp per year.

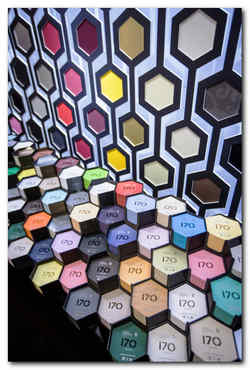

JAMES CROPPER SHOWCASES CLASSICS AT PAPERWORLD

With 170 years of British master papermaking experience, James Cropper presents its most traditional and timeless papers at this year’s Paperworld – the leading international trade fair for stationery and office supplies.

With 170 years of British master papermaking experience, James Cropper presents its most traditional and timeless papers at this year’s Paperworld – the leading international trade fair for stationery and office supplies.

The bespoke paper manufacturer will introduce a vibrant array of new shades in its classic Vanguard range at the event, which takes place in Frankfurt from 31 January to 2 February 2016. The kaleidoscopic assortment of 32 dazzling colours has been enhanced, with the addition of a medley of red and blue tones – Blueberry, Bordeaux, Cherry and Purple – following a trend for the hues.

In addition, two new papers being showcased – Elation and Porcelain – are specifically designed to be versatile for a range of printing outcomes. Porcelain is a pure white product that provides the sharpest and smoothest of blank canvases for designers, while Elation – a tactile, high-grade and versatile felt-marked paper – exudes elegance.

Andy Smith, export sales director at James Cropper, said: “We’re incredibly proud of our originality and design at James Cropper, but also value the beauty of our tradition and heritage – Vanguard, Elation and Porcelain are fantastic examples of where tradition and innovation collide.

“Porcelain is a stunningly flawless and fresh paper, which is designed with effortless modern printing in mind, whilst Elation’s tactile qualities project a high-end corporate impression. Our Vanguard range has always offered a wide assortment of colours, from vivid reds to soothing pastels, and the latest additions to the collection reflect a demand for even deeper, bolder shades. We aim to offer a colour, texture and sensation for every occasion.”

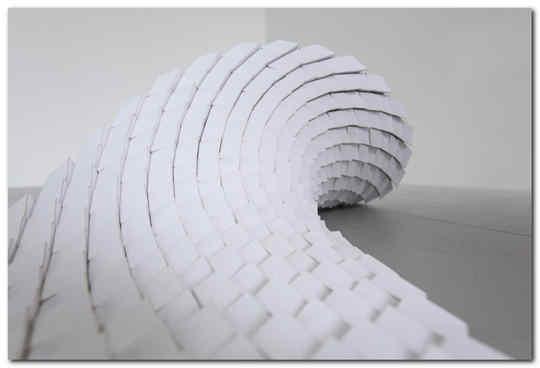

James Cropper will also present two existing paper collections that bring with them an undeniable sense of quality and class to business stationery. Ambassador, a FSC® pure fibre collection of watermarked papers, offers a tremendous choice of finishes from traditional Wove and Laid options to geometric Squares and a unique undulating Waves effect. Meanwhile, the illustrious British paper brand Croxley Heritage – available in classic Wove, Laid and Linen finishes – balances papermaking heritage with contemporary eco-friendly business requirements, being certified FSC® 100% Recycled.

James Cropper will also present two existing paper collections that bring with them an undeniable sense of quality and class to business stationery. Ambassador, a FSC® pure fibre collection of watermarked papers, offers a tremendous choice of finishes from traditional Wove and Laid options to geometric Squares and a unique undulating Waves effect. Meanwhile, the illustrious British paper brand Croxley Heritage – available in classic Wove, Laid and Linen finishes – balances papermaking heritage with contemporary eco-friendly business requirements, being certified FSC® 100% Recycled.

The multi-award-winning paper manufacturer, which celebrated its landmark 170 year anniversary this year, prides itself on its premium and uncoated papermaking, which is unrivalled in quality, versatility, sustainability and service.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is a prestige paper innovator based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

As well as paper products, James Cropper PLC also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors. For further information visit: www.jamescropper.com and www.tfpglobal.com

Metso's Board of Directors decides to continue the long-term incentive plan for senior management

The Board of Directors of Metso has decided to continue the long-term share-based incentive plan for the Group's senior management, with a Performance Share Plan (PSP) as the main structure. In addition, the Board decided to continue the Restricted Share Plan (RSP) as a complementary share-based incentive structure for specific situations.

The Board of Directors of Metso has decided to continue the long-term share-based incentive plan for the Group's senior management, with a Performance Share Plan (PSP) as the main structure. In addition, the Board decided to continue the Restricted Share Plan (RSP) as a complementary share-based incentive structure for specific situations.

The aim of this long-term incentive plan is to align the interests of the management with those of the shareholders in order to increase the value of Metso and to commit the senior management to Metso by offering them a competitive long-term incentive plan in the company.

Performance Share Plan

The Performance Share Plan consists of annually commencing performance share plans, each with a three-year earning period. The commencement of each new plan will be subject to a separate approval by the Board. In accordance with the decision taken by the Board, PSP 2016-2018 will commence at the beginning of 2016 and potential share rewards will be delivered in the spring 2019 if the performance targets set by the Board are achieved.

The potential share reward payable under the PSP 2016-2018 is based on the total shareholder return of Metso's share during calendar years 2016-2018. The PSP 2016-2018 may include a maximum of 100 employees and will comprise a maximum of460,000reward shares (gross before the deduction of applicable payroll tax).

Restricted Share Plan

The complementary Restricted Share Plan (RSP) consists of annually commencing restricted share plans, each with a three-year vesting period after which the allocated share rewards will be delivered to the participants provided that their employment with Metso continues until the delivery date of the share rewards. The commencement of each new plan is subject to a separate approval by the Board. In accordance with the decision taken by the Board, RSP 2016 will commence at the beginning of 2016 and any potential share rewards will be delivered in the spring 2019.

The maximum number of shares that may be allocated and delivered within the RSP 2016 totals40,000shares (gross before the deduction of applicable payroll tax).

Other terms

Metso applies a share ownership recommendation policy for the members of Metso Executive Team. In accordance with this policy at least fifty per cent of the share rewards (net shares after the deduction of applicable payroll tax) received by these individuals under the above plans shall be retained until the share ownership of the individual participant in Metso amounts to his/her annual gross base salary.

The incentive plans will have no diluting effect as no new shares will be issued in connection with them.

Metso is the world's leading industrial company in the mining and aggregates industries and in the flow control business. Our knowledge, people and solutions help drive sustainable improvements in performance and profitability in our customers' businesses.

Metso has an uncompromising attitude towards safety. Our products range from mining and construction equipment and systems to industrial valves and controls. Our solutions are delivered and supported by decades of process knowledge and a broad scope of services backed by a global footprint of over 90 service centers, thousands of service employees, and an extensive logistics network.

Metso is listed on the NASDAQ OMX Helsinki, Finland. In 2014, Metso's net sales totaled EUR 3.7 billion. Metso employs approximately 13,000 industry experts in more than 50 countries. Expect results.