Ianadmin

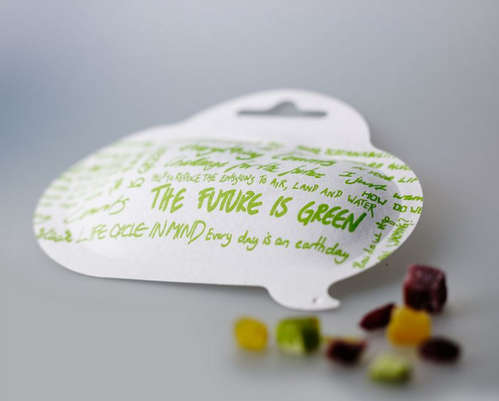

BillerudKorsnäs launches an engaging digital campaign

BillerudKorsnäs launches an engaging digital campaign - Clarifies mission to challenge the conventional for a sustainable future

Leading provider of packaging solutions and materials, BillerudKorsnäs, unveils its first ever brand campaign today. The brand campaign will primarily target customers and customers’ customers in an aim to elucidate the company’s mission, increase brand awareness, boost brand preference and position the brand forward in the value chain.

“It has been two and a half years since BillerudKorsnäs was formed and we are now ready to communicate our brand mission more explicitly than we have done so far. We have evolved from Billlerud and Korsnäs, two paper and board manufacturing companies, into a materials and solutions provider to brand owners and retailers”, says Per Lindberg, CEO BillerudKorsnäs.

The campaign will use stories, articles, cases and insights to illustrate the essence of the company’s mission. The notion of challenging the conventional for a sustainable future entails both an ambitious innovation agenda as well as a strengthened sustainability commitment, themes which will be central to the campaign.

“We want the audience to associate us with fresh thinking and smarter packaging solutions with economic and sustainability advantages. We believe that the best way to do so is to show what we have achieved and realized over the past couple of years, as well as to give the audience a flavour of what we have on our agenda”, says Peter Malmqvist, Marketing Director, BillerudKorsnäs.

The hub of the campaign will be an interactive digital platform where brand ambassadors will be free to share content in their own channels.

“We will be able to engage industry professionals and the general public in a way that we never have done before. Anyone who is moved by what we say can simply click, post, share and comment via social media”, says Peter Malmqvist.

To take part of the BillerudKorsnäs brand campaign, please visit the campaign site, which will be live from the 7th of May until August 2015.

For more information, please contact:

Peter Malmqvist, Marketing Director, BillerudKorsnäs,

+46 72 210 62 45, This email address is being protected from spambots. You need JavaScript enabled to view it.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world leading provider of primary fiber based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4200 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 21 billion and is listed on Nasdaq Stockholm.

Sappi to increase its European coated fine and coated mechanical paper prices by 8%

Continuously rising input costs and consequently declining profit margins make corrective pricing measures inevitable as Sappi Europe’s business is unsustainable at current price levels.

Continuously rising input costs and consequently declining profit margins make corrective pricing measures inevitable as Sappi Europe’s business is unsustainable at current price levels.

We are therefore announcing a price increase of 8% for all European coated fine and coated mechanical reels business as per the 1st of July 2015.

The timing and extent of a price rise for coated fine paper sheets will be announced separately.

Our customers will be personally informed by our sales managers who will provide them with any information they may require.

About Sappi

Sappi Europe SA is the leading European producer of coated fine paper used in premium magazines, catalogues, books and high-end print advertising. Headquartered in Brussels, Belgium, Sappi Europe is recognised for innovation and quality. Its graphic paper brands include Magno™, Quatro™, Vantage™, Royal™, Galerie™, GalerieArt™ and Jaz™ ranges. Algro®, Fusion®, Leine® and Parade® are the brands for speciality labelling, topliner, packaging papers and boards. Sappi papers are produced in mills accredited with ISO 9001, ISO 14001 and OHSAS 18001 certification and EMAS registration for all our mills in the EU. Sappi European mills hold chain-of-custody certification under the Forest Stewardship Council (FSC®) and/or the Programme for the Endorsement of Forest Certification (PEFC™) schemes.

Sappi Europe SA is a division of Sappi Limited (JSE), a global company headquartered in Johannesburg, South Africa, with over 12,800 employees and manufacturing operations on three continents in seven countries, sales offices in 50 countries, and customers in over 100 countries around the world. Learn more about Sappi at www.sappi.com.

ZELLCHEMING-Expo 2015 with attractive fringe program

Besides the comprehensive range of exhibits along the process chain of the pulp and paper production as well as in the sector of fiber based materials, ZELLCHEMING-Expo 2015 also offers an attractive and informative fringe program beyond the exhibition stands.

The hot topics “Technology & Services“, “Materials & Processing“ and “Research & Development“ will be the focus of the market place „Fibers in Process@ZELLCHEMING-Expo“ that takes place under the direction of Deutscher Fachverlag. The represented universities and institutions give an insight into future trends of the industry and show their current research projects and innovative developments under the topic “Research & Development”.

In free lectures and panel discussions at the Trend Lounge experts of the industry take up current topics and demonstrate where the change of the industry may lead. Further highlights are the material wall “MaterialsgateSHOW” that present extraordinary material applications and therefore illustrate touchable future trends of the industry as well as the “Job & Career Corner” that informs about vacant positions of the exhibiting companies.

Conference with late-breaking topics

According to the motto “Paper & Fiber World 2030 – What does the future hold for the paper industry?” the parallel held conference offers a top-class and informative lecture program.

The results of the future project “Paper & Fiber World 2030” will be presented to the public for the first time at the conference by Dipl. Ing. Thomas Strobel (Managing Director FENWIS GmbH). The project – jointly supported by VDP, HPV and FPT – reveal opportunities and risks of the paper industry to identify fields of actions at an early stage.

Further conference highlights at a glance:

- Keynote of Dr. Utz Tillmann (Director General of the German Chemical Industry Association).

- Keynote of Bertram Staudenmaier (Member of the Corporate Board of Management and Chairman of the Management Board of Voith Paper).

- Panel discussion „Paper & Fiber World 2030“ presented by Markus Gürne (Head Stock Exchange ARD-TV).

The series of lectures to the topics “Light weight construction with paper in construction and packaging“, “Functional barriers for paper and board” as well as the Cellulose Chemists’ Symposium round off the lectures with first-class speakers.

The early bird price for the registration for the ZELLCHEMING-Expo conference 2015 is valid for all bookings received until 31 May 2015 at www.zelllcheming-expo.com.

The free visitor registration as well as detailed information are available at www.zelllcheming-expo.com.

About Mesago

Mesago Messe Frankfurt, founded in 1982 and located in Stuttgart, specializes in exhibitions and conferences on various topics of technology. The company belongs to the network of Messe Frankfurt. Mesago operates internationally and is not tied to a specific venue. With 125 members of staff Mesago organizes events for the benefit of more than 2,700 exhibitors and over 100,000 trade visitors, conference delegates and speakers from all over the world. Numerous trade associations, publishing houses, scientific institutes and universities work with Mesago closely as advisers, co-organizers and partners.

ZELLCHMING e. V. - The Association of Chemical Pulp and Paper Chemists and Engineers is an association which has dedicated itself fully to the various issues and topics surrounding chemical pulp production and paper making. We see ourselves as a technical-scientific professional association for the chemical pulp paper industry as well as its suppliers. Anybody who is involved with chemical pulp production and paper making in Europe will find that we offer a comprehensive range of information as well as strong representation of interests for the concerns and issues affecting our high-tech sector. We provide our members with an international network for the exchange of information and technical contacts in which topics discussed range from research and development concerning paper making through to ecology and the future of the chemical pulp industry and paper industry.

Fitch Publishes Latin America Pulp Dashboard

Fitch Ratings has published its Latin America Pulp Dashboard.

This dashboard explores key topics affecting the credit profiles of the major players within the Latin America market pulp industry. Items that are monitored in the report include: expectations of pulp prices, Chinese demand, cost curve, softwood and hardwood price differentials, and the expectation that free cash flow (FCF) should benefit from high sales volumes, reduced capex and weaker currencies.

This dashboard explores key topics affecting the credit profiles of the major players within the Latin America market pulp industry. Items that are monitored in the report include: expectations of pulp prices, Chinese demand, cost curve, softwood and hardwood price differentials, and the expectation that free cash flow (FCF) should benefit from high sales volumes, reduced capex and weaker currencies.

Fitch's ratings for the Latin America pulp companies have built in an expectation of low prices for 2015 and credit fundamentals remain closely linked to cost positions that are among the lowest in the industry.

A complete review of these topics is included in the dashboard available at www.fitchratings.com or by clicking the link above.

Additional information is available at 'www.fitchratings.com.

Applicable Criteria and Related Research: Latin American Pulp Dashboard

http://www.fitchratings.com/creditdesk/reports/report_frame.cfm?rpt_id=865549

Fitch Ratings

Fernanda Rezende, +55 21 4503-2619

Director

Fitch Ratings Brasil Ltda.

Praca XV de Novembro, 20 - Sala 401 B - Centro

Rio de Janeiro - RJ - CEP: 20010-010

or

Monica Coeymans, +56 22 499-3314

Director

or

Elizabeth Fogerty, +1-212-908-0526

Media Relations, New York

This email address is being protected from spambots. You need JavaScript enabled to view it.

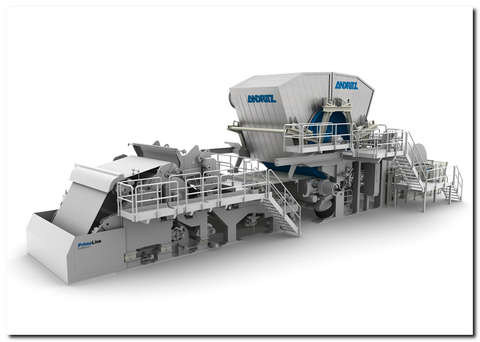

ANDRITZ successfully starts up tissue machine with steel Yankee for LLC Pulp Invest, Russia

International technology Group ANDRITZ has successfully completed the start-up of the PrimeLineCOMPACT II tissue machine with steel Yankee supplied to LLC Pulp Invest, Kazan, Russia.

The machine has a design speed of 1,700 m/min and a width of 2.8 m. The Yankee, manufactured entirely of steel, has a diameter of 3.6 m.

The ANDRITZ PrimeLineCOMPACT II tissue machine PHOTO: Andritz

ANDRITZ supplied the full turnkey package, comprising a new PrimeLineCOMPACT II tissue machine with steel Yankee as well as the complete stock preparation plant, pumps, automation, and electrification.

“We are very pleased that we have been able to complete this important project for LLC Pulp Invest and the Russian pulp and paper industry thanks to ANDRITZ technologies. The very good cooperation between our company and ANDRITZ made it a success. ANDRITZ was quick to respond to our needs and had a solution for any challenge,” says Yury Nuzhin, General Director of LLC Pulp Invest.

With this turnkey supply, ANDRITZ PULP & PAPER is further strengthening its market position as a leading global supplier of plants and key components for tissue production.

For further information, please contact:

Oliver Pokorny

Group Treasury, Corporate Communications & Investor Relations

This email address is being protected from spambots. You need JavaScript enabled to view it.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of almost 25,000 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, production equipment for biofuel (second generation), biomass torrefaction equipment, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

Kemira Oyj issues a EUR 150 million bond

Kemira issues a senior unsecured bond of EUR 150 million. The seven-year bond matures on May 13, 2022 and it carries a fixed annual interest of 2.250 percent. The offering was allocated to approximately 50 investors. Kemira will apply for the listing of the bond on NASDAQ OMX Helsinki.

Kemira issues a senior unsecured bond of EUR 150 million. The seven-year bond matures on May 13, 2022 and it carries a fixed annual interest of 2.250 percent. The offering was allocated to approximately 50 investors. Kemira will apply for the listing of the bond on NASDAQ OMX Helsinki.

The proceeds from the bond offering will be used for general corporate purposes.

Danske Bank and SEB acted as lead managers for the transaction.

For more information, please contact

Kemira Oyj

Petri Castrén, CFO

+358 40 532 7639

Tuomas Kivimäki, VP, Treasury

+358 10 862 1778

Tero Huovinen, VP, Investor Relations

+358 10 862 1980

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2014, Kemira had annual revenue of EUR 2.1 billion and around 4,250 employees. Kemira shares are listed on the NASDAQ OMX Helsinki Ltd.

www.kemira.com

Another successful start-up of a new A.Celli Paper Tissue Machine.

The rebuild project in El Salvador for a major industrial group that has, for the time being, chosen to remain confidential, began in September 2014, when the machine was shipped from Italy to Central America. The start-up scheduled for April 2015, successfully completed with no delays, is doubtlessly a further piece in the mosaic of collaborations that A.Celli is compiling with the international group.

The new A.Celli Tissue Machine represents a strategically interesting project through which the Italian technology supplier once again underscores its role as leading-edge partner in the field of Tissue Machines, the company’s core business. The long-standing competence, dependable reliability and technological excellence that have always distinguished the Group make A.Celli Paper the ideal supplier for every customer, whether Italian, European, Asian, large, medium or small, or international group.

This machine has a 2800-mm web width, a working speed of 1500 m/min and a production capacity of 65 tpd. It was designed to answer all the customer’s requests and demands in order to guarantee an enhancement in production level, assured by optimal performance and paper quality, with consequent improvement in the finished product. With this new Tissue Machine, A.Celli Paper offers the customer a leap forward in quality, aiming for important and ambitious production milestones in its quest to conquer an extremely particular territory such as Central America.

KapStone To Acquire Victory Packaging

KapStone Paper and Packaging Corporation (NYSE: KS) ("KapStone") and Victory Packaging/Golden State Container ("Victory") jointly announced today that they have signed an agreement for KapStone to acquire the assets of Victory Packaging in a cash-free, debt-free transaction for $615 million in cash, subject to post-closing adjustments. In addition, two contingent earnouts totaling $45 million could be payable two and a half to four years after the close and are based on the continued strong growth of the business. Closing of the acquisition is subject to a number of customary conditions, including regulatory review.

KapStone Paper and Packaging Corporation (NYSE: KS) ("KapStone") and Victory Packaging/Golden State Container ("Victory") jointly announced today that they have signed an agreement for KapStone to acquire the assets of Victory Packaging in a cash-free, debt-free transaction for $615 million in cash, subject to post-closing adjustments. In addition, two contingent earnouts totaling $45 million could be payable two and a half to four years after the close and are based on the continued strong growth of the business. Closing of the acquisition is subject to a number of customary conditions, including regulatory review.

The structure of the transaction will enable KapStone to realize a tax benefit that has an estimated net present value of approximately $100 million. Taking this benefit into account, the net purchase is about $515 million.

Founded in 1976, Victory Packaging, headquartered in Houston, TX, is a large, national distributor of all types of packaging specializing in providing unique solutions for its clients. Through its 65 distribution centers located in the United States, Mexico and Canada, Victory services customers with complex needs that often are not attractive to other integrated box manufacturers. Victory's net sales grew to $953 million and adjusted EBITDA reached $55 million for the year ended December 31, 2014, and the CAGR for both net sales and adjusted EBITDA was in excess of 14% for the past four years.

Chairman and Chief Executive Officer of KapStone, Roger W. Stone, stated, "Acquiring Victory will provide KapStone with growth based on Victory's impressive, profitable track record. The acquisition will allow KapStone to de-risk operations by providing a higher level of integration. Victory is a unique strategic fit that will simultaneously increases utilization of our converting assets and mills. Victory currently buys approximately 370,000 tons of corrugated products annually of which KapStone expects to supply an incremental 115,000 tons. Victory will still rely heavily on their current supplier base to fill the remainder. Conservatively estimated, these synergies are expected to reach $30 million of EBITDA in 24 months. The deal is accretive to our bottom-line from Day 1. Our balance sheet, which was strong going into this transaction, remains strong after the acquisition. The combined company is expected to deliver substantial free cash flow in the first year allowing KapStone to quickly de-lever."

Matt Kaplan, President and Chief Operating Officer of KapStone, added, "As a previous board member of Victory, I was able to fully gain an appreciation for their abilities to deliver superior services, drive excellent operating performance, and deliver results to the bottom line. Therefore, I am delighted to have the Victory team join KapStone and am looking forward to the significant benefits that the combined companies will achieve."

Benjamin Samuels, Chief Executive Officer of Victory, commented, "Victory recognizes that making our next leap will take more resources and experience. We are excited about the match of KapStone's people and business model to where Victory is headed. Almost forty years ago, Vic Samuels started with a dream of building a new packaging experience focused on the customer. Today, we are taking the next step in the fulfillment of that dream by partnering not only with some of the best people in the industry, but with good friends."

Robert Egan, Chief Operations Officer/President of Victory Packaging, further commented, "We are excited about the opportunities the business combination brings to our Victory family, our customers and the packaging community. The integrated business models of KapStone and Victory Packaging allow both organizations to meet their expansion goals, add immediate value and provide an avenue for future growth. We are thrilled to join the KapStone family and expand our North American presence and capabilities."

Mr. Stone concluded, "Strategically, the acquisition of Victory is a great next step for KapStone. The acquisition transforms KapStone into a much stronger company providing additional momentum for KapStone to continue its record of excellence in increasing value to our shareholders."

KapStone has committed financing from Bank of America, Barclays Bank, and Wells Fargo Bank.

The transaction is expected to close in the second quarter of 2015.

About KapStone

Headquartered in Northbrook, IL, KapStone Paper and Packaging Corporation is the fifth largest producer of containerboard and corrugated packaging products and is the largest kraft paper producer in the United States. The Company is the parent company of KapStone Kraft Paper Corporation and KapStone Container Corporation which includes four paper mills and 22 converting plants, respectively, across the U.S. The business employs approximately 4,600 people.

About Victory

Based in Houston, TX, Victory Packaging has more than 65 warehouses and distribution facilities in the United States, Canada and Mexico, and operates in California under the company name of Golden State Container. Victory Packaging is a leading national distributor company specialized in solving packaging complexities and finding total cost optimization associated with packaging for its clients. Victory Packaging provides just-in-time delivery and inventory management to a diverse customer base. Its national network includes more than 6 million square feet of warehouse space and approximately 400 delivery vehicles. Victory Packaging is a privately-held limited partnership and employs approximately 1,500 people. For more information visit http://www.victorypackaging.com.

Södra's sawmill in Mönsterås to apply for permit to expand production

Södra is to apply for a new permit for expanded production at its sawmill in Mönsterås. A permit has been sought for 800,000 cubic meters. The current permit is for 450,000 cubic meters.

Södra is to apply for a new permit for expanded production at its sawmill in Mönsterås. A permit has been sought for 800,000 cubic meters. The current permit is for 450,000 cubic meters.

"We have strong confidence in our sawmill in Mönsterås. This permit application is important for the sawmill's future, growth and profitability. On 12 May, a consultation meeting will be held with local residents. The application will subsequently be submitted to the County Council in the early summer," says President of Södra Wood Håkan Svensson.

As a result of production enhancements, the sawmill has now reached the ceiling of the current environmental permit. Södra wants to continue to improve and develop the operation.

"Already now, we have the capacity to process 480,000 cubic metres and in the near future, 500,000-550,000 cubic metres. At that point, new investments will be required. A successive increase will take place, but we are applying for a permit now that will allow for growth," says Håkan Svensson, President of Södra Wood.

Södra is confident in Mönsterås as a sawmill that offers several advantages.

"The sawmill in Mönsterås is a modern facility with an excellent location. This location, next to the pulp mill, provides several integration benefits, for example, the sawmill gets the heat for its dryers from the pulp mill. The sawmill also has access to its own harbour and can quickly ship its goods to the world. From the perspective of forest ownership, the Mönsterås catchment area is important and we want to prepare to capitalize on the forest owners' increasing growth in the forests," says Håkan Svensson.

The increased production is primarily destined for the UK and US, which are two currently expanding markets, where Mönsterås is already a large player.

"We also foresee large potential in China. We have doubled our volumes to China in the past year and have a positive view of the future," says Håkan Svensson.

For further information, please contact:

Håkan Svensson, President of Södra Wood, tel. +46 (0)457-316 00

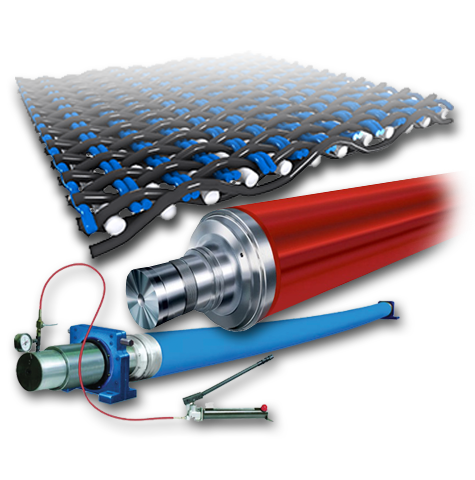

Xerium Launches Huycon Air Belt Technology for Nonwoven Airlaid Applications

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched Huycon Air technology for nonwoven airlaid applications. An extension to the globally established Huycon portfolio, Huycon Air incorporates a 2-1/2 layer base fabric with a fine-mesh product side with engineered air-channel-geometry for excellent web formation, retention and release. Huycon Air also incorporates conductive yarns cross-linked by a specially engineered conductive edge sealing providing superb static electricity dissipation. Additional information about Huycon Air is available at http://www.xerium.com/news/xerium-news.aspx.

(detailed product information is available on our Nonwovens section of our website here)

“The industry-proven Huycon product portfolio provides a complete range of belts specifically designed to produce top quality webs ranging from robust industrial fabrics to highly critical medical and hygiene products. Our newly introduced Huycon Air belt extends our Huycon spunlaid technology to the airlaid manufacturing process,” said Mr. Bill Butterfield, EVP and CTO of Xerium. “Huycon Air is ideal for the forming and transfer position on all kinds of airlaid machines, and we are delighted to further enhance our product line for our global customers.”

About Xerium

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 26 manufacturing facilities in 12 countries, two new plants under construction in 2 countries and employs approximately 3,100 employees.

Source: Xerium Technologies, Inc.