Ianadmin

Tieto to deliver self-services for signing electricity contracts to Turku Energia

Tieto will deliver a self-service solution that will automate the process of signing new electricity contracts at Turku Energia. The service enables consumers to independently sign new electricity contracts and renew existing contracts online. This way the service automates the contract process at Turku Energia. In addition, the service provides opportunities for Turku Energia to market electricity products and contracts on the Internet in an entirely new way.

The possibility to sign electricity contracts online is a key part of the online self-services offered by energy companies. Self-service tools enable customers to browse the products offered by the energy company regardless of the time or the place and select the most suitable option. In addition, contracts can be renewed, switched or changed, using the self-service tools. Self-service solutions increase the efficiency of customer service and provide real-time information for customers.

"When the customer and the customer's electricity delivery site is recognised at the ordering stage, the contract order can be processed into the system automatically, which means the manual work done by customer service agents is reduced significantly. We aim to develop our online services to be so user-oriented that our customers will want to contact us primarily through digital channels. This requires us and our service providers to have the ability to make our electronic services sufficiently distinct, useful and easy for customers to see as additional benefits received as part of their custom," Yrjö Kujala, Development Director at Turku Energia, says of the increased efficiency provided by the electronic process.

"The Electronic Electricity Contract service is a feature that is seamlessly integrated into operational processes and the operational system. Signing of an electricity contract is a simple and logical step-by-step process for the customer. Using bank authentication to identify the customer adds to the reliability and security of the solution. The service is based on a new and efficient technology platform that ensures the solution's longevity and future development," says Risto Poutiainen, Director of Energy & Utilities at Tieto.

Siemens consolidates its industrial software business with acquisition of 3D specialist VRcontext

The Siemens Industry Automation Division has announced the expansion of its industry software portfolio with the acquisition of VRcontext International S.A., Brussels, Belgium. The announcement was made today at the Digital Plant Congress in Würzburg, Germany. With its Walkinside product family, VRcontext is one of the leading developers of 3D visualization and training software for displaying complex engineering data in the shipbuilding and plant construction industries. This acquisition will help Siemens to further strengthen its established position in the industrial software market. The parties agreed not to disclosed details of the purchase price.

The Siemens Industry Automation Division has announced the expansion of its industry software portfolio with the acquisition of VRcontext International S.A., Brussels, Belgium. The announcement was made today at the Digital Plant Congress in Würzburg, Germany. With its Walkinside product family, VRcontext is one of the leading developers of 3D visualization and training software for displaying complex engineering data in the shipbuilding and plant construction industries. This acquisition will help Siemens to further strengthen its established position in the industrial software market. The parties agreed not to disclosed details of the purchase price.

VRcontext International S.A. was founded in the year 2000 and is represented around the world by numerous strategic partners, dealer networks and a branch office in Houston, Texas, USA. Walkinside 3D visualization software is currently in use in plant operation, maintenance and servicing in more than 200 companies in over 30 countries. Whatever the system used, the software directly accesses all plant information to display the current status of a plant in visually appealing, realistic 3D graphics. VRcontext has specialized particularly in remote offshore installations for the oil and gas industry. With Walkinside, the company has created a globally accepted standard for 3D visualization in the process industry. "The integration of the Walkinside 3D visualization and training software of our long-standing partner VRcontext into our industrial software portfolio will benefit our customers significantly. Using intelligent 3D models can make plant engineering and operation safer and more efficient in a great many sectors of industry," said Eckard Eberle, CEO of the Siemens Industrial Automation Systems Business Unit, to which VRcontext will be assigned.

Walkinside will be the perfect supplement for Comos, the Siemens software solution for holistic plant management, in providing fast access to 3D engineering data from the basic and detail engineering phases. A standard interface links Comos bidirectionally with Walkinside. The geometric elements from a virtual reality model are linked to the latest plant information throughout the entire plant lifecycle. Highly complex plant models can thus be represented realistically in three dimensions, with Comos acting as a global data center. As a result, up-to-date plant data is always available as a 3D model in all lifecycles and can be used not only for engineering and monitoring purposes, but also for operation and training. Service and maintenance work can be planned efficiently and maintenance times reduced.

The Siemens Industry Automation Division has now acquired a number of software companies and, in so doing, has consolidated its leading position in the industrial software market. All the firms concerned are leading suppliers in their respective segment: namely, UGS (USA, 2007), Innotec (Germany, 2008), Elan Software Systems (France, 2009), Active Tecnologia em Sistemas de Automação (Brazil, 2011), Vistagy (USA, 2011), IBS AG (Germany, 2012) and Perfect Costing Solutions GmbH (Germany, 2012).

Product Status Change: 635 Series Servo Drive from Parker

Parker's SSD Drives Division would like to inform you that due to the insufficient availability of components, the complete series of 635 servo drives and all accessories including line filters, racks, power supplies, motor chokes etc. will be discontinued by March 31, 2013.

Parker's SSD Drives Division would like to inform you that due to the insufficient availability of components, the complete series of 635 servo drives and all accessories including line filters, racks, power supplies, motor chokes etc. will be discontinued by March 31, 2013.

Subject to availability, orders will be accepted up to December 31, 2012, after which these products will be no longer available. Existing blanket orders with end dates after December 31, 2012 will not be affected, but we highly recommend using the opportunity for a last buy before final expiration of the deadline.

Despite the necessity for this obsolescence, we are pleased to offer alternative servo drive solutions for many of the discontinued parts, in particular the 638 drive servo series which can be used as a good technical alternative as it is software and pin (partially) compatible. Note that the mechanical specification does differ and rack solutions are not available for the 638 drives series. For more information on the 638 series, please visit our website at www.parker.com/ssdusa, then select "Servo Drives". Feel free to contact our customer support team if you require any further assistance.

Songwon and Sabo join forces to establish Light Stabilizers for the Polymer Industry

Songwon is pleased to announce it has entered into long term distribution arrangements with Sabo SpA representing a further milestone in its long-term strategic ambition to be a leading supplier of polymer stabilizer solutions to the global polymer industry. Sabo SpA, based in Levate, Italy, is a leading producer of monomeric and polymeric HALS (Hindered Amine Light Stabilizer) and enjoys a reputation as a supplier of high quality products and a provider of innovative solutions.

Songwon is pleased to announce it has entered into long term distribution arrangements with Sabo SpA representing a further milestone in its long-term strategic ambition to be a leading supplier of polymer stabilizer solutions to the global polymer industry. Sabo SpA, based in Levate, Italy, is a leading producer of monomeric and polymeric HALS (Hindered Amine Light Stabilizer) and enjoys a reputation as a supplier of high quality products and a provider of innovative solutions.

The distribution agreements, which are largely in effect since September 1, 2012 are concluded for the long term whereby Songwon distributes Sabo's HALS product range of light stabilizers on a global basis. Songwon will closely cooperate with Sabo on the regional HALS-markets outside Europe where both of them see big potential for growth. However, on the European HALS-market Songwon and Sabo will act strictly independent from each other whereby Songwon will be free in distributing Sabo´s as well as other HALS products.

The distribution agreements, which are largely in effect since September 1, 2012 are concluded for the long term whereby Songwon distributes Sabo's HALS product range of light stabilizers on a global basis. Songwon will closely cooperate with Sabo on the regional HALS-markets outside Europe where both of them see big potential for growth. However, on the European HALS-market Songwon and Sabo will act strictly independent from each other whereby Songwon will be free in distributing Sabo´s as well as other HALS products.

Both companies will also contribute their technology and expertise to develop future solutions that meet customers’ demands for innovative and high performance light stabilization packages solving challenges in outdoor applications for polymers.

“As a globally leading supplier of polymer stabilizers to the polymer industry, we have secured an ideal partner in Sabo,” said Jongho Park, Chairman and CEO and Head of the Songwon Industrial Group Executive Committee. “Like Songwon, Sabo is committed to be a partner of choice in supplying high performance products to the polymer industry and have an ambition to expand their geographical footprint to a truly global presence. The Sabo product range and production capabilities are an excellent fit with Songwon's global sales and distribution network and the customer intimacy that we enjoy. The distribution agreements are a significant strategic commitment for both parties to develop a leading position in the fast growing light stabilizer markets outside Europe.”

Germano Peverelli, Managing Director Sabo, said: “These distribution agreements are excellent news for our customers. They extend our reach and provide support locally, and to all key customers along the value chain, particularly in non-European regions which would have been otherwise more restricted. Our joint capabilities will drive significant growth in these regions as our broader customer reach will allow us together with Songwon to meet the market needs now and in the future.”

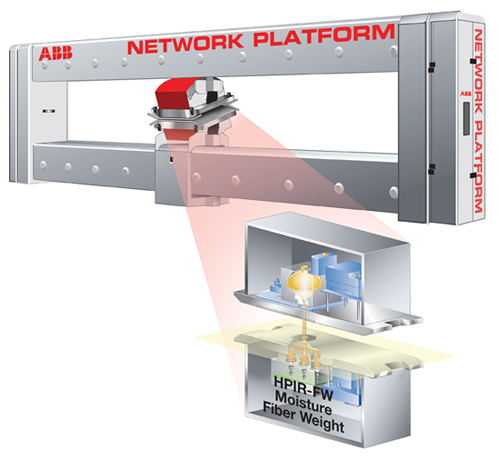

ABB Introduce New HPIR-FW Sensor to Reduce Energy and Fiber Costs

Exceptional moisture and weight measurement, without the need for an ionizing radiological source, enables tissue makers to improve measurement and control

ABB, the leading power and automation technology group, recently launched its new High-Performance Infrared and Fiber Weight (HPIR-FW) sensor that provides precise, high resolution moisture and fiber weight measurement. The HPIR-FW sensor directly measures the most critical parameters of MD and CD control using a single sensor module, allowing tissue makers to precisely control two of their most expensive costs – fiber and energy.

The ABB HPIR-FW sensor measures fiber weight, web moisture and web temperature simultaneously, with just one infrared instrument. It’s simple and proven design delivers safe and reliable performance. Importantly, the HPIR-FW sensor measures without radiological isotopes and the many regulations associated with them.

“The HPIR-FW sensor helps tissue makers meet today’s profitability and sustainability challenges because it gives them the ability to respond more quickly and flexibly to global customer demand,” says Steven St. Jarre, Global Sales & Marketing Manager for ABB Quality Control Systems.

Heidelberg Packaging Days Attract Some 120 Participants

The Packaging Days of Heidelberger Druckmaschinen AG (Heidelberg) on September 25 and 26 at the Print Media Center in Wiesloch-Walldorf enabled some 120 customers and industry experts from across Europe, USA and Brazil to obtain information about the company's packaging solutions. The focus was on the interaction of technology, services, and consumables for successful business models in packaging printing and folding carton gluing. Key topics included HEI Productivity through intelligent material logistics and HEI Quality, as represented by the automated color measurement and control systems Prinect Inpress Control, Prinect Image Control and the inline inspection systems Prinect Inspection Control and Diana Inspection Control. An entire day of the event was dedicated to showcasing the benefits of the optimized production processes that can be achieved using the Prinect Packaging Workflow.

The Packaging Days of Heidelberger Druckmaschinen AG (Heidelberg) on September 25 and 26 at the Print Media Center in Wiesloch-Walldorf enabled some 120 customers and industry experts from across Europe, USA and Brazil to obtain information about the company's packaging solutions. The focus was on the interaction of technology, services, and consumables for successful business models in packaging printing and folding carton gluing. Key topics included HEI Productivity through intelligent material logistics and HEI Quality, as represented by the automated color measurement and control systems Prinect Inpress Control, Prinect Image Control and the inline inspection systems Prinect Inspection Control and Diana Inspection Control. An entire day of the event was dedicated to showcasing the benefits of the optimized production processes that can be achieved using the Prinect Packaging Workflow.

Practical customer demonstration based on complete valued-added chains

Complete HEI End value-added chains for folding carton production - from prepress and press to postpress - showed participants the benefits of integrated, sustainable production. Each of the production lines was built around a press with a complete logistics system, such as the Speedmaster XL 106 for the 70 x 100 centimeter (27.56 x 39.37 inch) format that was unveiled at drupa and the large-format Speedmaster XL 145. Postpress equipment on show included the Dymatrix 106 Pro CSB die cutter, and the Diana X 80 and Diana X 115 folding carton gluing machines. On the Diana X 80, Heidelberg also demonstrated the new Diana Inspection Control inline inspection system, which identifies defective repeats prior to gluing and ejects them from the production process at full machine speed. In addition, the company showcased the benefits of the new Braille module, which has been developed specifically for the manufacture of pharmaceutical packaging and enables fast and reliable inline Braille embossing of packaging.

Besides the actual technology, highlighting the importance of an efficient service portfolio and the smooth interaction of equipment and consumables for reliable and stable production formed an integral part of all the demonstrations.

Entire day dedicated to demonstrating the Prinect Packaging Workflow

Entire day dedicated to demonstrating the Prinect Packaging Workflow

This was the first time in the history of the Packaging Days that Heidelberg had devoted an entire day to the topic of HEI Integration, demonstrating the many different applications of the Prinect Packaging Workflow that was extended to coincide with drupa. Job management and production were fully integrated and all the individual steps were demonstrated - from structural design to delivery of the finished cartons. The complete integration of all print shop steps is even more important in the highly industrialized production of folding cartons than in purely commercial printing, because reducing makeready times and paper waste at the press and postpress stages significantly boosts the profitability of production for both initial and repeat orders. The Prinect Packaging Workflow offers a comprehensive range of functions for this kind of cost-efficient industrialized production. The workflow presentation focused on saving material, reliability in production, and optimum repeatability. Participants were also treated to a detailed presentation of Prinect Package Designer, which integrates structural packaging design in Prinect to create the graphic design directly on the contour data with Adobe Illustrator while also performing a 3D check.

Accompanying workshops and opportunities to chat with experts

Participants could use the accompanying workshops that took place on both days of the event to obtain detailed information about specific Heidelberg products and services in which they had a particular interest and determine how important they were for their business model. Heidelberg experts were available for in-depth discussions on all topics.

"The great interest in our solutions for packaging printing underlines the importance of this growth segment for both our customers and our company. Although it's not that long since drupa, many participants took the opportunity offered by our customer demonstration center to obtain detailed information about how to structure their business more profitably in terms of both technology and business management," explains Stephan Plenz, member of the Management Board responsible for Heidelberg Equipment.

Facial masks with fibres from FSC® certified wood

A range of innovative facial masks by Forest Stewardship Council® (FSC) Chain of Custody certified cosmetics company Kose now contain FSC certified materials in their products and packaging. The facial mask range contains now the fibre TENCEL® by Lenzig, which is made from wood and can decompose completely in soil burial or waste water treatment plants due to its botanic origin. Pioneered in Japan this product is now available all over Asia.

A range of innovative facial masks by Forest Stewardship Council® (FSC) Chain of Custody certified cosmetics company Kose now contain FSC certified materials in their products and packaging. The facial mask range contains now the fibre TENCEL® by Lenzig, which is made from wood and can decompose completely in soil burial or waste water treatment plants due to its botanic origin. Pioneered in Japan this product is now available all over Asia.

A range of innovative facial masks by Forest Stewardship Council® (FSC) Chain of Custody certified cosmetics company Kose now contain FSC certified materials in their products and packaging. The facial mask range contains now the fibre TENCEL® by Lenzig, which is made from wood and can decompose completely in soil burial or waste water treatment plants due to its botanic origin. Pioneered in Japan this product is now available all over Asia.

Kose have a strong ethical ethos, expressed by their corporate banner “Wisdom and Beauty for People and the Earth”. To reinforce this message Kose Cosmeport have now upgraded their entire facial mask product range to include the FSC label, indicating that their products and packaging are derived from responsibly managed forests.

All products within the Kose Cosmeport Clear Turn facial mask range include the botanic fiber TENCEL®, based on the renewable raw material wood. TENCEL® is the leading edge cellulosic fiber from Lenzing which was awarded the European eco-label. As part of the certified chain of custody both Lenzing and Kose Cosmeport are well aware of the need to help customers make responsible choices in the products for their everyday life. The well-recognized FSC logo is a key part of this message. A spokesperson for product development within Kose Cosmeport states: “Using TENCEL® from Lenzing helps Kose Cosmeport to deliver the highest quality cosmetic product to our customers whilst the FSC logo ensures we maintain our corporate commitment to protect the global environment.”

Elisabeth Stanger, Global Marketing Director from Lenzing, adds: “We are excited and proud to work with Kose Cosmeport and see TENCEL® used in facial mask applications. We are glad to see that ingredients are disclosed on the packages to inform consumers and let them make an educated choice. Quality proven by certificates and the botanic origin of TENCEL® makes it a perfect fibre for Kose Cosmeport’s Clear Turn facial masks.”

Siemens equips Chinese paper board greenfield

Shandong Bohui Paper Industry Co., Ltd., China, selected Siemens to provide drive technology for its new board paper mill at Dafeng, Yancheng city, in Jiangsu province, East China. The new mill is scheduled to produce 750,000 tons board paper per year based on wood pulp. With the new manufacturing base, Bohui Paper will become China’s biggest board paper mill. The project has a total volume of around 3.8 million euros and is scheduled for completion by end of 2012.

Shandong Bohui Paper Industry Co., Ltd is engaged in the research, development, manufacture, and sale of paper products and paper pulp in China. To increase the production capacity of high-end packaging boards the company is to build a new mill in Yancheng. Siemens will provide the motors for the new board paper machine and for two winder machines.

They are supplied with power via power inverters and rectifiers of the type Sinamics S120. A Sipaper Drives Controller based on Simatic PCS7 is responsible for open-loop and closed-loop control of the machines. The board paper mill will thus have a uniform operator control and visualization platform for all the drive and automation equipment. All together Siemens will install 205 motors, 207 drive loops, and automation and control systems. The company will also be responsible for the engineering and commissioning of the supplied equipment.

The drive system application to be used is part of the Sipaper solution specially developed for the pulp and paper industry.

International Paper Increases Cash Dividend 14% to $1.20 per share

International Paper's (NYSE: IP) board of directors have increased the company's quarterly dividend by 14% to $0.30 per share for the period from October 1, 2012, to December 31, 2012, inclusive, on its common stock, par value $1.00. This dividend is payable on December 17, 2012, to holders of record at the close of business on November 15, 2012.

"This dividend increase underlines our commitment to return value to our shareholders while maintaining financial flexibility, and reflects management's expectations of improving free cash flow generation and earnings performance in 2013," said John Faraci, Chairman and Chief Executive Officer. "International Paper is committed to a sustainable dividend, which is reviewed periodically and will be increased as earnings and cash flow permit."

Additionally, the company also declared a regular quarterly dividend of $1.00 per share for the period from October 1, 2012, to December 31, 2012, inclusive, on the cumulative $4.00 preferred stock of the company. This dividend is also payable on December 17, 2012, to holders of record at the close of business on November 15, 2012.

SOURCE

Emerson releases hands-free wireless voice and video communications system for plant field operations

Mobile Worker: Voice and Video enables field personnel to interactively problem-solve with off-site experts

Emerson has released Mobile Worker: Voice and Video, a communications technology designed to help process manufacturers save time and money on plant maintenance and trouble-shooting by bringing the problem to the experts, rather than bringing the experts to the problem.

Emerson has released Mobile Worker: Voice and Video, a communications technology designed to help process manufacturers save time and money on plant maintenance and trouble-shooting by bringing the problem to the experts, rather than bringing the experts to the problem.

In the face of reduced plant work forces, more experienced personnel nearing retirement age, and increasing travel costs, Emerson has partnered with AudiSoft to deliver a hands-free, high-definition voice and video solution that plant personnel can wear into remote field locations anywhere in the world.

From the problem area, the field engineer can securely, visually and verbally, communicate live via a Wi-Fi access point, cellular, or satellite wireless connection with remote experts who, from their laptop or PC, can see and diagnose the problem, then instruct the field engineer through the problem’s resolution.

"We have a lot of customers with processes and field devices in remote locations - from diamond mines near the Arctic Circle, to platforms hundreds of miles offshore. If we can help them resolve their problems without flying expert consultants to the location, we can save them critical time and potentially millions of dollars in downtime," said Emerson’s Bob Karschnia, Vice President of wireless. "We continue to find new wireless applications to help our customers manage their processes in challenging industrial environments. This is another valuable application they can add to their toolbox."

The Mobile Worker kit includes a video camera and noise-cancelling microphone that attach to a hardhat, a small touch-screen interface that straps to the chest, and an additional video camera that can be hand-held to zoom into areas too small for the headset camera to access. From any area where a wireless signal can be reached, HD, VGA or QVGA video (depending on available signal strength and bandwidth) can reach either a PC loaded with the Frontline Expert software, or a dedicated server or host subscriber via a web browser. Secure, encrypted communication allows real-time conferencing over the plant network or the internet, to solve remote problems much faster and more cost-effectively than transporting an expert to the site.

The Mobile Worker kit is rated for ATEX Zone 2 use, with Class 1 Division 2 certification available in the near future.