Displaying items by tag: Metsä Group

The role of companies in funding nature projects is growing – Metsä Group is funding 26 projects across Finland this year

Metsä Group funds biodiversity management and restoration projects with a total of 600,000 euros in 2024. This year, 26 new projects were approved for the funding programme for nature projects. With this year's selections, the themes of the projects are increasingly diverse and their geographical coverage is expanding.

The themes of the funded projects include, for example, condition of water bodies, restoration of flowing waters, removal of invasive species and predators, pollinator services, management of traditional habitats and restoration of bird wetlands.

"In the funding programme for nature projects, expert networks focusing on different nature themes have started implementing projects that improve the state of nature regionally. Our goal is to mainstream the operating culture, where Finnish nature is the force that unites us. We invite all companies to participate, regardless of industry”, says Metsä Group's leading nature expert Timo Lehesvirta.

The expansion of the funding base for nature projects was discussed at the beginning of June at an event organized by Metsä Group and the Association for the Management and Protection of Archipelago Nature. The experience and knowledge shared at the event create a basis for the development of a more diverse and stable funding base than before in projects that strengthen the state of nature.

"We are a small but active association that promotes and supports nationally set nature goals through voluntary activities. We welcome the fact that the private sector is getting involved in financing the well-being of Finnish nature", says Tommy Arfman from the Association for the Management and Protection of the Archipelago Nature.

"Metsä Group's funding channel is an example and a welcome opening for the environmental work of the private and public sector to play towards the same goal. The expansion of the funding base in the direction of companies is a welcome message. There is potential in the projects selected now. Personally I especially like the nature initiatives from schools", commented Pekka Pesonen, head of the office of the Ministry of Agriculture and Forestry and chairman of the expert council.

Metsä Group has set the goal of strengthening the state of nature in its operations by 2030. In order to achieve the goal, action programmes for regenerative forestry and land use are implemented, recognizing the nature effects of the company's own operations.

The funding programme for nature projects is the company's free additional contribution to support Finland's national nature goals. A total of 67 different projects have been financed within the framework of the program since 2022. An independent panel of experts from organizations in the natural resources sector participates in the evaluation of the projects.

Metsä Group

www.metsagroup.com

Metsä Group has its roots in the Finnish forests: our parent company Metsäliitto Cooperative is owned by over 90,000 forest owners. We use wood to make recyclable products for the day-to-day lives of millions of people globally. We focus on wood supply and forest services, wood products, pulp, paperboards, and tissue and greaseproof papers. We are committed to the principles of regenerative forestry to measurably strengthen the state of forest nature. We promote a culture of diversity, equality and inclusion. In 2023 our sales totaled EUR 6.1 billion, and we have around 9,500 employees.

Metsä Group and ANDRITZ start pioneering investigation on capturing wood-based carbon dioxide

Metsä Group and the technology company ANDRITZ will investigate the possibility of building a carbon capture facility in connection with the bioproduct mill. The work focuses on the capture of four million tonnes of carbon dioxide from a mill the size of the Kemi bioproduct mill. The Kemi mill is the largest wood-processing mill in the northern hemisphere.

The study will determine the optimal size of a recovery system that would be the most energy efficient combined with the bioproduct mill, as well as the cooling and logistical requirements of the system. The goal is to use the electricity, heat and steam generated in the bioproduct mill as efficiently as possible so that no waste heat is generated.

This work follows on from the carbon capture study launched in 2023. Carbon dioxide capture using an amine solution is an existing proven technology that has been used for decades around the world. However, combining this technology with a pulp or bioproduct mill is progressive.

After the investigation with ANDRITZ, the project will proceed to the pilot phase in Metsä Group’s mill area in Rauma in 2025.

Wood-based carbon dioxide to replace fossil raw materials

If carbon dioxide capture proves viable, a new high-volume wood-based raw material will emerge for the forest industry.

"Our goal at Metsä Group is to process northern wood into increasingly valuable products. If implemented, carbon dioxide capture would open up opportunities for a significant new chemical industry in Finland and boost the Finnish hydrogen economy,” says Sari Pajari-Sederholm, Metsä Group’s EVP, Strategy.

Metsä Group generates about 12 million tonnes of wood-based carbon dioxide annually, which could be used as a raw material for fossil material substitutes as the related technology and markets develop. For example, renewable hydrogen and wood-based carbon dioxide could be used to produce synthetic methane and methanol to be used as raw material in the chemical industry.

"The investigation by ANDRITZ and Metsä Group is pioneering work in carbon dioxide capture and the first step towards the production of renewable fuels from wood-based carbon dioxide. Efforts to reduce carbon dioxide emissions are increasing the demand for renewable fuels, which can be met by the side streams from bioproduct mills," says Klaus Bärnthaler, Vice President, Sales and Business Development, Carbon Capture, from ANDRITZ.

Metsä Group

www.metsagroup.com

Metsä Group has its roots in the Finnish forests: our parent company Metsäliitto Cooperative is owned by over 90,000 forest owners. We use wood to make recyclable products for the day-to-day lives of millions of people globally. We focus on wood supply and forest services, wood products, pulp, paperboards, and tissue and greaseproof papers. We are committed to the principles of regenerative forestry to measurably strengthen the state of forest nature. We promote a culture of diversity, equality and inclusion. In 2023 our sales totaled EUR 6.1 billion, and we have around 9,500 employees.

Metsä Group and CollectiveCrunch's AI application wins an international innovation competition

The AI application developed by Metsä Group and CollectiveCrunch for detecting insect damage won the international Innovation of Innovations prize. Metsä Fibre’s Future Sawmill concept was recognised in the Business innovations category.

The international Quality Innovation Award (QIA) 2023 competition rewards the most notable innovations of the year. The award-winning application from Metsä Group and CollectiveCrunch detects insect damage in forests such as damage caused by spruce bark beetles before it is visible to the human eye. The application is based on artificial intelligence, machine learning and open data. The AI application shared the first prize with a technology innovation in the field of medicine.

“Global warming is increasing the risks to the health of forests. This real-time method for detecting insect damage helps us preserve forest health and carbon sinks in a changing climate,” says Olli Leino, SVP, Development from Metsä Group’s Wood Supply and Forest Services.

Metsä Group’s wood supply personnel has been using the application since June 2023. The application can be used to both pinpoint damage and schedule wood trade and harvesting to reduce the risk of damage spreading.

The map material of risk sites produced by the application is visible in the Metsäverkko mobile application used by Metsä Group’s owner-members. If they wish, forest owners can use this material to visit the sites in person to check the risk areas and plan forestry work.

The Future Sawmill concept developed by Metsä Fibre, part of Metsä Group, was recognised in the Business Innovations (large companies) category. The concept improves the efficiency of sawn timber production, safety at work, the production operating model and product quality management.

“We’re happy to have received this international recognition. We aim to develop the mechanical forest industry with industrial efficiency in mind. We wanted to create a concept for our sawmill, which is the most modern in the world, a forerunner in its technology, operating model and efficiency, and a global trendsetter in the field. This resulted in the Future Sawmill concept, which we used at our Rauma pine sawmill that came online in 2022,” says Ismo Nousiainen, Metsä Fibre’s CEO.

The Quality Innovation Award was now organised for the 17th time. This year, the competition received 562 entries from eight countries/areas, and the best 24 of them were rewarded. The winners of national quality contests can enter the international competition. National quality associations selected the winners in a tight vote. The China Association for Quality hosted the traditional award ceremony in April 2024.

Video presentation of the application on Youtube.

Metsä Group

www.metsagroup.com

Metsä Group’s Wood Supply and Forest Services provides and develops services for the members of Metsä Group’s parent company, Metsäliitto Cooperative. The company procures all the wood used by Metsä Group’s production units. The cooperative consists of more than 90,000 forest owners, who own about half of Finland’s privately owned forests. We are committed to regenerative forestry that measurably strengthens the forest ecosystem. We promote a culture of diversity, equality and inclusion.

Metsä Group and Sweco have signed an agreement for the design of Kerto LVL mill in Äänekoski

Metsä Group and Sweco, a specialist in the built environment and industry, have signed an agreement for the implementation planning of the new Kerto LVL mill in Äänekoski, Finland.

"We have strong confidence in Sweco's expertise and resources from our previous collaboration projects. It is therefore natural that we continue our cooperation in this project to develop the Äänekoski mill area," says Jaakko Anttila, Executive Vice President at Metsä Wood.

Sweco is responsible for the complete implementation planning of the mill project, including structural, process and plant design. Sweco was also responsible for the design of Metsä Group’s Äänekoski bioproduct mill, which started operations in 2017, and the planned wood product mill will apply the synergy benefits offered by the mill area.

"For example, the steam needed in the production process of Kerto LVL will be produced at the Äänekoski bioproduct mill, and the condensate generated in the process will be utilized for heating the building. It is great to be involved in designing a resource-efficient production plant whose material-efficient wood products store carbon and reduce the carbon footprint of construction," says Tuulamari Helaja, Business Unit Director, Industry and Energy at Sweco Finland.

Construction of the Kerto LVL mill in Äänekoski has progressed according to plan. Land construction works and the main frame installations are currently underway in the area.

The mill will have an annual production capacity of around 160,000 cubic metres of Kerto LVL and is expected to start production in the second half of 2026. When completed, the mill will employ around 150 people directly and 200 people in its value chain.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 7 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by more than 90,000 forest owners.

Metsä Group to draw up biodiversity plans for its mill areas – Kemi the first in line

Metsä Group plans to boost biodiversity on its land areas in Kemi. Covering more than 650 hectares, the designated site encompasses Metsä Group’s mill area and other areas in the Kemi urban environment. Metsä Group’s operations in Kemi include a bioproduct mill, currently under construction, and a paperboard mill. The company aims to increase regional biodiversity at all its mill locations across Europe, which number more than 20.

The goal is to modify land use on the Metsä Group Kemi site to improve the state of nature in the industrial environment. The special features of local nature will be taken into account in the project, and the living conditions of endangered species will be improved. Biodiversity in the area will be increased experimentally and by adopting new operating methods.

For example, more than 12 hectares of meadows and sunlit habitats will be added to the Kemi mill area. Only local vegetation will be used in establishing open habitats, and these habitats will be made suitable for endangered species. Various other approaches to increasing the biodiversity of industrial environments will also be tested on the mill site.

The biodiversity plans will also extend outside the mill site to land areas owned by Metsä Group that belong to the Kemi built environment. Residents use these areas for recreational purposes. New ways to increase biodiversity are being developed collaboratively with the town of Kemi.

“Improving the state of nature is one of the goals of Metsä Group’s regenerative forestry approach, and the Kemi pilot project will expand its scope from the forest to the mill area and urban environments. Their biodiversity can also be improved if you have the will and competence and if things are done together. This could be a course adopted industry-wide,” says Ilkka Hämälä, Metsä Group’s President and CEO.

Metsä Group’s collaborative network will grow as the project progresses. One of the key partners is the Villi Vyöhyke association, a leading expert in the biodiversity of the built environment.

“Metsä Group is showing courage, as well as an impressive and high ambition in protecting biodiversity in Kemi. The scope of the new nature targets is exceptionally wide and varied, encompassing the built environment as part of regenerative land use. Metsä Group is a big operator, which gives our actions greater leverage for a wider cultural change towards the international mainstream of biodiversity protection,” says Jere Nieminen, Chair of Villi Vyöhyke.

“Metsä Group’s initiative is important for the town of Kemi. Together, we can develop and strengthen the pioneering role that the Sea Lapland region plays in protecting our nature. The coexistence of industry and nature benefits all of us,” says Matti Ruotsalainen, Mayor of Kemi.

The Kemi pilot project is now underway. The various measures concerning other Metsä Group mills will be carried out gradually over the next few years, using the operating models developed in Kemi.

Metsä Group intends to make the mill areas’ biodiversity plans part of the environmental reporting of mills. In the next few years, the company also plans to collaborate with its stakeholders to develop the plans for the built environment into internationally approved criteria and standards.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 7 billion, and we have around 9,500 employees in around 30 countries. We promote a culture of diversity, equality and inclusion. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by over 90,000 forest owners.

New development stage at Metsä Group’s demo plant for the Kuura® textile fibre

Metsä Group’s innovation company Metsä Spring is developing a new method for using Metsä Group’s softwood pulp to produce the Kuura textile fibre. Adjustments to the original production method and equipment are now being made at the Äänekoski demo plant, which has been operating since late 2020. The development work at the demo plant will then continue in the early summer.

The global demand for textile fibres has continued to grow after a market disruption caused by the pandemic. Interest has been shown especially in sustainably produced textile fibres that replace materials made out of oil, natural gas and cotton. Metsä Group’s Kuura textile fibre, currently under development, is one of these sustainable alternatives. In addition to having a strong connection to sustainably grown Finnish wood raw material from family-owned forests, Kuura benefits from its integration with an efficient bioproduct mill and offers a particularly small environmental footprint.

The global demand for textile fibres has continued to grow after a market disruption caused by the pandemic. Interest has been shown especially in sustainably produced textile fibres that replace materials made out of oil, natural gas and cotton. Metsä Group’s Kuura textile fibre, currently under development, is one of these sustainable alternatives. In addition to having a strong connection to sustainably grown Finnish wood raw material from family-owned forests, Kuura benefits from its integration with an efficient bioproduct mill and offers a particularly small environmental footprint.

“We ended up making changes to our original project plan. We mainly need to make changes to the process chemistry, which also calls for equipment improvements. I believe the changes will give a considerable boost to our development work,” says Niklas von Weymarn, CEO of Metsä Spring.

The goal of Metsä Spring’s Kuura project is to develop a competitive concept that will enable Metsä Group to consider the commercial production of the textile fibre. This would also require the construction of the first commercial mill. The prerequisites for this will be assessed in 2024. The idea is to construct the first commercial mill in Finland. The planning of the mill’s technical concept has already been started.

In addition to developing the production method of the Kuura textile fibre, we are also collecting customer feedback. This customer collaboration is done by Itochu. The Japanese general trading and investment company Itochu is one of the world’s leading players in the textile sector, with around 100 offices in more than 60 countries.

Metsä Group invests in fossil free future by modernising and expanding Mariestad mill in Sweden

Metsä Group, through its tissue business Metsä Tissue, has made a decision to invest in world leading environmental performance in tissue production by modernising and expanding Metsä Tissue’s Mariestad tissue paper mill in Sweden. The investment will increase the availability of locally and sustainably produced tissue products in the Scandinavian market, in which approximately 40% of tissue usage is currently imported. The value of the investment is EUR 370 million and it is one of the largest in the tissue business in Europe and the largest within Metsä Tissue. The construction works will start during spring 2023 and the renewed mill is planned to be operational in the second half of 2025.

With this investment Metsä Tissue will be a forerunning company in investing into sustainable tissue production in Sweden and Scandinavia with its strong brands Lambi, Serla and Katrin. The investment will help to safeguard the security of supply in daily hygiene tissue products with the state-of-the-art mill expansion utilizing most advanced technology. The modernisation and expansion investment is part of Metsä Tissue´s Future Mill Programme which targets world leading environmental and operational performance in tissue production.

”Tissue production is local and it is not sustainable to transport tissue products across long distances. These daily necessity products need to be available in all situations and sustainable local production helps to safeguard the security of supply in the market. This investment aims at just that – availability of sustainable, locally made tissues in a region, which is currently one of the largest net importers of tissue finished goods in Europe. We are proud to develop this business to even more sustainable and locally driven to make what we think are the best tissues in the world, available to consumers in all situations”, says CEO Esa Kaikkonen, Metsä Tissue.

The mill produces high quality Lambi, Serla and Katrin tissue products for both consumer and professional use and the current capacity will be doubled to approximately 145,000 t/a. After the expansion the mill will have a new modern tissue paper machine with the capacity of 70,000 t/a, three new converting lines, for both rolled and folded tissues. Also a fully automated warehouse for finished goods and raw material handling will be built as well as a new office facility.

Mariestad mill in Sweden

Mariestad mill in Sweden

Improved energy efficiency, lower emissions and improved noise and odor plans used as design criteria in the new expansion

- The expansion of the Mariestad mill will bring considerable improvements in the environmental performance of tissue production. Despite the doubled production capacity, the fossil CO2 emissions will drop to zero latest by 2030 due to new technology in use.

- The expansion will focus purely on sustainable fresh fibre production, after which the total fresh fibre share at the mill is 80%.

- The water consumption per ton will be diminished by 50% to 10 m3/t because of the new paper machine technology, fresh fibre based production and effluent plant modernization which is enabling better utilization of purified water in the Mariestad’s mill water circulation.

- Tissue as a bulky product with high air content is not economically viable nor sustainable to transport long distances. Logistics emissions are planned to drop by 25% per year due to replacing paper imports with local production.

- The modernisation brings improvements also to the mill’s neighborhood. With the modern production technology, the mill will have lower noise and odor levels than today. A new noise barrier will lower the noise levels by 3-5 dBA because of new embankments between the mill and residential area and additional 26 silencers will block noise effectively.

- The mill will be equipped with new technology for water management and more efficient technology for purification, which will have a positive effect on odors. The majority of the new water treatment equipment will be covered, further improving the odour management.

Significant impact on local employment

Through this investment Metsä Tissue will be hiring around 100 people at the mill before the new extension is in operation. The majority, approximately 75%, will be multiskilled production workers with technical competences. The recruitment for the key positions, like Production Engineers and Automation Specialists, will begin already this year. During the construction phase, the total employment impact is estimated to be around 2,000 person-years.

Manufacturing at the mill will continue normally during the expansion.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 6 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by nearly 100,000 forest owners.

Metsä Tissue

www.metsagroup.com/metsatissue

Metsä Tissue creates a cleaner everyday life. We are one of the leading tissue paper suppliers in Europe to households and professionals and one of the leading greaseproof paper suppliers globally.

Our brands are Lambi, Serla, Mola, Tento, Katrin and SAGA. With production units in five countries, we employ around 2,500 people. In 2021, our sales totalled EUR 0.9 billion. Metsä Tissue is part of Metsä Group.

Quality Innovation Award for Valmet’s and Metsä Group’s 3D fiber demo plant

Valmet and Metsä Group's innovation company Metsä Spring have received national Quality Innovation Award 2022 in Finland with their demo plant that manufactures new kind of fiber products called Muoto®. The joint development project won the category of potential innovations. The criteria of the competition were novelty value, usability, learning, customer orientation and profitability. Excellence Finland announced the winners in Helsinki, Finland on November 10th, 2022.

The demo plant was inaugurated in August 2022. The goal of the plant is to develop a competitive and recyclable fiber-based package to replace plastics. The products are manufactured ready-to-use for different end uses. Thanks to the multi-layer structure, the product's properties, such as strength and surface smoothness, stand out from products made with other, competing methods.

The 3D technology combines the production process of both the packaging material and the packaging into the same production line and guarantees a resource-efficient production process for example in terms of water use. The production line has a high degree of automation and a large production capacity. No waste is generated in the production process since the side streams can be reused in the process. After the currently ongoing demo phase is completed, market testing of the products with pilot customers will follow.

“3D fiber product technology is a very interesting future area for Valmet – molded fiber packaging is predicted to be the fastest growing segment in the packaging industry in terms of volume. Its growth is supported by restrictions on the use of plastic, the decreasing average size of a package and the growth in the takeaway food market. The 3D fiber product technology is completely new to Valmet, but we have been able to utilize our long experience and know-how in board machine technology and processes. The goal is to bring to the market a technology that is competitive not only in terms of production capacity, but also in terms of production costs and the quality of the final product,” says Petri Rasinmäki, Vice President, Board and Paper Mills Business Unit, Paper business line, Valmet.

“The growing packaging industry requires a variety of new sustainable alternatives; Muoto is our answer to these needs. We’ve moved quickly from an idea that emerged in our internal training programme to a demo plant thanks to our competence and – of course – our excellent partner network. There is every reason to be proud of the Finnish forest industry’s capacity for renewal,” says Jarkko Tuominen, Metsä Group’s Project Director.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Metsä Group’s state-of-the-art sawmill starts in Rauma, Finland

The new state-of-the-art pine sawmill in Rauma in Finland, owned by Metsä Fibre, part of Metsä Group, has moved from production test run to continuous sawn timber production. The sawmill is operating continuously in three shifts.

Construction of the Rauma sawmill started in the spring of 2020, and the value of the investment is approximately EUR 260 million. This is the largest sawmill investment ever in Finland.

“The Rauma sawmill implements Metsä Group’s strategic goals of increasing the value of Finnish forests, growing profitably with our customers, enabling fossil free production and increasing the production of products that store carbon for a long time. The role of the mechanical forest industry is very important for our whole value chain, and I’m happy that new ways to significantly improve performance have been found also there,” says Ilkka Hämälä, President and CEO of Metsä Group.

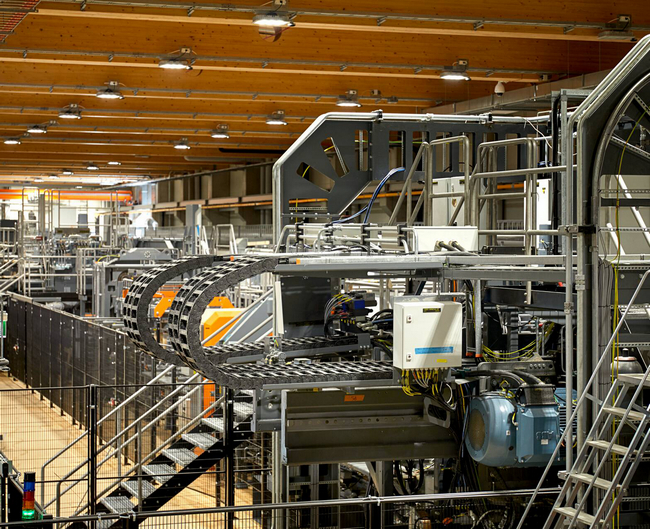

The Rauma sawmill is a worldwide forerunner in technology, efficiency and operating models. Technological innovations such as machine vision, self-learning artificial intelligence and integrated information systems that control the sawline’s various functions provide improved conditions for the production of sawn timber of consistent quality and the sawmill’s industrial efficiency. With the aid of new technology, the Rauma sawmill’s operation is controlled from a single central control room, and sawn timber moves along the converting line without any manual work stages.

“Demand for high-quality, sustainably produced sawn timber is growing worldwide, particularly in demanding component and woodworking industry applications. The new sawing capacity helps us respond to this growth. Sawn timber is an excellent example of a responsible and sustainable product, since the carbon contained in trees is stored in buildings or in various wood products made from sawn timber throughout their life cycle. The sustainability of the sawn timber we produce is based on sustainably managed forests, certified and traceable wood raw material and low-carbon production,” says Ismo Nousiainen, CEO of Metsä Fibre.

Metsä Group's state of the art sawmill starts in Rauma, Finland

Metsä Group's state of the art sawmill starts in Rauma, Finland

A significant development leap for the whole industry

“The Rauma sawmill represents a significant leap in development for the whole sawmill industry, even from a global perspective, and the development work carried out with equipment suppliers benefits the whole industry. It’s therefore been particularly great that the degree of Finnish origin in the project is high. In Finland, we have high-quality wood raw material, excellent competence and the ability to renew operations,” Nousiainen says.

The new sawmill has directly created 100 new jobs in Rauma. The sawmill also provides work to approximately 500 people across its direct value chain. The sawmill’s employment impact during the construction phase was roughly 1,500 person-years.

The annual capacity of the Rauma sawmill is 750,000 cubic metres of pine sawn timber, and the annual use of pine logs sourced in Finland is around 1.5 million cubic metres. The sawn timber produced in Rauma is sold mainly to Europe and Asia. The sawmill’s location enables smooth logistics to transport the sawn timber to customers through the Port of Rauma. The new sawmill does not have its own warehouses. Instead, finished sawn timber is packaged and automatically loaded onto lorries, which transport it directly to the port.

The new sawmill has been built next to Metsä Fibre’s Rauma pulp mill. “The full utilisation of the wood raw material is central to our unique bioproduct concept. Log wood is used as raw material for the sawmill. The bark and sawdust generated during the production of sawn timber are used for bioenergy and the chips are used as raw material for pulp. Pulp production generates bioenergy for the sawmill, and the surplus energy is sold outside the integrated mill. In the future, this investment will enable both the Rauma sawmill and pulp mill to operate without using any fossil fuels,” says Nousiainen.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 6 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by nearly 100,000 forest owners.

Metsä Group to recruit 65 new specialists through apprenticeship training

Metsä Group is inviting applications for its apprenticeship training programme, which will begin in January 2023. Approximately 65 new jobs will be offered in our production units across Finland.

Metsä Group’s 18-month apprenticeship training programme has become a well-established way for the company to secure its future labour needs and promote competence development.

In the apprenticeship training programme starting in January 2023, successful applicants can complete a further vocational qualification, specialising in the wood product or process industry, electrical engineering and automation technology, or machine mechanics and maintenance technology. The studies and related competence demonstrations will be completed in an employment relationship, during which the students are members of our workplace community entitling them to the same fringe benefits as our permanent employees.

After completing their training, the participants will be qualified to work in duties such as process operator and machine operator at Metsä Group’s pulp, paperboard, tissue paper, Kerto® LVL and plywood mills. A suitable educational background for the apprenticeship is a vocational qualification in electrical engineering and automation technology, process technology or mechanical engineering, or an engineering degree from a university of applied sciences.

“The operating model adopted at Metsä Group’s production units is based on providing employees with multiple skill sets. Broad-based apprenticeship training offers a solid foundation and the opportunity to carry out varied and interesting tasks, both during and after training,” says Pertti Hietaniemi, SVP, Human Resources, Metsä Group.

As safety at work is an important element of professional skills, the entire personnel of Metsä Group is committed to proactive safety work and safe work methods.

The final application date for the training beginning in January 2023 is 25 September 2022.

Apprenticeship training will be organised at the following mills.

Metsä Wood: Punkaharju, Lohja, Suolahti and Äänekoski

Metsä Fibre: Joutseno, Kemi, Rauma and Äänekoski

Metsä Board: Kaskinen, Simpele and Äänekoski

Metsä Tissue: Mänttä

Read more about Metsä Group’s apprenticeship training programme on our website (in Finnish).

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 6 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by nearly 100,000 forest owners.