These are the main elements on which the clear vision of A.Celli Paper is based.

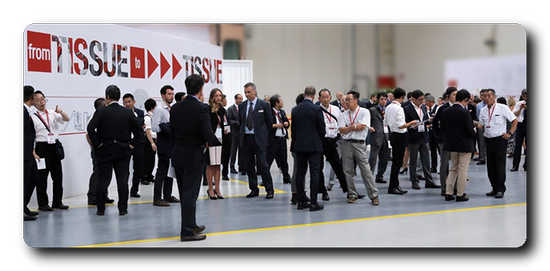

During the third edition of iT’s Tissue (Lucca, 25-29 June 2018), A.Celli Paper welcomed visitors to discover the great path it has chosen, inviting them to see for themselves the 11 technology stations representing the same number of system solutions for complete turnkey plants.

The FROM TISSUE TO TISSUE tour was a unique experience, offering a special opportunity to view a complete Tissue production line.

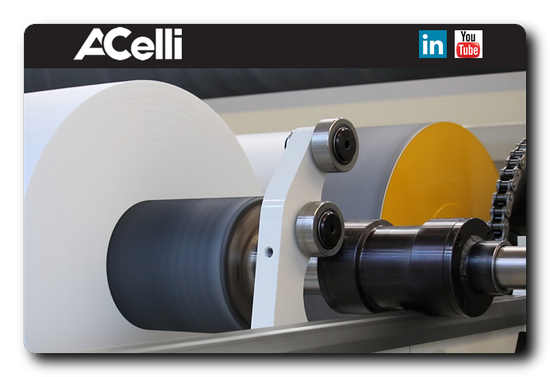

It was an occasion to present the new generation of the iDEAL® Tissue Machine, the E-WIND® winders and the innovative R-WAY® Roll Handling & Packaging system.

But this was just the beginning, because the journey planned for the visitor also included a look at Research and Development and the new solutions in the context of the Yankee Dryer, with our FORGED YD®; the revolutionary iREEL® data traceability and analysis system; and the latest R-WAY® reel management system with automated guided vehicles (AGVs): all in the name of efficiency, safety and automation.

The visitors were impressed by this direct contact with the world of A.Celli equipment solutions, which is all about the best in production efficiency, reduced consumption and costs, and excellence in terms of both quality and technology.

We would like to thank all those who came, and hope to see you again next time.

A.Celli is on a roll!

A.Celli Paper presents a new revolutionary concept for the production of Yankee Dryer Shells.

A.Celli Paper presents a new revolutionary concept for the production of Yankee Dryer Shells.