Displaying items by tag: valmet

Valmet to supply new sizing technology for Papierfabrik Niederauer Mühle GmbH in Germany

Valmet will supply Papierfabrik Niederauer Mühle GmbH with a sizer and auxiliaries for its PM3 containerboard machine located in the company's Kreuzau mill in Germany. The target of the project is to improve the strength properties of the white top liner grades. This high quality paper is used for instance as printed cover layer for cardboards and as headliner. The sizer is scheduled to start up during the first quarter of 2015.

The order is included in Valmet's second quarter 2014 orders received. The value of the order will not be disclosed.

Valmet's innovative sizing technology will boost the quality of white top linerboard

In addition to the new sizer, Valmet's delivery will include a calender rebuild, an air dryer, starch preparation and starch supply systems as well as ropeless tail threading equipment.

"The new sizer will combine the best features of both spray application and film application, and improve the strength properties of the white top liner grades. The main advantages of the back side spray application technology compared to conventional starch application method are drying energy reduction, fast and accurate starch amount control as well as elimination of wearing parts. The top side film application ensures excellent properties of the white top liner surface," says Ilkka Naatti, Product Manager of coaters and sizers in Valmet.

"Niederauer Mühle will also be the first paper mill in the Central Europe to benefit from the advantages of safe, reliable and fully ropeless tail threading technology in the size press area. After the rebuild the tail threading process of PM3 will be totally ropeless for all machine parts."

About Papierfabrik Niederauer Mühle GmbH

Niederauer Mühle specializes in white corrugated medium paper of which basis weight ranges from 120 - 200 g/m2. Its production volume is more than 300,000 tons of paper per year today. The company has currently 155 employees.

Valmet's SealFlo cuts suction roll lubrication water use by up to 50%

There is a continuous need for paper manufacturers to reduce their environmental impact. Valmet is contributing to this need by introducing SealFlo, an easy upgrade for suction roll lubrication showers.

"Valmet's new SealFlo technology reduces water consumption by as much as 50%, while maintaining or improving lubrication results," says Pekka Kivioja, director of Roll Maintenance at Valmet.

Worn, aged and outdated showers and nozzles lead to substandard lubrication results and consume excessive amounts of water. The new SealFlo axial seal lubrication shower from Valmet features a design which improves the lubrication process, as well as reducing the roll's environmental impact through significantly reduced water consumption.

Significant savings

In addition to improved lubrication results, many applications show an improved moisture profile and reduced costs of shower water preparation. Kivioja gives an example: "On a paper or board machine, this could mean savings of as much as 2,500 to 5,000 euros per roll meter per year, resulting in average savings of 100,000 to 200,000 euros a year on a ten-meter wide machine that has four suction rolls." The improved shower functionality also has a positive effect on the lifespan of the axial seal and on the suction roll shell.

This modification is now available with suction roll maintenance through Valmet's extensive roll service network.

Further information, please contact:

Pekka Kivioja, Director, Roll Maintenance, tel. +358 400 546 779, This email address is being protected from spambots. You need JavaScript enabled to view it.

Read more: Improved suction roll operation with SealFlo

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to supply part of a pulp mill capacity upgrade at Portucel Soporcel's Cacia mill in Portugal

Valmet will supply Portucel Soporcel with upgrades for its Cacia mill in Portugal. Valmet's delivery will secure high pulp quality at the new increased production level. The start-up of the renewed plant is planned for the summer 2015. The order is included in Valmet's second quarter 2014 orders received and the value of the order will not be disclosed.

Valmet will supply Portucel Soporcel with upgrades for its Cacia mill in Portugal. Valmet's delivery will secure high pulp quality at the new increased production level. The start-up of the renewed plant is planned for the summer 2015. The order is included in Valmet's second quarter 2014 orders received and the value of the order will not be disclosed.

"This order is a continuation of a long-lasting relationship between Portucel and Valmet. The new lime kiln will support the increased demand for lime, as Cacia mill increases its pulp production," says Stefan Mattsson, Vice President, Fiber Processing Business Unit, from Valmet.

Technical details of Valmet's delivery

Valmet's delivery includes batch cooking, screening, bleaching and a new lime kiln with a capacity of 110 metric tons per day (MTPD). The bleach plant rebuild includes a new TwinRoll press, which replaces two drum filters. The new lime kiln with flash dryer and electro static precipitator (ESP) will be able to burn both heavy fuel oil (HFO) and natural gas.

About Portucel Soporcel Group

The Portucel Soporcel group is Portugal's second largest exporter. The group operates paper and pulp mills in Setúbal, Figueira da Foz and Cacia. The group is a leading European manufacturer of uncoated woodfree (UWF) printing and writing paper and Europe's top producer of BEKP (Bleached Eucalyptus Kraft Pulp). The Cacia mill is located in central Portugal at the heart of the country's largest area of eucalyptus forest. The Cacia pulp mill produces currently 285 thousand tons a year of pulp designed for special applications.

Luvata solution wins Valmet business

Valmet Corporation has placed an order with Luvata for 900-industrial heat exchangers valued at EUR 5.7 million. The industrial coils will be used in paper pulp dryers at Valmet customer facilities in Brazil and Indonesia.

Valmet Corporation has placed an order with Luvata for 900-industrial heat exchangers valued at EUR 5.7 million. The industrial coils will be used in paper pulp dryers at Valmet customer facilities in Brazil and Indonesia.

With each heat exchanger weighing approximately 2-tons and measuring approximately 6 x 1,5 x 0,5 meters, the total project will involve over 217-tonnes of steel tube, 900-tonnes of steel bands and more than 143,800 tube plate drill holes, all delivered in two fixed delivery months.

"We have a very strong supplier network, and Luvata is one of them,” says Hannu T. Pietilä, Valmet Area President, Asia Pacific. “The evaporation system and pulp dryers delivering to Indonesia will be the largest in the world. This requires an unprecedented scale of pieces and parts that must all come together in a well-organized fashion.”

“We’ve designed and manufactured high-quality coils and coolers for industrial applications for over 70 years. Today that’s no longer enough,” indicates Mattias Lindhe, Commercial Director EMEA – Industrial with Luvata Söderköping. “We must also deliver complex, logistically challenging, turnkey supply solutions. And that’s when Luvata excels.”

Valmet signed a contract with OKI Pulp & Paper Mills to supply key technology for a pulp mill project in South Sumatra, Indonesia. The new mill is expected to produce approximately 2 million ADT (air dry tonne) of pulp annually. The commercial production is expected to begin in 2016.

Valmet will also supply two pulp drying lines to Klabin's new plant in Ortigueira in Parana, Brazil. The annual production capacity of Klabin's new plant will be 1.5 million tons, with start-up of the new plant scheduled for the first half of 2016..

Valmet's iRoll technology improves paper quality and machine runnability

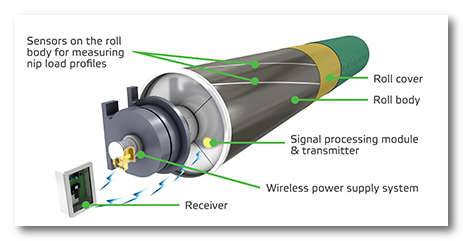

Valmet's iRoll product family is a complete set of tools for controlling paper tension and nip profiles. iRolls are now available for all main processes and positions in pulp, paper, board and tissue machines with the latest Valmet roll covers.

Thanks to good market feedback, Valmet is now expanding its iRoll manufacturing capability. By the end of June 2014, iRoll manufacturing will expand to cover Finland, France, the United States, Thailand and China. Valmet has also developed local field service competencies through an iRoll academy training program.

"After installing an iRoll, our customers have thanked us for 50% fewer wet end breaks per day, improved runnability, 100% longer grinding intervals and a 40% improvement in the coat weight 2-sigma value, just to name a few of the results iRoll has achieved," says Samppa Ahmaniemi, director of Roll Covers at Valmet.

Accurate online measurements

The main benefit of the iRoll technology is its accurate online profile measurement and process control opportunity in press, sizer, coater, reel and winder applications. Valmet's iRoll is the fastest and most sensitive online profile measurement tool in the industry.

In addition to nip load profile, iRoll also measures applicator rod load profile (sizer) and parent roll hardness profile (reel), as well as paper, board or tissue tension profiles in selected positions. iRoll can even be connected to the machine automation system for closed loop process control.

iRoll Portable is a quick, cost-effective process analysis and tuning tool that is based on dynamic nip profile or paper/fabric tension profile measurements. iRoll Portable provides rapid results as Valmet's experts can carry out an iRoll Portable analysis during shutdowns.

Valmet selected as the main supplier for Södra Cell's major pulp mill rebuild in Sweden

Valmet has received a major rebuild and new equipment order from Södra Cell for the Värö pulp mill in Sweden. The order is part of Södra Cell's over 400 million euro investment to increase the Värö mill's pulp production capacity from 425,000 tons to 700,000 tons per year.

Valmet has received a major rebuild and new equipment order from Södra Cell for the Värö pulp mill in Sweden. The order is part of Södra Cell's over 400 million euro investment to increase the Värö mill's pulp production capacity from 425,000 tons to 700,000 tons per year.

The order is included in Valmet's second quarter 2014 orders received and is valued at around EUR 200 million.

Valmet's delivery will contribute to Södra's performance by significantly increasing the Värö mill's pulp production capacity and energy efficiency. The order consists of a new continuous cooking plant and upgrades of wood handling, fiber line, evaporation plant, recovery boiler, recausticizing, flash dryer, pulp dryer and baling. On completion of the project, Värö will be one of the world's largest softwood sulphate pulp mills. The start-up of the renewed pulp mill is scheduled in the third quarter of 2016.

"We have good experiences of Valmet and feel confident that this project will be a success. We have worked closely together with Valmet in planning the project and it gives us a good start. This investment increases our pulp production, makes the mill more energy efficient and increases its bioenergy supply potential", says Gunilla Saltin, CEO, Södra Cell.

"We are very pleased that Södra Cell trusted us with this significant order. It is a strong token of our technological leadership and competitiveness in the pulp technology market. Investments in pulp production are active at the moment and Valmet is strongly involved with many major on-going projects", says Jyrki Holmala, President, Pulp and Energy Business Line, Valmet.

Significant employment impact

The estimated employment impact of the order is about 650 man years mainly in Sweden. A large part of the order will be delivered from Valmet's operations in Sweden: the cooking plant and recausticizing from Karlstad, fiber line, flash dryer and baling from Sundsvall, and evaporation and recovery boiler from Gothenburg. The wood handling and pulp dryer delivery will come from Finland.

A prerequisite for construction start is the receipt of a permit from the Environmental Court of Appeal.

About Södra Cell

Södra is an economic association with a membership base of 51,000 forest owners in southern Sweden. Södra has built up a considerable production of paper pulp, wood products and biofuels. Södra employs about 3,800 people and has four business areas Södra Skog, Södra Cell, Södra Timber and Södra Interiör.

Södra Cell is one of the world's largest market pulp supplier, with a total annual production of 1.6 million tonnes.

Södra chooses Valmet as main supplier for Värö

Södra has appointed Valmet of Finland as its main supplier for process equipment for the expansion of the pulp mill in Värö, near Varberg. This order is part of Södra's investment totalling more than SEK 4 billion.

The order placed with Valmet includes a new continuous digester and upgrades to wood handling, the fibre line, evaporation plant, soda recovery boiler, causticisation, flashdryer, drying machine and baling.

A large portion of the order will be supplied by Valmet in Sweden: The digester and causticisation will be supplied by Karlstad, the fibre line, flashdryer and baling by Sundsvall, and evaporation and the soda recovery boiler by Gothenburg. The wood handling and pulp dryer will be supplied by Finland. Valmet states that the order from Södra is worth around SEK 2 billion.

"We have good experiences of Valmet and feel confident that this project will be a success. We have worked closely together with Valmet in planning the project and it gives us a good start. This investment increases our pulp production, makes the mill more energy efficient and increases its bioenergy supply potential", says Gunilla Saltin, President, Södra Cell.

"We are very pleased that Södra Cell trusted us with this significant order. It is a strong token of our technological leadership and competitiveness in the pulp technology market. Investments in pulp production are active at the moment and Valmet is strongly involved with many major on-going projects", says Jyrki Holmala, President, Pulp and Energy Business Line, Valmet.

Södra has previously purchased groundwork, building work and construction work from NCC with regard to the expansion of Värö. Another major supplier is Raumaster, which will be supplying storage and transport equipment for chips and bark.

When the expansion work is complete, Värö will be one of the biggest pine sulphate pulp mills in the world, with a total production capacity of 700,000 tonnes of pulp per year. These investments will also considerably increase Värö's energy efficiency.

Valmet Corporation is a global developer and supplier of services and technology for the pulp, paper and energy industry. Valmet has revenues of around EUR 2.6 billion (2013) and employs 11,000 staff, and its head office is based in Espoo, Finland.

Valmet to supply new equipment as part of major rebuild for Siam Cellulose Co., Ltd. in Thailand

Valmet will supply a part of a major rebuild and some new equipment to a pulp mill of Siam Cellulose Co., Ltd. (SCL) in Thailand. The mill is located in Wangsala, Kanchanaburi province. The value of the order is around EUR 30 million. The order is included in Valmet's second quarter 2014 orders received.

Valmet will supply a part of a major rebuild and some new equipment to a pulp mill of Siam Cellulose Co., Ltd. (SCL) in Thailand. The mill is located in Wangsala, Kanchanaburi province. The value of the order is around EUR 30 million. The order is included in Valmet's second quarter 2014 orders received.

The order includes an upgrade of the cooking plant and a fiber line rebuild. The new equipment delivery includes an evaporation plant, a recovery boiler, an ash leaching plant and a non-condensable gas treatment (CNCG) collection and burning system. The rebuilt plant is planned to be in operation in the beginning of 2016.

"We chose Valmet based on our earlier successful experience with the Phoenix Mill's recovery boiler performance and CompactCooking G2 technology," says Surasak Amawat, Managing Director of Siam Cellulose Co., Ltd.

"This order continues our successful cooperation with Siam Cellulose, and proves our commitment to move our customers' performance forward with fit-for-purpose and value-adding solutions", says Anil W. Purankar, Vice President, Pulp and Energy Business Line, Asia Pacific, Valmet.

Details about the order

The existing cooking plant will be converted to Compact Cooking G2 by adding an ImpBinTM impregnation system, a decision based on the successful experience of improved pulp quality in Phoenix mill. The rebuild of the fiber line includes installation of Delta screens, wash presses, screw conveyors and medium consistency pumps.

The new evaporation plant will replace the existing plant and support the need for increased pulp production. The new RECOX recovery boiler is a repeat order from SCG Paper and will replace the existing boiler and increase the pulp production capacity. The new ash leaching system will help the mill to maintain low levels of potassium (K) and chloride (Cl).

About Siam Cellulose Co., Ltd. (SCL)

Siam Cellulose is a subsidiary of SCG Paper and a leading producer of eucalyptus based pulp. SCG Paper is the largest integrated paper and corrugated containers producer in ASEAN.