Ian Melin-Jones

Pulp-paperworld's E-Magazine Issue 4 is published

New materials by mimicking nature

Last week, Innventia’s Jasna Stevanic Srndovic submitted her thesis on interactions between polymers in the cell wall of spruce wood fibres. The new knowledge in this area contributes to making existing paper industry processes more efficient and to develop new materials from biopolymers. The driving force behind her work is to find means to make better use of the earth’s resources in a sustainable way.

Last week, Innventia’s Jasna Stevanic Srndovic submitted her thesis on interactions between polymers in the cell wall of spruce wood fibres. The new knowledge in this area contributes to making existing paper industry processes more efficient and to develop new materials from biopolymers. The driving force behind her work is to find means to make better use of the earth’s resources in a sustainable way.

The threat of global warming and limited fossil resources calls for ways to better use our resources. One way could be to streamline industry processes, such as in the paper industry, by reducing energy consumption in the production of thermomechanical pulp (TMP). This can be done by applying various chemical and / or enzymatic pretreatments of wood. Jasna’s thesis presents results that provide a better understanding of polymer interactions within the primary cell wall of spruce wood fibres and its implications for the energy demand in the refining process. She demonstrates how applying a low degree of sulphonation pre-treatment to spruce wood chips caused a weakening of these molecular interactions, as well as an increased softening and swelling of the material, thereby reducing the energy consumption within the refining process.

Another way to better protect the environment is to use renewable resources to a greater extent. Large quantities of polymers, such as cellulose, hemicelluloses and lignin, recovered from residual materials from the paper industry and agriculture, can be used to produce new renewable packaging materials. In her work, Jasna has investigated the ultrastructure of the secondary cell wall of spruce wood fibres, and has tried to imitate the structures found in wood fibres by preparing biocomposites and evaluating these as packaging materials.

“Nature’s unique material structures have many excellent qualities,” explains Jasna. “For example, they can withstand variations in climatic conditions. By attempting to imitate these synthetically, it may be possible to develop new bio-based materials with adapted qualities. I’ve produced hemicellulose films with improved mechanical properties by strengthening these with nanocellulose.”

“Increased knowledge regarding the interactions between the wood polymers is very important in order to be able to separate these in a better way, for use in new materials and other applications,” says Lennart Salmén, head of the Fibre and Material Science group at Innventia.

“Working towards a more sustainable society is the driving force behind my work and I hope the results will find an application in the industry”, concludes Jasna.

Jasna Stevanic Srndovic work is largely financed by Formas Wood Wisdom NET and the Wallenberg Wood Science Centre.

Nalco's Dr. Rodney Banks Wins 2011 Perkin Medal

The Society of Chemical Industry, America International Group, announced today that the 2011 SCI Perkin Medal will be presented to Dr. Rodney H. Banks, a research fellow at Nalco. He will receive the medal at a dinner in his honor on Sept. 20, 2011, at the Hyatt Hotel in Philadelphia.

"Rod Banks is an outstanding industrial technologist," said Stephanie Burns, Chairperson of the SCI. "This award recognizes his fundamental contributions to new sensor technologies that have led to improved water and energy efficiencies for a variety of industries."

"Rod Banks is an outstanding industrial technologist," said Stephanie Burns, Chairperson of the SCI. "This award recognizes his fundamental contributions to new sensor technologies that have led to improved water and energy efficiencies for a variety of industries."

Banks holds a Ph.D. in Inorganic/Physical Chemistry from the University of California, Berkeley, where he worked for Nobel laureate and fellow Perkin winner Glenn Seaborg. In the mid-1980s, Banks and his co-workers at Nalco identified the need for improved control of industrial water treatment and commercial processes. He and colleague John Hoots subsequently led the invention and commercialization of TRASAR® fluorescent tracing technology. During the past decade, Banks invented a broad suite of technologies incorporating chemical and mechanical sensors for intelligent monitoring and control of industrial water and process applications that have saved more than 300 billion gallons of fresh water at thousands of customer locations around the world.

"Nalco is very proud for Rod to receive this prestigious recognition for his work," said Erik Fyrwald, Nalco Chairman and Chief Executive Officer. "The evolution of sensor technology that Rod and his team have developed is transforming how water systems are treated, delivering enormous water and energy savings."

The current generation, 3D TRASAR automation technology, has won a United States Presidential Green Chemistry Challenge Award for its cooling water application. Its use is being expanded to a variety of additional applications, including boiler water treatment, membrane operations, papermaking and refinery process applications.

In addition to TRASAR sensing and control, Banks has also created various electrochemical, optical, quartz crystal microbalance-based sensors for chemical treatment levels, corrosion, scale and microbial fouling detection. These detect system performance in real time and allow optimum control of chemical treatments, increasing the longevity of mechanical assets, improving process and worker safety, optimizing water and energy usage and minimizing impact on the environment. He holds more than 20 patents and has published nine scientific papers.

About the SCI Perkin Medal

The annual award is recognized as the highest honor given for outstanding work in applied chemistry in the United States. It commemorates the discovery of the first synthetic dye (the so-called Perkin mauve) by Sir William Henry Perkin in 1856. This discovery was a significant step forward in organic chemistry that led to the birth of a major segment of the chemical industry. The SCI Perkin Medal was first awarded to Sir William at a banquet held by the SCI in New York in 1906. Since then, more than 100 such awards have been given to notable scientists.

About the Society of Chemical Industry

SCI America International Group, launched in 1894, is part of the Society of Chemical Industry's international organization. It provides a unique networking forum for chemical industry leaders, industrial scientists and technologists to exchange new business ideas and best practices. It celebrates achievement to promote public awareness of the contributions of industrial chemistry and inspire students to enter technical careers.

SCI America section also offers its members the opportunity to become part of an international network of industry thought leaders and researchers. Through specialized conferences, e-events, and publications, it helps foster best practices in fields as diverse as fine and commodity chemicals, food, pharmaceuticals, biotechnology, agriculture, and environmental protection.

SCI America events are managed by Chemical Heritage Foundation. http://www.chemheritage.org/. The award dinner will be the final event of Innovation Day, a full day of research collaboration in the molecular sciences held at Chemical Heritage Foundation on Sept. 20.

AbitibiBowater Announces Closing of Sale of its 75% Interest in its Ontario Hydro Assets for Cash Proceeds of C$300 Million

AbitibiBowater has announced the closing of the sale of its 75% indirect interest in ACH Limited Partnership ("ACH LP") to a consortium formed by a major Canadian institutional investor and a private Canadian renewable energy company.

"With the sale of our interest in ACH LP, the Company is able to pay off a considerable amount of debt and further improve our financial flexibility. We will continue to focus on reducing AbitibiBowater's debt, and this represents an important step forward in line with our commitment," stated Richard Garneau, President and Chief Executive Officer.

As previously announced, cash proceeds for AbitibiBowater's 75% indirect interest will amount to approximately C$300 million, $185 million of which the Company intends to use to redeem a portion of outstanding 10.25% senior secured notes due 2018, while the balance of proceeds will be used for general corporate purposes. As part of the transaction, ACH LP will maintain its outstanding debt with the Caisse de dépôt et placement du Québec with a face value of C$250 million.

About AbitibiBowater

AbitibiBowater is a global leader in the forest products industry, producing a diverse range of products, including newsprint, commercial printing papers, market pulp and wood products. The Company owns or operates 18 pulp and paper mills and 24 wood products facilities located in the United States, Canada and South Korea. Marketing its products in close to 90 countries, AbitibiBowater is also among the largest recyclers of old newspapers and magazines in North America, and has third-party certified 100% of its managed woodlands to sustainable forest management standards. AbitibiBowater's shares trade under the stock symbol ABH on both the New York Stock Exchange and the Toronto Stock Exchange.

Cautionary Statements Regarding Forward-Looking Information

Statements in this press release that are not reported financial results or other historical information of AbitibiBowater Inc. are "forward-looking statements" within the meaning of the Private Securities Litigation Reform Act of 1995. They include, for example, statements relating to intended use of proceeds from the transaction. Forward-looking statements may be identified by the use of forward-looking terminology such as the words "should," "would," "could," "will," "may," "expect," "believe," "anticipate," "attempt," "project" and other terms with similar meaning indicating possible future events or potential impact on our business or AbitibiBowater's shareholders.

The reader is cautioned not to place undue reliance on these forward-looking statements, which are not guarantees of future performance. These statements are based on management's current assumptions, beliefs and expectations, all of which involve a number of business risks and uncertainties that could cause actual results to differ materially. The potential risks and uncertainties that could cause our actual future financial condition, results of operations and performance to differ materially from those expressed or implied in this press release include those set forth under the heading "Risk Factors" in Part I, Item 1A in our annual report on Form 10-K for the year ended December 31, 2010, filed with the United States Securities and Exchange Commission and the Canadian securities regulatory authorities.

All forward-looking statements in this press release are expressly qualified by such cautionary statements. We disclaim any obligation to publicly update or revise any forward-looking information, whether as a result of new information, future events or otherwise, except as required by law.

Endress+Hauser Group increases net sales and profit, creates new jobs and invests in the future

The deep slump 2009 was followed by an almost dizzying rate of growth last year: the Endress+Hauser Group (Reinach, Switzerland) reported a new all-time high in net sales and profit for 2010. The company, specializing in measurement engineering and automation solutions, created additional jobs and invested in its worldwide sales and production network.

The Group increased its net sales in 2010 by almost 19.8 percent to over 1.31 billion euros – not only compensating for the drop in sales in 2009, but even significantly exceeding the previous best results of 2008. “We have recovered more quickly from the effects of the worldwide economic and financial crisis than expected,” said Chief Executive Officer (CEO) Klaus Endress at the media conference on the financial statement in Basel. He stressed the dynamic nature of this development. “In 2009 we didn’t know where the work would come from at times. Last year we often struggled to complete all orders on time.”

The economic recovery was noticeable right from the start of the year. Only a few markets – such as Greece, Ireland and the Scandinavian countries – experienced no upturn. The company had the strongest growth in America, with an increase of 38.2 percent, even exceeding growth in Asia (28.5 percent). In Europe sales grew by 12.9 percent, in Africa and the Middle East by 10.0 percent. “As a result of the crisis, the emerging markets have grown in significance much faster than predicted,” explained Chief Operating Officer (COO) Michael Ziesemer.

Growth was driven in particular by the food & beverage industry, the largest sector for Endress+Hauser, where recovery was especially rapid in the plant building and machinery sectors (for example the manufacturers of filling machines). The primaries industry also made an above-average contribution – mining, for example, profited from the worldwide hunger for raw materials – as well as the pharmaceutical industry. The chemical, oil & gas, metal, power & energy and water & wastewater industries also developed well. Only the pulp & paper industry continued to struggle.

Strong influence of exchange rates

The development of the exchange rates had a marked effect on both the income statement and the balance sheet. On the one hand the weak euro supported the recovery of export-oriented industries in Europe. In addition, business carried out in US dollars, yen, British pounds or Swiss francs brought correspondingly higher yields. On the other hand, the loss in value of the euro – in the course of the year it slumped by 16 percent against the Swiss franc – led to net foreign exchange losses of 20.5 million euros. Nevertheless Endress+Hauser was still able to more than double its operating profit (187.4 million euros, plus 123.2 percent), as well as the net income (126.6 million euros, plus 114.6 percent). “This shows that we kept costs under control and budgeted carefully during the recovery, too,” emphasized the Group’s Chief Financial Officer (CFO), Fernando Fuenzalida.

As the equity (888.5 million euros, plus 30.5 percent) grew considerably stronger than the total capital employed (1.30 billion euros, plus 24.1 percent), the equity ratio increased by 3.4 points to currently 68.3 percent. Cash and cash equivalents have grown considerably, by 54.4 percent to 377.3 million euros, and meanwhile exceed bank loans (50.5 million euros, 24.8 percent less than 2009) more than sixfold. “We thus ensure that we are not dependent on third party investors,” stressed Fernando Fuenzalida.

New jobs, further investments

This financial independence allows the family-owned company to follow long-term goals and remain true to their own convictions. “As we had hardly reduced the size of our workforce during the crisis, we were able to respond immediately once recovery began,” emphasized the CEO. In 2010 jobs, on a small scale, were created once more, above all in worldwide sales. The number of employees in the Group increased by 175 to a total of 8,594; in the region of Basel, where 4,251 people are employed by Endress+Hauser, 33 new jobs were added.

Both during the crisis and throughout last year the company continued to invest in research and development. The Group earmarked 96.4 million euros (plus 2.5 percent) for this, 7.3 percent of net sales. With 219, patent applications reached a new record high. “We were able to provide our customers with important new products,” commented Klaus Endress. Endress+Hauser holds over 4,400 ‘live’ patents and patent applications worldwide.

Investment in buildings, plants and machinery decreased by 15.2 percent to 57.0 million euros. Previous years had been marked by many major building projects, most of which have now been completed. In Stahnsdorf on the outskirts of Berlin, a new facility for the development and production of silicon pressure sensors was inaugurated; in Cernay, eastern France, work on a customer center for the magnetic flowmeter plant has been completed. “In the meantime some of our production facilities have already reached the limit of their capacities,” the CEO added. The plants in Maulburg (level and pressure measurement) and Waldheim (glass sensors for fluid analysis), Germany, have already been expanded. Other building projects outside Europe are also in the pipeline.

The network for sales and marketing is also to be further reinforced. In 2010 Endress+Hauser Poland inaugurated new premises in Wrocław, the Chinese sales center took up operation of a goods distribution center in Shanghai, the Dutch sales center recently moved into a new building in Naarden, Endress+Hauser Thailand is to enlarge its current headquarters in Bangkok and the sales center in Malaysia is to invest in its own premises. The company’s presence in the Middle East is also to be strengthened with the opening of a sales office in Abu Dhabi. Working together with a partner, Endress+Hauser will set up a subsidiary in Saudi Arabia before the end of the year.

Excellent start to 2011

Just as 2010 ended well for Endress+Hauser, 2011 has started equally well – incoming orders and net sales currently exceed last year’s good figures by a two-digit number. Although the Group expects a weakening in this development in the second half of the year, the CFO is confident that the cautious target of 7 to 8 percent growth in sales will be significantly exceeded. Profit and equity are also expected to continue to grow. The Group has earmarked 88 million euros for investments in 2011 and expects to create over 600 jobs worldwide.

CEO Klaus Endress pointed out that there were still major uncertainties to contend with. In his eyes, the financial crisis is far from over, and the debts of many countries – especially in the euro zone – remain a burden for the future. He called the political unrest in northern Africa and the Middle East, as well as earthquake, tsunami and nuclear disaster in Japan a clear reminder that a company must always expect the unexpected. “We have to remain agile and alerted,” warned Klaus Endress. “We want to continue to make use of opportunities, but must not overlook the risks.”

Lenzing AG Produces the Five Millionth Ton of Sodium Sulfate

For more than 70 years Lenzing AG has been manufacturing fibers from the renewable raw material wood. The environmentally-friendly production process, the maximum attainable closed cycle as well as the optimized use of beech wood as a raw material are unique in the industry, and make Lenzing a global trailblazer.

It is less well-known that for each ton of fiber produced, approximately the same amount of sodium sulfate is also derived (NA2SO4) from the manufacturing as a white crystalline powder. This means that the enormous increase in fiber production in recent years has also expanded Lenzing's role as a "salt factory." In the middle of April, the Lenzing, Austria plant reached the milestone of having produced five million tons of this substance. The product is delivered to the detergent and cleaner industry, the glass industry and the food and pharmaceutical industries, to name a few examples.

"This comprises an outstanding achievement of the production team at the site. In addition to the very successful fiber production, it also contributes to the overall output of the Lenzing facility", says Friedrich Weninger, Member of Management Board and Chief Operating Officer with responsibility for fiber production.

CEO Peter Untersperger says: "The sale of co-products of Lenzing AG derived from beech wood within the context of Lenzing's biorefinery, such as acetic acid, furfural and xylose, also encompasses the marketing of large amounts of sodium sulfate. This is an important part of the business carried out at the Lenzing site, and generates a significant share of the positive results achieved by the plant".

Recently in December 2010, Quality Austria carried out an official audit in accordance with the principles of a HACCP concept in addition to the existing ISO certifications. The HAACP1 system focuses on ensuring food and consumer safety. For Lenzing AG the HAACP certificate is a further important step in the company's development as a supplier of high quality products for the food, animal feed and pharmaceutical industries.

Creating Value in a World of Paper

Clariant to present functional chemicals for paper at Zellcheming Expo 2011 from June 28 to 30, 2011, in Wiesbaden in Hall 3, Booth 318

Clariant presents new optical brightening agent Leucophor® XL at Zellcheming Expo 2011 (Booth 318, Hall 3) as part of the product’s global market launch. The novel tinted optical brightening agent for surface application gives a truer white and less red cast, providing high-white grades of paper with less OBA and accordingly less cost. The innovation is an excellent combination of cost-optimization and performance.

Clariant presents new optical brightening agent Leucophor® XL at Zellcheming Expo 2011 (Booth 318, Hall 3) as part of the product’s global market launch. The novel tinted optical brightening agent for surface application gives a truer white and less red cast, providing high-white grades of paper with less OBA and accordingly less cost. The innovation is an excellent combination of cost-optimization and performance.

A further highlight at Zellcheming is Cartaspers® PSM, which reduces stickies and pitch on sieves and felts by passivation and thereby increases running time. At the same time exposure of both factory staff and the environment to volatile organic compounds is reduced. In acknowledgement of this, the US Environmental Protection Agency (EPA) awarded the Pollution Prevention Recognition Award to Cartaspers PSM.

The rapid boom in 2010 brought about shortage and an increase in price for energy, raw materials and intermediary products. This development is still ongoing and presents a great challenge to each link in the supply chain. Clariant sees its role as a supplier of specialty chemicals within this environment as being to provide customers with cost-effective solutions to enhance their products and processes. Higher cost pressure need not lead to quality limitations for paper and cardboard. In line with this Clariant will also present the product groups Cartabond®, Cartacol®, Cartacoat®, Cartafix®, Cartafluor® and Cartaseal®.

With the product groups Carta®, Cartasol®, Diresul®, Cartaren®, Flexonyl® Clariant presents colorants and pigments for nuancing white and highly white paper as well as for mass-coloring paper and surfaces to suit all demands, for every chromaticity coordinate and in any tinting strength.

Cartabond® crosslinker for better moisture resistance of paper coating.

Cartabond® surface strength improvers also increase drainage and save energy in paper production.

Cartacol® surface treatment chemicals improve printability, and paper- and print gloss.

The synthetic emulsion polymers for special papers, Cartacoat®, improve rheology for coating colors.

Cartafix® provides better fixation of dyestuffs, improved retention as well as control of interfering substances.

Cartafluor® fluorochemical grease barriers for high barrier demands.

The barrier chemicals Cartaseal® can be used for a variety of purposes such as anti-slip coating, water and water vapor barriers, and temperature resistance.

Ahlstrom to increase transportation filtration material capacity in Louveira, Brazil

Ahlstrom, a global high performance materials company, will invest into additional capacity in transportation filtration materials at its site in Louveira, Brazil. The investment will be completed in the first quarter of 2012.

"We have been pleased to grow with our key customers and as a commitment to the filtration business we are expanding the operation. This is another important step in our global growth roadmap where we have strengthened our global platform in Europe, Asia, and now in South America. We will continue to keep our focus on our markets in all four geographies - enabling Ahlstrom to be a global supplier in the filtration market with a full offering of filter media", states Gary Blevins, Vice President, Transportation Filtration.

Ahlstrom is a leading manufacturer of filtration materials globally with 11 production sites across four continents. In 2010, the company acquired a transportation filtration plant in Binzhou, China and announced a EUR 17.5 million investment to expand capacity in Turin, Italy.

Fibre Solutions for Recycling Paper

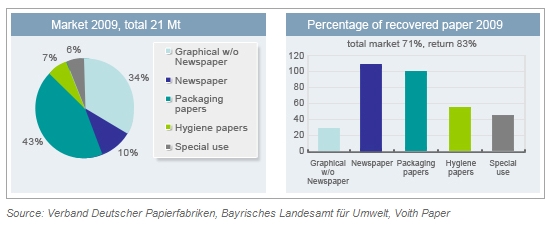

Worldwide there is an expected rapid growth of paper as in the past paper demand grew more rapidly than Gross National Product and has been unaffected by the often predicted “paperless office”. Covering this huge demand only by using fresh fibre pulp would lead to en overexploitation of forest resources. Therefore it has mainly to be covered by recycling of used paper products.

Even though 80% of used paper is collected still only 70% of it is recycled even though recycling is economically very attractive. 30% of paper is still made out of virgin fibres.

Why don′t we recycle all of the paper we collect? During the recycling process paper is ground. Its fibres are shortened and hence the stability of the paper is reduced making it unsuitable for many applications. We have to consider that “70% recycled” also means 50% has been recycled more than once, leading to a further deterioration in performance. To compensate this 30% of fresh fibres are added to the paper. Particularly graphical papers have a very low content of recovered material.

With our viscose fibres we were able to achieve an increase of paper quality demonstrated by e.g. higher double fold numbers and tear lengths by adding only 2–3% of our short cut viscose fibres to the pulp. With these short cut fibres it is possible to use nearly 100% of the cheaper recycled pulp. Instead of adding 20–30% of fresh fibre pulp there is only a need to add 2–3 % of viscose fibres such as Bellini.

This means that resource consumption can be reduced by up to 90%. Furthermore savings can be made on the raw material price because adding 2–3 % of viscose fibres is still cheaper than adding 20–30% of virgin pulp.

Caroline Sundewall and Marie Hallén elected on to Södra's Board of Directors

Caroline Sundewall and Marie Hallén were elected as new board members of Södra at today's Annual General Meeting. Caroline Sundewall started out as a financial controller, then switched to journalism and is today a consultant and board professional with years of experience. Alongside her new assignment at Södra she also serves on the board of directors of Svolder, Haldex, Tradedoubler, SJ (Swedish Railways), Lifco, Pågen, Ahlsell and Mertzig Kapitalförvaltning.

Marie Hallén is an agricultural technologist and a farmer and forester in Sollebrunn, Sweden. She has previously held several positions of trust in the agricultural cooperation sector. In addition to working on her farm she is employed at LRF Konsult where she handles EU matters, EU applications, corporate tax returns and annual accounts.

Gunilla Aschan declined re-election and is therefore no longer on the board of directors.