Ianadmin

Nalco Named Most Preferred Paper Industry Supplier for Fifth Consecutive Year

Nalco, an Ecolab company, has been selected as the most preferred paper industry supplier by readers of Pulp & Paper International (PPI) magazine for the fifth consecutive year.

Nalco, an Ecolab company, has been selected as the most preferred paper industry supplier by readers of Pulp & Paper International (PPI) magazine for the fifth consecutive year.

PPI's 2014 Brand Awareness and Preference Study among pulp, paper and paperboard manufacturers throughout the world indicated that more readers anticipated buying products and services from Nalco within the next twelve months than from any other supplier in the following key categories of specialty chemical programs: biocides, retention & drainage aids, boiler & steam systems, and cooling systems.

"The survey results highlight Nalco's commitment to delivering innovative solutions to the global paper industry," said Jeffrey Bulischeck, senior vice president and general manager, Global Paper, Nalco. "Our industry-leading solutions and expertise help our pulp and papermaking customers improve operational efficiency, environmental performance and ultimately, profitability."

PPI's publisher RISI conducts the annual Brand Awareness and Preference Study. RISI is an information provider for the global forest products industry, including the pulp and paper, wood products, timber, biomass, tissue, nonwovens, printing and publishing industries.

About Ecolab

Nalco is an Ecolab company. A trusted partner at more than one million customer locations, Ecolab (ECL) is the global leader in water, hygiene and energy technologies and services that protect people and vital resources. With 2013 sales of $13 billion and 45,000 associates, Ecolab delivers comprehensive solutions and on-site service to promote safe food, maintain clean environments, optimize water and energy use, and improve operational efficiencies for customers in the food, healthcare, energy, hospitality and industrial markets in more than 170 countries around the world.

For more Ecolab news and information, visit www.ecolab.com. Follow us on Twitter @ecolab or Facebook at facebook.com/ecolab.

PMP Group will supply 2nd Intelli-Tissue® 1200 EcoEc tissue machine for Hebei Xuesong Paper Co., Ltd

In January, Hebei Xuesong Paper Co., Ltd has signed a contract with PMP Group for 2nd Intelli- Tissue® EcoEc machine. Only 6 months after TM#1 successful start-up, Hebei Xuesong Paper choose PMP Group again as the provider of TM continuing fruitful partnership.

TM#2 (twin line to TM#1) with the brand name of Intelli-Tissue® 1200 EcoEc tissue machine, is characterized by reel trim of 2850 mm, design speed of 1200 m/min and capacity 60 t/d (basis weight 12.5-20 gsm). After TM#2 installation, Hebei Xuesong Paper will have two machines (right and left hand) in the same building based on integrated tissue mill concept.

Hebei Xuesong Paper - a famous tissue-making enterprise in Hebei Province, China - was founded in 1987and produces high-quality tissue products under “Xuesong” brand. PMP Group is a global provider of paper, board and tissue technology and has been serving pulp & paper industry for over 160 years. Efficient cooperation between two companies started from TM#1 project in 2013. First Intelli-Tissue® 1200 EcoEc was brought on stream in April 2014 and thanks to excellent cooperation between Hebei Xuesong Paper and the PMP teams, just 5 days after start-up, the maximum production capacity and tissue quality guarantees were achieved. Recently steam consumption reached an ultra-low level of 1.6- 1.8 t/t, which help to significantly minimize production costs.

TM#2 is actually a twin-sister machine of TM#1 and will also be executed based on philosophy of Optimum Cost Solution including tissue machine full design in Europe (PMPoland), manufacturing of the key components such as a Intelli-JetV® hydraulic headbox and a Intelli-YD™ steel Yankee in Europe (PMPoland), and the remaining manufacturing, tissue machine pre-assembly and tests completed at the Center of Excellence of PMP Group: PMP IB (Changzhou) Machinery & Technology, Changzhou (China). This combination ensures to lower the cost investment for the customer, while maintaining excellent quality of the equipment supplied. PMP will provide a stock approach system, Intelli-Tissue® 1200 EcoEc machine, mechanical drives, electrical drives, a lubrication system, a steam & condensate system and PLC. The PMP team will be responsible for an erection supervision and technological start-up.

The same model of right and left hand machines layout in one building is the most compact solution and the two machines can share a common spare parts base. As a result, both space and costs are saved as well as number of personnel required to run the installations. Finally, the valuable experience of PMP gained from TM#1 project will make TM#2 even more adapted to the customer’s requirements.

Year by year, PMP Group increases its presence in China through implementation of projects for both tissue & paper customers. Last decade in this market, has brought 11 CF tissue machines and 17 capital rebuilds including core technological units such as Intelli-Jet V® headboxes, Intelli-Nip® shoe presses, Intelli-Sizer™ size presses, etc. Combination of advanced technology and rich experience from PMP Group headquarters and convenient local service from PMP IB results in smart integration of assets & competences. This way PMP Intelli-Tissue® 1200 EcoEc tissue machine brings excellent support for its users daily.

Andreas Fall Awarded 2015 Alf de Ruvo Scholarship

The 2015 Alf de Ruvo scholarship, worth SEK 500,000, has been awarded to Dr. Andreas Fall for his comprehensive mapping of colloid chemistry interactions in nanocellulose systems, which may contribute to the development of entirely new materials.

The 2015 Alf de Ruvo scholarship, worth SEK 500,000, has been awarded to Dr. Andreas Fall for his comprehensive mapping of colloid chemistry interactions in nanocellulose systems, which may contribute to the development of entirely new materials.

The Alf de Ruvo Memorial Foundation awards scholarships to researchers within the sphere of cellulose-fibre-based materials. The amount of each scholarship is SEK 500,000. The foundation was formed in 2000 with funds donated in memory of Alf de Ruvo (1938–2000), Licentiate of Engineering and Executive Vice President of SCA.

Through experiments, the 2015 Alf de Ruvo scholarship winner Andreas Fall has shown which factors that control the surface potential of nanoscale cellulose, and how, by controlling the surface potential, the cellulose nanofibrils can be oriented, so strong continuous fibres can be produced. Andreas has also managed to produce fibril reinforced composites of polymethylmethacrylate by checking the gel formation of nanoscale cellulose.

This work has deepened our understanding of the fundamental mechanisms that will contribute to the development of entirely new material types such as foams, composites and reconstituted cellulose fibres based on nanocellulose.

“My vision is to in future work be able to orient and modify fibrils so that they may be used in, for example, oriented water-absorbing foams, batteries, super strong composites or ultra-capacitors”, says Andreas.

Andreas Fall currently works at the Environmental and Material Chemistry Department at Stockholm University. His new task is to utilize his colloidal knowledge to develop lightweight and mechanically robust porous materials based on cellulose nanofibrils (CNF) with improved fire retardency. A potential application is thermal isolation, for example in house walls and in electronic components. A suitable research environment for Andreas’ continued work is with Professor Christopher Weder at the University of Fribourg in Switzerland, which this scholarship makes possible.

Andreas Fall was born in Västerås, Sweden, 1981. He obtained his Master’s Degree in Biotechnology from Chalmers University of Technology, and achieved his Ph.D. in Fibre and Polymer Science 2014 from the Royal Institute of Technology (KTH), where Professor Lars Wågberg was his main supervisor.

The scholarship was awarded today at a ceremony in Stockholm in conjunction with the Ekman Days conference sponsored by the Swedish Association of Pulp and Paper Engineers.

About Alf de Ruvo

Alf de Ruvo (1938-2000) was well-known and respected within the forest and paper industry. He held several leading positions, including Deputy CEO of SCA. He was also the Chairperson of FPIRC the Forest Products Industrial Research College at KTH. He carried out broad research within the field of cellulose fibre-based materials and contributed to the development of world class technical paper research. Within the packaging field he worked with the mechanical properties of paper and their importance for conversion and final use.

The Alf de Ruvo’s Memorial Foundation was established in 2000 with funds donated in his memory. Its purpose is to support forestry industry education and research activities that benefit technical and scientific progress within the industry.

The scholarships are appointed by the members of the Board of the Foundation in consultation with a research council. There is no application process.

Members of the Board: Prof. Tom Lindström (Innventia and KTH), Dir. Mikael Schmidt (Senior Vice President, SCA) and Associate Professor Rolf Andersson (Fellow Scientist Hygiene/Microbiology, SCA).

Research Council: Dir. Christer Söremark (consultant and researcher within the forest industry), Prof. Myat Htun (Mid Sweden University, Sundsvall), Prof. Gunilla Jönson (Principal of the Technical University of Lund), Prof. em. Gunnar Svedberg (consultant and former CEO STFI-Packforsk), Dr Micael Stehr (Head of FPIRC, KTH), and Head of Dept Ulf Carlson (Chalmers).

For more information please contact:

Tom Lindström

Principal scientist

INNVENTIA AB

Phone direct +46 (0)8 676 7370

Cell: +46 (0)70 657 01 94

e-mail; This email address is being protected from spambots. You need JavaScript enabled to view it.

Hammermill® Paper Raises $327,657 During St. Jude Thanks And Giving® Campaign

Hammermill® Paper, manufactured by International Paper, raised $327,657 during an exciting holiday shopping season as part of the paper manufacturer's participation in the 11th annual St. Jude Thanks and Giving® campaign. This marks the fourth year of the Hammermill brand's partnership with St. Jude Children's Research Hospital®, and brings the total amount contributed by Hammermill to St. Jude to more than one million dollars. The Thanks and Giving campaign raises millions of dollars to support St. Jude Children's Research Hospital® and its mission of finding cures and saving children battling cancer and other life-threatening diseases.

Hammermill Paper supported the campaign by producing special reams of paper which featured original artwork on the front, drawn by actual St. Jude patients. Customers could also learn about the artists by reading the St. Jude stories on the back of the reams. Extending the partnership even further this year, International Paper sponsored the St. Jude Memphis Marathon Weekend in December with a spirit station at mile marker #8. More than 100 runners joined the Hammermill Heroes team and raised almost $32,000 for the hospital. "For the Hammermill Heroes team, partnering with St. Jude is about more than just business. It's a way for the entire International Paper family to come together, have fun and support a great cause," said John Sims, Vice President of Printing Papers.

The St. Jude Thanks and Giving campaign is a multi-media effort that unites celebrities, media and corporate partners in asking consumers to donate while they shop and support the lifesaving mission of St. Jude. Hammermill Paper joined more than 60 of America's leading companies and brands to participate in the campaign. What began as a holiday-focused fundraising effort by St. Jude has now grown into an annual tradition that raises funds to help St. Jude provide cutting-edge treatment and pursue visionary research. These funds are critical given that no family ever pays St. Jude for anything.

"As we enter the second decade of our St. Jude Thanks and Giving campaign, we could not have asked for a more wonderful performance from our partners," said Marlo Thomas, National Outreach Director for St. Jude Children's Research Hospital. "Hammermill Paper and its customers truly came through for us this year, not only raising vital funds for the hospital, but also showing such care and concern for the children and their Moms and Dads. This makes all the difference in the world, and we are enormously thankful to Hammermill for its unwavering generosity and commitment."

To learn more about Hammermill Paper, please visit www.hammermill.com.

To learn more about St. Jude Children's Research Hospital, please visit www.stjude.org.

About Hammermill Paper:

Hammermill is a brand of office papers that has been trusted to deliver superior quality for over 100 years. Hammermill is universally compatible with today's digital office equipment, so the result is superior print quality and smooth performance on every print job. Plus it's backed by a 99.99% Jam-Free Guarantee™. The Hammermill portfolio consists of 20 lb. copy paper for everyday documents, versatile multi-purpose and recycled content sheets, as well as heavier, super smooth presentation-quality papers for documents that get you noticed.

About International Paper:

International Paper (NYSE: IP) is a global leader in packaging and paper with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include industrial and consumer packaging along with uncoated papers and pulp. Headquartered in Memphis, Tenn., the company employs approximately 58,000 people and is strategically located in more than 24 countries serving customers worldwide. International Paper net sales for 2014 were $24 billion. For more information about International Paper, its products and stewardship efforts, visit internationalpaper.com.

About St. Jude Children's Research Hospital:

St. Jude Children's Research Hospital is leading the way the world understands, treats and defeats childhood cancer and other life-threatening diseases. St. Jude has the world's best survival rates for the most aggressive childhood cancers, and treatments invented at St. Jude have helped push the overall childhood cancer survival rate from 20 percent to 80 percent since we opened more than 50 years ago. St. Jude is working to drive the overall survival rate for childhood cancer to 90 percent in the next decade. St. Jude freely shares the breakthroughs we make, and every child saved at St. Jude means doctors and scientists worldwide can use that knowledge to save thousands more children. Families never receive a bill from St. Jude for treatment, travel, housing or food – because all a family should worry about is helping their child live. Join the St. Jude mission by visiting stjude.org or following St. Jude on facebook.com/stjude and twitter.com/stjude.

SOURCE International Paper

Domtar expands The Paper Trail, digital transparency tool that traces impacts of paper production

Domtar Corporation (NYSE: UFS) (TSX: UFS) has announced significant updates to The Paper Trail®, its award-winning interactive tool that helps customers trace the impacts of their paper purchases. The totally renovated site includes social and economic information in addition to environmental data, broadening the meaning of sustainability. It represents Domtar's belief that businesses should operate transparently, pulling back the curtain on their operations and the resulting impacts.

Domtar Corporation (NYSE: UFS) (TSX: UFS) has announced significant updates to The Paper Trail®, its award-winning interactive tool that helps customers trace the impacts of their paper purchases. The totally renovated site includes social and economic information in addition to environmental data, broadening the meaning of sustainability. It represents Domtar's belief that businesses should operate transparently, pulling back the curtain on their operations and the resulting impacts.

With the latest additions, The Paper Trail (www.domtarpapertrail.com) now showcases the people and places behind the products, featuring stories and photos from all 13 of Domtar's North American mills. The tool assesses Domtar's community investments by tracking charitable donations and volunteer efforts, such as recycling programs or educational initiatives. It also demonstrates the paper industry's impact on the economy, as Domtar employs nearly 9,000 people across the United States and Canada. In doing so, The Paper Trail helps both businesses and consumers understand the holistic impact of their purchases.

"Since first introducing The Paper Trail in 2011, our thinking has continued to evolve regarding what sustainability encompasses," said Paige Goff, Vice President of Sustainability and Business Communication. "The new site embraces all three legs of the 'sustainability stool' by assessing not only our environmental footprint, but our social and economic impact as well. It demonstrates Domtar's commitment to the towns we operate in - not only as an environmental advocate, but also as a driver of community initiatives and a creator of thousands of jobs."

The Paper Trail provides gate-to-gate impact estimates for Domtar products across five environmental categories: fiber, greenhouse gas (GHG) emissions, water, renewable energy and waste. It provides relevant context by illustrating how Domtar compares to the rest of the industry in these categories and, importantly, highlights areas for improvement in addition to showcasing what Domtar is doing well.

"The Paper Trail illustrates many of the complex issues we carefully consider when evaluating opportunities to improve our performance," said Brian Kozlowski, Senior Manager, Sustainability Performance Optimization. "We've used the tool to display mill sustainability data in an interesting and interactive way - and we're inviting the public to come along on the journey."

In addition to providing social and economic data, The Paper Trail also:

- Includes an expanded list of responsibly produced paper grades, representing the entire EarthChoice® Product Line

- Displays histories, pictures and stories from all 13 of Domtar's North American pulp and paper mills

- Offers users personalized impact report options with broader sustainability information, including topics of interest such as bleaching processes used and tree species utilized

- Is optimized for use on all smartphone, tablet and desktop devices

- Uses Google Maps to create a geographic trail to the closest mill that produces a select paper grade

With these improvements in place, The Paper Trail offers a clear and complete answer to the question "where does my paper come from?" It goes beyond environmental data to show customers how their purchase of North American paper can create a positive ripple effect on local communities.

"We can't always promise perfection, but we believe our customers deserve transparency. That's a promise we will always deliver - and it's the reason we created The Paper Trail in the first place." said Goff. "Now, consumers can also take pride in the fact they're helping to drive philanthropic efforts and create jobs across North America when they purchase from Domtar."

About Domtar

Domtar Corporation (NYSE: UFS) (TSX: UFS) designs, manufactures, markets and distributes a wide variety of fiber-based products including communication papers, specialty and packaging papers and absorbent hygiene products. The foundation of its business is a network of world class wood fiber converting assets that produce papergrade, fluff and specialty pulps. The majority of its pulp production is consumed internally to manufacture paper and consumer products. Domtar is the largest integrated marketer of uncoated freesheet paper in North America with recognized brands such as Cougar®, Lynx® Opaque Ultra, Husky® Opaque Offset, First Choice® and Domtar EarthChoice®. Domtar is also a leading marketer and producer of a broad line of absorbent hygiene products marketed primarily under the Attends®, IncoPack and Indasec® brand names. In 2013, Domtar had sales of $5.4 billion from some 50 countries. The Company employs approximately 10,000 people. To learn more, visit www.domtar.com.

SOURCE Domtar Corporation

Valmet-supplied OptiConcept M boardmaking line officially launched at SCG Paper's mill in Thailand

SCG Paper's Valmet-supplied containerboard production line, PM 16, successfully came on stream on October 01, 2014, 11 days ahead of the targeted date, at the Siam Kraft Industry Ban Pong mill in Ratchaburi, Thailand. The official Inauguration Ceremony at the Ban Pong mill took place on January 23, 2015, with over 400 guests celebrating the new well performing production line.

"PM 16 showcases the cutting edge technology of paper packaging manufacturing. It combines the world's latest technologies with SCG Paper's expertise, which means our company can now manufacture the products to meet the needs of customers in all and finer details," says Wichan Jitpukdee, Managing Director of Siam Kraft Industry.

The new 7.25 m wide PM 16 is the third OptiConcept M -type containerboard production line already started up. Earlier two lines have been started-up for Liansheng Paper Industry and Lee & Man Paper Manufacturing in China. This SCG Paper's line has an annual production capacity of approximately 300,000 tonnes of high-quality 100% recycled fluting grades in the basis weight range of 90 to 150 g/m2.The design speed of the machine is 1,300 m/min.

"Siam Kraft PM 16 is one of the most successful projects in South East Asia. It proves that Valmet can offer the very efficient technology in terms of energy consumption and operating cost reduction", says Pornpracha Wattanakijsiri, Head of South East Asia region, Valmet, Thailand.

Wichan Jitpukdee, Managing Director Siam Kraft Industry Co., Ltd., Pornpracha Wattanakijsiri, Head of South East Asia region, Valmet, Hannu T Pietilä, Area President, Asia Pacific, Valmet, Roongrote Rangsiyopash, President of SCG Paper, and Chartchai Leukulwatanachai, Packaging Paper Business Head, at Siam Kraft PM 16 Inaugural Ceremony on the 23rd of January, 2015

Energy efficient OptiConcept M board machine

Valmet's delivery included a complete OptiConcept M boardmaking line from headbox to reel including an approach flow system, steam and condensate systems, surface size preparation and supply systems, a winder as well as machine clothing. In addition, Valmet provided an extended scope of supply implementation covering complete mill engineering, installation and supervision services related to commissioning, testing and start-up. Training services were also included in the delivery.

The Siam Kraft PM 16 containerboard production line combines high productivity with low energy usage per produced ton of paper. The real-time energy consumption monitoring shows that the production line is performing as expected in energy efficiency. "One important driver for this project was to achieve the efficient energy consumption level, which means we could optimize the operating costs yet, remain competitive", says Sompob Witworrasakul, Director of Engineering Division, SCG Paper.

The Valmet OptiConcept M containerboard production line started up on October 01, 2014 for Siam Kraft Industry Co., Ltd. at the Ban Pong mill in Ratchaburi, Thailand.

About SCG Paper and its subsidiary Siam Kraft Industry

SCG Paper and its subsidiary company Siam Kraft Industry Co., Ltd produce and market industrial and packaging paper in Thailand and internationally. The company offers corrugating medium, linerboard, coreboard, industrial sack kraft, bag papers, plaster linerboard, duplex board as well as converted and finished products. The company was founded in 1984 and is based in Bangkok, Thailand.

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

For further information, please contact:

Pornpracha Wattanakijsiri, Head of South East Asia region, Valmet, Thailand, tel: +66 81825 1578

Seppo Kaukiainen, Senior Project Manager, Paper Mills Business Unit, Valmet, tel: +358 40 589 7964

Canfor Sells Taylor Pulp Mill to Canfor Pulp Products Incorporated

Canfor Corporation (TSX: CFP) has announced the sale of its Taylor, BC pulp mill to its subsidiary company, Canfor Pulp Products Incorporated (TSX: CFX). This transaction will impact the management reporting structure of Taylor Pulp within Canfor Corporation but is not anticipated to have any operational impacts. The agreement includes a purchase price of approximately $15 million including working capital, along with additional consideration to be paid by Canfor Pulp over a three year period contingent on the financial results of Taylor Pulp over that time.

Canfor Corporation (TSX: CFP) has announced the sale of its Taylor, BC pulp mill to its subsidiary company, Canfor Pulp Products Incorporated (TSX: CFX). This transaction will impact the management reporting structure of Taylor Pulp within Canfor Corporation but is not anticipated to have any operational impacts. The agreement includes a purchase price of approximately $15 million including working capital, along with additional consideration to be paid by Canfor Pulp over a three year period contingent on the financial results of Taylor Pulp over that time.

“This transaction serves to align all of our pulp and paper operations under the expertise of our Canfor Pulp leadership team,” said Canfor Corporation President and CEO Don Kayne. “Our excellent employees at Taylor Pulp will continue to make high‐quality products for our customers around the globe, and this agreement will simplify the management of our operating divisions.”

Taylor Pulp employs 106 people and has an annual production capacity of 220,000 tonnes of bleached chemi‐thermo‐mechanical pulp.

Forward Looking Statements

Certain statements in this press release constitute “forward‐looking statements” which involve known and unknown risks, uncertainties and other factors that may cause actual results to be materially different from any future results, performance or achievements expressed or implied by such statements. Words such as “expects”, “anticipates”, “projects”, “intends”, “plans”, “will”, “believes”, “seeks”, “estimates”, “should”, “may”, “could”, and variations of such words and similar expressions are intended to identify such forward‐looking statements. These statements are based on management’s current expectations and beliefs and actual events or results may differ materially. There are many factors that could cause such actual events or results expressed or implied by such forward‐looking statements to differ materially from any future results expressed or implied by such statements. Forward‐looking statements are based on current expectations and Canfor assumes no obligation to update such information to reflect later events or developments, except as required by law.

Canfor is a leading integrated forest products company based in Vancouver, British Columbia (BC) with operations in BC, Alberta, North and South Carolina and Alabama. Canfor produces primarily softwood lumber, and also produces bleached chemi‐thermo‐mechanical pulp and specialized wood products. Canfor also owns a 50.5% interest in Canfor Pulp Products Inc., which is one of the largest producers of northern softwood kraft pulp in Canada and a leading producer of high performance kraft paper. Canfor shares are traded on the Toronto Stock Exchange under the symbol Canfor.

Kemira Oyj: Proposals of the Nomination Board to the Annual General Meeting 2015

The Nomination Board proposes to the Annual General Meeting of Kemira Oyj that six members be elected to the Board of Directors and that the present members Wolfgang Büchele, Winnie Fok, Juha Laaksonen, Timo Lappalainen, Jari Paasikivi and Kerttu Tuomas be re-elected as members of the Board of Directors. In addition, the Nomination Board proposes Jari Paasikivi to be re-elected as the Chairman of the Board of Directors and Kerttu Tuomas to be re-elected as the Vice Chairman. All the nominees have given their consent to the position.

The Nomination Board proposes to the Annual General Meeting of Kemira Oyj that six members be elected to the Board of Directors and that the present members Wolfgang Büchele, Winnie Fok, Juha Laaksonen, Timo Lappalainen, Jari Paasikivi and Kerttu Tuomas be re-elected as members of the Board of Directors. In addition, the Nomination Board proposes Jari Paasikivi to be re-elected as the Chairman of the Board of Directors and Kerttu Tuomas to be re-elected as the Vice Chairman. All the nominees have given their consent to the position.

The Nomination Board proposes to the Annual General Meeting that the annual fees paid to the members of the Board of Directors would increase. The annual fee for the Chairman is proposed to be increased to EUR 80,000 from EUR 74,000 per year, for the Vice Chairman and the Chairman of the Audit Committee to EUR 49,000 from EUR 45,000 per year and for the other members to EUR 39,000 from EUR 36,000 per year. Annual fees have not been increased since 2011, except the annual fee for the Chairman of the Audit Committee which was increased in 2013. A fee payable for each meeting of the Board of Directors and the Board Committees is proposed to remain unchanged. A fee payable for each meeting would thus be as follows; members residing in Finland EUR 600, for the members residing in rest of Europe EUR 1,200 and for the members residing outside Europe EUR 2,400. Meeting fees have not been increased for the members of the Board of Directors residing in Finland since 2005, and for the members of the Board of Directors residing outside Finland since 2006. Travel expenses are proposed to be paid according to Kemira's travel policy.

In addition, the Nomination Board proposes to the Annual General Meeting that the annual fee be paid as a combination of the company's shares and cash in such a manner that 40% of the annual fee is paid with the company's shares owned by the company or, if this is not possible, shares purchased from the market, and 60% is paid in cash. The shares will be transferred to the members of the Board of Directors and, if necessary, acquired directly on behalf of the members of the Board of Directors within two weeks from the release of Kemira's interim report January 1 - March 31, 2015. The meeting fees are proposed to be paid in cash.

The Nomination Board has consisted of the following representatives: Pekka Paasikivi, Chairman of the Board of Oras Invest Oy as the Chairman of the Nomination Board; Kari Järvinen, Managing Director of Solidium Oy; Risto Murto, President and CEO, Varma Mutual Pension Insurance Company and Timo Ritakallio, Deputy CEO, Ilmarinen Mutual Pension Insurance Company as members of the Nomination Board and Jari Paasikivi, Chairman of Kemira's Board of Directors as an expert member.

For more information, please contact

Pekka Paasikivi, Chairman of the Kemira Nomination Board

+358 10 2868 100

Kemira Oyj

Tero Huovinen, VP, Investor Relations

+358 10 862 1980

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2013, Kemira had annual revenue of EUR 2.2 billion and around 4,500 employees. Kemira shares are listed on the NASDAQ OMX Helsinki Ltd.

www.kemira.com

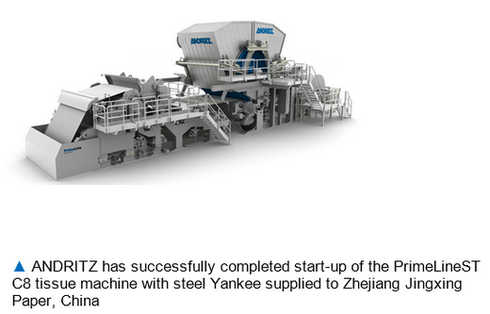

ANDRITZ successfully starts up tissue machine with steel Yankee for Zhejiang Jingxing Paper, China

International technology Group ANDRITZ has successfully completed start-up of the tissue machine with an 18-foot steel Yankee supplied to Zhejiang Jingxing Paper in Pinghu city, Zhejiang province, China. The PrimeLineST C8 machine, which is producing high quality facial wipes and toilet paper grades, has a design speed of 1,900 m/min and a paper width of 2.85 m.

“Photo: ANDRITZ”.

“Photo: ANDRITZ”.

The steel Yankee with head insulation, in combination with a steam-heated hood, enables a high drying capacity at minimized energy costs. Start-up of a second ANDRITZ tissue machine for Zhejiang Jingxing Paper has been scheduled before the end of this year.

For further information, please contact:

Oliver Pokorny

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.andritz.com

The ANDRITZ GROUP

The ANDRITZ GROUP is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and solid/liquid separation in the municipal and industrial sectors. The publicly listed, international technology Group is headquartered in Graz, Austria, and has a staff of around 24,500 employees. ANDRITZ operates over 250 production sites as well as service and sales companies all around the world. The ANDRITZ GROUP ranks among the global market leaders in all four of its business areas. One of the Group’s overall strategic goals is to strengthen and extend this position. At the same time, the company aims to secure the continuation of profitable growth in the long-term.

ANDRITZ PULP & PAPER

The business area is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, production equipment for biofuel (second generation), biomass torrefaction equipment, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

Valmet to supply key board machine solutions for Zhejiang Long Chen Paper in China

Valmet will supply Zhejiang Long Chen Paper with a new headbox, press section and sizer for its new PM7 containerboard machine to be located in the company's Dushan mill in Jiaxing City in China. The start-up of the machine is scheduled for 2015.

Valmet will supply Zhejiang Long Chen Paper with a new headbox, press section and sizer for its new PM7 containerboard machine to be located in the company's Dushan mill in Jiaxing City in China. The start-up of the machine is scheduled for 2015.

The order is included in Valmet's fourth quarter 2014 orders received. The value of the order will not be disclosed.

Valmet's key technologies for containerboard

Valmet's delivery for the new containerboard machine will include a new OptiFlo Fourdrinier headbox for improved product quality and increased productivity, a center-roll based OptiPress press section with modern shoe press technology for lighter basis weights, as well as a new OptiSizer Film sizing section utilizing film application.

"In containerboard manufacturing, headbox, press section and sizer are key components in order to secure production quality. That's why also Long Chen chose Valmet to supply those parts for their PM7 machine," comments Kari Räisänen, Area Sales Director of Valmet.

The 7250mm wide (wire) PM7 will produce containerboard grades at maximum speed of 900 m/min.

About Zhejiang Long Chen

Long Chen Paper Co. is a service-oriented company that manufactures recycled containerboard, corrugated medium paper, corrugated board, and packaging materials. The company has operations in Taiwan and China. Long Chen Paper has 3,318 employees worldwide.

For further information, please contact:

Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills, Valmet, tel. +358 40 744 8182

Fan Ze, Area Vice President, Sales, Valmet tel. +86 139 0133 6277

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal