Ianadmin

Cham Paper Group Holding AG: Results of the Consultation Procedure

On 21 August 2014 the Cham Paper Group announced that it will be boosting the competitive strength of its speciality papers by planning the continued transfer of technology from Switzerland to Italy. The relocation affects the coating technology operations currently run in Cham for producing the digital imaging and barrier papers. Continued relocation of operations is to take place in the first quarter of 2015 and is expected to result in a further reduction of approx. 50 staff at the Group's registered office in Switzerland.

On 21 August 2014 the Cham Paper Group announced that it will be boosting the competitive strength of its speciality papers by planning the continued transfer of technology from Switzerland to Italy. The relocation affects the coating technology operations currently run in Cham for producing the digital imaging and barrier papers. Continued relocation of operations is to take place in the first quarter of 2015 and is expected to result in a further reduction of approx. 50 staff at the Group's registered office in Switzerland.

The Board of Directors and the Executive Management Board immediately contacted the social partner organisations and cantonal authorities for the purpose of carefully planning the current redundancies with the involvement of all stakeholders in a socially responsible manner. The goal of this is to sustainably secure the remaining 30 to 40 positions at Cham in Research & Development (Digital Imaging), Marketing & Sales, Small roll processing and Group administration.

During the three-week consultation period, proposals for alternative solutions could be submitted to the employee representation committee of the mill in Cham. The consultation period ended on 14 September. No petitions were received from the employee representation committee during this period. The Executive Management Board will now initiate talks as planned with the social partner organisations for the purpose of fleshing out the details of the redundancy scheme with a view to finalising the scheme in the fourth quarter of 2014.

Cham Paper Group

Cham Paper Group is a leading manufacturer of coated speciality papers. The group generates added value for its customers by providing finishing-based functional capabilities. Founded in 1657, at its three locations in Switzerland and Italy the company develops and manufactures speciality papers for use in the consumer goods, industrial release and digital imaging sectors. The consumer goods sector encompasses papers for flexible packaging and base papers for label printing in the food, non-food, tobacco, beverage and pharmaceutical industries. In terms of the industrial release sector, Cham Paper Group supplies silicone-base papers for release liners used in graphical applications and for adhesive tapes and labels. The company also supplies base papers for process liners used in industrial casting and laminating process applications. Facestock papers for the self-adhesive industry round off the range. In addition to large-format inkjet papers for indoor and outdoor applications, the digital imaging sector also includes sublimation papers for digital textile printing. Cham Paper Group has benefited from the trend for sustainable products and is well established on the market thanks to the company's technological innovation. Cham Paper Group (stock exchange symbol: CPGN) is listed on the SIX Swiss Exchange as an independent company.

Huffman announces end of Samoa Pulp Mill clean-up

Press release from Congressman Jared Huffman's office:

Congressman Jared Huffman (D-San Rafael) has announced that the final shipment of some three million gallons of dangerous chemicals has left the former Samoa Pulp Mill site, in Humboldt County, Calif., drastically reducing a potentially catastrophic environmental threat to Humboldt Bay.

Huffman praised the Humboldt Bay Harbor, Recreation and Conservation District, the U.S. Environmental Protection Agency (EPA), the U.S. Coast Guard and Coast Seafoods for their rapid response to what was a potential disaster. Last summer, EPA was approached by the Harbor District about millions of gallons of highly caustic pulping liquors abandoned by previous owners in tanks that were inappropriate for storage and actively leaking. Due to the volume of the liquors on site and their proximity to Humboldt Bay, all parties worked diligently to secure the site and began working on a plan to remove the chemicals.

Huffman praised the Humboldt Bay Harbor, Recreation and Conservation District, the U.S. Environmental Protection Agency (EPA), the U.S. Coast Guard and Coast Seafoods for their rapid response to what was a potential disaster. Last summer, EPA was approached by the Harbor District about millions of gallons of highly caustic pulping liquors abandoned by previous owners in tanks that were inappropriate for storage and actively leaking. Due to the volume of the liquors on site and their proximity to Humboldt Bay, all parties worked diligently to secure the site and began working on a plan to remove the chemicals.

"I'm very pleased that the final truckloads of caustic chemicals have left the Samoa pulp mill site, ensuring that Humboldt Bay is protected from a toxic legacy irresponsibly abandoned by previous owners," Huffman said. "I thank the Harbor District, the EPA, the Coast Guard, Coast Seafoods and the community for their response to such a grave threat to one of my district's most precious resources."

The Harbor District purchased the mill last year, which never restarted following its 2008 shut down.

When the potential for severe environmental harm became clear, Coast Seafoods extended a line of credit to get the shipping under way, recognizing the threat to the shellfish resources in the Bay. As the EPA became involved, the cleanup was elevated to the highest level of the agency. Kapstone Paper and Packaging Corporation in Longview, Wash. was willing to receive the chemicals for reuse and recycling. The North Coast Regional Water Quality Control Board and the state Department of Toxic Substances Control also assisted in the cleanup.

"I am thankful to our local, state and federal partners in this incredible effort to address the dire threat to Humboldt Bay," said Harbor District President Richard Marks. "The completion of the cleanup will allow the Harbor District to use this important property to create jobs and build an economy on the Bay appropriate for the 21st century."

"Completing this first phase of work is an important milestone as EPA protects Humboldt Bay and the community from the threat of toxic releases from the abandoned Samoa Pulp Mill," said Jared Blumenfeld, EPA's Regional Administrator for the Pacific Southwest. "Reusing hazardous chemicals from the site promotes our mission to both protect the environment and conserve resources. Our partners at the Harbor District, the Coast Guard, and Kapstone Paper and Packaging were essential to our success."

"Without the hard work and partnership between these local, state and federal agencies, this could have been a massive disaster that polluted Humboldt Bay beyond repair," Huffman said. "Instead, it's an ongoing success story that will continue until the cleanup is complete and the property can be put to better use for the benefit of the local economy and environment."

Mondi’s recycled NAUTILUS® papers awarded Buyers Lab (BLI) performance certification

Consistent quality of NAUTILUS® SuperWhite and NAUTILUS® ReFresh externally verified

Mondi’s recycled brands NAUTILUS® SuperWhite and NAUTILUS® ReFresh have been awarded with the Buyer’s Lab (BLI) performance certification based on independent testing across numerous digital imaging devices. Buyer’s Lab (BLI), the leading global independent office products test lab and business consumer advocate, tested the NAUTILUS® papers on a total of 15 different office document imaging devices (including copiers, printers, fax machines and multifunctional products) representing Canon, Epson, Kyosera, Ricoh and Brother and evaluated the results based on paper dust, runnability (curl, double-sheeting and misfeeds), image performance, packaging and cut defects. According to the certificates awarded, both NAUTILUS® brands have proven to be highly reliable, with excellent performance related to image quality, dusting and curl.

Mondi’s recycled brands NAUTILUS® SuperWhite and NAUTILUS® ReFresh have been awarded with the Buyer’s Lab (BLI) performance certification based on independent testing across numerous digital imaging devices. Buyer’s Lab (BLI), the leading global independent office products test lab and business consumer advocate, tested the NAUTILUS® papers on a total of 15 different office document imaging devices (including copiers, printers, fax machines and multifunctional products) representing Canon, Epson, Kyosera, Ricoh and Brother and evaluated the results based on paper dust, runnability (curl, double-sheeting and misfeeds), image performance, packaging and cut defects. According to the certificates awarded, both NAUTILUS® brands have proven to be highly reliable, with excellent performance related to image quality, dusting and curl.

“I can confirm that both Mondi papers - NAUTILUS® ReFresh and NAUTILUS® SuperWhite - have been awarded BLI’s Performance Certification, which means that it has delivered very good results across a wide range of devices and brands in BLI’s testing program,” says David Sweetnam, Head of European Research and Lab Services.

Beyond awarding the performance certification of NAUTILUS®, BLI has also chosen to use the NAUTILUS® brands for its ongoing lab testing. “All of BLI’s Environmental Testing on a wide range of imaging devices is conducted with Mondi NAUTILUS® Refresh Triotec 30% and NAUTILUS® SuperWhite 100% recycled papers, both of which are quality-grade recycled multipurpose papers. A number of other Mondi media types, including NAUTILUS® SuperWhite are also used in BLI’s Public and Custom testing, and they have always delivered outstanding quality and reliability,” confirms Dr. Simon Plumtree, European Managing Editor.

“Having purchased NAUTILUS® recycled paper from Mondi for several years now, I have to say that the consistent quality performance of the brand is excellent. We’re satisfied and more importantly, our customers are satisfied. Can’t ask for more,” says Hanspeter Albrecht, Head of Marketing, Berberich Papier, sharing a customer perspective.

“We were thrilled to receive the external verification of our high quality recycled NAUTILUS® papers. It is one thing if we say we produce excellent recycled papers, but another thing entirely if an independent body and customers confirm it,” says Johannes Klumpp, Marketing & Sales Director, Mondi Uncoated Fine Paper. “The clear benefits for users – less machine wear and reduced maintenance costs – are combined with an excellent eco-profile and externally verified. So there are no compromises between quality and environmental benefits. It doesn’t get any better than that,” concludes Klumpp.

More information about Mondi’s recycled paper portfolio is available at: www.mondigroup.com/nautilus

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is a business unit of Mondi’s Europe & International Division. In 4 paper mills in Austria, Slovakia, Russia and South Africa, Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

About Mondi

Mondi is an international packaging and paper Group, employing around 26,000 people in production facilities across 31 countries. In 2013, Mondi had revenues of €6.5 billion and a ROCE of 15.3%. The Group's key operations are located in central Europe, Russia, the Americas and South Africa.

The Mondi Group is fully integrated across the packaging and paper value chain - from the management of its own forests and the production of pulp and paper (packaging paper and uncoated fine paper), to the conversion of packaging paper into corrugated packaging, industrial bags, extrusion coatings and release liner. Mondi is also a supplier of innovative consumer packaging solutions, advanced films and hygiene products components.

Mondi has a dual listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc, under the ticker code MNDI. The Group’s performance, and the responsible approach it takes to good business practice, has been recognised by its inclusion in the FTSE4Good Global, European and UK Index Series (since 2008) and the JSE's Socially Responsible Investment (SRI) Index since 2007.

Susan Brunner, Sustainability & Marketing Communications Manager, Uncoated Fine Paper

Tel: +43 1 79013 – 5654, e-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Mondi Uncoated Fine Paper Sales GmbH, Marxergasse 4a, A-1030 Wien

www.mondigroup.com

Thermographic method reveals the drying time in the sheet

Lower grammages significantly changes the behaviour of the drying rate and air flow during tissue production. This was pointed out in a new Licentiate thesis presented by Aron Tysén on 30 September at Karlstad University.

The removal of water is an integral part of tissue production. Through air drying (TAD) is used for premium tissue grade products. This process provides both better absorption and bulk compared to traditional dewatering by pressing, but is very energy intensive. A better understanding of the TAD process may lower energy demand.

Aron Tysén has in his licentiate work at Innventia investigated the influence of grammage, formation, i.e. variation in local grammage, and pulp type on non-uniform drying and air flow through the sheet. A method was developed, based on infrared thermography, to determine local drying time of laboratory sheets on a sub mm-scale, while monitoring air flow and pressure drop of the TAD process. Modified permeability, i.e. the air flow through the fibre network at a given grammage, was used to evaluate air flow characteristics.

The results from the studies presented in the thesis "Through air drying - The influence of formation and pulp type on non-uniform drying and air flow" show, somewhat unexpectedly, that neither the pulp type, nor the formation has much influence on the drying rate and the non-uniformity of drying. Grammage, however, seems to play a crucial role. For low grammages, only small mass-specific drying rate variations between the sheets were noted. For higher grammages, however, the mass-specific drying rate became dependent on the modified permeability to an increasing extent, suggesting a change in drying mechanisms with grammage.

"This implies that TAD at low grammages would not benefit from high through air flows. It might be better to have a longer drying section with less air flow, allowing saturation of the drying air", says Aron Tysén.

The Licentiate degree was the first milestone towards a PhD degree. For Aron's further studies, many avenues are possible with the developed technique. For instance a closer look at the influence of the TAD wire design on the local drying times, which would be possible with the high resolution obtained with the thermographic method.

"The methodology developed by Aron has shown that thermography can be used to calculate the drying rate. In the next step, it would also be possible to match the drying time maps against other measurements such as grammage maps which could lead to greater understanding of connections between, for instance, grammage variations, moisture variations, and local drying times, says Hannes Vomhoff who has been Aron's supervisor at Innventia.

For more information, contact

Aron Tysen, tel. +46 768 767497, This email address is being protected from spambots. You need JavaScript enabled to view it.

Hannes Vomhoff, tel. +46 768 767488, This email address is being protected from spambots. You need JavaScript enabled to view it.

This study was performed as part of the Industrial Graduate School VIPP (Values Created in Fiber Based Processes and Products) at Karlstad University, with the financial support of the Knowledge Foundation.

Team SCA In Global Sailing Race to Strengthen Awareness of SCA

InPort Race kicks off the Volvo Ocean Race, October 4

SCA is continuing its journey as a leading global hygiene and forest products company to boost awareness of the Group as the company behind strong customer and consumer brands such as TENA, Tork, Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. Team SCA in the Volvo Ocean Race plays a great role in this journey.

Team SCA, the first female team in over a decade, will start its participation in the Volvo Ocean Race with the first InPort Race on October 4 in Alicante, Spain. Prince Carl Philip of Sweden and SCA’s President and CEO Jan Johansson will join the Team on board. As of today SCA will also be opening its Pavilion to further increase awareness of SCA and meet with consumers, customers and other key stakeholders.

“Many consumers today want to know the company behind the products and brands that they buy and use. This race is a unique global platform to increase awareness of SCA and to connect SCA to its customer and consumer brands, such as TENA, Tork, Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda” says Joséphine Edwall-Björklund, Senior Vice President Group Function Communication, SCA.

Several Team SCA activities will form part of the Pavilion experience including:

Amazing Women Everywhere Starting today, SCA launches a global storytelling mosaic to celebrate amazing women. The mosaic will include images and stories of inspiring women from across the globe. For every image/story uploaded to the mosaic, SCA will make a donation to WWF. Visit www.teamsca.com/awemosaic

“No Ordinary Women” is a unique four-episode television series about Team SCA as they prepare to take on the tough nine-month, round-the-world offshore marathon, the Volvo Ocean Race. The series, which will be broadcasted in more than 30 countries, is produced by the television production company Strix Television. Watch the trailer

InPort Race – The InPort Race is a short race held at each stopover as close as possible to land so that the public can watch the battle between the Volvo Ocean 65s. During the InPort Races, the teams are allowed to have guests join them on board. For Saturday’s race in Alicante, Prince Carl Philip of Sweden will join the team onboard.

SCA Pavilion – SCA’s Pavilion is located in the Volvo Ocean Race village. The Pavilion, which will follow the race around the world, is approximately 580 square meters and consists of a triangular, two-storey structure. The exterior design has a strong link to the design of the boat, while the interior allows visitors to explore SCA – as a leading global hygiene and forest products company – its customer and consumer brands, story and values. Guests will also have the opportunity to get to know the amazing women of Team SCA through a number of interactive features.

Team SCA App – There are several ways to follow Team SCA on this nine-month journey around the world. The Team SCA App provides the latest news and images from the Race. It also contains information about SCA as well as other exciting features. The App is available through the App Store. You can also follow the team at www.teamsca.com and via our social media channels.

For further information, please contact:

Karl Stoltz, Media Relations Manager, +46 8 788 51 55

Elisabeth Lennhede, Communications specialist, +46 8 788 51 98

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2013 amounted to approximately SEK 93bn (EUR 10.7bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Verso Announces Closure of Bucksport, Maine Paper Mill

Verso Paper Corp. (NYSE: VRS) has announced plans to close its paper mill in Bucksport, Maine. The closure of the mill is expected to occur in the fourth quarter of 2014. The mill closure will reduce Verso's coated groundwood paper production capacity by approximately 350,000 tons and its specialty paper production capacity by approximately 55,000 tons.

Verso Paper Corp. (NYSE: VRS) has announced plans to close its paper mill in Bucksport, Maine. The closure of the mill is expected to occur in the fourth quarter of 2014. The mill closure will reduce Verso's coated groundwood paper production capacity by approximately 350,000 tons and its specialty paper production capacity by approximately 55,000 tons.

"The Bucksport mill unfortunately has not been profitable for a number of years, in spite of our employees' dedicated efforts to make it so. Our assessment indicates that it is impossible for the mill to achieve profitability in today's marketplace," said Verso President and Chief Executive Officer, Dave Paterson.

"This decision is especially difficult because of the significant impact that the closure of the Bucksport mill will have on many people across the region, especially our long-serving and hard-working employees and their families," said Verso Senior Vice President of Manufacturing and Energy, Lyle Fellows.

Verso is committed to helping the Bucksport mill employees who will be affected by the closure. Verso will work closely with union officials and salaried employees concerning severance benefits and other assistance. Verso also will work with local and state officials to help the affected employees access resources to identify alternative employment opportunities.

Verso will work with its customers to find the best long-term solutions for their product needs after the closure of the Bucksport mill. "Our desire in this process is to minimize disruption to our customers' businesses to the extent possible. Even in the face of reduced production capacity, our customers know that they can depend on Verso to deliver high-quality paper products and exceptional customer service," said Verso Senior Vice President of Sales, Marketing and Product Development, Mike Weinhold.

Verso estimates that the closure of the Bucksport mill will result in pre-tax cash severance and other shutdown charges of approximately $35-45 million to be recorded in 2014 and 2015. The estimated cash charges consist of approximately $30-35 million in severance costs and approximately $5-10 million in other shutdown costs. Verso currently is analyzing options for the disposition of mill assets and thus does not have sufficient information to estimate the pre-tax noncash asset impairment and accelerated depreciation charges at this time. Verso expects that the noncash charges will be recognized in 2014.

"The Bucksport mill has a long and proud history. We thank all of our employees, the surrounding communities, and the many local and state officials who have partnered with us over the years," said Bucksport Mill Manager, Dennis Castonguay. "It's difficult to put into words how much your support has meant to us."

About Verso Paper Corp.

Verso Paper Corp. is a leading North American producer of coated papers, including coated groundwood and coated freesheet, and specialty products. Verso is headquartered in Memphis, Tennessee, and owns three paper mills located in Maine and Michigan. Verso's paper products are used primarily in media and marketing applications, including magazines, catalogs and commercial printing applications such as high-end advertising brochures, annual reports and direct-mail advertising. Additional information about Verso is available on its website at www.versopaper.com.

Forward-Looking Statements

In this press release, all statements that are not purely historical facts are forward-looking statements within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934. Forward-looking statements may be identified by the words "believe," "expect," "anticipate," "project," "plan," "estimate," "intend" and other similar expressions. Forward-looking statements are based on currently available business, economic, financial and other information and reflect management's current beliefs, expectations and views with respect to future developments and their potential effects on Verso. Actual results could vary materially depending on risks and uncertainties that may affect Verso and its business. For a discussion of such risks and uncertainties, please refer to Verso's filings with the Securities and Exchange Commission. Verso assumes no obligation to update any forward-looking statement made in this press release to reflect subsequent events or circumstances or actual outcomes.

Contact

Verso Paper Corp.

Robert P. Mundy

Senior Vice President and Chief Financial Officer

901-369-4128

Email Contact

www.versopaper.com

Source: Verso Paper Corp.

CANFOR PURCHASES MILL FROM SOUTHERN LUMBER COMPANY

Canfor Corporation (TSX:CFP) is pleased to announce the purchase of the operating assets of Southern Lumber Company, Inc. The acquisition includes a sawmill located in Hermanville, Mississippi which is a large log southern yellow pine dimension mill manufacturing predominately long, wide width lumber. The sawmill is in an area of exceptionally high quality fibre and is well suited for higher value product lines. After reflecting near term capital, the operation has a capacity of 90 million board feet.

Canfor Corporation (TSX:CFP) is pleased to announce the purchase of the operating assets of Southern Lumber Company, Inc. The acquisition includes a sawmill located in Hermanville, Mississippi which is a large log southern yellow pine dimension mill manufacturing predominately long, wide width lumber. The sawmill is in an area of exceptionally high quality fibre and is well suited for higher value product lines. After reflecting near term capital, the operation has a capacity of 90 million board feet.

The purchase price excluding working capital is $48.7 million (USD) and the completion of the transaction is expected at the end of the first quarter of 2015 and is subject to customary closing conditions.

“The Southern Lumber sawmill is a top quartile margin business located in an excellent fibre supply area that will provide us with additional higher value opportunities for our global markets” said Canfor Corporation President and CEO Don Kayne. “This, together with an excellent management team, will continue to ensure Canfor’s ongoing commitment to our customers.”

Canfor is a leading integrated forest products company based in Vancouver, British Columbia (BC) with operations in BC, Alberta, North and South Carolina and Alabama. Canfor produces primarily softwood lumber, and also produces bleached chemi-thermo-mechanical pulp and specialized wood products. Canfor also owns a 50.4% interest in Canfor Pulp Products Inc., which is one of the largest producers of northern softwood kraft pulp in Canada and a leading producer of high performance kraft paper. Canfor shares are traded on the Toronto Stock Exchange under the symbol CFP.

Forward Looking Statements

Certain statements in this press release constitute “forward-looking statements” which involve known and unknown risks, uncertainties and other factors that may cause actual results to be materially different from any future results, performance or achievements expressed or implied by such statements. Words such as “expects”, “anticipates”, “projects”, “intends”, “plans”, “will”, “believes”, “seeks”, “estimates”, “should”, “may”, “could”, and variations of such words and similar expressions are intended to identify such forward-looking statements. These statements are based on management’s current expectations and beliefs and actual events or results may differ materially. There are many factors that could cause such actual events or results expressed or implied by such forward-looking statements to differ materially from any future results expressed or implied by such statements. Forward-looking statements are based on current expectations and Canfor assumes no obligation to update such information to reflect later events or developments, except as required by law.

Investor Contact:

Pat Elliott

Vice President and Treasurer

(604) 661-5441

This email address is being protected from spambots. You need JavaScript enabled to view it.

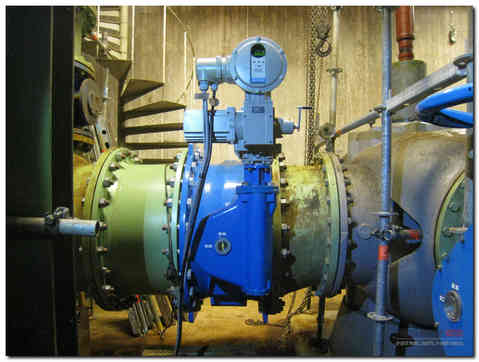

Swedish Paper Mill Safety Supported by SIPOS

Via its Agent in Sweden, Erichs Armatur AB, SIPOS Aktorik has supplied uninterruptible power supply (UPS) enabled actuators to the Södra Cell Morrum paper mill to aid control of main raw water intake processes. The contract reinforces SIPOS’ expertise providing fail-safe actuation solutions for high levels of operational safety.

The mill’s product range comprises long and short-fibre, plus textile pulp. With an annual production capacity of 460,000 tonnes, it is a significant exporter of pulp topaper mills in Europe, where it is converted into paper products. At full capacity, 170,000 tons of hardwood textile pulp is exported to mills in Asia.

Commenting on how SIPOS actuators, combined with UPS Systems, have provided safe and economic valve control solutions across a range of sectors for over ten years, Gerda Noelp, an International Sales Manager for SIPOS Aktorik said:

“At SIPOS we are aware that high safety requirements should be met as efficiently as possible: we therefore provide integrated frequency converters as standard, which means that our actuators are ideally suited for use with UPS systems. Advantages include variable output speed capability which minimises water hammer and reduces valve damage.”

Local support is central to SIPOS’ service and technical regional representatives handled the commissioning, including mounting the company’s actuators onto DN 600 butterfly valves.

Other UPS installations for SIPOS include pump stations in Colorado, Poland, Finland and Denmark; wastewater treatment in Sweden and surface water flood control in Denmark.

SIPOS Aktorik GmbH, Im Erlet 2, D-90518 Altdorf, Germany

Tel. +49 (0) 9187 / 9227- 0 Fax +49 (0) 9187 / 9227-5111

Email This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet delivered biomass boiler handed over to RWE Innogy in the UK

Valmet handed over a new biomass boiler and flue gas treatment for RWE Innogy UK's Markinch combined heat and power plant (CHP) in July 2014 following a commissioning period and test-runs. The plant is located in Fife Scotland, and is the largest of its type in the UK. The new plant provides the Tullis Russell Papermakers with steam and electricity to run the facilities. In addition, excess electricity is exported to the grid.

The new plant helps Tullis Russell to reduce its fossil fuel emissions and significantly contributes to Scotland's ambitious renewable energy targets. Replacing the paper mill's 60-year-old coal-fired plant with this new biomass-fired plant reduces CO2 emissions by 250,000 tonnes per annum. Also the amount of waste wood currently ending up at the landfill and there, over time, emitting methane is reduced since the main fuel for Valmet's CYMIC boiler is recovered waste wood.

The new biomass boiler provides the Tullis Russell paper mill with a more sustainable, efficient and reliable supply of steam and electricity.

"RWE is delighted to take the CYMIC boiler into operation as part of the largest portfolio of renewable energy technologies in the UK. The biomass boiler will help provide steam and electricity to the adjacent Tullis Russell paper mill and export electricity to the National Grid whilst significantly reducing CO2 emissions. The successful handover is the culmination of close cooperation and partnership between RWE and Valmet since 2010 and is testament to the dedication of the Valmet team," said RWE's project engineering manager Robert Dunk.

The CHP plant's installed capacity is 50MWe. It has the capability to supply up to 120 tonnes of industrial steam per hour for paper manufacturing. Out of the produced electricity the paper mill will consume approximately 17MW and approximately 25MW will be delivered to the grid.

The plant has been in commercial operation since February 2014 with full handover of plant in late 2014.

"This project was pretty massive both from the size and timescales involved. To put it into perspective, the CHP plant fills an area equivalent to the size of four football pitches and more than 1 million man hours have been invested in its construction. At the height of the construction process, there were around 650 people employed at the whole site with around half of them working at our boiler site", describes Valmet's Project Manager Peter Anson.

Technical information about the delivery

Valmet's CYMIC boiler, supplied to the Markinch CHP plant, utilizes proven circulating fluidized bed (CFB) technology. The boiler's capacity is 155 MWth and it is fuelled by approximately 90% recovered waste wood and approximately 10% virgin wood, sourced from sustainably managed forests. The biomass requirement is around 400,000 tonnes per annum. The new technology novelty in this boiler makes it possible to reduce the required shutdown time.

For further information, please contact:

Peter Anson, Manager, Project Management, Pulp & Energy business line, Valmet, tel. +358 10 672 0000

Read more at valmet.com: Valmet's technology helps to reduce CO2 emissions in UK

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Information about RWE Innogy UK

RWE Innogy UK is the UK subsidiary of RWE Innogy and one of the UK's leading renewable energy developers and operators. We are committed to developing and operating renewable energy projects to produce sustainable electricity. We operate 22 hydroelectric power schemes, 30 onshore wind farms and two offshore wind farms, including the UK's first major offshore wind farm, North Hoyle. Construction of RWE Innogy UK's Biomass Combined Heat and Power (CHP) plant in Fife, Scotland, is now complete and the plant has entered its operational testing phase, and construction of the 576 megawatt Gwynt y Môr Offshore Wind Farm, off the North Wales coast, is progressing well.

From development, to construction and operation, our staff in area offices across Wales, Scotland and England work in close partnership with local communities and companies. In 2013, renewable energy sites operated by RWE Innogy UK invested over £1 million into communities across the UK. The investments made by RWE in the UK are creating substantial new job opportunities, developing the supply chain and, very importantly, helping the UK Government achieve the EU target of supplying 30% of electricity from renewables, by 2020.

RWE Innogy pools the renewable energy expertise and generating plant of the RWE Group. RWE Innogy is fully committed to growth in renewable energy across Europe and the UK continues to play a significant role.

RWE Innogy UK is a sister company to RWE npower, a leading UK energy company with around 5.4 million customer accounts.

For further information about RWE Innogy UK and RWE Innogy visit www.rweinnogy.com/uk and www.rweinnogy.com

For further information about RWE npower visit www.rwenpower.com

ANDRITZ to supply another tissue machine to Hebei Yihoucheng, China

Following successful start-up of the TM1 tissue machine, international technology Group ANDRITZ has received a follow-up order from Hebei Yihoucheng Commodity, one of the leading producers of sanitary papers in China, to supply another PrimeLineCOMPACT II tissue machine with steel Yankee. Start-up is scheduled for the end of 2015.

The machine has a design speed of 1,600 m/min and a width of 2.85 m. The steel Yankee’s diameter amounts to 3.66 m. The scope of supply also includes the complete stock preparation plant, automation, and drives.

The machine and equipment will be manufactured at ANDRITZ’s sites in Europe and China. With this order, ANDRITZ PULP & PAPER is strengthening its position as one of the leading suppliers of tissue machines – including local services – in China.