Ianadmin

Old Town, Maine Pulp Mill Pays Fine for Clean Water Act Violations

Red Shield Acquisition LLC has agreed to pay a $126,000 fine to resolve claims that it violated the terms of wastewater and stormwater permits at its Old Town, Maine pulp mill, in violation of the Clean Water Act.

EPA alleged that Red Shield, which does business under the trade name Old Town Fuel & Fiber, discharged process wastewater and stormwater from the facility in violation of the terms and conditions of permits issued by the Maine Dept. of Environmental Protection. According to EPA, Red Shield failed to comply with the requirement under its wastewater permit to properly operate and maintain all components of the wastewater treatment system at the facility. EPA also alleged that Red Shield failed to adequately maintain control measures put in place to reduce pollutants in stormwater discharges from the facility and failed to properly prepare a Stormwater Pollution Prevention Plan for the site. Red Shield also violated the federal Oil Pollution Prevention Regulations by failing to fully maintain and implement its Spill Prevention, Control, and Countermeasure Plan.

The Clean Water Act prohibits the discharge of process wastewater in violation of the terms and conditions of a permit and requires that industrial facilities, such as pulp mills, have controls in place to minimize pollutants from being discharged with stormwater into nearby waterways. Each site must have a stormwater pollution prevention plan that sets guidelines and best management practices that the company will follow to prevent runoff from being contaminated by pollutants. Without on-site controls, runoff from pulp mills can flow directly to the nearest waterway and can have significant effects on water quality and the aquatic ecosystem, including effects on oxygen demand, interference with photosynthesis, and disruption to the aquatic food chain.

Every year, thousands of gallons of oil are spilled from oil storage facilities, polluting New England waters. Even the effects of smaller spills add up and damage aquatic life, as well as public and private property. Spill prevention plans are critical to prevent such spills or, if they do occur, adequately address them.

The company cooperated with EPA throughout its investigation, and since EPA’s Complaint was filed in August 2012, the company has completed some work and pledged to complete additional work to fix the problems identified at the facility.

Source: EPA United States Enviromental Protection Agency

Metso: Get inspired by tissue

Tissue paper can be attractive for many reasons depending on your needs and who you are. In an “emergency” situation you don’t even want to think about being without it. No way! An iPad may be good for many reasons or uses but it can never replace a roll of tissue paper.

But last week, attending the Tissue World exhibition in Barcelona, Spain I realized that tissue paper can be most valuable for other reasons.

I happened to meet there a guy who is collecting tissue hankies. In his collection, he has handkerchiefs from all over the world and from most companies, and some of the samples are really old. Last time he counted them there were more than 12.000 different packages of various brands. The collection is so amazing that the organizers of Tissue World sponsored his booth.

Creative use of tissue

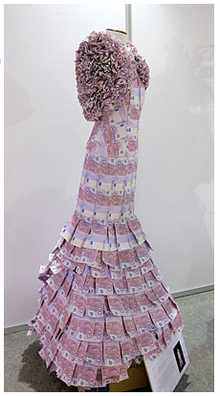

In the opposite part of the exhibition hall I found another exhibitor who has developed a new creative way of utilizing tissue.

In the booth they exposed the most fascinating and beautiful dresses; made of tissue paper. One more attractive than the other with embroideries and other fantastic decorations.

The most valuable I suppose was the one made of 500 Euro bills. Who wouldn’t want to own that? But on the other hand I hope they were fake 500 Euro bills or otherwise there will not be much left of the dress when the exhibition closes!

The most valuable I suppose was the one made of 500 Euro bills. Who wouldn’t want to own that? But on the other hand I hope they were fake 500 Euro bills or otherwise there will not be much left of the dress when the exhibition closes!

There might be one small disadvantage with these dresses though. You have to stay indoors.

Imagine what would happen if you went out wearing a dress made of tissue paper and it started to rain…

What is best in tissue?

However, most of the people were at Tissue World Barcelona exhibition to learn about new developments and the latest in tissue technology. They wanted to meet the supplier who can provide a machine that produces the best tissue paper with highest softness and bulk and of course to the lowest price!?

Most of the big machine suppliers were exhibiting in Barcelona (except the Italians who boycotted the event this year for various reasons). All tissue machine suppliers provided paper samples.

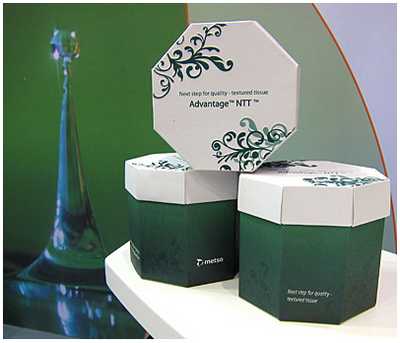

We are of course stating that our Advantage NTT paper is the best in the market and we are also offering paper rolls to potential customers. But one thing is for sure. Our competitors do not provide as attractive packages as we do. In fact they don’t have any packages at all.

Maybe Metso’s toilet paper gift box will be the next collector's item?

MD bill phases out paper mill energy source

MD senate passes bill phasing out credit for paper mill waste as Tier 1 alternative energy.

Maryland's senate has passed a bill that phases out paper mill waste as a preferred alternative energy source.

Supporters say paper mill waste now accounts for nearly half of the Tier 1 renewable energy credits being bought to meet state alternative energy requirements. And they say paper mills, most of which are outside of Maryland, were already using the waste as a power source before the alternative energy requirements were put into place. That means money being used to buy credits for power produced by the mills, is not going to develop solar and wind power.

A compromise in the bill protects the subsidies for a Maryland paper mill in Luke.

The bill passed Thursday now heads to the House of Delegates.

source: yahoo news

ERPC Launches Call for Candidates for European Paper Recycling Award 2013

Paper recycling initiatives are invited to apply for the fourth European Paper Recycling Award. NGOs, educational institutes, local authorities and industry have implemented many innovative projects to enhance paper recycling all over Europe but these initiatives are generally not well known. By promoting these initiatives and raising their profile with an award the European Recovered Paper Council (ERPC) recognises these efforts and hopes to inspire others to copy good practices. The award will identify projects, initiatives and campaigns that contribute to Europe‟s sustainability through activities supporting paper recycling.

Paper recycling initiatives are invited to apply for the fourth European Paper Recycling Award. NGOs, educational institutes, local authorities and industry have implemented many innovative projects to enhance paper recycling all over Europe but these initiatives are generally not well known. By promoting these initiatives and raising their profile with an award the European Recovered Paper Council (ERPC) recognises these efforts and hopes to inspire others to copy good practices. The award will identify projects, initiatives and campaigns that contribute to Europe‟s sustainability through activities supporting paper recycling.

“Recycling is the key to achieving sustainability in production and consumption in Europe. Paper recycling, in particular, contributes significantly to green growth, combating climate change and improving resource efficiency. This makes a valuable contribution to the environment”, explains Beatrice Klose, Chairperson of the ERPC.

Eligible projects, initiatives or campaigns will be evaluated based on the following criteria:

• Relevance and originality

• Achievements

• Possibility to reproduce the project

• Cost effectiveness

There are two award categories:

• Information & Education

• Technology improvement & R&D

The initiatives may be ongoing or completed, but they must already have started; however, not before January 2009. All entries must be submitted by Friday 28 June 2013 before midday Brussels time. To apply please go to www.paperforrecycling.eu Should you need some inspiration, the website also contains information from past awards.

An independent jury from across Europe will judge the entries in each category. The jury includes representatives from the European institutions as well as civic organisations and NGOs. European wide recognition of the winning candidate‟s efforts will be accompanied by an original piece of paper artwork, which will be officially handed over to the winners in an award ceremony at the European Parliament in Brussels.

Olea – the hydrophobic fibre: reliable quality on a larger scale

We have already introduced you to Olea, the first viscose fibre with intrinsic water repellent properties. Now, Olea has taken the next step towards a commercial launch: during the first production trial, we have confirmed that the fibre can be manufactured at a reliable quality level on a larger scale. The fibre process, including its stability and consistency, ran well within the anticipated parameters.

After this first successful production trial, there are more tests planned which will prove Olea’s processing properties. First results have already shown that Olea fibre can be processed in the same way as our standard viscose fibres.

During the next weeks we will be showing the first samples of nonwoven fabrics made using Olea fibre to our customers. At the same time we will continue to optimise the fibre for its respective end applications in nonwovens, textile, paper and short cut products.

UPM signs contract with Aliplast for release liner recovery in France

UPM has announced cooperation for release liner recovery with the French subsidiary of Aliplast, an Italian company specializing in the collection and treatment of recovered plastic films. This partnership expands Aliplast’s recycling services to polypropylene (PP) and paper-based release liners through UPM Raflatac’s RafCycle® waste management concept. Aliplast now collects, sorts and distributes all types of release liner to different recycling processes, avoiding landfill or incineration.

Large collection bags are installed by Aliplast for use by self-adhesive label end-users like drinks bottlers and companies from the food, cosmetics and pharmaceutical industries. Aliplast collects the bags regularly and directs them to its two sorting centres near Strasbourg and Lyon. After sorting, the waste is transported to its final place of re-use.

Polypropylene liners, including UPM Raflatac’s ProLiner PP30, are re-used as raw material in the manufacture of wood-plastic composite products at the UPM ProFi® factory in Bruchsal, Germany. Other wrapping films are recycled into various packaging products by Aliplast Italy.

Aliplast also collects paper-based release liners for fibre re-use. The recovered paper liners are re-pulped and de-siliconized, and the pulp is used for papermaking at UPM’s paper mills.

Through the partnership with Aliplast, UPM Raflatac has extended the reach of its RafCycle concept to even more label end-users. This unique service provides a sustainable solution for recycling paper and film release liners, reducing the environmental impact and bringing down waste management costs. By giving release liner a second life, UPM is making yet another advance in the sustainable management of the labelstock lifecycle.

Mondi Syktyvkar launches new packing design for leading office paper “Snegurochka”

The company will promote the new design with a Russia-wide campaign from March to May 2013 to introduce the new packaging to end users, dealers and distributors at all levels.

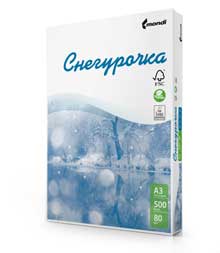

Russia’s office paper market will soon see a new look to a familiar brand. Mondi Syktyvkar has launched a new packaging design for its popular domestic brand Snegurochka.

Snegurochka is Russia’s leading office paper brand recognised for its high whiteness level, smooth surface, good opacity for double sided printing and excellent printer runnability. It is also the first Russian-produced FSC® certified paper.

Snegurochka is Russia’s leading office paper brand recognised for its high whiteness level, smooth surface, good opacity for double sided printing and excellent printer runnability. It is also the first Russian-produced FSC® certified paper.

“Snegurochka’s new packing design reflects the paper’s high-quality profile and strong position in the Russian market. It’s an up-to-date design that clearly displays Snegurochka’s environmental labels, grammage, format and key details that our customers look for,” said Alexey Shamin, Head of Sales for Russia & CIS, Mondi Uncoated Fine Paper.

The Snegurochka brand was first developed at Mondi Syktyvkar in 1999. The new packaging preserves the brand’s well-known packaging features, such as the recognizable color scheme and Cyrillic brand name, though it is now written in a more contemporary style. The paper’s technical characteristics will also remain in CIS languages. Among the changes to the packaging design, the brand’s environmental profile will feature more prominently.

In addition to being FSC® certified and part of Mondi’s Green Range, Snegurochka was awarded the EU Ecolabel in 2012. Products and services bearing the EU Ecolabel are certified as having a lower impact on the environment than other products in the same product group. It is a means by which customers choose products deemed environmentally conscious based on core environmental parameters.

Moreover, Snegurochka received a rating of “good” on the WWF Check Your Paper environmental benchmarking tool -- a voluntary initiative which encourages transparency regarding environmental performance in the paper industry and identifies sustainably produced papers on a global scale.

All Mondi branded paper are part of the Green Range and are FSC® or PECF certified, totally chlorine free bleached (TCF) or 100% recycled. More information about Snegurochka and Mondi Syktyvkar is available at www.mondigroup.com/syktyvkar

Northern Pulp ordered to fix pollution problem again

For the second time in a year, Nova Scotia's Northern Pulp has been ordered to stop a high amount of air pollution being emitted from the paper mill, Inspectors said sulphur emissions have exceeded allowable levels.

Over the fall and winter, Northern Pulp tested emissions coming from its plant. The findings were recently passed on to the Nova Scotia Department of Environment. “Their levels for particulate and total reduced sulphur were in excess of the limits specified in their approval,” said regional director Jay Brenton.

On March 8, the department ordered the company to fix the air pollution. “The directive requires the company to take an engineering study of their recovery boiler system and to choose an option to address the exceedances,” said Brenton.

In April 2011, the department ordered the mill to install air pollution equipment, six years after a scrubber ceased to function. All of this comes after the federal government gave the mill $28 million to improve its environmental performance.

The company claims its reduced odour compounds by 70 per cent. Jane Thomson, a vocal critic, doesn’t buy it “Local residents were being bombarded constantly by this incredible stench,” she said.

The province said company consultants will begin work on April 1. It has until the end of September to comply with the directive.

source: cbcnews

Analysis of the Pulp and Paper Chemicals Market in Brazil

Awareness Regarding Environmental Impact and Product Final Quality is Expect to Drive the Market

The research service focuses on the Brazilian pulp and paper chemicals market, including main products regarding pulping, bleaching, finishing, and coating processing. The analyzed pulp and paper chemicals have been an important presence in the market for years. Even though they present as a mature stage in the market, the total pulp and paper chemicals market is also expected to offer positive results through the forecast. Regarding the total vertical market analysis, finishing and coatings chemicals presented highest CAGR for the period. The study covers data since 2009 and forecasts to 2017. The main market competitors in Brazil are Carbocloro, Eka Chemicals, Corn, Peroxidos do Brazil, Cargill, and Evonik-Degussa.

Key Questions This Study Will Answer

• Is the market growing, how long will it continue to grow, and at what rate?• Are the existing competitors structured correctly to meet customer needs?• Is this an industry or a market? Will these companies/products/services continue to exist or will they get acquired by other companies? Will the products/services become features in other markets?• Are the products/services offered today meeting customer needs, or is there additional development needed?

Executive Summary

• Brazil has about X paper mills and about X pulp mills across eighteen states, with Sao Paulo,Santa Catarina, and Paraná accounting for X% of paper mills.• The analyzed pulp and paper chemicals have been an important presence in the market for years. Even though they present as a mature stage in the market, with the country presenting remarkable economic results and growth of the end-user sector, the total pulp and paper chemicals market is also expected to offer positive results trough the forecast period.• From 2012 to 2017, the total pulp and paper chemicals market is expected to increase by X% in revenue.• Regarding the total vertical market analysis, finishing and coatings chemicals presented the highest compound annual growth rate (CAGR) for the period of 2012 to 2017, accounting for X% of the market. By the end of the forecast period, the market revenue is expected to increase by X%.• The main market competitors in Brazil are Carbocloro, Eka Chemicals, Corn, Peroxidos do Brazil, Cargill, and Evonik-Degussa.

Definitions

Compound Annual Growth Rate

• The CAGR is the general projected growth rate of the industry from the base year to the end of the forecast period.

Pulping Process

• The chemical pulping process removes the degraded lignin, hemicellulose and other chemicals contained in the pulping solution. The solution, known as black liquor, is further processed to obtain valuable chemicals that are utilized in industrial applications.

• The by-products have been classified into lignin (lignosulfonates and lignin sulfates), tall oil, and black liquor gasification products. Lignin are widely applied in agriculture for plant and animal nutrition and the high-purity lignin are used in food and cosmetic applications.

• Lignin are also used in concrete as dispersants and lignosulphonates are used as retarding agents.

Bleaching Process

• The bleaching process is used to brighten paper, decreasing the color of the pulp.• The process is often called as delignification. In the bleaching process, where as the largest amount of lignin was removed in the pulping process, the color removal only reach the remaining lignin and its derivatives. The market had been used chorine, but as for environmental impacts, end- users have been trading it for hydrogen peroxide, chlorine dioxide, oxygen, and ozone.

Coating and Finishing Process

• Paper coating is done primarily to improve the printability, optical properties and strength of paper. Printing and writing papers are the two major sectors that require the highest volumes of coating chemicals.

• Paper coating additives are used in the paper production process in order to adapt the paper surface to various environmental conditions. The main coating and finishing chemical used in the market is starch.

• Tall oil fatty acids are applied as binders in paints and coatings, polytrophic industry, and floatation reagents.

• The main pulping chemicals used in the market are sodium hydroxide and sodium sulfate.

Research Scope • This research service focuses on the Brazilian Pulp and paper chemicals market.

• Pulp and paper chemicals market segmentation is highlighted below.

Total Pulp and Paper Chemicals Market: Product Scope, Brazil, 2012 Pulping Chemicals

• Sodium Hydroxide

• Sodium Sulfate

Bleaching Chemicals

• Chlorine Dioxide• Hydrogen Peroxide

Finishing and Coating Chemicals

• Starch

Table Of Contents

1. Executive Summary

2. Market Overview

3. Total Pulp and Paper Chemicals Market

• External Challenges: Drivers and Restraints

• Forecasts and Trends

• Market Share and Competitive Analysis

• Mega Trends and Industry Convergence Implications

4. The Last Word (Conclusions and Implications)

5. Appendix

To order this report:Paper Industry: Analysis of the Pulp and Paper Chemicals Market in Brazil

Source: Frost & Sullivan

Canfor Pulp Announces Normal Course Issuer Bid

Canfor Pulp Products Inc. (TSX:CFX) has announced that it has received regulatory approval for a normal course issuer bid to purchase for cancellation up to 3,563,489 Common Shares or approximately 5% of the 71,269,790 Shares outstanding on February 25, 2013, at prevailing market prices in accordance with the rules of The Toronto Stock Exchange. The normal course issuer bid will commence on March 5, 2013 and continue until March 4, 2014, unless completed or terminated earlier. Canfor Pulp believes the normal course issuer bid is in the best interests of the company. Purchases of Common Shares made under the bid will be effected through the facilities of the TSX, alternative trading systems, or as otherwise previously approved by the TSX.

Canfor Pulp's parent company, Canfor Corporation, has today also announced its initiation of a normal course issuer bid for the purchase of up to 5% of its issued share capital, through the facilities and in accordance with the Rules of The Toronto Stock Exchange.

Purchases will be made at the discretion of the Company at prevailing market prices, through the facilities of the TSX, in compliance with regulatory requirements. Daily purchases will be restricted to not more than 21,188 shares, representing 25% of the average daily trading volume of the Company's shares on the TSX, subject to certain prescribed exemptions. There can be no assurance as to the precise number of shares that will be repurchased under the share repurchase program. The Company may discontinue its purchases at any time, subject to compliance with applicable regulatory requirements. The Company intends to hold all shares acquired under the issuer bid for cancellation. The Company has not purchased any of its common shares in the last 12 months.