Ianadmin

PMT Italia to startup its latest ÆGO™FLX SHOE at Longview Fibre Paper and Packaging

PMT Italia S.p.A. announces the successful startup of its latest ÆGO™FLX SHOE at Longview Fibre Paper and Packaging, Inc. in Longview, Washington (USA).

PMT Italia S.p.A. announces the successful startup of its latest ÆGO™FLX SHOE at Longview Fibre Paper and Packaging, Inc. in Longview, Washington (USA).

PMT recently rebuilt the PM11 press section of Longview Fibre Paper and Packaging, Inc. in Longview, Washington. The press section was upgraded to improve the Sack Kraft paper quality and production. The results of the upgrade are meeting expectations.

The scope of the rebuild included a new ÆGO™FLX SHOE module mated to a ceramic coated ÆGO™FLX ROLL with a new double doctor. The equipment was successfully delivered, installed and started up under a tight schedule due to the cooperative efforts of the Longview and PMT project teams.

PMT is a global paper machinery producer, able to provide suppliers of every kind of paper with advanced equipment from headbox through winders, including integrated projects with basic or detailed engineering of associated auxiliary plant.

Serla launched cooperation with Tukikummit Foundation

Serla’s good deed for 2013 is donating 100,000 euros to prevent the social exclusion of underprivileged kids.

Serla’s good deed for 2013 is donating 100,000 euros to prevent the social exclusion of underprivileged kids.

Serla is participating in the charity campaign Nuorten hyväksi’ (Let’s Help Young People) organised in Finland by the Tukikummit Foundation. The aim of the campaign, which has President of the Republic, Sauli Niinistö, as its patron, is to encourage people to make donations that will be used to improve and promote debate on the wellbeing of young people.

“Serla wants to encourage everyone to do good deeds locally, both great and small. In 2011–2012 we donated 50,000 euros for various community projects as part of our Local Good campaign. Our good deed for 2013 is our new cooperation with the Tukikummit Foundation,” says CEO Mika Joukio from Metsä Tissue.

Through the Tukikummit Foundation Serla will provide financial support to underprivileged children and teens living in Finland. The funds will go in full towards improving their prospects and circumstances. The church welfare fund will handle the practical coordination of these efforts, but the donated funds will not support church institutions.

“We feel that everyone deserves a wonderful everyday life, so we want to help and encourage people to make their lives with their families as rewarding as possible. A happy childhood consists of simple things: hobbies, friends, stress-free school and the support of responsible adults. Serla wants to be part of building a better future for our kids,” says Brand Director Moona Pohjola. “We believe that responsible daily acts are the path to a better everyday life.”

Serla’s donations will be granted to cover expenses for which no other funding is available, such as the immediate cost of schooling, training, recreation or travel to visit a parent or grandparent. Priority status will be given to children and teens in single-parent families. Individual donations will range between 200 and 2,000 euros.

In addition to providing monetary support, Serla will also support the Tukikummit Foundation by presenting its work through channels such as the Serla Squirrel’s Facebook page and Serla marketing material, packaging and retail displays.

ANDRITZ to supply eco-friendly biomass boiler plant to Fortum Värme, Sweden

International technology Group ANDRITZ has received an order from Fortum Värme to supply a circulating fluidized bed boiler for the new Värtaverket combined heat and power plant in Stockholm, Sweden. The biomass boiler plant will be one of the largest of its kind worldwide. Start-up is scheduled for the third quarter of 2015.

International technology Group ANDRITZ has received an order from Fortum Värme to supply a circulating fluidized bed boiler for the new Värtaverket combined heat and power plant in Stockholm, Sweden. The biomass boiler plant will be one of the largest of its kind worldwide. Start-up is scheduled for the third quarter of 2015.

The order includes the supply of a PowerFluid fluidized bed boiler with useful heat output of 330 MW, a flue gas cleaning plant, as well as the electrical and control systems. With the new plant from ANDRITZ Energy & Environment, which will cover the rising demand for district heating in Stockholm, fossil-based fuels like coal and oil can be replaced largely with eco-friendly biomass. When the biomass boiler plant is started up, the proportion of renewable fuels used at the Värtaverket power station will increase from 45% to 70%.

The heating generated in the new Värtaverket combined heat and power plant will be equivalent to the demand from a total of 190,000 households. Current investments by Fortum Värme make a substantial contribution towards placing Stockholm among the leading capital cities worldwide in terms of air quality. Fortum Värme’s goal is to supply Stockholm entirely with climate-neutral heat by 2030.

Hugo D’Amours Appointed Vice-President, Communications and Public Affairs at Cascades

Cascades, a leader in recovery and the production of green packaging and tissue products, is pleased to announce the appointment of Hugo D'Amours to the position of Vice-President, Communications and Public Affairs.

Cascades, a leader in recovery and the production of green packaging and tissue products, is pleased to announce the appointment of Hugo D'Amours to the position of Vice-President, Communications and Public Affairs.Until last fall, Mr. D'Amours was Director of Media Relations for Quebec Premier Jean Charest. He holds a Bachelor of Arts and a Masters of Public Administration. Over the past 15 years he has developed solid expertise in communications and public relations, and he has earned an excellent reputation. His skills will be a valuable resource and an undeniable asset to the company's management

"Hugo seemed to be the ideal person to join us as we undergo significant changes, and to continue to promote the innovative and sustainable nature of the company," said Mr. Alain Lemaire, President and Chief Executive Officer of Cascades.

Mr. Lemaire also thanked his predecessor, Mr. Hubert Bolduc, for eight years of dedicated service. He wishes to take this opportunity to wish Mr. Bolduc the best of luck in his new career.

Södra celebrates 75 years in 2013

In 2013, Södra will have its 75th anniversary. Södra's anniversary will be celebrated and marked in several ways.

In 2013, Södra will have its 75th anniversary. Södra's anniversary will be celebrated and marked in several ways.The theme of the 75th anniversary celebration is the past, the present and the future, where the focus is on Södra's stability, sustainability and development. It is thanks to the development and innovations that we have achieved that have made Södra what it is today and it is with continued investment and sustainable pursuits that we will face the future.

Södra's 51,000 members, who work hard running their family-owned forestry enterprises, are the backbone of the company. Together they manage a legacy, a raw material, as well as biological diversity, but also continue the hard work started by previous generations to restore forests in southern Sweden.

During the 75 years that Södra has existed, it has been our fundamental goal to support family owned and operated forestry enterprises by creating opportunities for the sale of our member's forest products, but also to develop products and services that will help increase their productivity and profitability. Södra will continue the work to ensure future profitability, sustainable production and encompassing support to help in the work done by family-owned forestry enterprises.

A large, public 75th anniversary celebration, will be held during the international forestry fair Elmia Wood on 5-8 June 2013. The anniversary will also be noted in articles in the membership magazine Södrakontakt, at Södra's annual meeting and at board meetings.

BillerudKorsnäs Info on non-recurring items and preliminary results for 4th qtr 2012

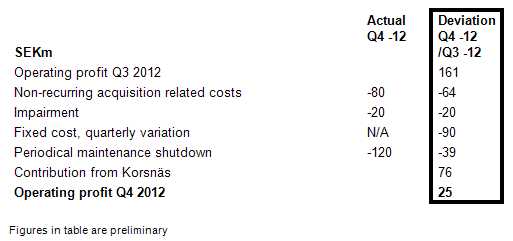

Q4 2012 will be the first quarterly report for BillerudKorsnäs. Korsnäs is consolidated into the group with effect from closing November 29 2012. Q4 2012 is charged with approximately SEK 220 million in non-recurring acquisition related costs, goodwill impairment and periodical maintenance shutdown costs. BillerudKorsnäs’ operating profit for Q4 2012 is estimated at approximately SEK 25 million. Excluding additional costs and Korsnäs contribution, the Q4 2012 operating profit is in line with the operating profit in Q3 2012.

Q4 2012 will be the first quarterly report for BillerudKorsnäs. Korsnäs is consolidated into the group with effect from closing November 29 2012. Q4 2012 is charged with approximately SEK 220 million in non-recurring acquisition related costs, goodwill impairment and periodical maintenance shutdown costs. BillerudKorsnäs’ operating profit for Q4 2012 is estimated at approximately SEK 25 million. Excluding additional costs and Korsnäs contribution, the Q4 2012 operating profit is in line with the operating profit in Q3 2012.

CEO Per Lindberg comments Q4 2012 results:

“Quarter four was exceptionally eventful, and we concluded the historical combination between Billerud and Korsnäs. In the light of the changes in the group structure, we feel we should clarify to the market the implications on our financial performance. Even if the quarter has been charged with several additional costs, the underlying operating performance of the group remains stable. And above all, we continue to view the future prospects for BillerudKorsnäs as very positive.”

BillerudKorsnäs operating profit in Q4 2012 is affected by several additional cost items that result in deviations from Q3 2012, as shown below. Additional costs were approximately SEK 213 million higher than in Q3 2012.

In addition to previously stated SEK 45 million in acquisition related costs in Q4 2012, additional non-recurring costs of around SEK 36 million has been added, arising from reduction of surplus value in the acquired finished goods inventory relating to the sold part after the acquisition. Thus, in Q4 2012 non-recurring acquisition related costs total approximately SEK 80 million.

The operating profit for Q4 2012 is also charged with a goodwill impairment of approximately SEK 20 million due to the divestment of Tenova Bioplastics’ operations.

Compared to Q3 2012, fixed costs excluding the cost of periodical maintenance shutdowns are estimated to be approximately SEK 90 million higher in Q4 2012, due to normal quarterly variations. Costs attributable to periodical maintenance shutdowns in Q4 2012 total approximately SEK 120 million, in line with what has been previously communicated.

BillerudKorsnäs’ operating profit for Q4 2012 is estimated at approximately SEK 25 million. Adjusted to reflect non-recurring costs of approximately SEK 100 million, the operating profit is estimated at approximately SEK 125 million. Excluding the above-mentioned additional costs, and adjusted for Korsnäs’ contribution during Q4 2012, the operating profit is in line with the operating profit in Q3 2012. The operating profit is still provisional and has not been reviewed by the company’s auditor.

BillerudKorsnäs will publish its complete year-end report for 2012 on 8 February 2013.

The following files are available for download: PDF

Rottneros: Year-end Report January to December 2012

1. Income after net financial items amounted to SEK 6 (-120) million for the full year 2012. The result for the previous year included total write-down and one-off costs of SEK -148 million.

2. Income after net financial items amounted to SEK 0 million for the fourth quarter of 2012 compared with a loss of SEK -44 million for the same quarter of the previous year. Cash flow from operating activities amounted to SEK 8 ( 22) million for the fourth quarter of 2012 and SEK 41 (35) million for the full year 2012.

3. The Board proposes a dividend of SEK 0.10 (0.10) per share for the financial year 2012.

4. Arctic Paper S.A. made a public takeover bid for all of the Rottneros shares in November; this offer has been extended to 4 February 2013 owing to poor support. Arctic Paper’s shareholding amounted to 39.4% of the total number of shares at the turn of the year.

5. A decision was made to continue production of groundwood pulp at Rottneros Mill.

CEO’s statement

The operating surplus (referred to internationally as ‘EBITDA’) amounted to SEK 61 million for the full year 2012. The corresponding figure for the previous year was SEK 97 million. The result after net financial items (EBT) was once more in the black at ‘zero’ for the fourth quarter of the year and SEK 6 million for the full year. This is not a great result, although we are pleased to have been able to produce a profit in a year that was tough for many pulp manufacturers. Those of us based in Sweden not only had to struggle with an increasingly weak global economy but were also subject to a very strong Swedish currency during the autumn.

The operating surplus (referred to internationally as ‘EBITDA’) amounted to SEK 61 million for the full year 2012. The corresponding figure for the previous year was SEK 97 million. The result after net financial items (EBT) was once more in the black at ‘zero’ for the fourth quarter of the year and SEK 6 million for the full year. This is not a great result, although we are pleased to have been able to produce a profit in a year that was tough for many pulp manufacturers. Those of us based in Sweden not only had to struggle with an increasingly weak global economy but were also subject to a very strong Swedish currency during the autumn.

Despite things not running smoothly throughout the world, the consumption of pulp rose by approximately three per cent, slightly more for softwood and slightly less for hardwood. The demand outlook for 2013 appears as though it will remain more or less the same. Prices, which increased during the first half of 2012, peaked at just over USD 850 per tonne to fall by around USD 100 per tonne during the summer and autumn and subsequently rise again to just over USD 800 per tonne by the end of the year. Global stocks fell during the autumn, particularly for softwood pulp, so that we are entering 2013 with some positive market momentum. Total global manufacturing capacity for softwood pulp will fall rather than rise in 2013 as several pulp mills are being built or converted for other grades. Together with the increase in demand, capacity utilisation is likely to increase, and price trends should therefore continue to rise.

Focusing specifically on Rottneros, we have during the year, successfully continued our move towards more sales within customer segments having specific requirements, where our raw materials and process equipment can prove their worth. This will reduce our exposure to the constrained and less specialised printing paper market. This applies to both mechanical and chemical pulp and is a development that we will continue in 2013. Our sales for different filter applications continue to increase slowly but surely. Deliveries to board manufacturers with an express requirement for bulk are steadily growing. The market for our customers within electrical applications has been tough, with a temporary reduction in infrastructure investments and consequently lower deliveries, which meant that our sales fell despite retaining market shares. On the cost side, both our variable and fixed costs have fallen. It was primarily the cost of timber that fell during the autumn, and then remained stable during the winter. All-in-all, comparing 2011 with 2012, variable costs per tonne reduced by almost ten per cent. The corresponding figure for fixed costs per tonne for Rottneros Mill is over ten per cent despite falling production, and slightly less than ten per cent for Vallvik Mill thanks to our annual production record of almost 209,000 tonne, of which we are proud. Rottneros Mill produced a small positive operating surplus for 2012 despite the ongoing programme of staff cuts. The cash flow after investments amounted to SEK 17 million. Vallvik Mill’s operating surplus is SEK 55 million and has exceeded SEK 350 million for the past three years. This surplus is being reinvested in the mill. We do not intend to provide this kind of mill-specific result on an ongoing basis, but consider it was justified to do so on this occasion as in the course of last year certain information appeared in the media that conveyed erroneous perceptions.

Arctic Paper SA announced in early November 2012 an offer to all of the Rottneros shareholders to exchange their shares in Rottneros AB for shares in Arctic Paper. The intention was to subsequently merge the companies. A large number of shareholders declined the offer, for which reason a merger of the companies did not take place. A merger of the companies – with one management team and one income statement/balance sheet – could have realised substantial synergies. Rottneros is now continuing as an independent company, though with a different shareholder structure, where the shareholding within the sphere of influence of the main owner company increased from 20% to 40% while virtually all of the bank shareholdings have been relinquished. As we are two independent companies, only transactions for the benefit of both parties and all shareholders will be concluded, that is to say as is the situation is at present and as it has been for many years. We will continue t o develop our ongoing business and further improve our supplier and customer relationships. Our doors are open to the discussion promised by Arctic Paper SA in respect of synergies, even without a merger. Any way of improving Rottneros is welcome.

In conclusion, I would like to express my appreciation for the significant shareholder support expressed both by telephone calls and by email in recent months.

(For full report, Download here)

Metso's first OptiConcept M boardmaking line performs record-fast and efficient start-up at Liansheng Paper Industry in China

On December 12, 2012, Liansheng Paper Industry (Longhai) Co., Ltd. started up their new Metso-supplied containerboard production line, PM 6, at their Longhai site in Fujian Province in China. This is the first start-up of Metso’s novel OptiConcept M production line that represents a new way to design, build and operate a paper machine.

The PM 6 start-up was successful with record-breaking results. “The whole start-up was perfect. It took less than 3 hours in total from having stock on the machine to get the web on the reel, and we had a very good start-up speed of 800 min/min. No paper tails were seen on the hall floor during the start-up period,” Xue Rong Jun, Project Manager of Fujian Liansheng, proudly says.

The new 7.25-m-wide PM 6 production line has an annual production capacity of approximately 300,000 tonnes of recycled fluting in the basis weight range of 65 to 100 g/m2. The design speed is 1,200 m/min.

Metso’s delivery included a complete OptiConcept M boardmaking line from headbox to reel with air systems, a machine control system, a quality control system, two winders and Metso clothing.

The PM 6 OptiConcept M production line is designed for high productivity with low operating costs. Industrial design and new engineering innovations provide for simple assembly of the production line. “The installation required 30 to 40% less working hours compared with a conventional project,” comments Xue Rong Jun.

Also usability and safety aspects are at a new level. For instance, the design allows for easy, fast and safe changing of wear parts, which reduces the duration and costs of maintenance shutdowns. “The design of walkways is very ergonomic, spacious. Walkways are on one level, no running up and down stairs, so the machine is very safe and convenient to operate and maintain. Since there are no cantilevering beams at the wet end, the drive side and tending side are symmetric, and the machine drive side is very spacious compared to a traditional machine construction,” says Xue Rong Jun.

Liansheng Paper Industry (Longhai) Co., Ltd. is a subsidiary of Fujian Liansheng Paper Co., Ltd. The company was founded in 1999 and is based in Zhangzhou, China. PM 6 is the third Metso-supplied production line for Fujian Liansheng.

Lenzing Fibers Sold in Ja! Natürlich Products

Innovation with Lenzing fibers: vegetable nets of 100% natural origin for Ja! Natürlich – the organic brand of REWE International AG

Innovation with Lenzing fibers: vegetable nets of 100% natural origin for Ja! Natürlich – the organic brand of REWE International AG

Recently Lenzing fibers made of the renewable raw material wood also began to be used in the retail food sector. The organic food supplier Ja! Natürlich took a further step to avoid plastics within the context of its Green Packaging Initiative launched in the year 2011. Accordingly, onions, potatoes and beetroots are now being packaged in 100% biodegradable nets.

An regional solution

100% Lenzing Modal® Color is used for the production of the nets, which was developed in a joint project involving the Packaging Center Graz, Lenzing AG and Borckenstein, a long-standing partner company of Lenzing AG. These nets keep the vegetables fresh even longer thanks to their moisture- regulating and breathable properties. In addition, they can be conveniently disposed of in the home compost because the nets are biodegradable. The fine nets which are soft to the touch also protect the contents more effectively than the previously used plastic nets.

“The time is ripe for ecological innovations such as this one. For Lenzing this project means entering a completely new market, from which we expect a lot in the future”, says Friedrich Weninger, COO of Lenzing AG with responsibility for research and development.

“Lenzing and Borckenstein have been trusted partners for decades, cooperating at a high technical level”, Manfred Kern, Managing Director of Borckenstein adds. “This was a decisive reason for the incredible speed with which this idea could be implemented”.

Lenzing Modal® Color is produced from European beech wood and is thus 100% natural. More than one-third of the wood is derived from Austrian forests. Pulp and fiber production are carried out in line with the principle of sustainability. Lenzing manufactures the pulp it uses itself, and thus exerts control over the entire production process, which is considered to be a worldwide best practice. This is unique in the global fiber industry.

“We are proud that Lenzing fibers can make such an important contribution to a better life”, comments Peter Untersperger, Chief Executive Officer of the Lenzing Group. “Lenzing fibers have become a small but often indispensable part of our modern industrial society. We are doing everything we can to produce these consumer goods with the least possible environmental impact. This Austrian innovation in the field of food packaging is clearly a step in the right direction”, Peter Untersperger adds.

“I am very happy that we have taken a further step forward in green packaging. In the light of the fact that plastics have dominated the field of packaging materials over the last 40 years, we are now offering a sustainable alternative based on the use of natural materials”, says Martina Hörmer, Managing Director of Ja! Natürlich.

Simon Utsel awarded 2013 Alf de Ruvo scholarship

The 2013 Alf de Ruvo scholarship, worth SEK 500,000, has been awarded to Dr. Simon Utsel for his pioneering work on surface modification of cellulose-based materials.

The 2013 Alf de Ruvo scholarship, worth SEK 500,000, has been awarded to Dr. Simon Utsel for his pioneering work on surface modification of cellulose-based materials.

By modifying the surface properties of, or by adding new properties to, cellulose-based materials, these can be utilized more effectively in various products.

The research has provided a foundation for the future development of cellulose-based materials and fiber-reinforced composite materials and shows, for example, several methods to improve interfacial adhesion between cellulose fibers and matrix materials in composites.

In February, Simon Utsel will commence a six-month postdoctoral fellowship at Stanford University, California, in the US, where he will be a member of Professor Yu Cui’s group and perform research on new opportunities for the use of cellulose-based materials in electronic components, such as batteries, capacitors, touch screens and solar cells. The aim is to tailor the structure of the materials at a nanometer level to optimize the macroscopic properties of components.

Dr. Utsel hopes to be able to contribute his knowledge predominantly in the field of cellulose, but also his polymer, surface and colloid expertise.

Simon Utsel was born in Jönköping, Sweden, in 1984 and holds a Ph.D in Pulp and Paper Chemistry and Technology from the Department of Fibre and Polymer Technology, KTH Royal Institute of Technology, in Stockholm, Sweden. His Ph.D was supervised by Professor Lars Wågberg.

The scholarship was awarded on January 22, 2013 at a ceremony in Stockholm in conjunction with the Swedish Pulp and Paper Industry’s Ekman Days.