Ian Melin-Jones

Michael Rohde Pedersen appointed CEO of Brødrene Hartmann A/S

Brødrene Hartmann A/S has appointed Michael Rohde Pedersen as Chief Executive Officer (CEO) and member of the Group's Executive Board. Michael Rohde Pedersen will join Hartmann on 15 September 2010.

Michael Rohde Pedersen is 53 years old and comes from a position as General Manager of Georgia-Pacific, a US company with activities within building products and paper, where he was responsible for the Northern and Eastern European regions. Prior to his employment with Georgia-Pacific, Michael Rohde Pedersen held the position of General Manager of the Swedish paper group SCA Hygiene Products' Polish operations. Earlier in his career, Michael Rohde Pedersen has held positions with IBM Denmark and A.P. Moller, among other companies.

Michael Rohde Pedersen has worked in the paper industry for the past 13 years, and over the years he has gained extensive management experience in all aspects of the operations of international businesses engaged in the processing industry, including product and process optimisation and commercial relations.

Michael Rohde Pedersen holds a BA in International Marketing Management from Copenhagen Business School and an MBA from SDA Bocconi in Milan.

"We are confident that Michael Rohde Pedersen will be able to continue the positive development Hartmann has experienced in recent years. Michael Rohde Pedersen has extensive management experience and a strong international profile that will further consolidate Hartmann's international competitive position in the years ahead. We look forward to working with Michael Rohde Pedersen, and we are certain that he will deliver strong results for Hartmann, just as he has done in his previous jobs," said Agnete Raaschou-Nielsen, Chairman of the Board of Directors.

Michael Rohde Pedersen is taking over from Peter Arndrup Poulsen, who informed the company in May 2010 of his decision to resign and take up a position as CEO of Tvilum-Scanbirk (company announcement no. 10/2010 of 27 May 2010). Peter Arndrup Poulsen will leave Hartmann in mid-September 2010.

Please direct any questions to Agnete Raaschou-Nielsen, Chairman of the Board of Directors, on tel. +45 24 29 14 63.

Brødrene Hartmann A/S

Agnete Raaschou-Nielsen

Chairman

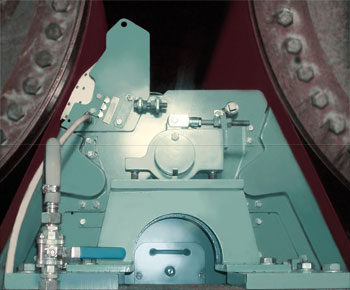

EV EasyOne optimizes the first single felted drying groups

Does your web run easily at the beginning of your drying section, at the first single felted groups?

Do you have sheet flutter and paper defects?

Does tail threading take too much time?

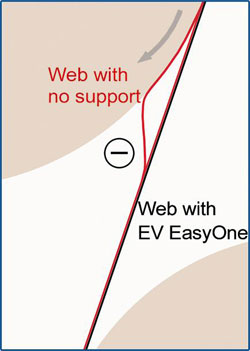

Especially in high-speed paper machines, the first single felted drying groups are very sensitive to run. Without support on web release between upper cylinder and vacuum roll the wet web tends to follow the upper cylinder, resulting in breaks and paper defects.

Especially in high-speed paper machines, the first single felted drying groups are very sensitive to run. Without support on web release between upper cylinder and vacuum roll the wet web tends to follow the upper cylinder, resulting in breaks and paper defects.

EV EasyOne™ optimizes the web release between upper cylinder and vacuum roll. It eliminates runnability problems that are caused when the sensitive wet web tends to follow the upper cylinder surface.

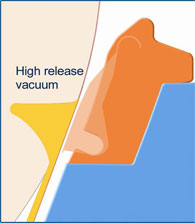

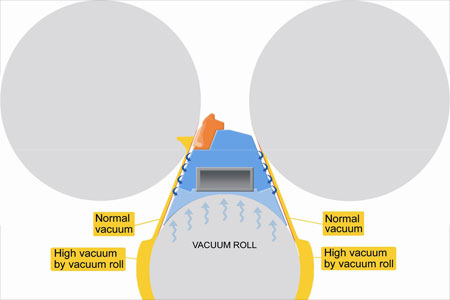

Traditionally, draw difference between press and drying section has been a tool to control runnability but this often causes problems in paper quality. With the EV EasyOne it is possible to improve the web release effectively with a special high vacuum area. This optimizes both drying section runnability and draws to improve paper quality.

EV EasyOne technology includes a special high vacuum area. This prevents web from following the upper cylinder and resulting in breaks and paper defects.

EV EasyOne technology is typically combined with the EV EasyGo concept combining web stabiling and vacuum roll technologies.

- EV EasyOne ensures:

- Excellent runnability of the first single felted drying groups

- Eliminates sheet flutter and paper defects

- Additional PM speed

- More tolerance to process fluctuations

- Reduction of raw material costs

Stora Enso Anjala PM 2 has ordered EV EasyOne™ runnability components and services to improve runnability at the 1st and the 2nd drying sections.

For more info please contact:

Timo Haverinen

Sales Director

Chairman of the board

tel.+358 2276 7675

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

M-real increases its one side coated label and flexible packaging paper prices

M-real is to increase the prices for its one side coated label and flexible packaging papers produced at its Simpele mill in Finland and M-real Zanders Gohrsmühle mill in Germany.

The price increase will range from 5 to 6 per cent depending on grade and region and is to come into effect for all invoicing from the 1 October 2010.

The increase is due to the continuing escalation of costs in paper manufacturing and distribution.

For any questions please contact:

Heikki Husso

Senior Vice President

M-real Speciality Papers business area

M-real Zanders GmbH

Tel.: +49 2202 15 2000

Fax: +49 2202 15 2874

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Sappi News: Peter Sarstedt to sing for conservation

Peter Sarstedt, the famous musician and supporter of conservation and the planet will be visiting South Africa during the month of September as a guest of Sappi Limited to help raise funds and awareness for various environmental conservation organisations. He has previously visited South Africa to provide support, along with Sappi Limited, for the Ann van Dyk Cheetah Centre at De Wildt. His upcoming visit will again benefit Ann van Dyk’s Cheetah Centre, along with Birdlife South Africa; the Freeme Rehabilitation Centre; the Pilansberg Wildlife Trust; the Two Oceans Aquarium Cape Town Harbour Seal Project; the Bergvlam Wetland Rehabilitation project in Nelspruit, in conjunction with the Innibos Arts Festival; the Water Sisulu National Botanical Gardens in Roodepoort; the Anatolian Sheppard Project with Cheetah Outreach at the Bienne Donne Outdoor and Travel Show in Franschoek and the Sappi Green Ambassador Recycling programme. He will also hold a number of ‘singer songwriter’ workshops for aspiring musicians, in keeping with both Sappi and his support and encouragement of music in South Africa.

Peter Sarstedt first came to prominence in February 1969 with the Number 1 hit single ‘Where do you go to, my lovely’. He held this position for six weeks on the British charts, as well as reached the No 1 position in 14 other countries. He was awarded the highly coveted Ivor Novello Award for Best Song 1969/70 for this composition. Today, this song is still an icon and recently the theme song for the big screen movie by Wes Anderson…… 'The Darjeeling Limited'. Sarstedt has also written hits for the likes of Eden Kane, Right Said Fred and Herb Alpert.

“We invited Peter back to South Africa to add a new dimension to our long-standing support for the arts, community development and conservation” said André Oberholzer, Group Head Corporate Affairs at Sappi Limited. He continued “Peter’s wonderful music and his passion for conservation will help generate much needed funds and awareness for a number of very worthy causes across the country”. Peter Sarstedt will also help Sappi celebrate 10 years of Sunday Picnic Concerts in support of the Walter Sisulu Botanical Gardens when he appears as a guest artist on the Mathys Roets programme at the Sappi Sunday Picnic Concert of 12 September 2010.

Sarstedt’s commitment to environmental conservation is highlighted in his ‘Green Alphabet’ song as it explores environmental issues that require urgent action from A to Z. ‘Hemmingway’ is a song of passion for Africa which depicts the ease in which we can lose the beauty of the natural world. Sarstedt’s signature songs were a product of a time when folk singing created an awareness of and protested many an injustice and captivated the world in passive protest that formed the basis of change in many communities and countries.

Today, Sarstedt continues to write and perform music and songs throughout the world. While his ’green music’ entertains, it importantly also speaks of the hope for sustainable improvement of our planet…….’Save the Rhino’ will be performed in South Africa to raise awareness of the plight of these magnificent creatures.

Further information regarding tickets for the fundraising events can be obtained through the beneficiary organisations or by contacting Tim Neary at This email address is being protected from spambots. You need JavaScript enabled to view it.

Pacific Northwest Market Summary—July and August

Earlier this summer, world-wide pulp prices reached an all time high with NBSK prices up 30% over 2009. Northwest chip and fiber prices were flat, however, as supplies were adequate to meet production needs. This was one of the few times in recent history where raw material costs for the Northwest pulp and paper industry moved in the opposite direction of pulp and paper prices.

We are now seeing a reversal in this trend. Wood chip and pulpwood prices in the Pacific Northwest increased in July, a result of tight supplies of mill residual chips and limited pulpwood availability.

Total fiber chip cost increased by 6.5 % in July reflecting competition for whole log chip supplies. Conifer pulpwood prices were up by nearly 6 percent across all Northwest regions, indicating anxiety about future supply.

Discouraged by falling lumber prices, mill operators responded with production curtailments, which led to a scarcity of mill residues in the market.

A weak housing market have constricted logging rates and therefore the availability of pulp logs, which are a by-product of harvesting more valuable sawmill quality logs. The State of Oregon announced earlier in August that timber harvests in 2009 declined by 20 percent to 2.6 billion board feet. This is the lowest level since the Great Depression of the 1930s.

Log exports from Oregon and Washington private forestlands are one of the few bright spots in the market, as they help offset lagging sawmill demand. If not for off-shore markets, harvest levels would be lower and pulp logs even more scarce.

Small sawmill log prices are off as much as $50/MBF since May’s highs. Declining prices invited whole log chippers to dip into the chip-n-saw supply to secure pulp wood logs. In some cases, timberland owners have committed their entire third-quarter chip-n-saw production for chips.

During the last three weeks, world-wide pulp inventories increased, causing NBSK prices to decline. Prices are likely to soften further in coming months. With tight supplies of mill residual chips and limited availability of pulpwood, Northwest pulp mills will be challenged over the near term to meet demand and maintain their profit margins.

Source: Forest2Market

NSW Government backs Amcor mill investment

The NSW Government has praised an investment of more than $400m by Amcor Australasia for a new paper recycling facility at Botany. The new facility is expected to be the most advanced and environmentally sustainable mill of its type in the Asia Pacific.

The facility will consolidate Amcor's entire recycled paper production for Australia and New Zealand, creating an Asia-Pacific centre for paper making.

NSW treasurer Eric Roozendaal said the investment would be the largest proposed capital investment in the 140 year history of Amcor.

He says, “Amcor has operated recycled paper machines at its Botany site for 50 years and has a proud history of paper making at the site. But growing international competition saw the Botany Mill facing possible closure with its work being consolidated elsewhere.

“The upgrade will mean that existing employees will have a chance to secure employment in the upgraded mill and additional new employees will be required at several levels to operate the mill.”

The new plant will be capable of producing Amcor’s total requirements of cardboard each year from recycled paper.

Also commenting, Member for Maroubra, Michael Daley said in addition to supporting the jobs of current employees, the project will create major work opportunities for new mill employees as well as sub-contractors and suppliers.

Daley says, “The upgrade is also expected to support more than 800 jobs during construction. I’m especially pleased that the new mill as will have a significant reduction in odours for local residents. This is something we have been working hard on for a long time.”NSW Government backs Amcor mill investment

Scholarship to honour memory of Chad Bennington

Professor Chad Bennington of the University of British Columbia, an active and dedicated member of the pulp and paper community for many years, passed away suddenly and unexpectedly on February 14, 2010 at age 53. Sunny in disposition and optimistic by nature, he was passionate about the pulp and paper industry. In his short life he contributed much to it through his work in education and research. He is sorely missed by all who knew him.

Chad obtained his BSc in Chemistry from the University of British Columbia in 1979. Following graduation, he worked for two years as a process engineer/chemist at MacMillan Bloedel's Powell River Mill. In 1981 he returned to UBC to pursue post-graduate studies in the Department of Chemical Engineering, completing his MASc in 1983 and his PhD in 1988. In 1988 he joined Paprican at the UBC Pulp and Paper Centre where he worked as a Senior Research Engineer (with Paprican, now FPInnovations) and as an Adjunct Professor in the Department of Chemical and Biological Engineering.

In March 2002 he was awarded an NSERC/Paprican Chair in Chemical Pulping Technology and in 2006 was appointed Professor in the Department of Chemical and Biological Engineering. At the time of his passing, his research group was thriving with 14 graduate students and 3 postdoctoral fellows.

To honour his memory, friends and colleagues are establishing an endowed Chad Bennington Memorial Scholarship for students at UBC involved in studies related to pulp and paper technology. Those who knew Chad are asked to please consider contributing in his memory by going to www.supporting.ubc.ca/chadbennington, or for further information, contact Dick Kerekes, chair of the committee at This email address is being protected from spambots. You need JavaScript enabled to view it.

Tembec shuts down permanently its Pine Falls newsprint mill

Tembec has announced the permanent closure of its newsprint mill located in Pine Falls, Manitoba. The mill had been indefinitely idled due to a labour dispute on September 1, 2009. After examining a full range of options, the Company initiated a sales process for the mill in early January 2010. This sales process has proved unsuccessful. After a thorough analysis of the situation, the Company concluded that the permanent closure of the facility was the only viable option. Approximately 230 employees will be affected.

“Although not an easy decision to make, the structural decline of the newsprint market and the cost structure of the mill prompted such a decision,” said Chris Black, Tembec’s Executive Vice President and President, Paper Group. “The Company intends to act in a manner that will ensure that employees receive their severance pay in accordance with the collective agreement.”

As a result of this announcement, a net charge of approximately $8 million related to the closure will be recorded in the quarter ending September 25, 2010.

Tembec is a large, diversified and integrated forest products company which stands as the global leader in sustainable forest management practices. The Company’s principal operations are located in Canada and in France. Tembec’s common shares are listed on the Toronto Stock Exchange under the symbol TMB and warrants under TMB.WT. Additional information on Tembec is available on its website at www.tembec.com.

This press release includes “forward-looking statements” within the meaning of securities laws. Such statements relate to the Company’s or management’s objectives, projections, estimates, expectations, or predictions of the future and can be identified by words such as “anticipate”, “estimate”, “expect” and “project” or variations of such words. These statements are based on certain assumptions and analyses by the Company that reflect its experience and its understanding of future developments. Such statements are subject to a number of uncertainties, including, but not limited to, changes in foreign exchange rates, product selling prices, raw material and operating costs, and other factors identified in the Company’s periodic filings with securities regulatory authorities in Canada and the United States. Many of these uncertainties are beyond the Company’s control and, therefore, may cause actual actions or results to differ from those expressed or implied herein. The Company disclaims any intention or obligation to update or revise any forward-looking statements, whether as a result of new information, future events or otherwise.

Information:

John Valley

Executive Vice President, Business Development and Corporate Affairs

Tel: 416-775-2819

This email address is being protected from spambots. You need JavaScript enabled to view it.

Michel J. Dumas

Executive Vice President, Finance and Chief Financial Officer

Tel: 819-627-4268

This email address is being protected from spambots. You need JavaScript enabled to view it.

Wood fiber costs for the global pulp industry fell in the 2Q/10

Wood fiber costs for the global pulp industry fell in the 2Q/10 after having increased for 18 months, reports the Wood Resource Quarterly

The global pulp industry benefited from lower wood fiber costs and higher product prices in the 2Q/10. Wood chip and pulpwood prices fell the most in the US, Sweden, Finland, Australia and Eastern Canada. Both the softwood and hardwood wood fiber price indices (SFPI and HFPI) fell for the first time since early 2009, according to the Wood Resource Quarterly.

The full article can be found in the attached PDF file.....

Europe shows global leadership in recycling

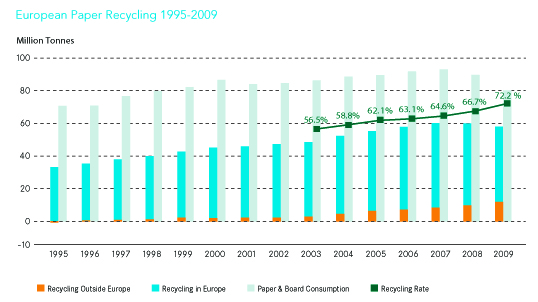

The latest Monitoring report of the European Recovered Paper Council (ERPC) shows that Europe has achieved a world record level of paper recycling in 2009. The rate reached 72.2% which is again higher than the target set in its Commitment for 2010 of 66%. The total amount recycled in paper mills came to 58 million tonnes in 2009.

“The economic recession continued in 2009 and made the paper consumption drop to the level of 1998. This, together with industry’s continued effort to increase recycling made, for the second year in a row, the recycling rate jump up, resulting in a record high 72.2%.” explained Jori Ringman, Secretary of the ERPC. The recycling rate is the ratio between the recycling and the consumption of paper.

A swing in the opposite direction may occur when the economy recovers as recycling may not be able to immediately match up to the reviving paper consumption; the recycling rate is likely to drop, temporarily. In 2010 the recycling rate is estimated to be under 70%, closer to the original target of 66% (±1.5%-points).

“Recycling is intrinsically a self-adjusting mechanism which, with a lag of three to six months, will adapt to any volume of consumption”, Ringman reminded. “In the trend, the industry will continue on its path to meeting ambitious targets of recycling paper at a steadily increasing rate in Europe”, he said. Since 1998, the base year of the first voluntary commitment, the paper industry has increased the annual paper recycling by 45%, growing from less than 40 million tonnes of paper recycled annually to 58 million tonnes last year.

For the commitment period of 2006 to 2010, PricewaterhouseCoopers has independently verified the recycling rate calculations using the International Standard on Assurance Engagements ISAE 3000. The 14 membersof the Council have also made good progress in the qualitative targets laid out in its Commitment particularly with respect to eco-design and waste prevention.

For more information, please contact the ERPC Secretariat, Jori Ringman, at

+32 2 627 49 19, +32 478 255070 (gsm), This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.paperrecovery.eu