Ian Melin-Jones

Stora Enso successfully issues two five-year bonds

Stora Enso has today successfully issued two five-year bonds total of SEK 2 300 million under its EMTN (Euro Medium Term Note) programme. Both bonds are due on 1 September 2015. A SEK 1 000 million bond pays a floating coupon 3 months Stibor + 370 basis points and has an issue/reoffer price of 100.000. A SEK 1 300 million bond pays a fixed coupon of 5.75% and has an issue/reoffer price of 99.778 to give a spread of 370 basis points over 5-year mid swap. The bonds have no financial covenants or change of control covenant. Sole arranger and bookrunner for the transaction was SEB.

“These bonds, extending the Group's maturity profile, were issued to benefit from the low levels of interest rates, resulting in an attractive all-in cost. The Group will continue to manage its maturity profile proactively to gain from favourable sources of financing. We have very strong liquidity with EUR 856 million of cash at the end of second quarter,” says Jyrki Tammivuori, SVP, Group Treasurer.

For further information, please contact:

Jyrki Tammivuori, SVP, Group Treasurer, tel. +358 2046 21043

Ulla Paajanen-Sainio, Head of Investor Relations, tel. +358 2046 21242

Brødrene Hartmann A/S (DK) - Report on extraordinary general meeting held on Tuesday, 24 August 2010

The resolution proposed by the Board of Directors to elect Agnete Raaschou-Nielsen as a new board member was adopted.

In the period leading up to the general meeting, Agnete Raaschou-Nielsen was attached to the Board of Directors in an advisory capacity. Provided that Agnete Raaschou-Nielsen was elected as a new board member by the shareholders, the Board of Directors would elect her new chairman of the Board at its first meeting to be held immediately after the general meeting.

Accordingly, at a subsequent board meeting, the Board of Directors elected Agnete Raaschou-Nielsen chairman and Walther Vishof Paulsen vice chairman of the Board.

Agnete Raaschou-Nielsen was elected for the period until the annual general meeting to be held in 2011.

Agnete Raaschou-Nielsen has the following background:

Agnete Raaschou-Nielsen (52) is Executive Vice President of Aalborg Portland A/S and has long-standing management experience as well as in-depth knowledge of international affairs. Her previous employment with the international organisation of Carlsberg Breweries has given her experience in international production and sales, and from her subsequent management positions with Aalborg Portland A/S, she has gained insight into international processing industries. Furthermore, she was previously a member of the board of directors of Höganäs AB, a listed international group in the processing industry.

Agnete Raaschou-Nielsen is lic.polit (PhD) from Copenhagen University, and among her previous positions are those of Managing Director of Zacco Denmark A/S, General Manager of Coca-Cola Tapperierne A/S and Group Vice President of Carlsberg A/S.

Agnete Raaschou-Nielsen is Chairman of the pension fund Juristernes og Økonomernes Pensionskasse, Vice-Chairman of Investeringsforeningen Danske Invest and six other investment funds, etc. She is a member of the board of Dalhoff Larsen & Horneman A/S, Danske Invest Management A/S and of foreign subsidiaries of Aalborg Portland A/S.

The chairman of the extraordinary general meeting was authorised to file the resolutions adopted with the Danish Commerce and Companies Agency.

Brødrene Hartmann A/S

Agnete Raaschou-Nielsen

Peter Arndrup Poulsen

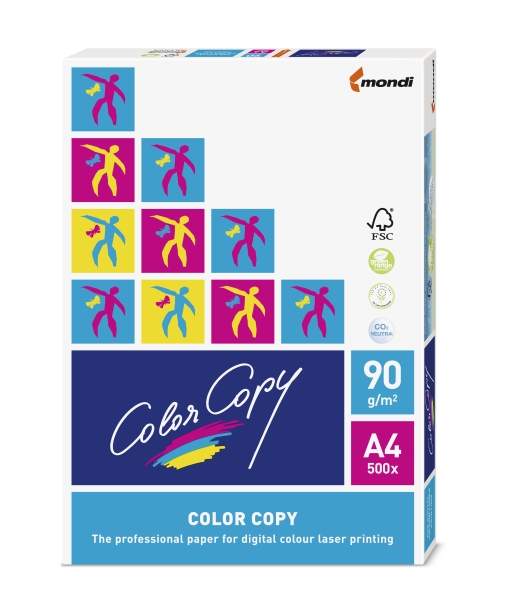

Mondi’s Color Copy gets a fresh new look and an even “greener” profile as Color Copy CO2 neutral

Color Copy announces its newly designed paper wrapper and CO2 neutral status. The new customer-friendly packaging incorporates a modernized design with more product and environmental information.

Vienna, August 24, 2010 – Color Copy, the professional digital colour laser paper from Mondi, will launch its re-designed environmentally friendly packaging in September 2010. Following the decision to switch from a transparent plastic wrapper to a paper one, Mondi also decided to make Color Copy a CO2 neutral product.

Customers will still recognize Color Copy by its playful cyan, magenta, and yellow design; however, the wrapper now clearly displays the paper’s environmental accreditations, grammage and format. Johannes Klumpp, Marketing and Sales Director for Uncoated Fine Paper, explains the motivation for the design change: “The environment is a main concern for our customers and for Mondi. The new paper wrapper displays the FSC, Green Range, EU Ecolabel, and CO2 neutral logos directly on the front side, while further environmental information is detailed on the back of the ream. The switch to paper packaging means less plastic waste for our customers – and for the environment.”

As a fully CO2 neutral product, Color Copy offers customers an additional environmental advantage. Like every other industrial process, the production of Color Copy emits CO2. These emissions are neutralized through verified emission reduction programmes that Mondi invests in. By purchasing Color Copy the customer takes a more proactive role in reducing CO2 emissions and countering the deleterious effects of climate change.

As a fully CO2 neutral product, Color Copy offers customers an additional environmental advantage. Like every other industrial process, the production of Color Copy emits CO2. These emissions are neutralized through verified emission reduction programmes that Mondi invests in. By purchasing Color Copy the customer takes a more proactive role in reducing CO2 emissions and countering the deleterious effects of climate change.

The new easy-to-read wrapper provides product information on the backside, including key facts about Mondi’s Green Range, Color Copy’s FSC certification, the EU Ecolabel and a description about making Color Copy a CO2 neutral product. It also includes images of the entire Color Copy line, grammages and sizes.

“For the past two years, Color Copy has been a FOGRA benchmark leader in overall total print quality,” says Johannes Klumpp. “Color Copy was the first paper specifically developed for color laser printing and we are continually developing and adapting this product to meet the needs and values of our customers and the growing digital print industry.”

Color Copy is available in grammages from 90 to 350 gsm, and A4, A3, SRA3, A3+, folio formats, continuous web reels and Xeikon reels. Color Copy is Forest Stewardship Council (FSC) certified and is part of Mondi’s Green Range family. All Green Range papers are FSC-certified, totally chlorine free (TCF) or 100% recycled.

For more information on the entire Color Copy product portfolio, please visit: www.colorcopy.com

Contact

Jolene Pozniak, Communications Manager, Uncoated Fine Paper

Tel: +43 (1) 79013 – 5663, e-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Mondi Uncoated Fine Paper Sales GmbH, Kelsenstraße 7, A-1032 Wien

www.mondigroup.com

ABB automation increases paper machine availability for Korsnäs paperboard mill

Delivery includes the first permanent magnetized motor from ABB in Sweden

ABB, the leading power and automation group, has won an order to supply automation and control systems for two paper machines and a winder at Korsnäs AB in Gävle, Sweden. The mill produces paperboard and other packaging materials.

ABB, the leading power and automation group, has won an order to supply automation and control systems for two paper machines and a winder at Korsnäs AB in Gävle, Sweden. The mill produces paperboard and other packaging materials.

ABB will replace all the automation and control systems in the roller machine RM5, install new converters and drives for the wet end of the paper machine PM5 as well as a new drive system for the pope on PM2.

Korsnäs is replacing the equipment on the machines to ensure a trouble-free operation with maximum machine availability and safety.

The reconstruction/conversion of the drive system solution for the PM2 pope is carried out mainly to increase machine handling safety. The customer chose to base the new solution on ABB’s energy-efficient permanent magnet motor that was awarded the Wallenberg Award 2009.

“Considering all the benefits of not needing any surrounding equipment that requires maintenance or any parts that must be replaced at intervals from ABB, we expect to save operational and maintenance costs. Furthermore, we want to test the new technique that we believe will be prevailing in the future,” said Lars Eriksson, project leader at Korsnäs in Gävle.

“Roller machine 5 is a critical point in the production process and must therefore perform with the highest possible availability. To eliminate potential bottlenecks and keep the process running efficiently we are installing a new control system for the drive system application and machine controlling based on System 800xA from ABB”, said Eriksson.

The System 800xA delivery for RM5 includes a redundant server system, operator station, engineer station and operator panel. To avoid separate safety systems and to increase operator control, the machine control will be integrated into SIL-classified controls that will also run the safety classified circuits. The control system for the pope on paper machine PM2 will be with Compact 800 controller and operator panel. The project includes all design, application programming, documentation, commissioning and customer training.

ABB (www.abb.com) is a leader in power and automation technologies that enable utility and industry customers to improve their performance while lowering environmental impact. The ABB Group of companies operates in around 100 countries and employs about 117,000 people.

For help with any technical terms in this release, please go to: www.abb.com/glossary

Tembec Fully Supports Proposed Ontario Energy Program

Tembec has indicated its full support for an energy conservation program announced earlier today by Ontario Energy and Infrastructure Minister Brad Duguid. The Company believes this program will encourage energy management practices that will have both a positive environmental impact and a positive impact on the competitiveness of several key Ontario industries.

The initiative will create a policy that rewards investments in efficiency and demand management and recognizes energy efficient practices by large industrial users. It will essentially bring the concept and benefits of time of use power currently available to residential users to industrial consumers.

“This program will result in energy, environmental and economic benefits—a great combination. By encouraging a shift away from peak demand periods, both the need for and use of peaking plants will be lessened, resulting in a reduced reliance on fossil fueled facilities,” said Jim Lopez, Tembec’s President and CEO. “With an industrial time of use framework available, the average cost of power, a critical cost element for many industries, will be lower. This will result in improved competitiveness and greater potential for job security.”

“This initiative comes at a critical time for the Ontario economy generally and the Northern Ontario economy in particular. Tembec fully supports this initiative,” concluded Mr. Lopez.

Tembec is a large, diversified and integrated forest products company which stands as the global leader in sustainable forest management practices. The Company’s principal operations are located in Canada and France. Tembec’s common shares are listed on the Toronto Stock Exchange under the symbol TMB and warrants under TMB.WT. Additional information on Tembec is available on its website at www.tembec.com.

This press release includes “forward-looking statements” within the meaning of securities laws. Such statements relate to the Company’s or management’s objectives, projections, estimates, expectations or predictions of the future and can be identified by words such as “will”, “anticipate”, “estimate”, “expect” and “project” or variations of such words. These statements are based on certain assumptions and analyses made by the Company in light of its experience and its perception of future developments and may not be appropriate for any purposes other than what is stated herein. Such statements are subject to a number of risks and uncertainties, including, but not limited to, changes in foreign exchange rates, product selling prices, raw material and operating costs and other factors identified in our periodic filings with securities regulatory authorities. Many of these risks are beyond the control of the Company and, therefore, may cause actual actions or results to materially differ from those expressed or implied herein. The Company disclaims any intention to update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, unless required by applicable securities legislation.

Information:

John Valley

Executive Vice President, Business Development and Corporate Affairs

Tel.: 416-775-2819

This email address is being protected from spambots. You need JavaScript enabled to view it.

Michel J. Dumas

Executive Vice President, Finance and Chief Financial Officer

Tel.: 819-627-4268

This email address is being protected from spambots. You need JavaScript enabled to view it.

New FM Global Research Report Explores Why Companies Flirt with Natural Disasters and Risk It All

FM Global, one of the world’s largest business property insurers, has released a new research report, Flirting with Natural Disasters: Why Companies Risk It All that examines why some companies prepare for the risk of natural disasters while others seemingly gamble with their future.

FM Global, one of the world’s largest business property insurers, has released a new research report, Flirting with Natural Disasters: Why Companies Risk It All that examines why some companies prepare for the risk of natural disasters while others seemingly gamble with their future.

FM Global, which insures one of every three Fortune 1000 companies, commissioned the report to help business leaders better understand the psychological barriers that can affect their business decisions when addressing vulnerabilities to natural disasters. The report also provides solutions that can guide change in organizational decision-making behavior with regard to natural disaster risks.

Flirting with Natural Disasters was prompted by the fifth anniversary of Hurricane Katrina—the costliest hurricane in history, which struck on Aug. 29, 2005, and caused billions of U.S. dollars in damage—much of which could have been prevented.

The report focuses on:

- Reasons why business leaders fail to plan for catastrophe, ranging from denial to short-range vision to the mistaken belief that insurance alone will enable a return to “business as usual” after a disaster.

- Consequences of inaction, especially in the face of evidence that proves most property damage from hurricanes, earthquakes, fires, floods or man-made hazards can be minimized or eliminated.

- Ways leaders can break through the barriers of human nature to better protect their businesses and communities.

“Natural disaster risks are real. They are not probabilities, thresholds, models or likelihoods,” said Ruud H. Bosman, vice chairman at FM Global. “The wrong discussion for business leaders is one around whether it will ever happen, because it will. If more organizations considered the impact of psychological behaviors on their disaster risk preparedness, as outlined in this report, the world would be a much safer place.”

Download a copy of Flirting with Natural Disasters: Why Companies Risk It All, at www.fmglobal.com/disaster.

About FM Global

Commemorating its 175th anniversary in October 2010, FM Global (www.fmglobal.com) ranks 545 among FORTUNE magazine’s largest companies in America. More than one out of every three Fortune 1000 companies and similar-sized organizations operating in more than 130 countries work with FM Global to develop robust property insurance and engineering solutions to protect business operations from property risk. The company has been named “Best Property Insurer in the World” by Euromoney magazine and “Best Global Property Insurer” by Global Finance magazine. The company is rated A+ (Superior) by A.M. Best and AA (Very Strong) by Fitch Ratings.

Standard & Poor's upgrades M-real's credit rating

Standard & Poor's has today upgraded M-real Corporation's CCC+ rating to B-. The outlook of the rating is stable.

Upgrade has a positive impact of approximately EUR 1 million on M-real's current annual financing costs.

M-REAL CORPORATION

Further information:

Matti Mörsky, CFO, tel. +358 10 465 4321

Juha Laine, Vice President, IR and Communications, tel. +358 10 465 4335

Ahlstrom increases its coating capacity in Brazil

Ahlstrom, a global leader in nonwowens and specialty papers, today announces the completion of an investment to increase the speed of an off-line coater at its Jacareì plant in Brazil.

The higher speed of the coater will markedly increase the coating capacity of the plant. This investment will enable Ahlstrom to better satisfy the growing demand for coated papers and further reinforce Ahlstrom's leadership in the Brazilian and South American markets.

The Jacareì plant mainly produces one-side coated papers for release liners, labels, packaging and other coated specialties.

A large part of Ahlstrom's coated papers are also produced in Europe at the sites located in Stenay, France, and Osnabrück, Germany.

Stenay, Osnabrück and Jacareì plants are part of the Label and Processing Business Area. The business area operates seven production sites located in France (3), Germany (2), Italy (1) and Brazil (1).

For further information, please contact:

Daniele Borlatto, Vice President, Release & Label:

+39 011 926 0111, This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmir Piton, Vice President, Release & Label, South America:

+55 19 3878 9201,This email address is being protected from spambots. You need JavaScript enabled to view it.

HiDrain boosts dry content at Norske Skog Skogn PM2

The Norske Skog Skogn mill in Norway is one of the largest newsprint producers in Europe. The mill has decisively sought ways in which to improve the operation and efficiency of its three newsprint machines, PM 1, PM 2 and PM 3.

Last year, the mill decided to convert PM 2 so that it is able to run on a neutral system, from pH 5.4 to pH 7, at a filler content of 10%, with the possibility of using recycled furnish. This would improve the density and opacity of the produced newsprint.

Morten Skrove, Production Manager of PM 1 and PM 2: “One important stage in this project was to increase the web dry content after the forming section, which also improves runnability and web stability. Based on the good experience gained with PM 3 through the HiDrain high-vacuum suction box, it was natural to rely on the same technology for PM 2.”

The successful installation and start-up with Metso took place in early January 2010.

Web dry content increase of 2.5% after couch roll

Three days after the HiDrain start-up, the dry content after couch roll increased to 16.5% from the earlier average of 15%, both for 45 g/m2 and 48.8 g/m2 basis weights, at the vacuum level of 55 kPa.

Around one month after the start-up the dry content after couch roll was already 17.5%, and runnability has been exceptionally good. The furnish chemistry and mix optimization are still on-going at the TMP plant, so it is therefore still too early to estimate the final effect of the HiDrain suction box on speed increase or reduction in steam consumption.

Benefits of the HiDrain suction box

• higher sheet dry content after forming section

• improved runnability, especially at the press and dryer section

• fewer breaks

• potential for speed increase thanks to higher sheet dry content

Clear plans for the future

After the optimization work at PM 2 has been completed the mill has clear plans to improve formation through an upgrade or rebuild after which the quality of newsprint produced by PM 2 will match the high-standards produced by PM 1 and PM 3.

Norske Skog Skogn was founded in 1962. Serving demanding customers worldwide, the mill has its own port facilities, and a regular twice weekly shipping delivery is made to the UK and Continental Europe. The three paper machines, PM 1, PM 2 and PM 3, have a total annual capacity of 600,000 tonnes and produce paper under the Nornews brand.

Orient Paper Launches Corporate and Investor Relations Website

Orient Paper, Inc. (AMEX: ONP) ("Orient Paper" or the "Company"), a leading manufacturer and distributor of diversified paper products in Hebei, China, today announced the launch of its new corporate website under the domain name http://www.orientpaperinc.com .

The Company's new website provides detailed information about Orient Paper's corporate history, product portfolio, environmentally friendly manufacturing practices, and a note from Chairman and Chief Executive Officer, Mr. Zhenyong Liu, in both English and Chinese. The new website also includes a comprehensive investor relations section that provides investors access to the Company's operating and financial information including press releases, recent presentations, corporate governance, SEC filings, stock price information and upcoming investor events.

"We are pleased to officially launch our new corporate website," said Mr. Liu. "We believe our new website will further enhance our communications with our customers, investors and business partners. We expect our website to become an effective information resource and are committed to maintaining a high level of transparency and disclosure."

About Orient Paper, Inc.

Orient Paper, Inc., through its wholly owned subsidiary, Shengde Holdings, Inc., controls and operates Baoding Shengde Paper Co., Ltd. ("Baoding Shengde"), and Hebei Baoding Orient Paper Milling Co., Ltd ("HBOP"). Founded in 1996, HBOP is engaged in the production and distribution of products such as corrugating medium paper, offset printing paper, and other paper and packaging-related products in China. The Company uses recycled paper as its primary raw material. Baoding Shengde, founded in June 2009 located in Baoding, is engaged in the production and distribution of digital photo paper. As one of the largest paper producers in Hebei Province, China, HBOP is strategically located in Baoding, a city in close proximity to Beijing where the majority of publishing houses are based. Orient Paper is led by an experienced management team committed to diversifying the Company's product offering and delivering tailored services to its customers. For more information, please visit http://www.orientpaperinc.com .

Safe Harbor Statement

This announcement contains forward-looking statements within the meaning of the safe harbor provisions of the Private Securities Litigation Reform Act of 1995. All statements other than statements of historical fact in this announcement are forward-looking statements, including but not limited to the Company's ability to introduce new products; the Company's ability to implement the planned capacity expansion of corrugated medium paper; market acceptance of new products; general economic and business conditions; the ability to attract or retain qualified senior management personnel and research and development staff; and other risks detailed in the Company's filings with the Securities and Exchange Commission. These forward-looking statements involve known and unknown risks and uncertainties and are based on current expectations, assumptions, estimates and projections about the companies and the industry. The Company undertakes no obligation to update forward-looking statements to reflect subsequent occurring events or circumstances, or to changes in its expectations, except as may be required by law. Although the Company believes that the expectations expressed in these forward looking statements are reasonable, it cannot assure you that its expectations will turn out to be correct, and investors are cautioned that actual results may differ materially from the anticipated results.

For more information, please contact:

CCG Investor Relations

Mr. Crocker Coulson, President

Phone: +1-646-213-1915

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Web: http://www.ccgirasia.com

Orient Paper, Inc.

Winston Yen, Chief Financial Officer

Phone: +1-562-818-3817

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

SOURCE Orient Paper, Inc.