Ian Melin-Jones

New Metso on-line sensor measures formation like a papermaker

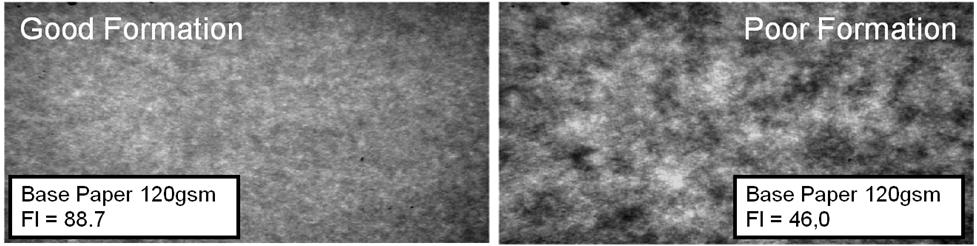

Metso has introduced a new scanning formation sensor, called Metso IQ Formation Measurement, which uses high-speed image capture and analysis technology to define small-scale sheet uniformity. Machine operators can quickly optimize sheet formation visually and meet formation index specifications to ensure customer quality is uniform while the paper machine is running.

Image based on high-speed image capture technology, the sensor provides sequential, instantaneous images of the sheet as it scans across the paper machine.

The sensor resolves sequential, instantaneous pictures of the sheet as it scans across the paper machine and displays them on the QCS operator interface. A formation index and other numerical data which defines the distribution of fiber floc and void sizes are determined by the sensor’s sophisticated image analysis software. Dark spots, light spots and pinholes are also detected and classified by the analysis software.

The sharply-focused picture of the sheet gives the machine operators a clear view of sheet formation exactly as they would see it by visually inspecting a paper tear-sheet. Operators can make a quick evaluation of how formation is changing as they adjust forming conditions and furnish quality. Formation can be optimized systematically during a working shift.

The formation index provided by the image analysis correlates very well with off-line Kajaani Formation Index from Metso’s automated testing laboratory. This enables papermakers to adjust forming conditions to comply with customer standards. This objective index, combined with a library of best-formation images stored in the computer system, ensures that shift-to-shift interpretation and operating practices are consistent and customer quality is the same.

Formation Measurement, like other Metso quality measurements, is designed to be easily plugged into the Metso scanning platform.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

For further information, please contact: Marko Toskala, Product Manager,

tel. +358 40 837 2459

Segezha Packaging group is to cease its operations in the company in Spain

Segezha Packaging Group ("Segezha") announced today that it will close its paper sack factory Segezha Packaging S.A.U, which is located in Almeria, Spain, due to DUE TO CONTINUED LOSSES AND THE NEGATIVE MARKET SITUATION. The closing down production and the offices will happen in autumn 2010.

This measure has been announced to the Workers Representatives and a compensation plan for the plant's 61 employees will be negotiated.

The economic and financial crisis in the last years has hit the Spanish market hard and the building and construction industry in particular has been and is no exception. A dramatically reduced demand for paper sacks for cement and building-mix products, combined with surplus capacity where sack production is concerned, has resulted in a serious decline in sack prices on the Spanish market over the past few years. This has made it very difficult to create a balance between costs and income, which has led to a loss of earnings for the Spanish company and had a negative influence on the financial result. It does not appear at present that there will be any change in this situation within the foreseeable future and a decision was therefore made to withdraw from the Spanish market.

The customers will be supplied and served as usual so the closure will not affect our commitments currently in force.

The factory closure is part of the ongoing work on and strategy of consolidating Segezha's sack production units to meet the new, changed market conditions consequent on the economic crisis. The purpose of consolidating production units to create major units is to ensure a certain production volume for the individual units and make them efficient. This strategy allows Segezha to offer our customers the highest quality products and services in the most cost effective manner possible.

Segezha, which owned by the Russian ILP Group, is the world's second-biggest manufacturer of paper sacks. Segezha Packaging makes approximately 1.2 billion paper sacks a year at 11 high-tech factories in nine countries in Europe and Russia. Segezha Packaging has 1,200 employees.

If you have any questions regarding the information above, please contact:

Ben Verheijden

COO Segezha Packaging

This email address is being protected from spambots. You need JavaScript enabled to view it.

Sonoco to Present at J.P. Morgan Diversified Industries Conference

HARTSVILLE, S.C., Jun 07, 2010 (BUSINESS WIRE) --Sonoco (NYSE: SON), one of the largest diversified global packaging companies, will speak to the investment community on Wednesday, June 9, 2010, at the J.P. Morgan 5th Annual Diversified Industries Conference held in its conference center at 383 Madison Avenue in New York City.

Harris E. DeLoach, Jr., chairman, president and chief executive officer, and Charles J. Hupfer, senior vice president and chief financial officer, are scheduled to speak at 2:30 p.m. Eastern Time. The audio presentation will be Webcast and can be accessed via the Internet at http://www.sonoco.com, under the "Latest News" section.

About Sonoco

Sonoco, founded in 1899, is a $3.6 billion global manufacturer of consumer and industrial packaging products and provider of packaging services, with more than 300 operations in 35 countries serving customers in some 85 nations. The Company is a proud member of the Dow Jones Sustainability World Index. For more information on Sonoco, visit our Web site at http://www.sonoco.com.

SOURCE: Sonoco

Sonoco

Roger Schrum, 843-339-6018

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.sonoco.com

Lighter weight boards reduce carbon footprints

New research, conducted for M-real Consumer Packaging, has found that within the same grade (brand), the carbon footprint of a cartonboard reduces at least in proportion to its basis weight. A 15% reduction in board weight equates to a 18% reduction in carbon footprint, which is important to users concerned about sustainability. If they can specify a lighter weight board, provided all criteria regarding stiffness and performance are met, their own carbon footprint will diminish accordingly.

New research, conducted for M-real Consumer Packaging, has found that within the same grade (brand), the carbon footprint of a cartonboard reduces at least in proportion to its basis weight. A 15% reduction in board weight equates to a 18% reduction in carbon footprint, which is important to users concerned about sustainability. If they can specify a lighter weight board, provided all criteria regarding stiffness and performance are met, their own carbon footprint will diminish accordingly.

For example, M-real has calculated that if you make 100,000 biscuit cartons using a 25 g/m2 lighter board, the CO2 saving per annum equals driving 1,000 km by car.

The research, commissioned from an external research institute, aimed to produce Life Cycle Assessments for three different weights of board. Carbon footprints were calculated for 10,000 biscuit cartons produced in 250, 270 and 295 g/m2 weights, to discover if the footprint would reduce proportionately when a lighter weight board was used.

Calculations assessed energy used in forestry, transport and manufacturing at all stages from harvesting the wood to making the cartons, including, for example, transporting the board to the customer.

Riikka Joukio, Vice President Marketing of M-real Consumer Packaging, says: “By making packaging more effective and less wasteful, sustainability goes hand in hand with cost savings, which can be achieved both by the choice of lightweighted materials and by a design that has the right impact.

“Packaging has a relatively small global warming potential in food products, when compared to other activities taking place in the production of a food product, most notably fertiliser and cultivation. At the same time, packaging’s importance in reducing food waste, which might otherwise rot down in landfill producing methane – a harmful greenhouse gas – is also well established. Up to 50% of food is wasted in developing countries, where food packaging is less common, compared to western countries where waste averages 2% and is mostly attributable to over-purchasing.”

For further information please contact M-real Consumer Packaging:

Ritva Mönkäre, Marketing Manager

Mobile +358 (0)50 598 7012

E-mail: ritva.monkare(at)m-real.com

News from EV Group Oy - The Runnability Team

Stora Enso Anjala PM 2 has ordered EV EasyOne™ runnability components and services to improve runnability at the 1st and 2nd drying sections.

Also the first foreign paper mills have ordered EV EasyOne™ technology and many customers worldwide are very interested of the concept.

Read More about EV EasyOne Concept Below:

EV EasyOne optimizes the first single felted drying groups

Does your web run easily at the beginning of your drying section, at the first single felted groups?

Do you have sheet flutter and paper defects?

Does tail threading take too much time?

Especially in high-speed paper machines, the first single felted drying groups are very sensitive to run. Without support on web release between upper cylinder and vacuum roll the wet web tends to follow the upper cylinder, resulting in breaks and paper defects.

EV EasyOne™ optimizes the web release between upper cylinder and vacuum roll. It eliminates runnability problems that are caused when the sensitive wet web tends to follow the upper cylinder surface.

Traditionally, draw difference between press and drying section has been a tool to control runnability but this often causes problems in paper quality. With the EV EasyOne it is possible to improve the web release effectively with a special high vacuum area. This optimizes both drying section runnability and draws to improve paper quality.

EV EasyOne technology includes a special high vacuum area. This prevents web from following the upper cylinder and resulting in breaks and paper defects.

EV EasyOne technology is typically combined with the EV EasyGo concept combining web stabiling and vacuum roll technologies.

EV EasyOne ensures:

- Excellent runnability of the first single felted drying groups

- Eliminates sheet flutter and paper defects

- Additional PM speed

- More tolerance to process fluctuations

- Reduction of raw material costs

M-real organises a Capital Markets Day on 10 June 2010 in Italy

M-real Corporation, a part of Metsäliitto Group, organises a Capital Markets Day on June 10, 2010 in Parma region, Italy. The event is organised on invitational basis for analysts. The theme of the day is ‘M-real's turn-around and future direction'. The focus will be on the outlook of the high quality virgin fiber based cartonboard.

As a part of the Capital Markets Day, there will be a visit at M-real's customer, an Italian food manufacturer Barilla. Participants will familiarize themselves with Barilla's operations and importance of packaging in the company's business.

Additionally, a guest speaker Mr Berry Wiersum, CEO of Sappi Fine Paper Europe, will give an overview and update of European coated paper markets.

Presentation materials will be available on M-real's website www.m-real.com on

10.6.2010 by 9 a.m. EET.

M-REAL CORPORATION

Further information:

Matti Mörsky, CFO, tel. +358 10 465 4913

Juha Laine, VP, IR and Communications, tel. +358 10 465 4335

“Innovating for the future: the forest and paper industry towards a low carbon economy”

Tokyo (Japan) – FAO Headquarters. “From the forests through to the end products we can provide solutions which are environmentally friendly, renewable and which ensure sustainable growth, and all of which contribute to climate change mitigation and carbon emission reduction”. That is the green output of the 51st session of the FAO Advisory Committee on Paper and Wood Products (ACPWP) and the International Council of Forest and Paper Associations (ICFPA). Industry executives, gathered in Tokyo (Japan) on 27 and 28 May 2010, agreed that a green future is not just a major concern of non-governmental organizations and environmentalists; it is also a priority on the agenda of the forest products and paper industry.

“Japan Paper Association (JPA) is delighted to have the opportunity to discuss and exchange opinions with the forestry industry as the host country of the meeting”, said Masataka Hayama, President of JPA. “We look forward to a continued exchange and partnership with FAO”, continued Mr Hayama. “Wood is a recyclable and renewable material and the life cycle doesn’t end when wood is harvested”, highlighted Michael Peter, Executive Director of Forestry South Africa. In fact, not only is carbon stored in trees, but, once trees are harvested, not just the end products but the replanted areas as well, continue to store carbon.

“Investors are recognizing the green opportunities inherent in forests and forest products, we would welcome even more investment to the sector”, stated Marie S. Arwidson, Managing Director of the Swedish Forest Industries Federation. This underscores the need to see the link between carbon sequestration and forestry. “Another challenge is the common perception that the forest would shrink if it is utilized. The contrary is true”, emphasised Michael Peter. “Whenever consumers buy sustainably harvested wood products, they help the forest industry keep the forests vibrant and growing through re-investment and new plantings.”

The growing population and the need to mitigate climate change bring an essential role for the world forests. Sustainable management of forests is a prerequisite in meeting the future world demand for products and services, while achieving the low carbon economy. This puts the industry in the centre of the debate, with policies influencing industry development. “For this, the partnership between the industry sector and FAO is so crucial” emphasized Teresa Presas, President of the International Council of Forest and Paper Associations.

“Government policies have an effect in the development of the forest industry. Sustainable future wood supply for this sector will be highly dependent on enabling and predictable policies, reconciling climate change, conservations and competitiveness objectives” said Bernard de Galembert, Forest & Research Director of the Confederation of European Paper Industries (CEPI).

“Energy policy and carbon policy are high priorities for both national governments and international bodies. In this context”, stressed Avrim Lazar, President and CEO, Forest Products Association of Canada (FPAC), “FAO has a unique role to play as catalyst of cross-sectoral cooperative measures and facilitator of the debate between the diverse actors and policy makers”.

The industry is responding positively to winds of change. It could be the dawn of a new era, and the upcoming International Year of Forests might help catalyze this transformation – with a wealth of opportunities lying ahead, from innovation to diversification. “Let’s be future oriented: let’s say what the future value sets are, what is it that people will be looking for”, concluded the meeting. The forest and paper industry has a lot to offer. Government support and partnership across sectors will be key to facing future challenges.

First International Stakeholder Members Announced

“PEFC membership provides a forum to meet and discuss the various challenges in the field of forestry and forest product markets amongst different stakeholders," explained Mikko Ohela, Senior Vice President of International Affairs at the Metsaliitto Group, one of the first five members of PEFC International's Stakeholder Membership category.

PEFC created this membership category for International Stakeholders in 2009, and has been receiving applications from entities wishing to become members since the beginning of 2010.

The other four entities to become International Stakeholder Members are the Confederation of European Paper Industries (CEPI), European Network of Forest Entrepreneurs (ENFE), the International Family Forestry Alliance (IFFA), and StoraEnso.

Commenting on ENFE's motivation for seeking PEFC membership, Simo Jaakkola, ENFE's Chairman stated, "our International Stakeholder membership will enable us to get more engaged in global forestry issues, whilst PEFC will gain a better understanding of the important role of contractors for sustainable forest management."

From CEPI's perspective, their involvement as an International Stakeholder Member is a positive step, and one that reflects industry's commitment towards sustainable forest management. This was mirrored by Stora Enso's Environmental Manager, Pekka Kallio-Mannila, "PEFC is very influential in promoting Sustainable Forest Management, and therefore it is important to strengthen stakeholder involvement to include all parties with environmental, social and economic interests."

Speaking on behalf of the International Family Forest Association, Chairperson Lea Jylhä commented that, "family forest owners have been one of the main driving forces behind PEFC since its early days, and the stakeholder membership category is a natural step in this development."

"We want to actively participate and share our most up-to-date knowledge to support PEFC's role in the enhancement of sustainable forest management. Forest owners all around the globe are contributing to sustainable forest management through their daily activities in the forests, and through PEFC we want to highlight this commitment to all parties interested in sustainable forestry," Ms Jylhä stressed. "This cooperation will offer clear benefits for PEFC as well since IFFA can inform its members and partners both in family and community forestry about PEFC's work, and in the new areas such as the tropics."

"PEFC has enjoyed a strong relationship with these organisations for many years now, and we warmly welcome them as International Stakeholder Members," said Ben Gunneberg, Secretary General of PEFC International. "We look forward to enhanced opportunities to cooperate in promoting sustainable forest management around the world."

Further Information

PEFC International Stakeholder Members

- Confederation of European Paper Industries

- European Network of Forest Entrepreneurs

- International Family Forestry Alliance

- Metsaliitto Group

- StoraEnso

Mayr-Melnhof Packaging acquires largest Chilean folding carton producer

Mayr-Melnhof Packaging has made a first step into the region of Latin America and announces the acquisition of a 70 % participation in Marinetti S.A., located in Santiago de Chile. The former family shareholders hold the remaining shares.

The company produces folding carton packaging for multinational as well as local producers of branded goods. Currently the site employs some 650 people and generates annual sales of approximately EUR 45 million.

A significant investment program shall broaden the technological basis and support the exploitation of market potential also in the neighboring countries.

The closing of the transaction is subject to specific conditions precedent.

For further information, please contact:

Stephan Sweerts-Sporck, Investor Relations, Mayr-Melnhof Karton AG, Brahmsplatz 6, A-1041 Vienna

Tel.: (+43/1) 50136 – 91180, Fax: (+43/1) 50136 – 91195

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it., Website: http://www.mayr-melnhof.com

Shareholding in Karton Deisswil AG sold to Swiss Investors’ Group

The Mayr-Melnhof Group has sold its entire shareholding in Karton Deisswil AG to a regional Swiss group of investors.

The production of cartonboard remains discontinued. A major part of the ongoing customer orders is already serviced through the plant network of the MM Karton Division.

This final step will be connected with one-off accounting results of approximately EUR -8 million.

For further information, please contact:

Stephan Sweerts-Sporck, Investor Relations, Mayr-Melnhof Karton AG, Brahmsplatz 6, A-1041 Vienna

Tel.: (+43/1) 50136 – 91180, Fax: (+43/1) 50136 – 91195

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it., Website: http://www.mayr-melnhof.com