Ian Melin-Jones

NEW Contact Impression Film from Sensor Products Inc.

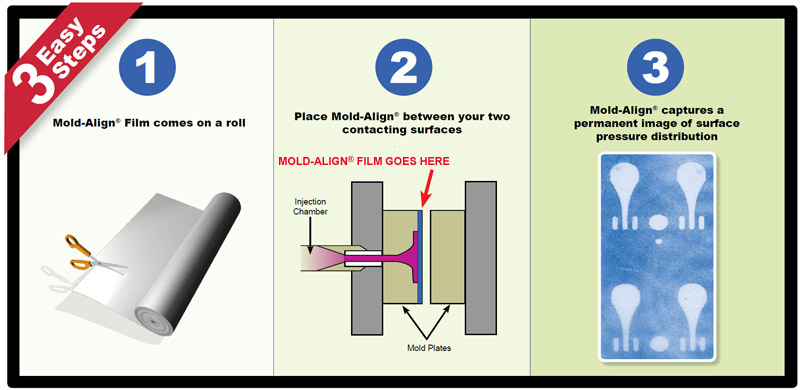

Mold-Align® is a unique, affordable and easy to use tool that reveals pressure distribution between mold platens.

Of the hundreds of variables involved in injection molding, clamping mechanisms and platens often get less attention than they deserve. Good clamp performance is critical to minimize cycle times, optimize part quality, and maintain process consistency. Alignment and uniformity of the mold halves, platens, and clamping system is therefore critical. When an alignment problem stems from the mold parting line, the platens, or the clamping mechanism and tie bars, the results can be unnecessary machine wear, mold damage, broken tie bars, mold flash, and scrap parts.

One way to ensure proper mating of the tool halves at the parting line is simply by having a level molding machine and parallel platens. Leveling a machine requires three machinist levels. If you have shorts and flash, you could have a mold or clamping alignment problem.

This may not be the case if you are running a high-speed, thin-wall product—the problem may be simply not enough clamp force. To help establish whether flash stems from a mold or clamp alignment issue, check parting-line mating. In one typical check for uniform clamp pressure at the parting line, bluing agent applied to one mold half will transfer to the other if there is contact at the parting line.

But it will not distinguish between low or high touch forces. More detailed information can be obtained with Mold-Align® paper, which changes color relative to the amount of contact force. Mold-Align® is an extremely economical and practical solution for determining proper mold alignment. Mold-Align® is a self contained (single sheet) paper that is quickly implemented, requires no training, and reveals a high resolution image of pressure distribution and void spots between mold plates.

SPECIFICATIONS

|

|||||||||||

For more info please contact:

Vadim Shalyt

Sr. Application Specialist

Sensor Products Inc. USA

300 Madison Ave.

Madison, NJ 07940

1.973.428.8985 (phone)

1.973.495.9800 (cell)

1.973.884.1699 (fax)

This email address is being protected from spambots. You need JavaScript enabled to view it.

IPX India International Paper Exhibition launched

Adforum, organizers of the World leading pulp and paper trade fairs PulPaper, SPCI and China Paper are now launching, IPX India, International Paper Exhibition, in association with Inter Ads-Brooks Exhibitions, a joint venture company between Inter Ads Exhibitions, India and Mack Brooks Exhibitions, U.K.

Adforum, organizers of the World leading pulp and paper trade fairs PulPaper, SPCI and China Paper are now launching, IPX India, International Paper Exhibition, in association with Inter Ads-Brooks Exhibitions, a joint venture company between Inter Ads Exhibitions, India and Mack Brooks Exhibitions, U.K.

- IPX India is scheduled to be held in December 2012 in Mumbai and with the aim of attracting at least 200 companies for its premier edition, says Rajan Sharma, Director, Inter Ads-Brooks Exhibitions, - Adforum is the world’s leading organizer of exhibitions for the pulp and paper industry and we are excited about the alliance with Adforum and about creating an International level exhibition for the pulp and paper technology industry in India, Rajan Sharma adds.

The first IPX India will be held in Mumbai 13 – 15 December 2012. A high level conference as well as various social activities will also be held concurrently with the exhibition.

The first IPX India will be held in Mumbai 13 – 15 December 2012. A high level conference as well as various social activities will also be held concurrently with the exhibition.

- We are very pleased to launch a new pulp and paper exhibition in India with Inter Ads-Brooks Exhibitions as our partner, said Bjorn Delin, CEO Adforum. - We want to expand our portfolio of large international shows and our objective has, since many years, been to launch a new exhibition in India, says Bjorn Delin.

- We believe that IPX India will be a new top quality exhibition and conference allowing Indian and international pulp and paper professionals to network, discuss the latest innovations and do business together. – And Mumbai, as the leading industrial and financial city, is the perfect place to organize a new exhibition for the Indian pulp and paper industry, Bjorn Delin concludes.

The Indian Paper industry is the fastest growing pulp and paper market in the world today. With an estimated turnover of approximately Rupees 150,000 millions (approx. USD 3,400 millions) 2010, the Indian pulp and paper industry is growing on a strong demand base with several expansion plans underway. The demand for newsprint and writing & printing paper is expected to grow with 9 % per year and the total Indian paper production is expected to grow from 9 million tonnes 2010 to 14 million tonnes in 2014. According to many industry experts, India will definitely be one of the most interesting markets for the global pulp and paper industry in the coming years

For more information about IPX India, please contact: This email address is being protected from spambots. You need JavaScript enabled to view it. or This email address is being protected from spambots. You need JavaScript enabled to view it.

Ahlstrom's new plant in Binzhou, China inaugurates today

Ahlstrom Group, a leading developer and manufacturer of nonwovens and specialty papers, today celebrates the inauguration of its new facility in Binzhou, Shandong province, in northeastern China.The plant produces transportation filtration materials and currently employs 170 people. Ahlstrom acquired the plant from Purico Group which it announced earlier this month.

Ahlstrom Group, a leading developer and manufacturer of nonwovens and specialty papers, today celebrates the inauguration of its new facility in Binzhou, Shandong province, in northeastern China.The plant produces transportation filtration materials and currently employs 170 people. Ahlstrom acquired the plant from Purico Group which it announced earlier this month.

According to Ahlstrom's President & CEO Jan Lång the acquisition plays a significant role in Ahlstrom's growth strategy in Asia.

"In addition to Ahlstrom´s strong footprint in Europe and the Americas, we have lately started to establish a solid manufacturing platform in Asia as well. Ahlstrom´s strengthened presence in China will also help us to better serve our global customers based in the area, increase our market share and build a platform for further growth in the region. As China is among the world's fastest growing major economies and the the industry of filtration media for transportation is growing at an annual rate of over 10%, the market in the country is expected to grow significantly in the coming years", Jan Lång says.

In addition to the Binzhou plant, Ahlstrom has three other manufacturing sites in Asia: one in Hyun Poong, South Korea, one in Mundra, India, and one in Wuxi, China.The Hyung Poong plant also manufactures filtration materials for automotive industry where as the Mundra plant produces nonwoven fabrics for the medical market and the Wuxi site for dust filtration. In addition to the manufacturing plants, Ahlstrom has sales offices in nine major cities in Asia. Altogether, Asia currently accounts for about 10% of the Group's net sales.

Binzhou region in brief

· The town of Binzhouis located on the northern part of the Shandong province, on the northern bank of the Yellow River

· The population of Binzhou town is around 3,600,000

· Several international companies have manufacturing presence in Binzhou

Further information:

Ahlstrom Group

Jan Lång, President & CEO, tel. +358 10 888 4700

Tommi Björnman, Executive Vice President, Filtration, tel. +39 011 926 0111

Roberto Boggio, Vice President, Filtration, Asia, tel. +82 53 611 0491/92

Sonoco-Alcore Announces European Paperboard Price Increase

Sonoco-Alcore S.a.r.l. will increase prices in Europe for all uncoated recycled paperboard (URB) grades by EUR 40, or £35, per metric ton, effective with shipments on October 18, 2010, according to Eddie Smith, vice president, Sonoco-Alcore.

"This price change is unfortunately unavoidable. Over the past quarter, we have seen a severe increase in the cost of starches and chemicals as well as an overall tightness of raw material supply and URB in the market," said Smith.

Sonoco-Alcore S.a.r.l. is wholly owned by Sonoco (NYSE: SON) and operates 30 tube and core plants and six paper mills in Europe.

SOURCE: Sonoco

Sonoco

Roger Schrum, 843-339-6018

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

| "Safe Harbor" Statement under the Private Securities Litigation Reform Act of 1995: Statements in this press release regarding Sonoco's business which are not historical facts are "forward-looking statements" that involve risks and uncertainties. For a discussion of such risks and uncertainties, which could cause actual results to differ from those contained in the forward-looking statements, see "Risk Factors" in the Company's Annual Report or Form 10-K for the most recently ended fiscal year. |

BASF to establish world-scale production of water treatment and paper chemicals in Nanjing, China

- Wholly-owned world-scale plants with capacities of 40,000 tons of quaternized cationic monomers and 20,000 tons of cationic polyacrylamides per year

- Production planned to start up in 2012

BASF has decided to establish a wholly-owned world-scale production base for water treatment and paper chemicals in Nanjing, China, with the construction of a 40,000 t/a quaternized cationic monomers plant and a 20,000 t/a cationic polyacrylamides plant.

The two BASF plants, which are designed to high international standards of safety and energy efficiency, are expected to start up production in the third quarter of 2012. They mark the first Asian manufacturing of these products for BASF.

The two BASF plants, which are designed to high international standards of safety and energy efficiency, are expected to start up production in the third quarter of 2012. They mark the first Asian manufacturing of these products for BASF.

“This investment underlines our long-term commitment to China both in economic and environmental terms,” said Dr. Albert Heuser, President Market and Business Development Asia Pacific. “The establishment of these plants is part of our growth strategy for Asia Pacific to double our sales by 2020 while contributing to a sustainable future.”

Cationic monomers are a key feedstock for cationic polyacrylamides. Cationic polyacrylamides are used as organic flocculants in the water treatment industry and as retention aids in the paper industry.

The water treatment and papermaking industries are growing at a high rate in Asia, particularly in China. This is a result of substantial investment in water treatment infrastructure and strongly increasing paper consumption, fuelled by high growth in regional GDP.

“We are one of the leading suppliers to the water treatment industry with a strong platform for future growth in a very attractive market. This investment is our long-term response to the growing demand from our customers in Asia,” said Hans W. Reiners, President Performance Chemicals division, which also includes BASF’s Water Solutions business. “Nanjing is an ideal location for such an investment as it offers BASF a high degree of backward integration”, Reiners added.

"Following our recent announcement of plans to build a plant for XSB dispersions in Huizhou, South China, this investment further demonstrates our commitment to the fast-growing paper industry in emerging Asia, especially in China. Our ability to produce within the region will underpin our supply reliability and the success of our customers," said EngSoo Chew, Senior Vice President Paper Chemicals Asia Pacific.

The plants will be built according to BASF’s high global standards of safety and environmental protection. This process for planning a plant is laid down in a binding guideline that is valid throughout the BASF Group. The five-step review system for environmental protection, health and safety (EHS reviews) covers all aspects of process safety, occupational health and environmental protection. Furthermore, BASF places particular importance on training its safety experts worldwide to implement the same high safety standards in all its production facilities.

About BASF’s Water Treatment Chemicals

The product range of BASF’s Water Solutions business includes products used in the key processes of municipal and industrial water treatment: products to clarify the raw water used for the production of potable water, as well as treating the wastewater stream and reducing sludge volumes. Our products are marketed worldwide. We are one of the leading suppliers in these fields. Further information on our products may be found at: www.watersolutions.basf.com

About BASF’s Paper Chemicals

BASF’s Paper Chemicals division offers process chemicals to optimize costs and increase machine efficiency, functional chemicals to lend specific properties to paper, and finishing chemicals to improve the appearance and performance characteristics of printed paper and board. With this comprehensive portfolio, BASF is the leading supplier of paper chemicals worldwide.

BASF established Paper Chemicals as a separate division when it acquired Ciba in April 2009. The ISO 9001-certified Paper Chemicals division operates sites in Europe, Asia and the Americas. For more information, go to

About BASF

BASF is the world’s leading chemical company: The Chemical Company. Its portfolio ranges from chemicals, plastics and performance products to agricultural products, fine chemicals and oil and gas. As a reliable partner BASF creates chemistry to help its customers in virtually all industries to be more successful. With its high-value products and intelligent solutions, BASF plays an important role in finding answers to global challenges such as climate protection, energy efficiency, nutrition and mobility. BASF posted sales of more than €50 billion in 2009 and had approximately 105,000 employees as of the end of the year. Further information on BASF is available on the Internet at www.basf.com.

Press contact:

Asia Pacific

Genevieve Hilton

Tel: +852 2731 0197

Mobile: +852 9025 9857

E-mail:

This email address is being protected from spambots. You need JavaScript enabled to view it.

For Greater China

Joanna Shen

Tel.: +86 21 2320 3053

Fax: +86 21 2320 3099

E-mail:

joanna.shen@basf.com

Woody biomass prices in the US increased in the 3Q/10 after having trended downward since early 2009, reports the North American Wood Fiber Review

Woody biomass prices in the US increased in the 3Q/10 after having trended downward since early 2009, reports the North American Wood Fiber Review

Prices of wood fiber used for energy declined during most of the recession, partly as a result of the low cost of fossil fuels, which can serve as an alternative source for many industrial energy consumers. However, in the 3Q, biomass prices were up in the South, the Northwest and Southwest, according to the North American Wood Fiber Review. This trend break occurred mainly because of reduced fiber supply and generally lower biomass inventories.

The full article can be found in the attached PDF file.....

FSC and AkzoNobel partner to promote forest stewardship

FSC is pleased to announce the launch of the FSC Global Partner Program through an exclusive partnership agreement with AkzoNobel. The official start of the partnership was celebrated at the FSC Global Partner Awards ceremony which honored companies from around the world for their commitment to FSC certification and promotion of responsible forest management worldwide.

The partnership between FSC and AkzoNobel will highlight the vital significance of forests and raise awareness of FSC’s mission to promote responsible forest management worldwide. As a global leader in sustainability and the largest global paints and coatings company, AkzoNobel will support FSC’s outreach efforts by educating customers and helping to drive demand for FSC certified products. AkzoNobel has also committed to support the development of local FSC National Initiatives and to set up a global partnership fund to support social policy projects.

Market demand for FSC certified products drives uptake of FSC certification at the forest management level, and contributes to improved environmental and social conditions. In this way, FSC certification is a tool through which businesses and consumers can help protect the world’s forests. The FSC Global Partner Program is designed to support the effective mechanism of FSC certification by increasing awareness and action towards responsible procurement decisions.

“As a global leader in sustainability, AkzoNobel is an ideal partner to promote awareness of FSC worldwide. Both FSC and AkzoNobel are invested in the care of natural resources, and the partnership draws on the synergy between sourcing from well-managed forests and maintaining long-term objectives for the life cycle of forest products. By working together through the FSC Global Partner Program, we will not only raise awareness of FSC certification but also bring attention to innovations that address environmental, social and economic issues in forest management,” FSC Director General Andre de Freitas.

The FSC Global Partner Program is closely aligned with FSC’s Global Strategy objectives to provide leadership in advancing globally responsible forest management, ensure equitable access to the benefits of the FSC system, to develop the market for FSC certified products and to strengthen its global network.

Insurance Buyers Rank Commercial Property Insurer FM Global #1 in Canada for Quality and Client Satisfaction

Canada-based corporate insurance buyers have ranked commercial property insurer FM Global as number one for “overall carrier quality” and “overall client satisfaction,” according to the latest independent research conducted by Greenwich Associates, a leading international research firm in institutional financial services.

More than 100 Canada-based risk managers and key decision makers for insurance services participated in the study, which was conducted between July and August 2010. Participants represent companies with annual revenue greater than CAN$256 million.

The news follows another study just released by Greenwich Associates in which U.S. insurance buyers ranked FM Global as number one for claims performance.

Commemorating its 175th anniversary in October 2010, more than one out of every three Fortune 1000 companies and similar-sized organizations operating in more than 130 countries work with FM Global to develop robust property insurance and engineering solutions to protect business operations from property risk. The company has been named “Best Property Insurer in the World” by Euromoneymagazine and “Best Global Property Insurer” by Global Finance magazine. The company is rated A+ (Superior) by A.M. Best and AA (Very Strong) by Fitch Ratings.

International Paper Completes Sale of 163,000 Acres of Real Estate Properties

International Paper has announced that it has closed the sale of 163,000 acres under contract with Figure 8 Partners, LP, an affiliate of Rock Creek Capital (the "Partnership").

The total consideration of $199 million includes $160 million in cash and $39 million, plus interest, to be received no later than three years from closing. In addition, IP has received a 20% profits interest in the Partnership. The properties are located in the southeastern part of the United States.

SOURCE International Paper

SCA enters into R&D cooperation

SCA has entered into a long-term cooperation agreement with BioGaia with the aim of developing new health-oriented products. The objective is to combine BioGaia’s expertise in the field of probiotic bacteria and applications technologies with SCA’s distribution network and know-how in the area of hygiene products.

“Probiotic bacteria are microorganisms that confer various types of health benefits. SCA is already active in this area and holds a number of interesting patents. By applying BioGaia’s work methods, we hope to transform these concepts into commercially viable products,” says Ingela Torstensson, head of global research for SCA’s hygiene products.

One example of a research area is the potential of probiotic bacteria to prevent urinary tract infections, which is very common among women suffering from incontinence.

The agreement enables the companies to share know-how in related areas, but from completely different perspectives.

SCA is one of the largest companies in personal care products, with the Libresse and TENA brands. As global market leader for incontinence products, Ingela Torstensson believes that it is particularly relevant for SCA to pursue development beyond the current work boundaries:

“The cooperation is a good example of open innovation, which in this case means that we take ideas from our own company and identify an external environment that offers optimal development potential. It is clear that we have complementary expertise and, given our knowledge of innovation programmes, it would not be surprising if we were to achieve results in entirely unexpected areas.”

BioGaia is listed on the small cap segment of the Nasdaq OMX Nordic Stockholm.

Stockholm, 23 September 2010

For additional information, please contact

Petter Tiger, Press & Media Officer, +46 8 788 53 62