Ian Melin-Jones

Mondi launches its new digital printing paper brand DNS®: Digital Needs Specialists

Mondi launches its new digital printing paper brand DNS®: Digital Needs Specialists

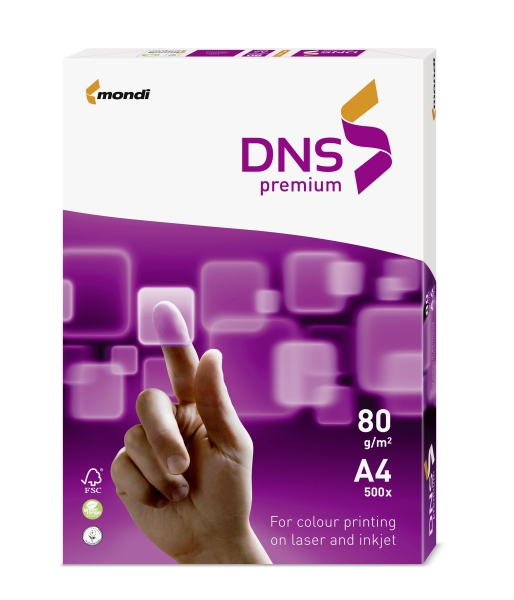

Mondi expands its digital printing portfolio to include DNS®, the new paper brand that offers professional printers a single solution for multiple applications on all digital printing presses. DNS® premium kicks-off the brand-launch as the first paper on the market from the DNS® range.

Mondi launches DNS®as its new brand of uncoated fine papers. “DNS® was developed with the requirements of digital specialists in mind. We recognized that professional printers needed a single paper they could rely on in an industry that demands a lot of versatility,” explains Johannes Klumpp, Marketing and Sales Director for Mondi Uncoated Fine Paper.

Mondi launches DNS®as its new brand of uncoated fine papers. “DNS® was developed with the requirements of digital specialists in mind. We recognized that professional printers needed a single paper they could rely on in an industry that demands a lot of versatility,” explains Johannes Klumpp, Marketing and Sales Director for Mondi Uncoated Fine Paper.

DNS® premium is the first product to stem from the DNS®brand. It is produced for use on digital production machines anddry toner machines such as iGen and Nexpress, as well as office laser printers, inkjet printers and copiers, making it a multifaceted product for use in both professional press rooms and offices.

“The launch of DNS® is an exciting milestone in the growth of our digital printing paper portfolio,” says Klumpp. “DNS® premium is also pre-print guaranteed and suitable for off-set printing, which is an attractive feature for professional printers, as having one paper on stock for every printing press is now a realistic option.”

DNS®premium has a high whiteness factor that shows excellent contrast for text and graphic printouts. Due to ColorLok® Technology, office inkjet printers with pigmented ink can also create impressive full colour brochures, presentations or other printed materials that demand high-impact colour saturation.

DNS® premium can be recognized by its purple wrapper with the digital motif of a hand operating a touch screen. “We will be adding more papers to the DNS® brand. Our customers have more to look forward to in the upcoming months,” says Klumpp.

Mondi has spearheaded a number of initiatives in response to the growing digital printing market. During the past year, Mondi introduced its ongoing series of Digital Specialist Forums, where professional printers and key customers familiar with professional and office printing environments convene to discuss current and upcoming trends in digital printing.

DNS®premium and the digital printing paper portfolio are developed and produced by Mondi Neusiedler, a mill renowned for its innovations, high quality paper production and environmental standards. DNS®premium is certified with the FSC® (Forest Stewardship Council) mark and the EU-Flower. It also belongs to Mondi’s Green Range. All Green Range papers are either FSC®-certified, bleached without chlorine (TCF) or 100% recycled.

and environmental standards. DNS®premium is certified with the FSC® (Forest Stewardship Council) mark and the EU-Flower. It also belongs to Mondi’s Green Range. All Green Range papers are either FSC®-certified, bleached without chlorine (TCF) or 100% recycled.

The Green Range reflects Mondi’s commitment to responsible manufacturing practices, as all products are produced according to the leading environmental and social guidelines. Keeping a steady focus on sustainability, Mondi continually strives for the careful selection and responsible use of raw materials and for significant reductions in emissions to air, water and land. The leading environmental position was recently recognized by WWF – Mondi ranks as number one in the global paper company environmental index.

Wood fiber prices for the global pulp industry rose 11%

Wood fiber prices for the global pulp industry rose 11%, reaching pre-financial crisis levels in the 1Q/2010, reports the Wood Resource Quarterly

The strong pulp market has pushed wood fiber costs upward in most regions around the world the past 12 months. Both the softwood and hardwood wood fiber price indices (SFPI and HFPI) have gone up the past year and were more than 11 percent higher in the 1Q/10 as compared to 1Q/09, reports the Wood Resource Quarterly.

The full article can be found in the attached PDF file.....

Stora Enso ranked best in Europe in the Dow Jones Sustainability Indexes

The Group has been included in the Index ten times

Stora Enso has received the highest score among the forestry and paper companies listed in the European Dow Jones STOXX Sustainability Index. This is the 10th year running that Stora Enso has been included in the index. This year Stora Enso was also listed in the DJSI World Index.

Stora Enso was given a higher score than any other company in the industry for eco-efficiency and social reporting. The Group was also equal top-ranked for the sustainable management of forests, as well as environmental policies and management systems.

The members of the DJSI for 2010-2011 were announced on Thursday 9 September 2010.

“We have been listed in the index for ten years already, but to be ranked the best European company in the DJSI World Index is a great achievement. I am happy to see that our efforts are paying off,” said Stora Enso's CEO Jouko Karvinen.

“It is all about improvement. To be listed in this index you need to improve your performance every single year. We have been working hard to get here, and we will keep on making such efforts.”

The Dow Jones Sustainability Indexes are the first global indexes to track the financial performance of leading sustainability-driven companies. Companies are included in or deleted from the indexes based on their economic, environmental and social performance. The indexes provide investors with reliable and objective benchmarks to manage their sustainability portfolios.

For more information about the indexes, see www.sustainability-index.com

For further information about Stora Enso's sustainability work, please contact:

Eija Pitkänen, SVP Sustainability, tel. +358 2046 21348

Eeva Taimisto, Communications Specialist, tel. +358 2046 21263

www.storaenso.com

Billions to save in the paper business

Innventia, a research institute, continues to revolutionise the paper business. Its research work has now produced a new method that will result in a stronger paper with lower production costs and reduced raw materials consumption. This dream scenario has now become a reality for many companies in the paper business.

Innventia, a research institute, continues to revolutionise the paper business. Its research work has now produced a new method that will result in a stronger paper with lower production costs and reduced raw materials consumption. This dream scenario has now become a reality for many companies in the paper business.

“For a paper mill that produces 450,000 tonnes of the new paper per year, this technology means an annual savings of approximately 120 million Swedish kronor,” says Daniel Söderberg, Research Manager and initiator at Innventia and the person behind the previous work.

A lighter IKEA catalogue

For a product such as the IKEA catalogue, approx. 200 million copies of which are distributed each year, this means enormous savings. For the papermaking industry as a whole, this implies a savings in billions of kronor.European collaborative project

As of June 2010, Innventia is leading BoostEff, an EU project with a total budget of 11 million Euro, to demonstrate the industrial and economical potential of the method. Using Aq-vane, with its possibilities for advanced dosage, Innventia, in collaboration with Stora Enso, a paper producer, is developing the kind of paper that is used in catalogues and magazines.

The Aq-vane technique has the potential to generate increased profits based on the form of savings in the fibre raw materials and energy.

“Within BoostEff several companies and institutes from around Europe are collaborating with us at Innventia,” explains Daniel. “When the project comes to an end in 2013, the technology will also be available to the rest of the industry giving the opportunity of an increased profitability and, most of all, an improved paper.”

Metso to perform service to earthquake damaged boiler for Arauco, Chile

Metso will perform service and restoration of one recovery boiler at Arauco pulp mill for Celulosa Arauco y Constitucíon S. A. The boiler was damaged during the earthquake eruption in Chile in February 2010. The total value of the order is EUR 27 million. Around 15% of the order was included in Energy and Environmental Technology´s Q2 orders received and 85% is included in Energy and Environmental Technology`s Q3 orders received.

Dismantling and erection service will proceed from July until December 2010, and includes inspection services, material supply as well as training and start up assistance.

Arauco is one of the largest forestry businesses in Latin America in terms of forest owner ship and plantation performance, and a global leader in the manufacture of market pulp, panels and sawn timber.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

Further information for the press, please contact:

Owe Asp, General Manager, Service sales, Power business line, Metso, tel. +46 708 22 09 29

Stora Enso to permanently close down 195 000 tonnes per year newsprint machine at Maxau

Stora Enso will, subject to decisions by the respective German corporate bodies, permanently shut down the 195 000 tonnes per year newsprint machine at Maxau Mill in Germany by the end of November 2010. Newsprint production at Maxau will end due to weak European market outlook and high production costs. Sales prices have fallen significantly while recovered paper and wood costs have risen strongly. As a result, there is no realistic prospect of newsprint production at Maxau Mill becoming profitable again in the foreseeable future.

“The European newsprint market is structurally heavily oversupplied and there has been no substantial recovery in demand since consumption collapsed in early 2009. The outlook for demand is negative too. In addition, the availability of wood and recycled fibre in Germany has been limited, so costs have been rising fast recently,” says Juha Vanhainen, EVP, Publication Paper Business Area.

The permanent shutdown of the newsprint machine at Maxau Mill will reduce European newsprint capacity by approximately 1.5%.

The shutdown will affect about 180 of the 617 people employed at Stora Enso's Maxau Mill. Stora Enso is working on a social plan for the employees affected by the restructuring measures. The two uncoated magazine paper machines with total annual capacity 530 000 tonnes at Maxau Mill will remain in operation.

Estimated financial impact

Stora Enso expects the permanent shutdown of the newsprint machine at Maxau to have the following financial impacts on the Newsprint segment:

--------------------------------------------------------------------------------

| | EUR million |

--------------------------------------------------------------------------------

| One-time non-cash fixed asset and working capital | 13 |

| write-downs in Q3/2010 | |

--------------------------------------------------------------------------------

| One-time cash provisions in Q3/2010 as non-recurring | 20 |

| items | |

--------------------------------------------------------------------------------

| One-time working capital reduction | 4 |

--------------------------------------------------------------------------------

| Annual sales reduction | 40 |

--------------------------------------------------------------------------------

| Annual operating profit improvement | 12 |

--------------------------------------------------------------------------------

For further information, please contact:

Bernd Rettig, EVP, Country Manager Germany, tel. +49 211 581 2310

Juha Vanhainen, EVP, Publication Paper Business Area, tel. +358 2046 21343

Lauri Peltola, Head of Communications, tel. +358 2046 21380

Ulla Paajanen-Sainio, Head of Investor Relations, tel. +358 2046 21242

www.storaenso.com

www.storaenso.com/investors

Verso Paper Corp. Launches Facebook Page

Verso Paper Corp. has announced the launch of its corporate Facebook page with an initial focus on increasing the reach of the company's college recruiting initiatives.

The Verso Paper Corp. Facebook page will provide potential college recruits with the company's campus recruitment schedule and timely news about Verso, including features on the company's sustainability initiatives and community activities.

"We believe our use of Facebook as an avenue to communicate with potential job applicants will help us continue attracting the right candidates to Verso," said Lyle Fellows, Senior Vice President of Manufacturing and Energy. "Finding and retaining the right talent for our manufacturing and corporate locations is critical to the ongoing success of our company."

Click here to access the Verso Paper Corp. Facebook page.

About Verso

Based in Memphis, Tennessee, Verso Paper Corp. is a leading North American producer of coated papers, including coated groundwood and coated freesheet, and supercalendered and specialty products. Verso's paper products are used primarily in media and marketing applications, including magazines, catalogs and commercial printing applications such as high-end advertising brochures, annual reports and direct-mail advertising. Additional information about Verso is available on the company's Web site at www.versopaper.com.

Forward-Looking Statements

In this press release all statements that are not purely historical facts are forward-looking statements within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934. Forward-looking statements may be identified by the words "believe," "expect," "anticipate," "project," "plan," "estimate," "intend," and similar expressions. Forward-looking statements are based on currently available business, economic, financial and other information and reflect management's current beliefs, expectations and views with respect to future developments and their potential effects on Verso. Actual results could vary materially depending on risks and uncertainties that may affect Verso and its business. For a discussion of such risks and uncertainties, please refer to Verso's filings with the Securities and Exchange Commission. Verso assumes no obligation to update any forward-looking statement made in this press release to reflect subsequent events or circumstances or actual outcomes.

SOURCE: Verso Paper Corp.

Verso Paper Corp. Sondra Dowdell, Corporate Communications Manager, 901-369-4128 This email address is being protected from spambots. You need JavaScript enabled to view it. www.versopaper.com

Yorkshire consortium plans commercial printable electronic products

A consortium of Yorkshire printers and designers led by Print Yorkshire - focusing on the development of products incorporating printed electronic elements is very close to a commercially produced and a commercially acceptable product.

The consortium successfully bid for funding from The Northern Way (an umbrella body set up by the three northern Regional Development Agencies) in a process administered by Printable Electronics Technology Centre (PETEC) in Sedgefield, County Durham.

Members of the consortium are award winning Sheffield printer Evolution, Leeds screen and digital printer RPS2000 and North Yorkshire designer and publisher Colour Heroes. The technical know how is provided by Cambridge-based interactive printed media company Novalia.

Print Yorkshire’s Project Manager Mike Hopkins comments on gaining funding: “We were in fierce competition for this funding but I think the panel liked the fact that we included in our consortium SME commercial printers, who are the cornerstone of the printing industry and most likely to achieve the maximum adoption of the technologies.”

The most technically challenging aspect of the project has been to find suitable litho inks. Novalia’s Chris Jones said: “Even with my ink experience I have been left scratching my head sometimes.” At the last team meeting PETEC’s Chief Executive Tom Taylor offered support and assistance to relieve any bottlenecks with this aspect of the development.

The project is entering its final phase with all the lessons of the first few months coming together. The final print trials will be carried out in the next two weeks and then designs finalised and production of the commercially orientated product will begin. The project is scheduled to end in November this year.

For more information contact: This email address is being protected from spambots. You need JavaScript enabled to view it.

DS Smith Plc Interim Management Statement

DS Smith Plc (“DS Smith” or “the Group”), the international packaging supplier and office products wholesaler, today publishes its Interim Management Statement in respect of the period since 1 May 2010. DS Smith will be holding its Annual General Meeting today at 12 noon.

DS Smith Group

Overall trading in the first quarter of financial year 2010/11 has been encouraging, with good volume growth throughout the group. This is led from progress in the FMCG (Fast Moving Consumer Goods) sector driven by our focus on service, innovation and efficiency.

Packaging

Our Paper and Corrugated Packaging businesses have had a good first quarter with positive demand trends, in Europe and the UK, feeding through to increased volumes. The anticipated phased recovery of paper price increases has led to profits in line with our expectations. Plastics have also had an encouraging start to the year with good volume growth and cost control.

Office Products Wholesaling

The trading performance at Spicers is ahead of last year with profitability increasing due to better product mix. The focus remains on improving mix and on tight cost control to ensure Spicers leverages its strong market positions to take advantage of improving economic conditions.

Business Review

The review of our business strategy is making considerable progress. As set out in June this year, our aims are to create a growing business that is more focused, producing higher margins and returns with less cyclicality. We expect to announce our conclusions at the time of our half-year results on 9 December this year.

Acquisition of Otor

On 7 July 2010 the acquisition of Otor for €247m was announced and completion took place, earlier than planned, on 1 September 2010.

As set out at the time of announcement of the acquisition, we expect Otor to be accretive, before exceptional costs, to both earnings and margins in the first full financial year of ownership, with a return on investment above DS Smith’s weighted average cost of capital.

The integration teams are established and the work is proceeding well to realise annual cost synergies of €9.3 million in the second full financial year of ownership. Combining Otor’s successful, well-established, FMCG focused corrugated packaging business with our existing French operations will create a platform for further revenue opportunities across the wider European market.

Save for the acquisition of Otor as described above, there has been no significant change to the financial position of the Group since the publication of the results for the full year to 30 April 2010.

Pension

We have started consultation with the remaining active employee members of the Group’s UK defined benefit pension scheme with a view to closing the scheme to future accrual. This will help the Group better manage this exposure in the future.

Outlook

The year is progressing in line with expectations underpinned by continued FMCG demand and we continue to grow our business through our continuous focus on innovation and servicing the customer. We look forward to the remainder of the year with confidence.

Enquiries

DS Smith Plc

+44 (0)1628 583 400

Miles Roberts, Group Chief Executive

Steve Dryden, Group Finance Director

Rachel Stevens, Head of Investor Relations

Tulchan

+44 (0)20 7353 4200

John Sunnucks

David Allchurch

Matthieu Roussellier

New High Performance Michem Flex P1883 is a Water Based Extrusion Primer

Michelman has introduced Michem® Flex P1883, a water-based extrusion primer that provides strong adhesion to aluminum foil and paper, bonds well to extrusion coated resins, and protects foil from corrosion. It provides excellent chemical resistance to water, many acids and spices, fragrances and flavors. Because of its strong adhesive properties, it also helps prevent packages from delaminating when in contact with aggressive contents.

The new primer is ideal for applications including foil-based packages for condiments such as ketchup, mustard and salad dressings, soup and seasoning packets, dry milk powders, fruit juice powders, gummy candies, and virtually any type of paper/poly/foil/poly pouches or paper-based cans found on grocery shelves.

Michem Flex P1883 features 25% solids content and excellent freeze/thaw stability. The relatively high solid content means converters are buying and shipping less water and more of the solids they need to achieve desired dry coat weights. The new primer further reduces costs since it requires less drying time.

Michelman’s Michem Flex Primers are all water-based extrusion primers designed specifically for converters of flexible packaging substrates including paper, film and foil. They meet regulations for food packaging, and come as concentrated dispersions, minimizing shipping costs. They can be applied with smooth roll, flexo or gravure coaters and dried with hot, circulating air.

About Michelman

Michelman is a global developer of water-based barrier and functional coatings for flexible film packaging, paperboard, and corrugated cartons; and water-based surface modifiers, additives and polymers for numerous industries including wood care, industrial coatings, inks, fibers, composites, and construction products. Michelman serves its multinational and regional customers with production facilities in the U.S., Europe and Singapore, and a worldwide network of highly trained field technical support personnel.

Michelman Global Headquarters

9080 Shell Road

Cincinnati, OH 45236

1-800-333-1723 (US & Canada); (513) 793-7766 (Worldwide)

(513) 793-2504 (Fax)

www.michelman.com