Ian Melin-Jones

NB hands out Crown forest biomass to eight companies

Eight allocations for Crown forest biomass have been awarded to New Brunswick companies, to be used for renewable carbon-neutral energy or to be incorporated into value-added products.

The biomass material consists of branches, tree tops and foliage not traditionally used by the forest industry. The allocations total 1,276,000 cubic metres of biomass, which the government estimates is enough to displace about 200 million litres of oil.

"Most of the biomass will be used in co-generation facilities to produce energy for use by these companies in their own facilities, and potentially surplus electricity for sale to the provincial power grid," said Natural Resources Minister Wally Stiles.

Twin Rivers Paper Co. Inc. received the largest allocation, 308,000 cu. m. The biomass will be used to produce carbon-neutral energy for its Edmundston mill.

The other allocations were: 272,000 cu. m to AV Cell Inc. for energy production at its mill in Atholville; 221,000 cu. m to AV Nackawic Inc. for a planned co-generation facility for its mill in Nackawic; 139,000 cu. m to Lake Utopia Paper to help fuel a planned co-generation facility at its mill in St. George; 138,000 cu. m to Irving Pulp and Paper Ltd. for co-generation at its Saint John plant; 76,000 cu. m to Irving Paper Ltd. of Saint John for co-generation; 62,000 cu. m to Groupe Savoie Inc. to integrate into value-added products produced at its plant in St. Quentin; and 60,000 cu. m for the J.D. Irving Ltd. sawmill in Chipman for co-generation.

Stiles said the Department of Natural Resources has developed a Crown Land Forest Biomass Harvesting Policy and related assessment tools to ensure that biomass material is harvested in a sustainable manner. The volume of this material available in any given year will depend on the amount of wood harvested in the same year.

Sixteen proposals were received by the Department of Natural Resources in response to a Request for Proposals (RFP) from parties interested in the biomass material. Individuals, corporations or other provincial bodies with existing or proposed New Brunswick-based processing facilities were eligible to apply.

"The response to the RFP was so overwhelming that the requested allocations far exceeded the level of biomass material that can be harvested on a sustainable basis,'" said Stiles.

"It is encouraging to see so many New Brunswick companies express such a strong desire to acquire Crown forest biomass for green energy projects," said Stiles. "Our government has worked hard to develop this new forest resource and bring about the benefits it will provide for the bio-energy sector as well as a cleaner environment."

M-real is planning to partially divest Reflex paper mill

M-real Corporation, part of Metsäliitto Group, has today signed a Memorandum of Understanding (MOU) regarding a partial divestment of the Reflex mill to Metsä Tissue Corporation, also a part of Metsäliitto Group, for approximately EUR 10 million. The planned divestment includes the paper machine 5 and related real estate as well as certain infrastructure assets. Metsä Tissue is planning to convert the paper machine to grades that are not competing with M-real's grades.

Based on preliminary plans, Metsä Tissue would employ about 50 employees, reducing the corresponding amount of redundancies agreed earlier at Reflex site.

If the transaction is consummated as planned M-real books a positive EUR 15 million non-recurring item in Speciality Papers business area's operating result related to the transaction proceeds and the partial reversal of earlier announced personnel cost provisions. Cash impact would be approximately EUR 10 million positive taking into account certain investments needed in the Premium Papers production at the site.

The transaction is expected to be closed during 4Q 2010. M-real will continue to further develop the paper park concept at Reflex site.

M-real announced on 21 May 2010 that Reflex mill will be developed based on a paper park concept and that the target is to find industrial partnerships and thus create new jobs at the mill site. At the same time, it was announced that negotiations to reduce M-real Zanders mills' headcount by 220 were finalized and Speciality Papers business area's 2Q 2010 operating result would include an approximately EUR 16 million non-recurring cost provisions.

For further information, please contact:

Matti Mörsky, CFO, tel. +358 10 465 4913

Juha Laine, Vice President, Investor Relations and Communications, tel. +358 10 465 4335

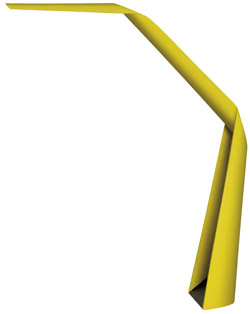

The paper task light in DuraPulp by Södra wins design award

w101 - the DuraPulp biodegradable lamp, developed by Swedish lighting company Wästberg in close collaboration with Swedish forestry industy company Södra and Swedish architects and designers Claesson Koivisto Rune, has been awarded Design S 2010: the Swedish Design Prize.

w101 - the DuraPulp biodegradable lamp, developed by Swedish lighting company Wästberg in close collaboration with Swedish forestry industy company Södra and Swedish architects and designers Claesson Koivisto Rune, has been awarded Design S 2010: the Swedish Design Prize.

The lamp was successfully launched in April 2010 at Superstudio Più during the Milan Design Week and generated massive interest. The public showing made it clear that the lamp was not only functional, but delivered perfect light from only five watts.

Now the lamp has won Sweden's biggest and most prestigious design prize, Design S. The bi-annual award is granted by the Swedish Design Association. A total of ten awards were given this year across all categories.

The jury's view:

"The lamp means a step towards a more sustainable future. It bears witness to the creativity that environmental challenges can inspire."

Magnus Wästberg, founder and CEO of Wästberg:

"Combining old wisdom with ground-breaking technology is elementary to Wästberg's philosophy. Paper has been used throughout history for making lamp shades. Now we are using paper for the actual structure of the fixture and adding advanced LED technology."

Karin Emilsson, director of technology at Södra and head of Södra Innovation:

"One principal mission for Södra is to, together with innovative partners, develop and supply tomorrow's raw materials based on renewable forest resources. The DuraPulp lamp by Wästberg meets high customer standards of functionality and design although it's made out of a new, totally renewable, material."

NewPage Announces Executive Leadership Changes

NewPage Corporation announced today that E. Thomas Curley has resigned as president and chief executive officer and as a director of NewPage and its affiliates. In addition, NewPage announced that the Boards of Directors of NewPage and its affiliates have accepted the resignations of Mark A. Suwyn as chairman and a director of the companies, and the resignation of Michael Edicola as vice president, human resources.

NewPage also announced the appointment of Robert L. Nardelli as a director and non-executive chairman of the Board of Directors of NewPage and its affiliates. Mr. Nardelli is currently the chief executive officer of Cerberus Operating and Advisory Company, an affiliate of the controlling stockholder of NewPage, a role that Mr. Nardelli will continue while acting as non-executive chairman of NewPage and its affiliates.

Mr. Nardelli stated "We thank Mark, Tom, and Mike for their accomplishments at NewPage, and wish them well in their future endeavors. I will be involved on an ongoing basis as NewPage undergoes this transition to new leadership."

The NewPage Board of Directors has formed an executive search committee to identify, interview and recommend to the Board a chief executive officer. The committee will consider both internal and external candidates for the position. The company will broadcast an investor and analyst conference call regarding these leadership changes today, June 15, 2010, at 11:00 a.m. (ET) with access available through the Internet and telephone. The teleconference is expected to last approximately one hour and will be hosted by Robert L. Nardelli, director and non-executive chairman of the Board of Directors of NewPage and its affiliates. Investors and analyst may access the call by dialing (866) 793-1343 (toll-free domestic) or (703) 639-1314 (international), conference ID 1464734. There will not be a replay of the call made available.

The live conference call and presentation slides may be accessed on the NewPage Web site at www.NewPageCorp.com. Click on the link to the Conference Call and Webcast and follow the instructions to access the Webcast in listen and view mode. Please go to the Web site at least one hour prior to the call to register, download and install any necessary audio software. After the live Webcast, the presentation may be found on company's Web site in the Investors Relations section.

Selig family buys back into print

Former Bluestar chief executive Geoff Selig has re-entered the print industry with the acquisition of Sydney-based web offset printer The Quality Print Group, which has begun trading under the newly created entity CaxtonWeb.

Under the agreement, CaxtonWeb will continue to operate from the current site. Quality Managing director Paul Canty retired from the business this week and will have no ongoing equity participation or operational involvement. Mike Shannon has been appointed managing director of CaxtonWeb.

Commenting on the acquisition Geoff Selig says, “The Selig family are very pleased to have re-entered the print communications sector and look forward to working with Mike and the team to recalibrate and strengthen the current business for the benefit of our customers, staff and suppliers.”

He continues, “The web offset market has held up and this company provides a niche service so we believe we can do well in the competitive market notwithstanding the secular decline.”

The CaxtonWeb board currently comprises Geoff Selig, Paul Selig, also formally of Bluestar, and Mike Shannon, former managing director of Webstar until his retirement last year. Further appointments to both the board and the senior management team of the business will be made in the near future.

Also commenting, Mike Shannon says, “Our goal is to drive a values based, technology driven, customer focused and sustainable business that is highly respected within the sector in which we operate.”

CaxtonWeb's print work will include niche publications, retails catalogues and government publications.

Billerud's Financial calendar for 2011 and date of AGM

Billerud's financial calendar for 2011 will be as follows:

Year-end report 2010 15 February 2011

Interim report January-March 2011 20 April 2011

Interim report January-June 2011 21 July 2011

Interim report January-September 2011 28 October 2011

The Annual General Meeting will be held on 4 May 2011.

For further information, please contact:

Bertil Carlsén, CFO, +46 8 55333507, +46 730211092 Sophie Arnius, Investor Relations Manager, +46 8 55333524, +46 705908072

The information is such that Billerud is obligated to publish under the Swedish Securities Market Act. Submitted for publication at 11.00 a.m. on 15 June 2010.

Stora Enso plans temporary lay-offs at sawmills in Finland

Stora Enso will start co-determination negotiations concerning possible temporary lay-offs at its Finnish sawmills, which are at Kitee, Uimaharju,Varkaus and Honkalahti. The planned lay-offs are in response to the threat that wood cost levels in Finland will become even more uncompetitive if current trends continue.

“We are increasingly concerned by the trend in Finnish raw material prices. We need to prepare ourselves to take rapid corrective actions if raw material prices continue to escalate and can no longer be compensated by increases in end-product prices or efficiency improvements,” says Hannu Kasurinen, EVP, Stora Enso Wood Products.

The total number of employees affected by the co-determination negotiations in Finland is about 500. The negotiations address the plan to curtail production at individual sawmills if necessary through temporary lay-offs between 1 September and 31 December 2010. In Finland Stora Enso has a total capacity of about 1.3 million cubic metres of sawn timber per year.

For further information, please contact:

Hannu Kasurinen, EVP, Stora Enso Wood Products, tel. +358 2046 21222

Ulla Paajanen-Sainio, Head of Investor Relations, tel. +358 2046 21242

Päivi Kauhanen, Director, Communications in Finland, tel. +358 2046 21380

Close contacts leads to efficient cooperation

- We informed about different methods and analysis equipments as well as about their respective strengths and weaknesses, says Per Lindgren. We focused on product development and problem solution techniques like gas chromatography, Fourier transform infrared spectroscopy, light microscopy and scanning electron microscopy. When our customers know more about our different possibilities we become even more efficient and the results are more easily coupled to the process itself.

-It was also useful for us go get more information about the customer's processes and product demands. We see ourselves as an integrated part of the customer's R&D and it is imperative to work closely for the best and fastest result. Several customers have asked for this type of meetings and we see this as an important part of our cooperation.

- It is very important for Husum to have the right problem solution support, often on short notice, says Marie-Louise Wallberg, process coordinator M-real Husum. Close cooperation with clear communication gives us the possibility to use MoRe's competence in the best way. Our aim is to constantly improve the cooperation and the exchange of knowledge by recurring meetings.

MoRe Research Örnsköldsvik AB, SE-891 80 Örnsköldsvik, Sweden, Tel +46 (0)660 751 00, Fax +46 (0)660 759 81, This email address is being protected from spambots. You need JavaScript enabled to view it.

Toscotec completes the SIPAT S.A. tissue machines rebuilds in Meknes Morocco

Toscotec has completed and started up in cooperation with Sipat S.A. the major rebuild of the two machines (#1 and #2 ) housed in the company facility in Meknes Morocco. Sipat S.A. - Societé Industrielle Des Papiers "Tissues" - born in 1978, is owned by the El Kendouci family. With a production capacity of 16.000 tpy, the company can satisfy the request of the Moroccan market, capable of absorbing 70% of SIPAT's capacity, and exports the rest to Senegal and Tunisia. The production comprises in first position facial tissue, second toilet rolls, then bronze medal for table napkins, and last but growing are kitchen towels.

Sipat S.A. - Societé Industrielle Des Papiers "Tissues" - born in 1978, is owned by the El Kendouci family. With a production capacity of 16.000 tpy, the company can satisfy the request of the Moroccan market, capable of absorbing 70% of SIPAT's capacity, and exports the rest to Senegal and Tunisia. The production comprises in first position facial tissue, second toilet rolls, then bronze medal for table napkins, and last but growing are kitchen towels.

The PM1 rebuild affected the dry end area of the production line with the installation of a new hood and new steam & condensate system, increasing the machine drying capacity and so the production of higher BW grades.

PM2 rebuild aim instead was to increase both the paper quality and the production speed with the following interventions: approach flow and headbox modification, the supply of a new steel dryer TT SYD 2500MM with new steam & condensate system, steam hood rebuild and upgrade of the vacuum system.

The rebuilds have been completed according to the time schedule and both of them have been carried out by Toscotec on a turn key basis.

With these important rebuilds Sipat S.A. can now optimise the production cycle, both in terms of production flexibility and in energy costs, and improve paper quality.

Goldenrod introduces new line of Lifting Carts

Goldenrod Corporation has introduced a new line of lifting carts for easy handling of heavy airshafts, chucks or material rolls. GoldenLIFT carts are available in both fixed and movable designs and come equipped with customized tooling to handle airshafts, tissue core plugs, or rolls of material up to 500 lbs. They are constructed of aluminum, which allows for lightweight, easy to maneuver performance and feature large caster wheels, a central, foot-operated brake system, and a detachable remote control pendant with multiple lift speeds, which allows for lift operation from all sides.

GoldenLIFT carts are available in both fixed and movable designs and come equipped with customized tooling to handle airshafts, tissue core plugs, or rolls of material up to 500 lbs. They are constructed of aluminum, which allows for lightweight, easy to maneuver performance and feature large caster wheels, a central, foot-operated brake system, and a detachable remote control pendant with multiple lift speeds, which allows for lift operation from all sides.

"These carts fill a need that we often see at our customer locations," said David Sullivan, Goldenrod Vice President of Sales. "Too often workers are forced to lift heavy shafts or rolls of material, which can lead to back injuries and lost time accidents. The GoldenLIFT carts are specifically designed for shafts, chucks and material rolls, and they provide a safe method for moving these items."

Other features of the new GoldenLIFT carts include:

- Adjustable load capacity

- Adjustable handlebars for setting best ergonomically correct position

- Completely enclosed, narrow, single-lift mast with electric lift screw, providing clear view for safe operation

- Exchangeable power packs