Ianadmin

Ecolab Announces Resignation of J. Erik Fyrwald, president of Ecolab

Ecolab announced that J. Erik Fyrwald, president of Ecolab, will leave the company to become the chief executive officer of Univar, a leading global distributor of commodity and specialty chemicals. Fyrwald joined Ecolab as part of the Nalco merger, which closed December 1, 2011, having served as the chairman and chief executive officer of Nalco since 2008.

Douglas M. Baker, Jr., Ecolab's Chairman and Chief Executive Officer, commented, saying, "While Erik's departure was not unexpected, I will truly miss partnering with him. He is a first-class individual and executive, and the progress we've made in bringing our two companies together is clearly a reflection of his outstanding leadership and support. By bringing Nalco andEcolab together, we've created the global leader in water, hygiene and energy services. Erik has been a strong and consistent partner throughout our negotiation, merger and integration, always operating in the best interests of his company, shareholders and employees. Erik made significant contributions during his tenure to see this merger through and we are grateful for his service. We thank Erik for his partnership and friendship, and wish him well in this next opportunity."

Fyrwald stated, "I have truly enjoyed my association with Doug and the rest of the Ecolab team. The combined company is stronger than either company was before the merger, with better growth prospects and an outstanding management team. I am confident in their ability to achieve superior growth and success in the years ahead. Further, our legacy Nalco businesses are in strong hands, led by excellent managers in whom I have the greatest confidence and expect will continue to aggressively grow and develop their businesses. It is difficult to leave this terrific company, as well as my many Nalco associates, but I look forward to this next phase of my career with excitement."

The Art of Choosing the Right Humidity Instrument

Humidity is measured in a wide variety of industrial applications. Each application has a different set of requirements for humidity instruments, such as measurement range, tolerance to extreme temperature and  pressure conditions, ability to recover from condensation, and ability to operate in hazardous environments.

pressure conditions, ability to recover from condensation, and ability to operate in hazardous environments.

There is no single humidity instrument that is suitable for all needs. The document 'How to Choose the Right Instrument for Measuring Humidity and Dew Point' covers the following topics in order to help in selecting the right humidity instrument:

- Description of different humidity parameters

- Environmental conditions that influence the choice of humidity instrument

- Sensor properties that influence the choice of humidity instrument

- Practical guidelines for selecting a humidity instrument

ISRI Presents Annual Design for Recycling® Award to Cascades

Award recognizes those who are committed to recycling safely and economically.

The Institute of Scrap Recycling Industries, Inc. (ISRI) today presented Cascades Fine Papers Group with their annual Design for Recycling® Award.

The Institute of Scrap Recycling Industries, Inc. (ISRI) today presented Cascades Fine Papers Group with their annual Design for Recycling® Award.

In order to be considered for the Design for Recycling® Award, candidates must demonstrate progress towards ensuring that the products they build and create can be recycled safely and economically, using existing recycling technologies and methods; eliminating or significantly reducing materials that may impede recycling, including hazardous or toxic materials; increasing the yield of a product's recyclable materials; and the increased use of recycled materials in manufacturing.

Cascades earned the recognition by developing and implementing a 100% Recycled and Recyclable Ream Wrapper for its fine paper that eliminates plastic contaminants, reduces waste, and turns waste that would have ended up in a landfill into a recyclable commodity.

ISRI is the force behind Design for Recycling®, a voluntary program that urges manufacturers to make products that can be recycled from the start. Such design benefits not only the environment, but the economy as well as shareholders and consumers recognize the benefits of designing a product that will have several lives.

"Most companies and design engineers are rightly concerned with things like consumer needs, production costs, energy efficiency, and safety," said ISRI President Robin Wiener. "But rarely do you find companies that put emphasis on what happens to their products when they have reached the end of their useful life. It is evident that Cascades is one such company that is concerned with overall life cycle of their products and producer product responsibility."

Cascades is always thinking of ways to reduce a product's footprint. As stated by Julie Loyer, Communication and Sustainable Development Advisor at Cascades Specialty Products Group, "Having to discard the wrapper because it contaminated the paper recycling process was an issue for us. We created a multi-disciplinary team to find a solution and we created a packaging that is as environmentally friendly as the paper it wraps. We are proud of the result, and also being recognized for such by the Design for Recycling Award."

ISRI created the concept of Design for Recycling® to encourage more companies like Cascades to help protect the environment and create a sustainable means for conserving natural resources. Design for Recycling® seeks to achieve two very basic goals: first, to eliminate or reduce the use of hazardous or toxic materials that may present a grave danger to the environment or put a recycler's workforce in jeopardy, and second, to discourage the use of materials that are not recyclable or manufacturing techniques that make a product non-recyclable using current technologies.

Past winner have included Wind Simplicity, Coca-Cola Recycling Company, The Herman Miller Company, the U.S. environmental Protection Agency, and Hewlett Packard.

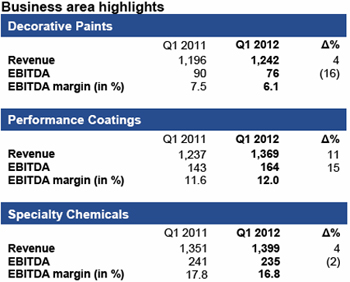

AkzoNobel publishes Q1 results

- Revenue up 6 percent to €3.97 billion, mainly driven by pricing actions

- EBITDA 3 percent lower at €423 million (2011: €437 million), as weaker end markets and cost inflation impacted results

- Net income from continuing operations €70 million (2011: €132 million), due to higher incidental charges

- Cash from operating activities was impacted by a one-time pension payment and seasonal build-up of operating working capital

- Adjusted EPS €0.63 (2011: €0.72)

- Performance improvement program on track

- Economic environment and certain raw materials remain principal sensitivities in 2012

Overall raw material prices remain a challenge. Looking forward, the company expects the higher oil and TiO2 prices on average to have an inflationary impact.

Cash from operating activities was impacted by a one-time pension payment and the seasonal build-up of operating working capital.

Decorative Paints achieved a revenue increase of 4 percent in the first quarter, primarily driven by margin management in weak markets. Lower volumes impacted EBITDA, particularly in North America which  benefited last year from a one-time positive customer load-in. Restructuring and cost reduction actions are underway in Europe and North America to offset weaker demand.

benefited last year from a one-time positive customer load-in. Restructuring and cost reduction actions are underway in Europe and North America to offset weaker demand.

In Performance Coatings, revenue increased 11 percent and EBITDA was up 15 percent compared with the previous year. Industrial Coatings – boosted by acquisition activity – achieved the strongest growth, followed by Marine and Protective Coatings. Although overall activity levels were flat, there was significant variability between individual segments.

Specialty Chemicals revenue was up 4 percent, mainly due to the Boxing Oleochemicals acquisition and a positive price/mix effect. EBITDA was 2 percent lower, reflecting different trading conditions in certain businesses.

CEO Hans Wijers

"We are continuing to focus on performance improvement. Our global margin management efforts are also proving successful as we continue to mitigate the adverse effects of higher raw material costs. However, our volumes were down slightly, reflecting the volatile nature of the economic conditions. Despite these challenges, we have solid fundamentals, renowned brands and a strong geographic spread. Furthermore, the ongoing performance improvement program shows that we are taking the right steps towards achieving our medium-term ambitions."

The 2012 Q1 report can be downloaded via the AkzoNobel Report iPad app or via the Quarterly Results page.

Ecolab's behind the Scenes Innovation Drives Environmental Sustainability

10 recent innovations empower global customers to preserve and protect Earth's resources

OnEarth Day, more than one million facilities around the world will be saving water and reducing energy use through innovations developed byEcolab, the global leader in water, hygiene and energy technologies and services. The company's products and services are used in hotels, restaurants, manufacturing plants, hospitals, refineries and many other locations to provide and protect clean water, safe food, abundant energy and healthy environments.

"Our more than 22,000 sales-and-service representatives around the world combine their expertise with our pioneering technology to deliver positive environmental outcomes for customers and society," said Doug Baker, chairman and chief executive officer, Ecolab.

Ecolab has long been a leader in the development of products and services that provide outstanding results while reducing environmental impact. One of the company's earliest innovations, introduced in 1928, was a dispenser to efficiently control chemical use and reduce waste. The company's long history of innovation continues today with a number of award-winningEcolab programs designed to produce superior results while reducing water, energy, labor and disposal impacts. These include:

3D TRASAR technology for cooling water, a U.S. Presidential Green Chemistry Award winner, saved customers nearly 93 billion gallons of water worldwide in 2011. The technology combines chemistry, remote services and sophisticated monitoring and control to improve a number of industrial operations. It is being expanded to other uses including boiler water and reverse osmosis membrane treatment, saving even more water and reducing energy use.

DryExx dry conveyor lubricant eliminates the water used in conveyors for glass packaging in beverage, brewing and food processing, reducing water use by as much as 500,000 gallons annually per production line. In a typical five-line plant, DryExx can save more than 2.5 million gallons per year. Dryer plant floors also enhance worker safety. It won Best Product design at the 2011 JustMeans Social Innovation Awards.

Aquanomic laundry system utilizes innovative wash processes and low-temperature chemistry to reduce water and energy consumption by up to 40 percent while providing clean, white and soft results. It received a Minnesota High Tech Association Cleantech Tekne Award, presented to businesses that manufacture environmentally sound solutions that reduce costs, inputs, energy consumption, waste or pollution.

PARETO mixing technology is a patented, engineered system that enhances chemical performance by optimizing the injection of chemical additives into industrial process streams. Initially launched in the papermaking industry, it saved customers more than 2 billion gallons of water and nearly 900 billion BTUs of energy in 2011. It is now expanding rapidly into new industrial applications including waste water treatment.

Apex Conveyor dish machine is designed to reduce water use and recapture heat, resulting in utility savings of up to 50 percent. The Apex Conveyor dish machine recycles heat, replenishes the wash-tank automatically and without interruption, and cleans and thoroughly de-limes itself automatically using an innovative, patent pending process. This innovative dish machine received the 2011 Kitchen Innovation Award from the National Restaurant Association.

BrightWaterTechnology is a patented nanoparticulate chemistry that increases production from existing oil reservoirs. Recovering up to an additional 5 percent of the original oil in place, this easy to implement and cost-effective technology reduces the need for drilling additional wells and extends the life of current oil reservoirs.

Envirocid Plus Clean In Place cleaner uses a patent-pending, blended acid formulation that helps reduce total phosphorus and nitrates in food processing plant effluent. It was named a 2011 International Dairy Foods Association Innovation Sustainability Award winner.

Excelerate ZTF zero trans-fat cleaning program supports food processors use of healthier zero trans-fat oils. However using these oils has the unexpected consequence of coating processing equipment and environmental surfaces with a stubborn residue. Ecolab's solution cleans this in half the time of other cleaning methods, improving the cleanliness of food processing environments. It was winner of an Institute of Food Technologists 2011 Food Expo Innovation Award.

Encompass Environmental Hygiene program provides healthcare facilities with a proven approach to improve the cleanliness of operating rooms and patient rooms, reducing the risk of infections. The process minimizes the amount of water and chemistry used during the cleaning and disinfecting process, reducing water use by 80 percent. The training and education program for operating rooms has received the Association of periOperative Registered Nurses (AORN) "Seal of Recognition" for meeting the guidelines set forth in AORN's Perioperative Standards and Recommended Practices.

COIL-FLO coil cleaning technology deep cleans and disinfects the coils in building heating and cooling systems. It helped the Fayetteville Veterans Administration Medical Center in North Carolina win a VA Sustainability award for reducing energy use and avoiding more than 1,900 tons of carbon emissions.

Ecolab has a strong commitment to innovation with 5,800 patents and 1,300 researchers; including 500 Ph.Ds., working in a network of 15 facilities located around the world. Over the past five years, the company has invested $750 million in R&D to develop programs to create cleaner, safer and healthier environments while helping reduce energy, water and natural resource consumption, enhance air quality, and minimize environmental impacts.

Mercer Withdraws its Cease Trade Application

AbitibiBowater Inc., doing business as Resolute Forest Products has announced that Mercer International Inc.has withdrawn its application requesting an order to cease trade Resolute's offer to acquire Fibrek Inc. Mercer filed its application with the Bureau de décision et de révision (Québec) on March 29.

Yesterday the Company announced that the Supreme Court of Canada had refused to hear an appeal by Fibrek and Mercer of the Québec Court of Appeal's decision concerning Fibrek's special warrants. Accordingly, the order issued by the Bureau de décision et de révision (Québec) on February 23 is now final and non-appealable, and Fibrek's dilutive private placement of 32,320,000 special warrants to Mercer is definitively cease traded.

On April 11, Resolute acquired 60,831,859 Fibrek shares, representing approximately 46.8% of those currently outstanding, and announced that it had extended the expiry time for its offer in order to allow additional Fibrek shareholders to participate. The offer currently expires at 5:00 p.m. (Eastern time) on April 23, 2012.

Questions and requests for assistance or further information on how to tender Fibrek common shares to the offer should be directed to, and copies of the above referenced documents may be obtained by contacting, Georgeson at 1-866-598-0048 or by email at This email address is being protected from spambots. You need JavaScript enabled to view it.

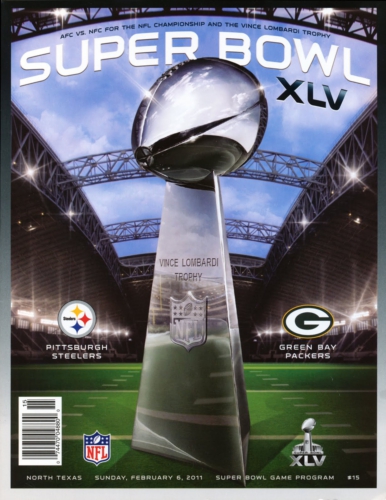

Hazen Paper And NewPage Earn Printing Industry Recognition For Super Bowl XLV Collector's Program

NewPage has announced that the company's 7 pt. Sterling® Ultra web cover paper served as a key component of an award-winning Super Bowl XLV collector's edition program cover produced by its customer, Hazen Paper.

NewPage has announced that the company's 7 pt. Sterling® Ultra web cover paper served as a key component of an award-winning Super Bowl XLV collector's edition program cover produced by its customer, Hazen Paper.

Hazen's marketing entry swept the "decorative/display category" in the Association of International Metallizers, Coaters and Laminators (AIMCAL) product competition awards.

Hazen created the custom holographic image and embossed it onto transfer film that was coated in-house. Hazen then metallized the transfer holographic material and transfer metallized the coated two-side NewPage paper stock. The final step involved sheeting and printing the 19x36 inch sheets in register with the holography. Once printed, the cover was bound to the program by Quad/Graphics, Sussex, Wisconsin.

The judges commented that they were impressed by how the elements of the 2011 Packers/Steelers Super Bowl program worked together. "These holographic images go beyond patterns to become an  integrated design," they concluded.

integrated design," they concluded.

John H. Hazen, president of the Holyoke, Massachusetts-based company said, "Hazen Paper is excited to have scored a touchdown with NewPage Sterling Ultra on the Stadium Edition Super Bowl Program Cover."

"With this award, Hazen has further distinguished itself in the customized holographics and transfer metallization industry," said David Diekelman, NewPage executive director of specialty papers Sales and Marketing. "We are delighted to have teamed with Hazen to provide a high-quality, highly engineered paper that would support such a sophisticated, technical and successful printing process."

SOURCE NewPage

Brigl & Bergmeister acquires the "ENAGES” thermal energy recovery plant from Energie Steiermark

The plant belonging to Energie- und Abfallverwertungs Ges.m.b.H. (ENAGES) was constructed on the B&B site in 2002. As ENAGES’ energy purchaser, it was natural for B&B to secure its long-term energy supply by this acquisition.

The purchase contract was signed between Energie Steiermark AG and Brigl & Bergmeister GmbH (B&B) on 23 March.

B&B gains the asset of an assured energy supply, and benefits from a sustainable improvement in its environmental performance. The minimal "carbon footprint" compared to the gas turbines normally used will in future become an even more important sales argument for paper.

As the only thermal energy recovery plant in Styria, ENAGES will remain a reliable waste disposal partner for companies and local authorities, and continue to make a valuable ecological contribution to the province.

After the takeover by ROXCEL Handelsges.m.b.H. only last year, this step means a further strengthening of the B&B location in Niklasdorf with 250 employees. B&B is a global market leader for label paper and paper for flexible packaging, with its factories in Niklasdorf and Vevce in Slovenia.

For Energie Steiermark, the sale of ENAGES underlines its systematic drive to focus on its core business in the field of energy. The acquisition of ENAGES by the highest bidder B&B as its main direct energy customer is considered the best option for securing the medium-term future of ENAGES from the regional policy point of view.

The seller and buyer have agreed to treat the purchase price as confidential. The transaction still requires merger control authority approval.

Cascades is launching a 100% recycled food waste bag

Cascades is launching a food waste bag made of 100% recycled fibres. These paper bags, manufactured in Canada, consist of a double layer to prevent leakage. This bag completes its collection of ecological household products, including yard waste bags which came out last September. Cascades bags are not only compostable*, they are also EcoLogo-certified.

Since its beginnings, Cascades has been committed to the transformation of recycled materials as a means of waste reduction. The food waste bag was created to promote composting and encourage people to adopt this sustainable practice, keeping in mind Quebec's waste materials management policy to recycle 60% of organic matter by the year 2015. For those at Cascades, composting is a practise that, in addition to recycling, allows us to reduce the amount of waste that ends up in landfills.

If every family in a small city of 10,000 homes used two 100% recycled food waste bags, rather than bags made of virgin fibers, every week for a year, the cutting of more than 660 trees, about the size of two football fields, would be avoided.

Yard Waste Bags

Yard waste bags may be filled with yard trimmings and dead leaves, even if they're wet! These paper bags are the perfect alternative to non-biodegradable plastic bags. They have a 30 lb. capacity for wet leaves and can withstand 150 lb. of dry weight.

Outlets

These bags may be purchased online at Boutique Cascades and in Canac hardware stores in Quebec.

*According to standards ASTM D6400 and ASTM D6868.

Clearwater Paper to Present at the Oppenheimer 7th Annual Industrials Conference

Clearwater Paper Corporation has announced that Gordon Jones, chairman and CEO, andLloyd Fillis, vice president treasurer and tax, will present at the Oppenheimer 7th Annual Industrials Conference on Tuesday, May 15, at 8:00 a.m. Eastern time. A live audio webcast of the presentation and accompanying slide materials will be accessible via Clearwater Paper's investor relations section of the company's website at http://ir.clearwaterpaper.com/events.cfm. An audio replay of the webcast will be available at the site for 90 days.

ABOUT CLEARWATER PAPER

Clearwater Paper manufactures quality consumer tissue, away-from-home tissue, hard roll tissue, machine glazed tissue, bleached paperboard and pulp at 15 manufacturing locations in the U.S. and Canada. The company is a premier supplier of private label tissue to major retailers and wholesale distributors. This includes grocery, drug, mass merchants and discount stores. The company also produces bleached paperboard used by quality-conscious printers and packaging converters. Clearwater Paper's employees build shareholder value by developing strong customer partnerships through quality and service.

For additional information on Clearwater Paper, please visit our website at www.clearwaterpaper.com.

Source: Clearwater Paper Corporation