Ianadmin

Cascades Sonoco Announces Multi-Million Dollar Investment in Birmingham, Ala., Facility to Support Innovative New Product Line

A Water-Based Barrier Coating That Allows Creation of Recyclable, Repulpable, Compostable Take-Out Containers

Cascades Sonoco, a joint venture of Sonoco Products Company (NYSE:SON) and Cascades Inc. (TSE:CAS) has just announced the investment of approximately $16 million for the expansion of its existing Birmingham, Ala., facility.This investment in world-class water based coating technology will provide coated paper and paperboard substrates using its new FlexShield™, FluteSHIELD® and SurfSHIELD™ coating technology. These coatings, recently introduced to the folding carton and corrugated industries, are revolutionary water-based functional and barrier coatings designed to replace the standard LDPE coating used in take-out container folding carton applications, as well as wax replacement technology for the corrugated industry. They offer solutions that are recyclable, repulpable and compostable.

“This investment represents a significant geographic expansion for water-based products by Cascades Sonoco, especially in the fast-growing Southeastern United States,” said Rodger Fuller, senior vice president of Sonoco’s Paper & Engineered Carriers, U.S. & Canada, and Display & Packaging. With this exciting addition to its product portfolio, Cascades Sonoco remains dedicated to maintain its market leadership position in protective roll packaging for the paper industry.”

“This investment represents a significant geographic expansion for water-based products by Cascades Sonoco, especially in the fast-growing Southeastern United States,” said Rodger Fuller, senior vice president of Sonoco’s Paper & Engineered Carriers, U.S. & Canada, and Display & Packaging. With this exciting addition to its product portfolio, Cascades Sonoco remains dedicated to maintain its market leadership position in protective roll packaging for the paper industry.”

“We also wish to acknowledge the support of the Birmingham Business Alliance and all our partners as it influenced our decision to invest in the region,” added Luc Langevin, president and chief operating officer of Cascades Specialty Products Group. “This strategic investment certainly helps Cascades Sonoco expand its product offerings into high-growth consumer-oriented markets.”

Installation of the new equipment and expansion of the existing Birmingham facility will begin early this year, and start-up is expected in the second quarter of 2018. Once at full capacity, the new water-based coating line will be capable of producing 40,000-50,000 tons of sustainable coated materials annually.

“The Jefferson County Commission is pleased that Cascades Sonoco has decided to invest more than $16 million to expand its operations in our community,” said Jefferson County Commissioner David Carrington. “This long-term commitment in capital and increased employment is a testament to our business climate and workforce.”

About Cascades

Founded in 1964, Cascades produces, converts and markets packaging and tissue products that are composed mainly of recycled fibers. The Company employs 11,000 employees, who work in close to 90 production units located in North America and Europe. With its management philosophy, half a century of experience in recycling, and continuous efforts in research and development as driving forces, Cascades continues to deliver the innovative products that customers have come to rely on. Cascades' shares trade on the Toronto Stock Exchange, under the ticker symbol CAS. For more information on the Company, visit our website at www.cascades.com.

About Sonoco

Founded in 1899, Sonoco (NYSE:SON) is a global provider of a variety of consumer packaging, industrial products, protective packaging, and displays and packaging supply chain services. With annualized net sales of nearly $4.8 billion, the Company has 20,000 employees working in more than 300 operations in 35 countries, serving some of the world's best known brands in some 85 nations. Sonoco is a proud member of the 2015/2016 Dow Jones Sustainability World Index. For more information on the Company, visit our website at www.sonoco.com.

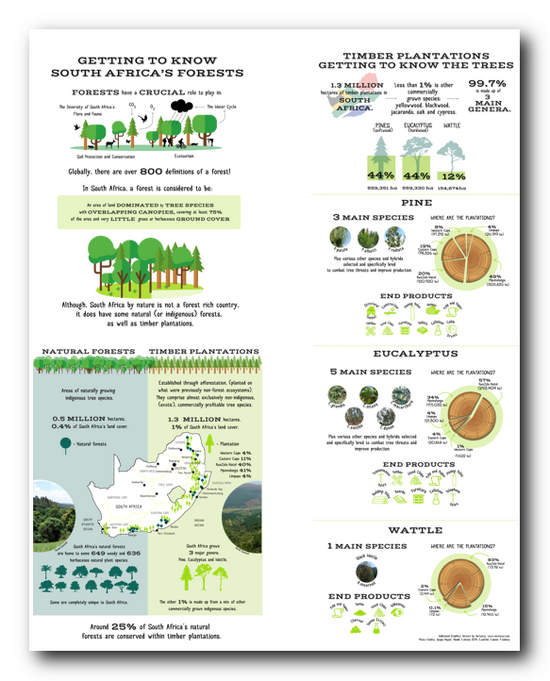

South Africa's forestry sector explained

Forestry South Africa heralds International Day of Forests with new infographic-rich website

The United Nations International Day of Forests on 21 March 2017 will be marked by Forestry South Africa with the launch of an information and illustration-rich website, ‘Forestry Explained’. The International Day of Forests is about celebrating all forests, indigenous and commercial.

Commercial forests are often forgotten despite the fact that they touch our lives in a myriad of ways. “From roof trusses and benches, to paper, packaging and tissue and the cellulose used in food and medicine, fibre from commercially grown trees plays an integral part in everyday life,” says Forestry South Africa executive director Michael Peter. “If we were to remove wood and paper-based products from our daily routines, we would soon appreciate the important function they perform.”

An indispensable sector

He adds that there is also more to forestry than planting and harvesting trees. “Thorough research, planning and management goes into keeping trees, and the land on which they grow, healthy and productive. The sector also provides jobs and supports communities.” Add to this the diverse animal and plant species that call forestry-owned land home, and you have an environmetally conscious sector that delivers an array of renewable, carbon neutral and versatile end-products.

At a local and personal level, forestry touches people – through the products they use every day without even knowing it – and communities, through education and skills development. Forestry also has a positive influence on climate change mitigation, provides a sustainable alternative to the deforestation of natural forests and is a renewable source of energy and construction materials.

One-stop guide to forestry

The new portal www.forestryexplained.co.za offers itself as ‘a beginner’s guide to forestry in South Africa’ and caters for users of all ages. It covers the basics of forestry and forest products, and everything from water-use to recreation, pest control, ownership and end-uses.

This one-stop resource offers in-depth but easy-to-read content supported by well-illustrated infographics and additional links for those who want to explore the industry further. It is ideal for learners and teachers.

Sustainably managed commercial forests should be celebrated for the benefits they bring to our daily life. To do this we need to understand them and the complex ecosystems that they are. Forestry Explained does this. It’s well worth a visit.

The Forestry Explained website supplements Forestry South Africa’s long-standing online directory platform www.forestry.co.za

ABOUT FORESTRY SOUTH AFRICA

Forestry South Africa (FSA) is South Africa's largest forestry organisation representing growers of timber in South Africa. The Association’s membership includes all 11 corporate forestry companies active in the Industry, approximately 1 300 commercial timber farmers and some 20 000 emergent small scale growers who between them own or control no less than 93% of the total plantation area in the country. Given these credentials FSA is regarded by Government and the private sector alike as being the Industry’s “representative body”. The Association’s structure mirrors its membership with three separate and distinct entities under the umbrella of an overall Executive Committee, namely:

|

◦ Large Growers Group |

(corporate timber growers) |

|

◦ Medium Growers Group |

(commercial timber farmers) |

|

◦ Small Growers Group |

(small-scale timber growers) |

Each of these groups have their own committee structure with proportional representation on the Executive Committee. FSA was granted registration as a Non-Profit Organisation in terms of the Non-Profit Organisation Act (Act No. 71 of 1997), by the Department of Social Development.

Global Forest and Paper Industry Celebrates International Day of Forests

The theme of the 2017 United Nations International Day of Forests is Forests and Energy. The International Council of Forest and Paper Associations (ICFPA) is proud to represent the global forest products industry, which plays an important role in contributing to the production of renewable energy and reducing dependence on fossil fuels by using wood manufacturing residuals, by products and forest residues – collectively known as biomass – to produce much of the energy required for its operations.

According to the international carbon accounting principle, when combusted for energy, biomass does not contribute to global climate change as growing trees sequester carbon from the atmosphere via photosynthesis. The ICFPA reiterates the carbon neutrality of biomass in a policy statement: http://www.icfpa.org/uploads/Modules/Publications/icfpa-statement-on-biomass-carbon-neutrality.pdf.

“The forest-based industry also can substitute for a wide range of fossil fuel-based products on the market, hence providing additional climate benefits as well as welfare to society,” current president of ICFPA and the Brazilian Tree Industry (Ibá).

According to the United Nations Food and Agriculture Organization, wood provides the world with roughly 40 percent of current global renewable energy supply – more than solar, hydroelectric or wind power. Sustainably-managed forests have a key role in meeting several United Nations Sustainable Development Goals and providing solutions for a growing green economy.

To increase the role of forests in providing renewable energy and to reduce the use of fossil fuels, the forest-based industry invests in technological innovation and sustainably-managed forests to improve yields and practices. In the past ten years, the energy share of biomass and other renewable fuels has increased ten percentage points from 53 to 63 percent.

ABOUT ICFPA

The ICFPA represents more than 30 national and regional forest and paper associations around the world. For more information about the sustainability of the global forest and paper industry, visit icfpa.org.

ABOUT IBÁ

The Brazilian Tree Industry (Ibá) is the association responsible for institutionally representing the planted tree production chain, from the field to the industry, before its main audience of interest. The association was launched in April 2014 and represents the 60 companies and nine state entities that provide products obtained from planted trees, with special mention to wood panels and laminate flooring, pulp, paper, energy forests and biomass, as well as independent producers of planted trees and institutional investors. Learn more at

Mohawk’s Tom O’Connor Jr. and Ted O’Connor Selected to Receive 2017 Peyton Shaner Award by AIPPM

Mohawk, North America’s largest privately-owned manufacturer of fine papers, envelopes and specialty substrates for commercial and digital printing, is pleased to announce Tom O’Connor Jr., Mohawk’s Chief Executive Officer and Ted O’Connor, Mohawk’s Senior Vice President and General Manager of Envelopes and Converting have been named 2017 Peyton Shaner Awards recipients by AIPPM.

AIPPM’s Peyton Shaner award was established to commemorate the founder of the Association of Independent Printing Paper Merchants. The recipients are recognized as someone who has shared Shaner’s passion for the industry.

AIPPM’s Peyton Shaner award was established to commemorate the founder of the Association of Independent Printing Paper Merchants. The recipients are recognized as someone who has shared Shaner’s passion for the industry.

“I have always been a big fan of the O’Connor family and feel they run a top notch family business that is not afraid to explore new markets or reenergize traditional ones!” say Don Clampitt of Clampitt Paper. Bayard Tynes of Strickland Paper adds “Tom and Ted are a dynamic duo. They are lions in our industry that represent the first family in paper with old fashioned values and exciting new products and services that make this crazy business fresh and fun. When the O’Connor family succeeds, we all succeed.”

Tom O'Connor Jr. joined Mohawk in 1986 and was named Chairman and Chief Executive Officer in 2004. During his tenure, Mr. O’Connor has grown the company to become North America’s largest privately-owned manufacturer of fine papers and envelopes which are preferred for commercial and digital printing, photo specialties and high-end direct mail. As Chief Executive Officer, Mr. O’Connor has doubled Mohawk’s business and positioned the organization for the future by leading Mohawk into new areas of growth. Through a series of strategic initiatives, Mr. O’Connor has expanded global sales, operations and distribution channels; diversified Mohawk’s product portfolio to include envelopes and specialty substrates for digital printing; upgraded IT and operational infrastructure; and has expanded Mohawk’s distribution base through strategic initiatives including the acquisition of several companies, including the iconic Strathmore line of fine papers which was acquired in 2005. Mr. O’Connor has served as chairman of the National Paper Trade Association, and on the boards of the American Forest Products Association, St. Gregory’s School, and the Advisory Board of M&T Bank. He is also a former member of The Capital Region Economic Development Council (CREDC).

Ted O’Connor has been in the paper business on and off since 1980. From 1980-1982 he worked for the Carter Rice Paper Company as a Sales Representative for their Boston and West Haven, CT divisions. In 1982 Ted came to work for Mohawk Fine Papers as a Specification Sales Representative for the New York City market. In 1985 he became the District Sales Manager for upstate New York and Canada. In 1987 Ted was promoted to National Sales Manager. In 1992 he left Mohawk to work in Bond Sales for Lehman Brothers in New York City. From 1998-2008 Ted continued his career in Bond Sales at First Albany Corporation. He returned to Mohawk in 2008 as National Sales Manager for the Eastern Region and in 2011 was promoted to Senior Vice President Sales, responsible for sales of fine paper across the United States and Canada as well as Mohawk's growing envelope business. In 2016, Ted was promoted to Senior Vice President and General Manager, Mohawk Envelope and Converting. In this new role, Ted leads Mohawk’s sales and marketing efforts for envelopes, while working closely with manufacturing and supply chain teams to enhance Mohawk’s rapidly growing envelope and converting businesses.

ABOUT MOHAWK

Mohawk is North America’s largest privately-owned manufacturer of fine papers and envelopes which are preferred for commercial and digital printing, photo specialties and high-end direct mail. Mohawk fine papers and envelopes include the signature brands Mohawk Superfine® and Strathmore®, as well as proprietary treatments Inxwell® and i-Tone®. With a culture of innovation, Mohawk’s business model now extends beyond paper manufacturing into new areas of growth, including digital substrates, which connect designers and printers to new markets.

As a leader in environmentally and socially responsible business practices, Mohawk was the first U.S. manufacturer of commercial printing papers to match 100% of its electricity with wind power renewable energy credits and the first U.S. premium paper mill to shift toward carbon neutral production. Mohawk’s portfolio of recycled papers is certified by Green Seal and the Forest Stewardship Council (FSC).

Mohawk is a fourth-generation, family-owned and operated business based in Cohoes, New York, with global sales and operations located throughout North America, Europe and Asia. For more information, please visit www.mohawkconnects.com.

Brussels Employee-led Tree Planting Initiative enters its 7th year

Dressed in wellington boots and rain jackets, the dedicated Tree Planting Team from Sappi Europe, including Berry Wiersum CEO, once again braved the Brussels weather to plant a further 1,250 saplings in the Forêt des Soignes. They were rewarded with rays of sunshine, and the feeling of satisfaction after a hard day’s work. The initiative has resulted in 16,250 trees planted since it started 7 years ago.

Jens Kriete is the Environmental Manager at Sappi Europe; “What better way to reconnect with our roots than to plant trees together; and what better way to teach future generations about our renewable industry than to also involve them in tree planting. Along with our CEO and colleagues, we had the pleasure of having some employees’ children to help us during the afternoon.” The team planted a mixture of hornbeams and oaks and celebrated their teamwork by each signing a panel erected on the site which says “These trees were planted with the support of Sappi Europe – 17th March 2017.”

CEO Berry Wiersum

CEO Berry Wiersum

Sappi’s employee-led tree planting initiative started in Spring 2010 in association with ANB (Agentschap voor Natuur en Bos), the equivalent of the Department of Forestry. This organisation is responsible for the planting of approximately 30,000 trees in the Forêt de Soignes every year as part of the National Forest Management Plan (Belgium).

Sappi employees

Sappi employees

Further Information

La Forêt de Soignes is a forest located in the south-eastern part of Brussels covering an area of over 4,400 hectares - http://www.zonienwoud.be

Our approach to sustainability is based on a holistic view of Planet, People and Prosperity (the 3P’s). These values and commitments underpin everything we do, from our business decisions and processes to our dealings with stakeholders and customers.

Through Eco-Effectiveness, we as Sappi Europe make sustainability very real, moving it from a corporate topic to a topic relevant to each and everyone of us, every single day.

About Sappi

Sappi Europe SA is the leading European producer of coated fine paper used in premium magazines, catalogues, books and high-end print advertising. Headquartered in Brussels, Belgium, Sappi Europe is recognised for innovation and quality. Its graphic paper brands include Magno™, Quatro™, Vantage™, Royal, Galerie™ and GalerieArt™ ranges. Algro®, Leine®, Parade®, Fusion® and atelier™ are the brands for innovative solutions of speciality papers and boards.

Sappi papers are produced in mills accredited with ISO 9001, ISO 14001 and OHSAS 18001 certification and EMAS registration for all our mills in the EU. Sappi European mills hold chain-of-custody certification under the Forest Stewardship Council (FSC®) and/or the Programme for the Endorsement of Forest Certification (PEFC™) schemes.

Sappi Europe SA is a division of Sappi Limited (JSE), a global company headquartered in Johannesburg, South Africa, with 12,000 employees and manufacturing operations on three continents in seven countries, sales offices in 50 countries, and customers in over 100 countries around the world.

Learn more about Sappi at www.sappi.com

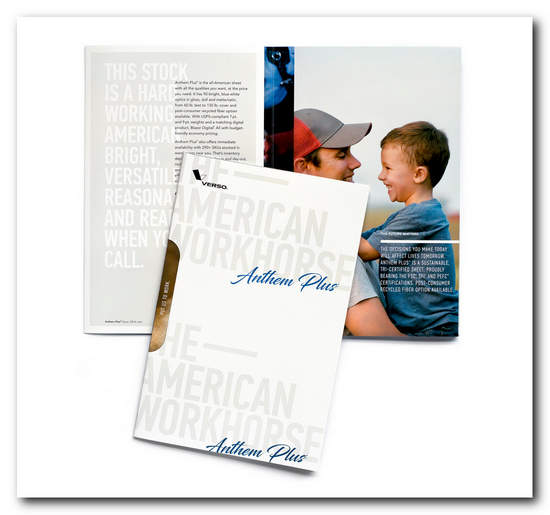

Verso Announces 92-Bright Anthem Plus® Coated Paper

The American Workhorse: American Product. American Jobs. American Pride.

Verso Corporation (NYSE: VRS), a leading producer of coated papers, has just introduced a new promotion titled Anthem Plus®. The American Workhorse. PUT US TO WORK., featuring its brighter, whiter Anthem Plus® economy coated paper.

"Anthem Plus® is the all-American economy coated paper with all the qualities and performance commercial printers want, at the price they need," said Verso President of Graphic Papers Mike Weinhold. "It has 92-bright, blue-white optics in gloss, dull and matte/satin, from 60 lb. text to 130 lb. cover. It also offers USPS-compliant 7 pt. and 9 pt. weights and a matching digital product, Blazer Digital®. Anthem Plus® has all of these attributes and is made with pride right here in the U.S., supporting local economies and American jobs. That's why it's become known as the American Workhorse."

Anthem Plus®. The American Workhorse. PUT US TO WORK. demonstrates the print quality of Anthem Plus® Gloss 100 lb. text and Matte/Satin 100 lb. cover and walks through all of the advantages of an American-made coated paper that is hard working, bright, versatile and economically priced.

"Anthem Plus® is a great sheet that comes with a commitment to service and availability, getting our customers what they need, when and where they need it," said Verso Brand Manager Tanya Pipo. "We carry over 200+ SKUs of Anthem Plus® in our warehouses across the country for immediate availability. That's inventory depth that meets our customers' day-in and day-out needs, including when demand surges. Verso is willing and able to cut custom sizes of Anthem Plus® fast to meet our customers' just-in-time delivery needs."

Anthem Plus® has the flexibility to perform in virtually every sheetfed printing application, including direct mail, brochures, catalogs, posters, newsletters, calendars, bill stuffers, flyers and manuals. It is available with post-consumer recycled fiber, complies with Lacey Act requirements and is chain-of-custody tri-certified to the Forest Stewardship Council® (FSC®), BV-COC-953662; Programme for the Endorsement of Forest Certification™ (PEFC™), BV-PEFCCOC-US09000012; and Sustainable Forestry Initiative® (SFI®), BV-SFICOC-US09000011.

To learn more about Anthem Plus® please visit us at versoco.com.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. The FSC® trademark license code for Verso Corporation is FSC® C014984. For more information, visit us online at versoco.com.

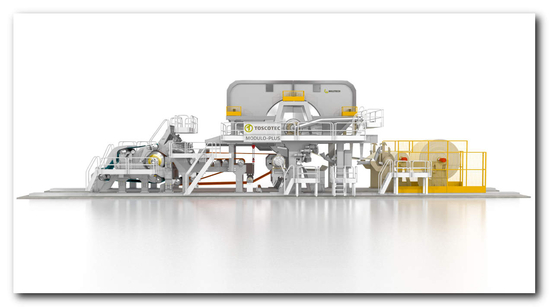

The parternship between Toscotec and EuroVast continues: a new MODULO-PLUS will be supplied for Cartiera della Basilica at Botticino’s plant.

The Italian company EuroVast has chosen Toscotec again to expand the capacity of its Cartiera della Basilica at Botticino’s plant.

The new machine, a MODULO-PLUS crescent former with single press configuration, TT SYD-3200MM and TT MilltechHood, is the perfect solution to meet Eurovast’s need: high quality tissue product, attention to energy saving and eco-sustainability were determining factors in choosing advanced Toscotec’s technology for this project .

The new TM with a maximum production capacity up to 30,000 tonnes/year and a paper trim width of 2740 mm will replace the existing suction breast roll machine and will be started up in the last quarter of 2017.

Engineering services, installation supervision, commissioning and start-up are all included in Toscotec’s scope of supply.

“Technological innovation begins purchasing new state-of-the-art production lines, involving not only an increase of production but above all achieving higher quality products to better meet our consumer needs. After almost 25 years of experience in the private label sector we are ready to satisfy every customer request, always focusing on the promotion of the product and in the development of new solutions.” said Vincenzo Romano, owner of Eurovast SpA.

The new tissue machine will increase the production of the four existing tissue plants: Botticino - LU, Bagni di Lucca - LU (that already houses a Toscotec MODULO-PLUS), Fabbriche di Vergemoli - LU and Lanciole - PT and the converting facilities of Toringo - LU and Socciglia - LU. Currently the production capacity of EuroVast Group is over 110.000 tons/year.

About Toscotec S.p.A.

Toscotec is a turnkey projects supplier to the global paper industry. Since 1948, the company offers complete production lines, plant retrofits, turnkey projects and individual machineries for the tissue, paper and board. Toscotec serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities.

For more info: www.toscotec.com

Valmet to supply a winder for Shandong Chenming Paper in China

Valmet will supply a new winder for Shandong Chenming Paper Ltd. at its Zhanjiang site in Guangdong province, China. The board machine BM 4 producing folding box board (FBB) will be equipped with a new winder to increase winding capacity. The new winder will be started-up in 2018.

The order is included in Valmet's first quarter of 2017 orders received. The value of the order will not be disclosed. The value of orders of this type and scope is typically around EUR 5-10 million.

Technical details about the delivery

Valmet's delivery for BM 4 includes a high-capacity OptiWin Drum two-drum winder. The winder is easy to operate, has excellent web separation and its set changes are reliable and fast.

"The high-capacity winder with the latest two-drum technologies is designed for the widest and fastest paper and board machines. This is the third winder with same modern sub-floor concept for Shandong Chenming. The customer has been very happy with the previous two. In this winder model, the winding drums are located below floor level and special attention has been paid to the dynamical behavior of the winder ensuring excellent runnability," comments Senior Technology Manager Jaakko Haapanen from Valmet.

9,620 mm wide (trimmed web width) BM 4 produces folding box board grades with a basis weight range of 175-450 g/m2. The design speed for the winder is 3,000 m/min. The daily production is about 1,670 tonnes.

Information about the customer Shandong Chenming Paper Ltd.

Founded in 1958, Chenming Group is one of the leading enterprises in papermaking industry. The group's annual pulp and paper capacity is 8.5 million tonnes with a wide variety of pulp, paper and board grades. Its production sites are located in the provinces of Shandong, Guangdong, Hubei, Jiangxi and Jilin.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

SkySoft Creping Blade with Ceramic Coating helps to increase Tissue Productivity

SkySoft is a new creping blade from Voith that ensures constant tissue quality. The specially developed ceramic tip of the SkySoft creping blade is highly wear-resistant for a longer lifetime and less machine downtime. SkySoft was also designed to reduce friction on the Yankee cylinder, avoiding damage to its surface.

Thanks to its special coating and high precision SkySoft ensures constant tissue quality through a longer service life.

Thanks to its special coating and high precision SkySoft ensures constant tissue quality through a longer service life.

Thanks to its special coating and high precision SkySoft ensures constant tissue quality through a longer service life. Furthermore, SkySoft has no limits on operation bevels, ensuring state-of-the-art technology for tissue production.

The SkySoft creping blades are produced at the Voith manufacturing site in Theresienfeld, Austria, where significant investments have been made into advanced grinding techniques. The fully automated production process guarantees constant characteristics and quality and allows creping blades to be supplied with a full range of angles to suit all applications. The new blades are compatible with all blade holders, and Voith OnSite Yankee specialists ensure that they fit perfectly with the customer’s machine setup at their production site.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

For 150 years, Voith’s technologies have been inspiring customers, business partners and employees around the world. Founded in 1867, Voith today has around 19,000 employees, sales of €4.3 billion and locations in more than 60 countries worldwide and is thus one of the largest family-owned companies in Europe. Being a technology leader, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive.

Sonoco Implementing Price Increases for All Rigid Paperboard Containers in North America

Sonoco (NYSE:SON) has just announced it is implementing price increases for all round composite cans and shaped rigid paperboard containers in North America by a minimum of 5 percent. The increase is effective with shipments beginning April 15, 2017.

“This price adjustment is necessary to recover continuing cost inflation, particularly in uncoated recycled paperboard, a primary raw material,” said Jeff Tomaszewski, vice president and general manager for Sonoco’s Rigid Paper and Closures North America Division.

“This price adjustment is necessary to recover continuing cost inflation, particularly in uncoated recycled paperboard, a primary raw material,” said Jeff Tomaszewski, vice president and general manager for Sonoco’s Rigid Paper and Closures North America Division.

Sonoco is the largest producer of rigid paper-based round and shaped containers globally. For more information about Sonoco’s complete line of products or to learn more about current pricing, please visit the Company’s website or contact the Company at +800-377-2692.

About Sonoco

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging and display and packaging supply chain services. With annualized net sales of approximately $4.8 billion, the Company has 20,000 employees working in more than 300 facilities in 33 countries, serving many of the world’s best known brands in some 85 nations. For more information on the Company, visit our website at www.sonoco.com.