Ianadmin

Commercial forests are full of untapped energy

The theme of the 2017 United Nations International Day of Forests is Forests and Energy. The International Council of Forest and Paper Associations (ICFPA) is proud to represent the global forest products industry, which plays an important role in contributing to the production of renewable energy and reducing dependence on fossil fuels by using wood manufacturing residuals, byproducts and forest residues – collectively known as biomass – to produce much of the energy required for its operations.

The South African sector is represented through the Paper Manufacturers Association of South Africa (PAMSA). Jane Molony, PAMSA executive director and ICFPA vice chair, says that the local pulp and paper sector is in some instances totally self-sufficient and has additional power to sell into the grid. “This energy, by virtue of the cogeneration process and biomass based lignin content in black liquor, uses less water and emits less CO2 than regular coal based power production. This is why PAMSA finds it particularly galling that the Department of Energy’s recently published draft Integrated Resource Plan for energy excludes cogeneration as a viable, green technology.”

According to the international carbon accounting principle, when combusted for energy, biomass does not contribute to global climate change as growing trees sequester carbon from the atmosphere via photosynthesis. The ICFPA reiterates the carbon neutrality of biomass in a policy statement: http://www.icfpa.org/uploads/Modules/Publications/icfpa-statement-on-biomass-carbon-neutrality.pdf

“The forest-based industry also can substitute for a wide range of fossil fuel-based products on the market, hence providing additional climate benefits as well as welfare to society,” said ICFPA President Elizabeth de Carvalhaes.

According to the United Nations Food and Agriculture Organization, wood provides the world with roughly 40 percent of current global renewable energy supply – more than solar, hydroelectric or wind power. Sustainably-managed forests have a key role in meeting several United Nations Sustainable Development Goals and providing solutions for a growing green economy.

To increase the role of forests in providing renewable energy and to reduce the use of fossil fuels, the forest-based industry invests in technological innovation and sustainably-managed forests to improve yields and practices. In the past ten years, the energy share of biomass and other renewable fuels has increased from 53 to 63 percent.

The ICFPA represents more than 30 national and regional forest and paper associations around the world. For more information about the sustainability of the global forest and paper industry, visit www.icfpa.org

ABOUT PAMSA

PAMSA has been promoting the interests and efforts of the South African pulp and paper industry since 1992. Any employer involved in the manufacture of pulp, paper, board, tissue and recycled paper in South Africa, may hold PAMSA membership. With our member companies continually striving to improve the way they do business, PAMSA supports their efforts by bringing them together on pre-competitive issues of mutual concern. These include education and training, energy production and use, water and waste, and research and development. The Paper Recycling Association of South Africa (PRASA) is housed within PAMSA.

www.thepaperstory.co.za | www.recyclepaper.co.za

South Africa’s 66% paper recovery rate exceeds global average

Paper Recycling Association of South Africa calls on citizens to do more to divert valuable ‘waste’ from going to landfill

Recovered paper fibre has been used in South Africa as a raw material since 1920 and is thus a well-established waste stream. Locally and sustainably produced paper is a renewable resource with recycling featuring as a key component in the lifecycle of many paper products. But how much is actually recovered for reuse by the paper and paper packaging sector?

In 2001, the Paper Recycling Association of South Africa (PRASA) reported a 38% paper recovery rate, rising to 59% in 2011. The association projected paper recycling rates to increase to 63% by the end of 2017 but by 2016 the paper and paper packaging industry well exceeded this with its 2015 figure of 66% of the nation’s recoverable paper and cardboard being recycled into new paper products.

“The 1.2 million tonnes of recyclable paper and paper packaging diverted from landfill in 2015 equated to 1,435 Olympic-sized swimming pools,” explains PRASA operations director Ursula Henneberry.

This means the country is well ahead of the global average of 57.9%as reported by the International Council of Forest and Paper Association (ICFPA) in its 2015 report.

Renewable and recyclable paper packaging - a prominent part of daily life

From sturdy fruit boxes and colourful cereal boxes to the classic toilet roll core, and from egg boxes to milk and juice cartons, a large proportion of paper packaging is recyclable. Once recovered, the paper fibre is repulped and made into new paper products that we use every day.

“Some paper products cannot be recovered for recycling because they are kept for long periods of time such as books or archived in the form of business and financial records; others are destroyed or contaminated when used like tissue and hygiene products,” comments Henneberry.

Promise for paper recycling

The growth in paper recovery rates is a promising trend for the country because of the environmental benefits to recycling. Recycling lessens the impact on already pressured landfill sites since the need for landfilling is avoided. One tonne of recovered paper saves three cubic metres of landfill space.

Recycling also opens up entrepreneurial opportunities for unemployed or unskilled citizens and provides dignified work for informal collectors especially if residents and businesses separate their recyclables from non-recyclable and food waste.

South Africans can definitely do more by being more disciplined withoffice and home recycling programmes - by using free and paid collection services or supporting school and community centres with their fundraising recycling initiatives.

“A very practical way to improve your paper recycling habits is to keep paper clean and dry, and separate from wet waste and other recyclables, and putting it on the pavement for an informal collector. This not only gives these people money in their pockets, but also gives them dignity,” says Henneberry.

South Africa shows progress in recycling

While the country does not have the same ease of recycling for the everyday consumer that exists in developed countries, such as recycling bins in every park or on every street corner, South Africa can be proud that it ranks firmly among the developed market rates.

“Apart of industry-led programmes, South Africa’s successful paper recovery can be largely attributed to the informal collector sector,” notes Henneberry.

Other BRICS countries, and even many developed countries, do not perform as well, such as Brazil at 47% and China at 44.7%. An article in The Hindu Times puts the level of recovery and utilisation of waste paper by paper mills in India at 27% of the total paper and paperboard consumed. On the top end of the scale, Australia recycles 85% of its paper and paper packaging.

PRASA is expected to release the 2016 paper recycling figures at the end of May 2017. A list of PRASA’s members and contact information is available on www.recyclepaper.co.za/prasa-members/

About PRASA

PRASA promotes paper recycling as one of the simplest ways to green our future, grow businesses and support job creation. Representing its members in the paper collection, sorting and processing sector, PRASA encourages paper recycling in homes, schools and businesses through a multitude of channels and activities.

www.recyclepaper.co.za We have lift-off! European paper industy launches bold investment Roadmap

The European paper industry has just launched the reviewed version of its 2050 Roadmap detailing the pathways and investment needed to cut its carbon emissions by 80% while creating 50% more added-value. The Roadmap projects the need for €44 billion more investment - a 40% increase on current levels - to transform industry in Europe and lead the low-carbon bioeconomy by 2050.

The Confederation of European Paper Industry (CEPI) pioneered in 2011 the first low-carbon industry Roadmap. It is today the first industry to table a blueprint to bolster industry transformation. Today the industry reaffirms its vision that decarbonisation and growth are mutually compatible and calls for a better alignment of policy, research and financing conditions to boost investment in Europe.

The Confederation of European Paper Industry (CEPI) pioneered in 2011 the first low-carbon industry Roadmap. It is today the first industry to table a blueprint to bolster industry transformation. Today the industry reaffirms its vision that decarbonisation and growth are mutually compatible and calls for a better alignment of policy, research and financing conditions to boost investment in Europe.

“Since our first Roadmap in 2011 the paper industry has invested €15 billion in Europe. More must be done to accelerate industry transformation in Europe over the next decade” say Sylvain Lhôte CEPI’s Director General. “It is now essential to lift-off the low-carbon bioeconomy and pace of transformation”

From energy efficiency to deployment of breakthrough technologies, emissions reduction pathways were estimated to require a combined additional investment of €24 billion by 2050. A further €20 billion of investment would be required to boost the production of new low carbon bio-based products.

“The European Commission has rightly put the focus back on investment” adds Sylvain Lhôte “However; it lacks a long-term commitment to drive manufacturing investments back to Europe. The time to act is now; the policy framework for the next decade is being shaped now and over the next three years”.

The full version of the Roadmap can be consulted here.

emtec at PaperCon 2017 in Minneapolis, Minnesota, USA

Special testing solutions for product and process optimization as well as cost savings

Emtec Electronic shows its novelties and known testing models for the wet and dry part of paper, board and tissue production at the PaperCon 2017

The measuring device manufacturer emtec Electronic will also participate at this years’ PaperCon 2017 from April 23 – 26, 2017 in Minneapolis, Minnesota, USA. The German company can be found at the Technidyne booth, which is the US sales partner of emtec (booth no. 611).

Paper, board and tissue – starting from the pulp until the final product – it can all be measured with the special measuring devices by emtec:

Paper, board and tissue – starting from the pulp until the final product – it can all be measured with the special measuring devices by emtec:

In the wet end, the new AFG touch! units can help to optimize the dosage of chemicals and stabilize the production process, and thereby, the final product. In particular, the new FPA touch! Fiber Potential Analyzer and CAS touch! Charge Analyzing System for measurement of the zeta potential of fibers and the particle charge in pulp suspensions are first time introductions to the visitors of the PaperCon.

Everyone, who is interested in the softness of its tissue products, has surely already heard of emtec Electronic and its TSA Tissue Softness Analyzer to determine the three single parameters of the softness (Real Softness, Smoothness, Stiffness) and the automatically computed Hand Feel value.

When issues with glueability, printability and coatability occur in the converting of paper and board, and no one knows where they come from, the EST12 Surface & Sizing Tester or the modular system PDA.C02 Penetration Dynamics Analyzer can help to solve these issues by the determination of the surface parameters – surface sizing and surface porosity. These are of real importance for the converting process.

We are happy to welcome you at our booth in order to discuss the innovative testing solutions, developed and manufactured by emtec, in more detail. All mentioned devices will be at the booth and it will also be possible to measure samples and to discuss the results.

Save up to 60% time and 70% water with this new powerful tank cleaning machine

Fast and cost effective cleaning

Saving time and water are some of the KPIs which have the most attention in the hygienic industries. The new Alfa Laval TJ40G rotary tank cleaning machine uses a high-impact jet stream to effectively clean tough tank residues and minimize the risk of product contamination. This four-nozzle rotary jet head also cleans tanks 60% faster than static spray ball technology, which increases production uptime. And because it cleans faster, this new device uses less water and less cleaning agents thereby reducing operating costs by up to 70%.

The Alfa Laval TJ40G is capable of handling tough tank residues as well as solids up to 1mm in the cleaning fluid in tank sizes 50-1000 m³. This is particularly important for demanding process lines, such as applications within the brewhouse, where both the size and the amount of particles may be re-circulated in cleaning media before completing the cleaning cycle.

The Alfa Laval TJ40G is capable of handling tough tank residues as well as solids up to 1mm in the cleaning fluid in tank sizes 50-1000 m³. This is particularly important for demanding process lines, such as applications within the brewhouse, where both the size and the amount of particles may be re-circulated in cleaning media before completing the cleaning cycle.

Complete self-cleaning system

Not only does the Alfa Laval TJ40G rotary tank cleaning machine provide spotless cleaning of the tank interior, it also cleans itself – inside and out.

Its hygienic self-cleaning construction ensures that the flow of the cleaning fluid reaches the exterior surfaces of the rotary jet head, as well as the critical interior components such as all bushings, bearings and inner surfaces. This minimizes the risk of product contamination and ensures a high product quality.

Alfa Laval's rotary tank cleaning machines are designed with numerous of features to ensure self-cleaning of the machine, such as directional flow from small jets in the hub that cleans the exterior of the machine. A low pressure loss over the machine provides increased cleaning efficiency compared with other tank cleaning machine running at same inlet pressure. This result in lower cleaning cost as the unit can run at lower pressure/flow compared to other tank cleaning machines.

All Alfa Laval rotary tank cleaning devices comply with Good Manufacturing Practice (GMP).

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

Alfa Laval is listed on Nasdaq OMX, and, in 2015, posted annual sales of about SEK 39.7 billion (approx. 4.25 billion Euros). The company has about 17 500 employees.

Made to measure ‘real’ recycling rates will target investment where it matters most

The European Parliament has just opted to follow the ambitious lead set by Environment committee’s vote on the Circular Economy package in January this year.

The most important outcome from today’s vote is that MEPs moved in favour of one single calculation method that enshrines real and comparable recycling rates both in and for Europe.

The most important outcome from today’s vote is that MEPs moved in favour of one single calculation method that enshrines real and comparable recycling rates both in and for Europe.

“Today, the European Parliament has fully grasped the opportunity to make the Circular Economy work for Europe by enabling industry and local authorities to better target where investment needs to take place” says CEPI Director General Sylvain Lhôte

CEPI recognises that the new recycling targets are ambitious while providing new opportunities in terms of improving quality.

“For an industry where over half of our feedstock comes from paper for recycling, the Parliament’s approach means greater use of raw materials whilst putting the emphasis on quality” says CEPI Raw Materials Director Ulrich Leberle

The vote to encourage the use of bio-based packaging also demonstrates the importance of a Circular Economy that builds upon Europe’s wealth of renewable resources while accelerating the transition towards a low-carbon economy.

Finally the continued assertion of the separate collection of paper is viewed by the European paper and board industry as a means to bridge ambitious targets with higher quality recycling.

CEPI together with other partners in the European paper value chain will shortly publish its updated European Declaration on Paper Recycling where it addresses its commitment to the new targets.

The Circular Economy is one of the core elements necessary to achieving industry transformation in Europe as outlined in our ‘Investment Roadmap’ towards a low-carbon bioeconomy. Check out our alignment matrix for the full picture.

Sonoco-Alcore to Increase Prices for Tubes & Cores in Europe

Sonoco-Alcore S.a.r.l. has just announced it will raise prices for paper-based tubes and cores by up to 8.5 percent, depending on product category, effective from shipments beginning on 15th April 2017.

Sonoco-Alcore S.a.r.l. has just announced it will raise prices for paper-based tubes and cores by up to 8.5 percent, depending on product category, effective from shipments beginning on 15th April 2017.

"The increase follows a continuous rise over the past six months in coreboard prices across Europe driven predominantly by higher OCC costs peaking now in a 60 Euro per ton or a 15 percent increase in coreboard," said Karsten Kemmerling, Director of Sales and Marketing - Tubes and Cores, Europe. "We are doing all we can to maintain tight cost control, but with coreboard a dominant part of our cost, we are unable to offset such movement."

Sonoco-Alcore S.a.r.l. is wholly owned by Sonoco (NYSE:SON) and operates 29 tubes and cores plants and four paperboard mills in Europe.

The new A.Celli generation of rewinders Open House.

Don’t miss the chance to see the new E-WIND® T200 in line with a Wrapping System in ACTION!

From April 10th until April 14th 2017, A.Celli Paper will host the event dedicated to the presentation of new E-WIND® technology at its facilities.

A.Celli’s new concept rewinder is the embodiment of the company’s level of excellence attained throughout the years – over 70 years of experience in machine building that is reflected in the expertise with which it is able to anticipate market demands, giving customers what they are looking for and what they need in order to be and stay competitive. Its wealth of knowledge makes it a fearless company, eager to experiment new solutions and to place its customers in the position of being able to create new products, exploiting new processes that it has perfected. Processes focused on giving customers a head start in this highly competitive world and a tool for safeguarding our most precious heritage: the environment.

E stands for Evolution, Excellence, for Experience & Expertise, Experimentation, Environment.

One letter that encompasses many important concepts, fundamental when speaking about machines, about products and about your business.

So come see for yourself the E-WIND® live demonstrations.

Contact A.Celli Paper (This email address is being protected from spambots. You need JavaScript enabled to view it.) for a quick consultancy or to plan your visit to our companies and to the Open House.

Next stop Cidpex for iT’s Tissue.

On behalf of the 12 companies which form the Tissue Italy network, iT’s Tissue is to participate in the China International Disposable Paper Expo (Cidpex), China’s main event for tissue and other disposable hygiene products.

Cidpex takes place from 22-24 March 2017 in Wuhan, China. More than 700 exhibitors and 30,000 visitors are expected. It is organised by the China National Household Paper Industry Association (CNHPIA).

Cidpex takes place from 22-24 March 2017 in Wuhan, China. More than 700 exhibitors and 30,000 visitors are expected. It is organised by the China National Household Paper Industry Association (CNHPIA).

Clients of all the network members are warmly invited to visit iT’s Tissue’s booth number B1F05 – HALL B1 (Tissue Converting & Tissue Paper Machinery and Related Apparatus Pavilion).

The 12 companies forming the Tissue Italy network are: A.Celli Paper, Elettric 80, Fabio Perini, Futura, Gambini, MTC, Omet, PCMC, Pulsar, Recard, TMC and Toscotec. All share the passion for tissue technology synonymous with Lucca, Bologna, Reggio Emilia and Lecco.

Arjowiggins Garaphic chooses HP to showcase endless possibilities of digital print with cocoon campaign

Arjowiggins Graphic, the leading manufacturer of environmental paper solutions has launched a creative campaign with HP to showcase the excellent print capabilities of sustainable papers and to celebrate innovation in digital printing.

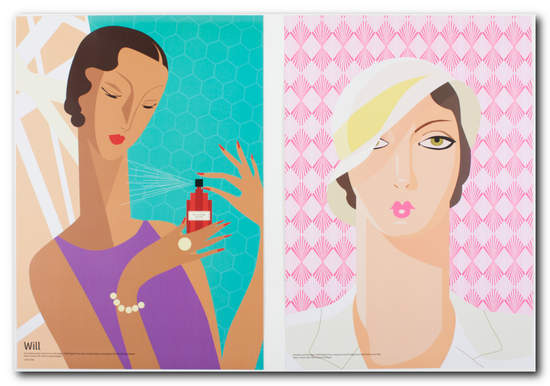

The campaign will feature two stunning, limited edition, Art Deco style posters printed on Cocoon Silk 100% recycled 300gsm B2 paper. It aims to educate and inspire graphic designers and printers to the endless possibilities of digital printing on sustainable papers using the unique HP Indigo 12000 press, which launched at Drupa last year.

‘The Girl with the Perfume’ poster capitalises on the trend for customised content. Using the HP SmartStream Mosaic application, Arjowiggins Graphic is creating 2,000 personalised and individualised prints so that every single one is totally unique. Each beautifully designed print will include a customer name and a unique background demonstrating print possibilities of HP SmartStream. HP SmartStream helps create sophisticated, custom prints through a simple variable data tool that allows designers to individualise any print job image, text, and colours, creating virtually unlimited variations of the design to maximise impact.

‘The Girl with a Cap’ poster incorporates the new HP Indigo Electroink in Fluorescent Pink in its design. Due to the fluorescent characteristics of the ink, the poster’s striking image will even glow under UV light. Both technologies are available on other HP Indigo presses and B2 size paper can also be printed on the HP Indigo 10000 press.

With this campaign, Arjowiggins Graphic and HP will demonstrate that it is possible to create prints which have a lower environmental impact and achieve innovative, high quality and unlimited design possibilities with cost effective short runs, or even individual prints that allow micro-segmentation, delivering a more personal, unique and emotionally engaging message.

Angela De Vorchik, Operational Marketing Manager, Arjowiggins Graphic UK says: “Sustainability and the environment are increasingly on everybody’s agenda, making these issues of key importance for designers and printers. With this campaign we are not only able to demonstrate print innovation but also the print excellence of Cocoon and recycled paper generally with a visually compelling and truly beautiful product. Cocoon is comparable to virgin fibre papers in whiteness and print quality yet saves energy, water, wood, CO2 and greenhouse gasses – diverting waste from landfill”.

Carlos Lahoz, sustainability and environmental manager at HP says: “We’re delighted to be able to demonstrate HP Indigo digital printing technology using Cocoon recycled paper. Our partnership with Arjowiggins Graphic started in 2012 as Alliance One partner, and we’ve continuously worked together to ensure that our industry-leading digital printing technology perfectly support sustainable papers. This campaign not only demonstrates the versatility of Arjowiggins Graphic’s recycled papers but also provides a glimpse of the power of personalisation and individualisation using some of the most advanced digital printing technology available on the market, the HP Indigo 12000.”

The campaign, which launches on 14 March 2017, will be supported by the launch of a new Cocoon swatch and website, available in five languages and with an improved customer experience. It will also offer designers the opportunity to participate in free workshops to discover and explore the infinite possibilities of digital print.

Cocoon 100% recycled is an extensive range of uncoated and coated papers. The UK range includes - Cocoon Offset, Preprint, Cocoon Silk and Gloss. There is also an addition to the range of Cocoon 60% recycled in a Silk and Gloss finish. Cocoon is exclusively distributed by Antalis.

For details on the poster print process visit www.YouTube.com/ArjoGraphic. For more information on Cocoon paper see cocoonpaper.com and to see how brands are using digital printing technology visit www.hp.com/go/discoverdigital