Ianadmin

Legality, transparency and social responsibility, Lucart earns maximum Legality Rating score

Lucart is the first company in the Italian paper industry to have obtained the maximum Legality Rating score, winning 3 stars out of 3.

On 25 January 2017, the Italian Competition Authority (AGCM), in agreement with the Ministry of Interior and the Ministry of Justice, renewed Lucart SpA's Legality Rating.

The Legality Rating is a new instrument, introduced in 2012 (Law no. 62/2012) for Italian companies, aimed at promoting and introducing principles of ethical conduct within business. This is done by awarding an "acknowledgement" - measured in "stars" - to indicate how much the company applying for the rating complies with the law and, more generally, the degree of attention it places on the proper management of its business.

In 2014, Lucart was already one of the first companies in Italy to have made an application to be awarded the Rating and, on the basis of the legal requisites as well as those based on conduct, traceability, business models and ethics etc., had obtained a 2-star ++ rating.

"We are very pleased and proud to have achieved this ambitious goal, which is reserved for only a small number of Italian companies. It's an acknowledgement that rewards consistency and compliance with all the regulations that protect Consumers and the Market", said Massimo Pasquini, Lucart Group's CEO.

The Legality Rating is valid for two years from its issue and is renewable upon request.

Lucart Group

Lucart Group, a multinational Italian industrial group founded in the province of Lucca in 1953, is one of the main producers in Europe of mono-glazed paper and tissue products (paper articles intended for daily consumption, such as toilet paper, kitchen paper, napkins, tablecloths, handkerchiefs, etc.).

The company's over 60 years of activity have allowed it to develop great know-how, experience and the technology needed to make top-quality products capable of meeting the customer's needs in the best way possible. The production systems installed at the Group's various plants make it possible to manufacture a wide range of products with complete control over every phase of the production process, from the choice of raw materials to the definition of the characteristics of the finished product.

Lucart Group's production capacity is equal to 319,000 tons of paper/year, split over 10 continuous machines (one of which for air-laid paper) and 58 converting lines. The company's production activities are distributed over 3 Business Units (Business to Business, Away from Home and Consumer) operating in the development and sales of various products with distinctive brands such as Tenderly, Tutto, Grazie Natural and Smile (Consumer area), Lucart Professional, Tenderly Professional, Fato and Velo (Away from Home area).

The ranges include products created to satisfy the needs of different types of users, from large companies to end consumers. The consolidated turnover is equal to about € 415 million, with a total workforce of 1,300 employees, 7 production plants (5 in Italy,1 in France and 1 in Hungary).

Taking Advantage of the US$400 Billion Dollar Industry

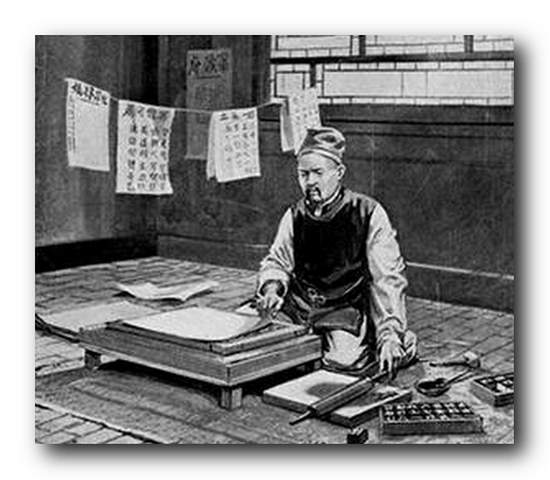

A government official in China, Ts'ai Lun was a figure who worked closely under Emperor Han of the Han Dynasty. In these ancient times, when inscriptions or writings were needed, they would be made on tablets of bamboo or on pieces of silk. With silk being costly, and bamboo heavy, written word was not common.

Ts'ai Lun was not happy with these options. One day as he watched outside his window, he noticed a swarm of wasps making their nests on a large Mulberry tree. With fibers from dead wood and plant stems, the small wasps would mix the fibers with saliva to construct their nests.

As he observed the wasps working, his mind hinted at an idea. The next morning he strolled over to the Mulberry tree. He collected bark from it and finely chopped it. Mixing it with hemp rags and water, he mashed it flat, pressed out the water and let it dry in the sun. Ts'ai Lun had invented paper.

Paper has come a long way since the Han Dynasty. In Australia, the industry is over 100 years old but certain sectors have been in a state of decline. Tim Woods is the Managing Director of IndustryEdge, which provides independent analysis for the Australian paper industry. He notes that "newsprint and some communication and advertising papers are experiencing decline, but office papers used in homes and offices remains very strong. It will be a long while before that changes dramatically."

"Paper really is a part of everyday life and that will continue into the future. In Australia, consumption of packaging papers (boxes, cartons, bags and so on) is increasing, and the same is true for tissue products."

The industry's main focus is on packaging. "Globally paper and paper board accounts for approximately one third of all packaging. The growth is linked to GDP and as a result, if a country is doing well, then there will be growth in the industry." tells Tony Johnson, a Technical Director at Beca AMEC. The packaging market is worth over US$400 billion globally and Australia is poised to take a slice.

However the industry is negotiating the challenges posed by the increased use of digital communications and cheaper imports. By placing their focus on innovation, they hope to drive investment, sustainability and productivity. With the competitive advantages of relatively inexpensive resources, a highly skilled labour force and strong regulatory frameworks, industry leaders are confident in the future. Australia has one other advantage up its sleeve. "What we've got in Australia and New Zealand is Virgin Softwood Fibre and that's really positive because Asia is short Virgin Fibre" adds Tony. The fibre gives Australia a boost, providing certain characteristics (fibre length and coarseness to name two) that add excellent strength properties to packaging papers.

Foreign investors have seen this opportunity and capitalised on it in the last 25 years. "These investors are very switched on when it comes to making the best use of their assets and from an outsiders point of view it is a very strategic move getting access to the Virgin Softwood Fibre" says Tony. Tim remarks that "global owners from Europe, the US and especially Japan, has been profound and ultimately healthy for the industry. At the same time, the rise of the privately owned local businesses has been little short of remarkable. Visy are the stand-out in this regard, but in many respects, ABC Tissue is the next company to watch."

Foreign investors have seen this opportunity and capitalised on it in the last 25 years. "These investors are very switched on when it comes to making the best use of their assets and from an outsiders point of view it is a very strategic move getting access to the Virgin Softwood Fibre" says Tony. Tim remarks that "global owners from Europe, the US and especially Japan, has been profound and ultimately healthy for the industry. At the same time, the rise of the privately owned local businesses has been little short of remarkable. Visy are the stand-out in this regard, but in many respects, ABC Tissue is the next company to watch."

But with manufacturing competing in this cut-throat environment, industry leaders feel that they have been left without government support. "It always surprises me that Governments in home countries do not mandate local procurement of their paper supplies in Australia. It certainly happens elsewhere in the world and there is plenty of independent evidence that shows the net cost of local procurement is lower than when imported products are purchased, even at the same price. That's because local businesses pay wages and suppliers and taxes locally." says Tim.

. Jim Stanford of the Centre for Future Work at the Australia Institute agrees with this sentiment. "Australia’s manufacturing downturn is partly the result of major policy errors by government — which accepted too readily the idea that Australia doesn’t really need manufacturing. The costs of those errors will be long-lasting and broad (felt not just by displaced manufacturing workers, but by the whole national economy)." Many in the industry believe that if there is no support, " things will get worse, not better".

We've come a long way from Ts'ai Lun and the Mulberry tree. The Paper Industry is innovating, using its competitive advantages to capitalise on big markets like packaging. With a focus on innovation, investment, sustainability and productivity, Australia's paper industry is poised to grow in the future. But with subsidised competitors, it will be a difficult tree to climb.

About

Tony Johnson is Technical Director at Beca AMEC and was recently recognised as a TAPPI Fellow. TAPPI is the Technical Association of the pulp & paper industry, based in the USA. It has >7,000 members worldwide. He is the 3rd recipient for NZ in TAPPI ’s 100 year history. Australia and New Zealand have previously each only had 2 TAPPI fellows.

Tim Woods is the Managing Director of IndustryEdge, which provides independent analysis for the Australian paper industry.

Trent Torkar is the General Manager at Document King, which specialises in document scanning, destruction and process automation.

Walki develops new biodegradable mulching paper

Walki has developed a new fibre-based soil mulching solution that is completely biodegradable. This organic mulch type, which is used for weed control and to optimise soil conditions and crop yield, is the first of its kind on the market.

Walki’s new mulch product, Agripap, is the only solution on the market that is entirely biodegradable. © Walki

Walki, a leading global producer of technical laminates and protective packaging materials, has developed the first-ever organic mulching solution that is based on natural biodegradable fibres instead of plastic. Mulch is a layer of material applied to the surface of an area of soil. It is designed to conserve moisture, improve the fertility and health of the soil and control weed growth. Soil mulching also reduces the need for pesticides, fertilisers and irrigation.

Traditionally, soil mulching materials have been made from plastic, and, most typically, from polyethylene film. While effective, plastic mulch is not biodegradable and eventually becomes waste material that has to be removed from the field and dumped or recycled at a high cost.

It is estimated that more than a million tonnes of plastic films are used for mulching every year around the world. In addition to having to be collected from the fields, the mulch often leaves behind plastic residues, which pollute the soil and reduce its future growth potential. Yields from polluted soil are typically up to 20 per cent lower than those from non-polluted soil.

It is estimated that more than a million tonnes of plastic films are used for mulching every year around the world. In addition to having to be collected from the fields, the mulch often leaves behind plastic residues, which pollute the soil and reduce its future growth potential. Yields from polluted soil are typically up to 20 per cent lower than those from non-polluted soil.

“Walki’s Agripap solution is the only organic mulch type on the market that is made from paper instead of plastic. It is entirely biodegradable, does not contribute to plastic pollution and, instead, simply dissolves into the soil. It also reduces the need for the chemicals used to control weed growth,” says Walki’s Vice President Technical Products, Sales & Marketing, Arno Wolff.

Walki®Agripap is made from kraft paper that is coated with a biodegradable coating layer, which slows down the degradation of the paper. Without the coating, the paper would degrade in the soil within a few weeks.

Walki’s new organic mulching solution has been the subject of extensive field-testing in Finland. The tests, which were carried out in 2016 by independent research institute Luke Piikkiö, compared the performance of different biodegradable mulches for growing iceberg lettuce and seedling onions. The tests demonstrated that Walki’s Agripap was easy to lay on the fields and delivered excellent weed control. The results in terms of yield and durability were also good.

“Having seen the kind of environmental impact that plastic film can have on the soil, Walki has understood that there is a need for a more sustainable mulching solution. Walki®Agripap is the perfect alternative for the farmers who care about our environment,” says Peter Martin, Technical Service & Development Director, Industrial Packaging.

Following the successful testing and approval of Agripap in Finland and Sweden, the next step will be to complete testing in Europe’s main mulching markets: Spain, France and Italy. Farmers and equipment manufacturers wishing to participate in testing Walki’s new organic mulching solution are encouraged to get in touch with Arno Wolff.

Walki in brief

Walki Group is a leading producer of technical laminates and protective packaging materials, specializing in the production of fibre based, intelligent, multilaminate products for markets ranging from energy saving construction facings and construction membranes to barrier packaging applications. The Group has plants in Finland, Germany, the Netherlands, Poland, the UK, Russia and China with a workforce of about 900 people. Annual net sales for the Group are over 300 million Euros.

Gratifying annual results for Cham Paper Group

Cham Paper Group enjoyed a largely satisfying annual result for 2016. The group has returned to growth after a long and challenging transformation process in the paper division. There were also improvements in terms of profitability whereas the lower end of the target margin range was achieved. The paper division benefited in a slightly weaker market environment from the efficiency improvements in production and from a return to normal raw material prices. In the real estate division the clear approval on the development of the Papieri site by the public voters was the crowning event after a four year planning phase, paving the way for the realization of the new quarter in Cham.

Cham Paper Group generated 2016 net revenue of approx. CHF 198 million (previous year: CHF 194.3 million) on the basis of unaudited figures and achieved markedly better operating results of about CHF 10 million (previous year: CHF 2.4 million). Net income is expected to reach about CHF 8 million (previous year: CHF 0.5 million).

Cham Paper Group generated 2016 net revenue of approx. CHF 198 million (previous year: CHF 194.3 million) on the basis of unaudited figures and achieved markedly better operating results of about CHF 10 million (previous year: CHF 2.4 million). Net income is expected to reach about CHF 8 million (previous year: CHF 0.5 million).

Cham Paper Group will publish the full year results and the annual report on 27. March 2017.

Cham Paper Group

The Cham Paper Group is a leading manufacturer of coated speciality papers. Surface finishing lends papers properties that generate value added for its customers. The company, which was founded in 1657, has three sites, one in Switzerland (Cham) and two in Italy (Carmignano and Condino), and a global sales network.

The decision to focus on development and sales and discontinue paper manufacturing in Switzerland has made way for a new project on the factory site in the centre of Cham. The Cham Paper Group is developing an eleven-hectare quarter there called the Papieri site.

The Cham Paper Group (stock exchange symbol: CPGN) is listed on Switzerland's SIX Swiss Exchange.

Valmet to supply a paper machine rebuild for Sappi Maastricht in the Netherlands

Valmet will supply a paper machine rebuild for Sappi Maastricht in the Netherlands. With the rebuilt paper machine 6 (PM 6), Sappi will be able to improve the existing graphical board products and move into producing high quality solid bleached board (SBB) and folding box board (FBB) grades. Today PM 6 is producing coated woodfree (CWF) paper grades. The start-up of the rebuilt machine is scheduled for early 2018.

The order is included in Valmet's first quarter 2017 orders received. The value of the order will not be disclosed.

"All the technical ideas were tested in pilot conditions at our Paper Technology Centers. With the results from the pilot trials and in close partnership, Sappi and Valmet were able to develop a new concept for Sappi Maastricht - a concept with some unique solutions", says Sales Manager Kari Sorsa from Valmet.

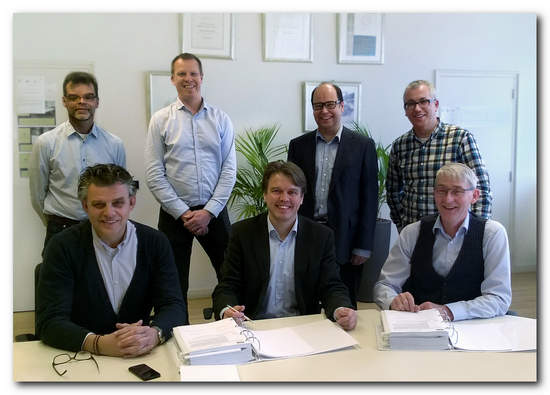

Signing the contract. Back row from the left Marco Duschak (Valmet), Iiro Luostarinen (Sappi), Kari Sorsa (Valmet), Peter Pijpers (Sappi), front row from the left Rob de Koning (Sappi), Marko Oinonen (Valmet) and Peter Loubele (Sappi)

Technical information about the delivery

Valmet's delivery for the PM 6 will include a new type of OptiFlo headbox and OptiCalender Metal Belt calender. With the headbox, an optimal sheet structure with improved paper properties can be achieved.

The calender ordered by Sappi Maastricht will be the ninth OptiCalender Metal Belt to be supplied by Valmet. With this unique technology, bulk of the produced board can be increased significantly. The surface smoothness, topography and printability of the calendered end products are excellent.

PM 6 will be producing graphical board, SBB and FBB in the basis weight range of 220-450 g/m². The mill has a total capacity of 280,000 tonnes/year.

Information about the customer Sappi Europe

Headquartered in Brussels, Belgium, Sappi Europe is the leading European producer and supplier of coated fine paper, packaging and specialty papers. In Europe the company has seven mills, 14 sales offices and 5,100 employees.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Pmp successfully starts green field tissue mill for universal paper manufacturers, South Africa - the gold eagle has spread its wings!

In December 2014, PMP (Paper Machinery Producer) signed a contract with Universal Paper Manufacturers (UPM), part of the Universal Paper group, for a turn-key green field tissue mill based on Intelli-Tissue® Advanced 1600 tissue making line. Thus it is our pleasure to announce that on the 19th of February 2017, 11:20 a.m. local time, TM#5 successfully started-up at UPM’s Ga-Rankuwa mill in South Africa!

In 2014 UPM made a decision regarding a significant expansion plan to shift its family-owned business to the next level by creating a green field tissue mill. Universal Paper’s biggest goal has been to become the preferred tissue supplier in the Southern Africa region, offering a wide span of ultra-premium, 100% virgin fibre tissue paper products. Its mission is to develop innovative products for the most demanding consumers adding flavors of creativity and education. Universal Paper branded products (FSC-certified) have already gained a significant number of enthusiasts who are fascinated with their uniqueness on a worldwide scale. Universal Paper is the proud manufacturer of Dinu, one of South Africa's leading household tissue brands.

The project was named “Gold Eagle”. Its goals were to double the annual capacity of UPM and to widen its product portfolio adding ultra-premium tissue products. PMP’s Intelli-Tissue® Advanced 1600 Crescent Former tissue making line was the best response for UPM’s defined needs.

PMP’s scope of delivery covered: collaboration with the building design engineers, a tissue making line (starting from stock preparation, a broke line, stock approach, baseplates, a tissue machine itself and a shaft puller), all auxiliary systems (a lubrication system, a steam & condensate system, a dust removal system, DCS, QCS, mechanical drives), field installations (pre-piping and pre-conduit) as well as a rich scope of engineering services (pre-erection, erection and start-up supervision). UPM’s Intelli-Tissue® Advanced 1600 has a total capacity of 28 000 tpa (operating speed 1600 m/min, reel trim 2670 mm), depending on the tissue grade (basis weight at reel from 13 to 40 gsm). An applied technology (PMP Intelli-Jet V® single layer hydraulic headbox, a Crescent Former Intelli-Former®, Intelli-Press® with a single press configuration, equipped with a 16’ steel Yankee Dryer - Intelli-YD® a steam heated hood and PMP Intelli-Reel® is focused to ensure the best quality of the final product - softness at a premium level and excellent hand feel to open the door to new market niches. In addition applied state-of-the art PMP Intelli-Tissue technology ensures ultra-low media consumption. Thanks to a unique partnership, TM#5 today has a bright future, ensuring high flexibility and world-class performance.

It is worth mentioning that the “Gold Eagle” project was implemented based on a philosophy of Premium Quality & Reliability. The investment has been the biggest in UPM’s entire history taking its value and scope into account. Also it is the 1st new high speed tissue line installed in South Africa within last 20.

After a successful and smooth start-up, both companies are ready to say that “Gold Eagle” has spread its wings empowering the future of UPM and bringing all involved pride and satisfaction.

About UPM:

Universal Paper Manufacturers (UPM) – is one of Universal Paper’s business units and is the sister company to Universal paper & Plastics (UPP). Both companies are still family owned. UPP was established by the Sher family in 1950 and has operated successfully for over 67 years. The company started as a manufacturer of various paper and plastic products, and has grown significantly since inception. However, during this time, its direction has changed – with the discontinuation of product lines in the plastics industry, while continuing to supply the tissue paper industry. The company has vertically integrated, by manufacturing raw materials within the inks and paper industry. Today, the focus is on high quality printed serviettes and napkins, bathroom tissue, household towels and hankies. (learn more: www.upap.co.za)

About PMP:

PMP – a global provider of tissue, paper & board technology, has been supporting pulp and paper industry for over 160 years, executing projects on 6 continents, in 34 countries. Company with headquarters in Jelenia Góra, Poland, owns 6 facilities in 4 countries (Poland, USA, China, Italy). PMP is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching a new logo & visual identity. (learn more: www.pmpgroup.com)

Maik Willig appointed Ehingen Mill Director

Sappi Europe is delighted to announce the appointment of Maik Willig as Ehingen Mill Director. He joined the company in 2012 as Production Manager and became Paper Mill Manager of Ehingen at the beginning of 2015. His new position reflects his leadership abilities and his knowledge of the industry.

Previous to Sappi, Maik worked for Rondo Ganahl, Austria where he held the position of Plant Manager Paper Mill, and for Stora Enso Reisholz, Germany where he started his career. Maik holds a master’s degree from the University of Munich in Pulp and Paper Engineering.

Steffen Wurdinger, VP Manufacturing, R&D and Technology (and the mill’s previous director) is very positive about the appointment. “Ehingen Mill is in line to support Sappi’s enhanced specialities offering over the next few years. In order to drive this programme of investments at the mill, we need to have the right person in place. Maik is that person. He understands the company’s objectives and is on board to ensure that Sappi fully meets its full potential.”

The appointment will be effective as of 01-03-2017. Maik Willig will report to Steffen Wurdinger, VP Manufacturing, R&D and Technology.

Ehingen Mill is situated on the Danube River in Ehingen, southern Germany. It is an integrated plant and produces chlorine-free sulphite pulp from beech and spruce wood. This is mainly used for its own paper production, with only a portion sold to external customers. Ehingen produces a range of coated paper in sheet and roll format in matt or silk-matt finish and Fusion Topliner®. The mill has over 500 employees.

For more information on the mill please visit https://www.sappi.com/ehingen-mill

Fifth Valmet supplied tissue machine started up at Hayat Kimya in Egypt

Hayat Kimya's Tissue Machine (TM6) started up at the company's new mill in Egypt in mid-January. It marked sixth successful start-up based on the same team from Valmet and Hayat Kimya working together in cooperation. Valmet has previously installed five new machines and provided an extensive rebuild of Hayat's TM1 in Izmit, in Turkey. The new line in Egypt will add 70.000 tons of high quality tissue to the company's current production of facial, toilet and towel tissue.

The new line is part of Hayat Kimya's expansion plan in the Middle East where Valmet have supplied five Advantage DCT 200TS tissue lines to Turkey, Iran, Russia and now also Egypt.

"I would like to express my gratitude to all members in the Valmet and Hayat teams. Once again excellent team work ensured a successful start-up of a new machine. To start-up five new machines and one rebuild with the same team has been a great and positive experience for us all. As our people are familiar with Valmet's Advantage tissue technology we can manage very fast start-ups and high production efficiency" says Lütfi Aydin, Director Paper Group, Hayat Kimya.

"I would like to express my gratitude to all members in the Valmet and Hayat teams. Once again excellent team work ensured a successful start-up of a new machine. To start-up five new machines and one rebuild with the same team has been a great and positive experience for us all. As our people are familiar with Valmet's Advantage tissue technology we can manage very fast start-ups and high production efficiency" says Lütfi Aydin, Director Paper Group, Hayat Kimya.

"During the years, we have developed a very open relationship where we work closely together towards a common goal: to support Hayat Kimya's expansion plan and future success. I am proud to be part of that work," says Rolf Tellack, Project manager, Valmet.

Technical information

The new tissue machine has a width of 5.6 m and a design speed of 2,200 m/min.

The raw material for the new line is virgin fiber and the production line is optimized to save energy and to enhance the quality of the final product.

Valmet's scope of delivery comprises a complete tissue production line featuring stock preparation systems, an Advantage DCT 200 TS tissue machine and two Valmet Focus Rewinder systems. The tissue machine is equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It is also featured with the Advantage tissue technology including a ViscoNip press, an AirCap hood prepared for co-generation, a WetDust dust system, sheet transfer system and a SoftReel L reel. The stock preparation line consists of OptiSlush pulpers, OptiFiner conical refiners and OptiScreen machine screens. To enhance the production efficiency, the tissue machine is complemented with two Focus Rewinders with a width of 2,8 meter and 5,6 meter.

Furthermore, the delivery includes an extensive automation package with Valmet DNA machine and process controls and Valmet IQ quality controls. Complete engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

Information about Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 210,000 tonnes and a converting capacity of 135,000 tonnes per year. Through the new start-up the total production capacity of Hayat Kimya will reach 420,000 tonnes.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

A new tissue rewinder for Sofidel America.

A.Celli Paper has recently concluded an order for a latest-generation rewinder model E-WIND® with the Italian group Sofidel for their facility in Circleville, Ohio, USA.

Sofidel America was founded in 2012 when Sofidel purchased Cellynne - a tissue paper manufacturer for Consumer and Away-from-Home business - and it is now operating in 7 states (Florida, Wisconsin, Nevada, Oklahoma, Pennsylvania, Mississippi and Ohio where a new integrated plant is under construction).

The tissue rewinder model E-WIND® T200, highly evolved from the point of view of design and equipped with sophisticated technological innovations, has a 5600-mm format and a working speed of 1600 mpm. The machine, whose start-up is scheduled in Q1 2018, will guarantee the Sofidel Group the opportunity to work and handle structured webs.

This new order by Sofidel is yet a further confirmation that A.Celli Paper is a reliable, expert and professional partner capable of walking side by side with its customers, building important relationships.

The Sofidel Group

The Sofidel Group is one of the leading manufacturer of paper for hygienic and domestic use worldwide. Established in 1966, the Group has subsidiaries in 13 countries – Italy, Spain, the UK, France, Belgium, Germany, Sweden, Poland, Hungary, Greece, Romania, Turkey and the USA - with more than 5,500 employees, a consolidated turnover of 1,809 million Euros (2015) and a production capacity of over one million tonnes per year (1,058,000 tonnes in 2015). “Regina”, its most well-known brand, is present on almost all the reference markets. Other brands include: Softis, Le Trèfle, Sopalin, Nouvelle, Thirst Pockets, KittenSoft, Nalys, Cosynel, Yumy, Soft & Easy, Volare, Onda, Lycke, Forest, Nicky, Papernet, Heavenly Soft. A member of UN Global Compact and the international WWF Climate Savers programme, the Sofidel Group considers sustainability a strategic factor with regards to growth and is committed to promoting socially and environmentally responsible development.

Sofidel America

Sofidel America is a subsidiary of the Sofidel Group. It was established in 2012 through the acquisition of the Cellynne tissue company which was founded in 1988 with three production sites in the USA - Haines City (FL), Green Bay (WI) and Henderson (NV). The company is now active in 7 States – the original three already listed, as well as Oklahoma (Tulsa), Ohio (Circleville), Pennsylvania (Philadelphia) and Mississippi (Hattiesburg).

PJSC Kiev Cardboard and Paper Mill

GL&V Sweden AB has delivered a major Recycled Pulp Line for fluting and test liner in Ukraine. The customer is PJSC Kiev Cardboard and Paper Mill. The process re-cycles local and Russian OCC.

The capacity on this recycled fiber production line is 600 BDTPD. The delivery scope contains bale conveyer, pulping station, centrifugal cleaning, fractionation, fine screening, reverse cleaning, thickening and refining.

“Everyone who saw the production figures of the OCC process said that they had never seen anything like it.”

PJSC Kiev Cardboard and Paper Mill, located in Obukhiv city in Kiev region in Ukraine, chose GL&V Sweden AB as their technology partner to deliver a new OCC Pulping Line for their production plant.

“When the OCC line was started up, the process ran just as it was supposed to”. – Peter Smirnov, Chief Engineer and Tero Jussila, Global Business Manager from GL&V (from left to right) and Alexander Yakovina, Director on Quality and Igor Oleshchuk, CTO, PJSC Kiev Cardboard and Paper Mill.

The new OCC pulping line was constructed for fluting and test liner from local and Russian OCC. The raw material dry content is 88%. Fiber production is min. 300 BDMTPD and max. 600 BDMTPD. The short fiber/long fiber split is SF 60–70% and LF 30–40%.

PJSC Kiev Cardboard and Paper Mill, part of the Austrian Pulp Mill Holding, is one of the biggest enterprises in Europe in cardboard and paper production. The mill accounts for about 30% of the total pulp and paper produced in Ukraine. The main raw material used for cardboard and paper production is recycled paper. The waste paper processing capacity is more than 1500 tons per day.

PJSC Kiev Cardboard and Paper Mill consists of three main production plants. The cardboard plant produces coated and uncoated cardboard and containerboard, including fluting for corrugated products with a total output of 240 000 tons per year. The tissue plant produces tissue materials used for mass-consumption, sanitary and hygiene products as well as finished goods such as toilet paper, napkins, and paper towels, with a total output of 70,000 tons per year. The corrugated packaging plant produces corrugated containers and packaging with a total output of 300 million square meters per year.

PJSC Kiev Cardboard and Paper Mill is currently implementing a challenging investment program. In December 2016, in an interview in Kiev, Igor Oleshchuk, CTO of the PJSC Kiev Cardboard and Paper Mill told GL&V’s representatives that the company has ongoing investment projects in three areas. The company needs to develop new fast-moving tissue products for the consumer markets. In late 2016, a new yankee cylinder was taken into use at PM1, and a new converting line for household products and modernization of tissue machine 2 (TM2) are under planning. Preparations are also under way to rebuild the refining of TM1, a project in which Igor Oleshchuk was hoping to start co-operation with GL&V’s experts.

The customer statement: “We wanted to ensure the use of best available technology in terms of both operational and financial aspects and GL&V´s solution seemed very promising in that respect”. – GL&V´s team in Kiev was headed by Tero Jussila (left) and Peter Smirnov.

The New OCC Recycled Pulp Line

In the interview in Kiev in December 2016, Igor Oleshchuk made an open statement on GL&V’s contribution in the project.

“The main target of our investment project was to improve the quality of the pulp such that our cardboard products would be recognized in the markets for their high quality criteria,” says Igor Oleshchuk, CTO of the PJSC Kiev Cardboard and Paper Mill.

- In addition to increasing the capacity of the new OCC pulp line, another important target was to reduce fiber loss and energy consumption. These are essential issues in terms of our production economy.

- We wanted to scale up the production of the PM2. Initially we aimed to increase the capacity of the pulp line to 600 t/d, and to reduce the use of secondary fiber by 50 kg/t and electricity by 50 kW/t.

- We wanted to ensure the use of best available technology in terms of both operational and financial aspects, and GL&V’s solution seemed very promising in that respect.

- Naturally, we were aware that GL&V offered novelty technology, which wasn’t in wide use as a complete process at that time. But we were willing to take the risk and choose GL&V as our partner. We knew that GL&V is a reliable company with global operations.

- The early stages of the investment ran smoother than we have ever seen before. As the project proceeded, we naturally faced some problems, but GL&V’s experts constantly came up with solutions. We were extremely happy with GL&V’s determined attitude.

- Once we reached the line start-up phase, the cooperation between our own project team and GL&V proved exemplary. The entire team was simply excellent. We contributed a great deal of our knowledge to the project, but we realized that GL&V did too.

- The start-up of the new OCC pulp line went without any major glitches, which allowed us to focus on further improving our processes without any delays. This phase lasted a while, since we didn’t simply aim to increase capacity, but also to save energy and reduce fiber loss. We successfully reached the process settings that we had set as a target. I remember well the latest negotiations with the team personnel at both our mill and GL&V’s location in Tampere, Finland.

- When the OCC line was started up, the process ran just as it was supposed to. The production personnel were able to run the new line from the get-go so that the targeted capacity increase was exceeded by 20%. It was at that moment we could – at the latest – congratulate each other for a job well done. We faced a huge challenge and overcame it.

- We also achieved great figures in terms of energy savings, and we are very pleased about that. Everyone who saw the production figures of the OCC process said that they had never seen anything like it. The pulp line’s energy consumption was reduced by 25% compared to existing OCC lines.

- For us, it is very important to monitor the dirt and sticky content of the pulp in order to prevent the contamination of the board machine’s cylinders. We had been using chemicals to keep the web clean, but we don’t need them anymore as we no longer have problems with stickies.

The Innovative Process High Lights

Pulping/HD-cleaning/Coarse Screening

The new patented Pulping and detrashing process, replaces conventional Pulping, HD-cleaning and coarse screening processes. Conventional systems require a lot of energy, beats up the contaminants into hard to remove fragments and suffer from heavy maintenance issues in the final stage coarse screening. GL&V´s patented process simplifies the process, eliminates problems in traditional processes and makes a very operator friendly solution since it even can be operated by one person.

Long Fiber Screening and Reverse Cleaning

The Long Fiber screening system is a three stage system, comprising a two-stage screen with both accepts sent forward to the LF disc filter thickener. Rejects from secondary stage is sent to a rejects chest from which it is pumped to a single stage tertiary screen. The tertiary accept is cascade coupled back to the feed tank of the primary screen.

The Long Fiber screen accepts is further treated in Reverse Cleaners, to remove light weight contaminants. Traditionary Light reject cleaners require high pressure drop and are at least in the primary stage using high volumetric reject flows. The drawbacks with these systems are high energy consumption and large recovery stages.

GL&V uses a new patented system combining high efficiency with low reject flows and high accepts consistency thickening. The solution is a cleaner that initially draws a large portion of water with the light reject, to obtain a high accepts consistency; the water is separated from the light reject in a second separation before leaving the cleaner. The water is used as dilution in the stock preparation.