Ianadmin

Global $595.3 Million Synthetic Paper Market Analysis & Trends 2017 - Industry Forecast to 2025

Research and Markets has announced the addition of the "Global Synthetic Paper Market Analysis & Trends - Industry Forecast to 2025" report to their offering.

![]() The Global Synthetic Paper Market is poised to grow at a CAGR of around 7.8% over the next decade to reach approximately $595.3 million by 2025.

The Global Synthetic Paper Market is poised to grow at a CAGR of around 7.8% over the next decade to reach approximately $595.3 million by 2025.

Some of the prominent trends that the market is witnessing include adoption of labeling in beverage industry, increasing internet penetration and the rising trend of online shopping, demand for packaging, labeling and printing industries due to industrialization and adoption of printed synthetic paper.

Based on application the market is categorized into Non-Label, Label and other applications. Depending on the material type the market is categorized into High-Density Polyethylene (HDPE), Biaxially Oriented Polypropylene (BOPP), Polyvinyl Chloride (PVC), Polyethylene Terephthalate (PET), Polystyrene (PS), High-Impact Polystyrene (HIPS), Linear Low-Density Polyethylene (LLDPE) and other material types.

Depending on the Manufacturing Process the market is categorized into tubular Film, synthetic pulp, spun-bonded papers, extruded flat film, coextruded film and other manufacturing processes. Based on End Users the market is segmented by transportation, pharmaceuticals, packaging & labeling, food & beverages, cosmetics and other end users.

This industry report analyzes the market estimates and forecasts for all the given segments on global as well as regional levels presented in the research scope. The study provides historical market data for 2013, 2014 revenue estimations are presented for 2015 and forecasts from 2016 till 2025. The study focuses on market trends, leading players, supply chain trends, technological innovations, key developments, and future strategies.

Key Topics Covered:

1 Market Outline

2 Executive Summary

3 Market Overview

4 Synthetic Paper Market, By Application

5 Synthetic Paper Market, By Material Type

6 Synthetic Paper Market, By Manufacturing Process

7 Synthetic Paper Market, By End User

8 Synthetic Paper Market, By Geography

9 Key Player Activities

10 Leading Companies

- AGFA-Gevaert N.V.

- Yupo Corporation

- Transilwrap Company, Inc.

- Taghleef Industries

- Seiko Epson Corporation

- Relyco Sales, Inc.

- PPG Industries, Inc

- Neenah Paper?

- Nan Ya Plastics Corporation

- MDV Papier-Und Kunststoffveredelung GmbH

- Lewis paper place

- HOP Industries Corporation

- Firestone polymers

- DuPont

- Castrol Limited

- Carolina Fiber Corporation

- Bluestar Silicons

- Avery Dennison

- Arjobex Sas

- American Profol Inc.

For more information about this report visit http://www.researchandmarkets.com/research/rp22l6/global_synthetic.

Record year sees Futura build market share

Futura has had a record 12 months, increasing its market share for high-end tissue converting solutions worldwide. Futura’s breakthrough Andromeda technology was delivered to Europe and the United States while additional lines were started up for key clients in Europe, South America and Mexico.

The same period also saw orders received and prospects developed from the Chinese market for Futura solutions.

The same period also saw orders received and prospects developed from the Chinese market for Futura solutions.

“Thanks to its people, passion, values and strong customer relationships, Futura has been able to set new benchmarks in integrated performance and significantly consolidate its technological leadership,” said VP of International Operations, Piero Ceccon.

“Futura is well-prepared for its next growth phase, with significant investments already committed for 2017. These include important developments in R&D at FuturaLab in Lucca, and in global service both at the manufacturing headquarters in Lucca and the North America hub of operations in Alpharetta, Georgia.”

Endress+Hauser Accredited as an Accredited Provider of IACET CEUs

Prestigious Accreditation Demonstrates Commitment to High-Quality Lifelong Learning

The International Association for Continuing Education and Training (IACET) has awarded accreditation status to Endress+Hauser. IACET Accredited Providers are the only organizations approved to offer IACET Continuing Education Units (CEUs). The accreditation period extends for five years, and includes all programs offered or created during that time. These CEUs are recognized, accepted and, even required by many state agencies and credentialing organizations.

“Endress+Hauser is proud of our education programs which train instrument technicians and engineers from the process automation industry in important installation, programming and troubleshooting skills so that our customers stay on the cutting edge,” stated Jerry Spindler, Customer and Field Service Training Manager, Endress+Hauser. Spindler added, “Our partnership with IACET is a demonstration of our commitment to lifelong learning and high standards for all of our programs, and we are very pleased to remain with such a prestigious organization and the elite group of organizations that offer excellent continuing education and training programs.”

“We are pleased to continue our relationship with Endress+Hauser as an Accredited Provider,” stated Lori Schnaider, president of IACET. Schnaider added, “Endress+Hauser joins nearly 600 organizations around the globe that have had their programs audited by third-party continuing education experts to ensure the highest possible standards are met.”

Upcoming classes in 2017 which offer CEUs at Endress+Hauser include I-101 Basic instrumentation in January, March, June, and September in Greenwood, IN.

Endress+Hauser completed a rigorous application process, including a review by an IACET site visitor, to achieve its Accredited Provider accreditation. The organization successfully demonstrated adherence to the ANSI/IACET 1-2013 Standard addressing the design, development, administration, and evaluation of its programs. Endress+Hauser has pledged its continued compliance with the Standard, and is now authorized to use the IACET name and Accredited Provider logo on promotional course material. In addition, Endress+Hauser is now linked to the IACET web site and is recognized as offering the highest quality continuing education and training programs.

About Endress+Hauser in the U.S.

Endress+Hauser is one of the largest instrument manufacturers in the United States’ industrial automation industry – specializing in automation solutions for the Chemical, Food & Beverage, Oil & Gas, Water and Wastewater, Life Sciences, Power and Energy, Primaries, and Pulp and Paper Industries. Endress+Hauser, a Switzerland based company, first began operations in the U.S. in 1970. Since that time, Endress+Hauser has continued to invest in its U.S. operations - investing an average of 10% of its annual revenue into its infrastructure.

About IACET: The International Association for Continuing Education and Training (IACET) is a non-profit association dedicated to quality continuing education and training programs. IACET is the only standard-setting organization approved by the American National Standards Institute (ANSI) for continuing education and training. The ANSI/IACET Standard is the core of thousands of educational programs worldwide. For more information, please visit www.iacet.org or call 703-234-4065.

Nanocellulose: The next big thing in bioeconomy?

While nanocellulose was discovered already in the late 1970s, it was only in the last ten years that a rise of patent applications related to nanocellulose occurred. As promising as the nanocellulose materials do sound, we are still waiting to see their concrete applications expand to mass production.

Nanocellulose is nano-structured material derived from cellulose fiber. Depending on the nanocellulose type, it typically measures between 2-50 nm in width and 100-5 000 nm in length, which compares to 80 000 nm of human hair width and 0.3 nm of a gold atom’s width. Nanocellulose has numerous beneficial qualities, including light weight as well as high strength and absorbency, which means it can improve the functionality and cost-effectiveness of various materials and products. Nanocellulose is completely renewable which gives it an advantage over fossil fuel based raw materials.

A variety of applications across industries

The potential applications for nanocellulose are numerous, including the paper and board, composites, food, cosmetic and pharmaceutical as well as electronics industries.

Probably the first application for bacterial nanocellulose, one of the main categories of nanocellulose, was developed back in 1989 when Sony made a limited set of 2,000 units of headphones. Sony apparently tried every conventional material for forming diaphragms but found nothing which would yield the 'broad, deep sound of a room speaker system' and eventually discovered "bio-cellulose”. The price for the headphones was a staggering 2,499.95 US dollars. Since then, due to its high purity, bacterial nanocellulose has been used in applications such as wound dressings, face masks and artificial blood vessels. It is produced synthetically from low molecular weight sugars such as glucose by using acetic acid bacteria.

Nanocrystalline cellulose (NCC or CNC), another type of nanocellulose, is produced by strong acid hydrolysis and is already being manufactured in a demo production plant in Canada by CelluForce. However, actual high volume applications are still missing. So far it has been tested in oil drilling applications and used in adhesives. As far as composite use, the problem is how to utilize the full strength potential of the crystals as they easily behave like a filler.

Nanofibrillated cellulose (NFC), the third main category, is produced by mechanical fibrillation and can be used in industrial and food applications as a rheology modifier. It has also potential for use as a barrier material in food packaging as it has better oxygen barrier properties than polyethylene for example. Wood-derived ingredients, such as xylitol (E967), microcrystalline cellulose (E460), cellulose powder (E460) and carboxymethylcellulose (E466) have been used as food additives already for decades. However, food additive or novel food legislation does not – at least yet – cover nanofibrillated cellulose. It seems likely though that nanofibrillated cellulose will be added to E460.

The packaging industry is driving ecological and lighter packaging material, favoring low grammage coated boards. With nanofibrillated cellulose, the basis weight of board material can be reduced without compromising the required strength properties. The result is light weight products that consume less raw materials, which, in turn, increases revenue and creates smaller ecological footprint. For this reason, nanofibrillated cellulose is already being produced in industrial scale and has found its way into a high volume application in the liquid packaging board industry.

Building a solid business case

The above means that the best option is to produce nanofibrillated cellulose at the same site where it is used. For example in the board application, this integration provides clear advantage in quality and in energy efficiency.

A large scale production of bacterial nanocellulose would require high volumes of sugars, nutrients and fermentation tanks. In addition, production capability is also very low, at 0.4 g/l/h. The solution could lie in genetically-altered algae that would be entirely self-sustaining. They could produce their own food from sunlight and water, and absorb carbon dioxide from the atmosphere.

Nanocelluloses are generally considered expensive and challenging to produce. High energy consumption and complicated chemistry create a hindrance for entry to market, added to the competition from already existing products. This means that it would be crucial to create completely new applications or significant added value compared to existing rivals. In addition, current low oil prices can have a negative effect on novel products that might not be able to compete in the same price league.

The key is to identify the applications where currently available products can be out-performed by nanocellulose. In the optimal case, nanocellulose would solve a problem where existing products have failed. This would also require that customers understand the potential of nanocellulose and create a market-pull for the product.

In the end, it all comes down to bringing together the right specialists with extensive knowhow and tuned mindset for solving these obstacles.

Did you know?

Pöyry is involved in nanocellulose business through its Pöyry µCellTM process concept for producing nanocellulose reinforced packaging board. We also provide market entry and business development strategies, technical concept studies and market analyses.

Valmet's roll service center extension strengthens service capabilities close to customers in Europe

Valmet has expanded its roll maintenance operations with the latest technology equipment for rubber and composite roll covers in Karlstad, Sweden. This investment particularly strengthens Valmet's service capabilities close to its customers in Scandinavia, while also supporting Valmet's roll service offering to customers throughout Europe. The extended roll service center started operating at the end of 2016.

In addition to Sweden, Valmet has three other European roll service centers, providing both roll maintenance and roll covers. The other centers are located in Finland, France and the UK.

Valmet's Karlstad location, the roll service center on the left in the middle

"Now we also have the capacity in Scandinavia to handle even the biggest rolls. We invest in supporting our customers at the mills by bringing roll cover production closer to them. Our customers can get all the covers they need for all the positions they want from us," says Anders Nilsson, Senior Workshop Manager at Valmet.

The increased roll cover capacity is also visible in shortened delivery times for Valmet's European customers.

Roll service agreements aligned to customer needs

"Valmet has a strong position in Scandinavia in roll maintenance service agreements, and we believe that now the additional possibility to offer roll covers close to our customers further strengthens our position. A Valmet service agreement gives customers tailor-made and cost-effective solutions for rolls. Customers' roll maintenance costs can be reduced significantly and higher machine reliability and improved process performance achieved with on-time maintenance and the right choice of roll covers. Our agreements are always aligned to the customer's needs," says Mikael Nyman, Director, Service Operations Scandinavia at Valmet.

By bringing services closer to customers and finding the right solutions together with the customer, Valmet realizes its new services approach, Shared Journey Forward.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Arjowiggins graphic announces full scale expansion into United States & North America

Arjowiggins Graphic, through its subsidiary Arjowiggins USA, has announced plans for a full-scale expansion into the United States and North America for its High quality recycled papers offer. The company has appointed Julie Brannen as North American Regional Sales Manager to spearhead the growth and development of the business in this market.

Julie, who was previously Vice President & National Sales Director at New Leaf Paper, has an extensive commercial print background, with nearly 20 years of experience across North America. During her considerable career, she has acquired the titles of designated FSC Expert and an industry specific expert in the field of FSC certified papers, Corporate Responsibility, Environmental Procedures, Procurement and Sustainable Business Practices.

Julie, who was previously Vice President & National Sales Director at New Leaf Paper, has an extensive commercial print background, with nearly 20 years of experience across North America. During her considerable career, she has acquired the titles of designated FSC Expert and an industry specific expert in the field of FSC certified papers, Corporate Responsibility, Environmental Procedures, Procurement and Sustainable Business Practices.

Arjowiggins Graphic is comprised of both an FSC-certified waste paper recycling facility in Greenfield SAS, and paper mill manufacturing sites at Le Bourray and Besse Sur Braye in France. These mills produce only the highest-quality recycled products for coated and uncoated print and packaging portfolio grades.

Arjowiggins Graphic unrivalled range of recycled and sustainable papers and boards will encompass the full range of print, web, sheetfed, digital and packaging portfolios, including brands such as: Cocoon® 100% recycled; Cyclus® 100% recycled and Teknocard® 100% recycled and virgin fiber. Stock will be available from warehouses strategically placed on both the east and west coasts of the US.

Commenting on her appointment, Julie says: "I am both pleased and proud to join the Arjowiggins Graphic team. I am most excited to facilitate the expansion of Arjowiggins Graphic products throughout North America. The idea of working with Arjowiggins was absolutely compelling to me. Simply put, we offer something that no one else here can: a total, closed-loop recycling and manufacturing solution for the print and packaging communities. This provides a long-awaited solution, one that has not been available in this marketplace until now. I am truly honored to be the first to supply such an innovative and uniquely sustainable product portfolio to the North American market."

Arjowiggins Graphic has been present in the US market for more than 20 years, The whole Arjowiggins USA team is very pleased to welcome Julie and support her with their experience and strong logistical capabilities. There is great potential in the USA for Arjowiggins recycled products and with Julie at the helm it is a unique and exciting opportunity to expand the Arjowiggins Graphic current portfolio.

For inquiries, order placements, sample requests and lead times contact Julie

Julie Brannen

North American Sales Manager

Arjowiggins USA, Inc

1200 High Ridge Rd, 2nd floor, Stamford, CT 06905

Phone: +1 (919) 599-7996

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

For more information on Arjowiggins Graphic, please visit: www.arjowigginsgraphic.com

About Arjowiggins Graphic

Arjowiggins Graphic is a leader in the development of innovative environmental paper solutions, offering consistently high quality coated and uncoated recycled papers. The branch is part of Arjowiggins, the world's leading manufacturer of creative high-tech materials and papers. With over 3,500 employees and 16 paper mills around the world, Arjowiggins generates sales of around €905 million. Arjowiggins is the manufacturing arm of Sequana.

HexArmor Partners with German Safety Innovator uvex safety group to Expand Product Offering in the Americas

HexArmor® has just announced that it has formed a strategic partnership with uvex Winter Holding, parent of the uvex safety group, to immediately expand HexArmor’s portfolio of industry-leading personal protective equipment (PPE).

Steve VanErmen, President and CEO of HexArmor, describes his enthusiasm for the partnership: “The uvex safety group is globally known for its leading role in the market and its innovation in safety. For several years HexArmor customers have asked us for solutions beyond our core technologies of cut, puncture and impact resistance in hand protection,” said VanErmen. “In partnership with the uvex safety group, the HexArmor product expertise immediately expands to deliver a broad range of new safety solutions and innovations for our customers. This partnership opens up new opportunities for our employees as well as allowing us to continue to accelerate growth.”

“The synergies are significant,” said VanErmen. “HexArmor is built on innovation, leadership, premium protection and differentiation. Our focus is to bring the best products to the market to protect people. The mission of uvex Winter Holding has always been protecting people. They have a 90-year track record of success, and have a portfolio of advanced products previously unavailable in North and South America. As a family owned business for over 90 years, they have built a powerful culture of innovation and sustainability. Their design expertise and manufacturing competence is simply unparalleled in the PPE sector. These new products made in Germany will further differentiate HexArmor from the rest of the market. The uvex safety group partnership with HexArmor perfectly aligns the interests of the shareholders of both companies.”

In 1993, uvex Winter Holding, parent of the uvex safety group, sold its U.S. business including the trademark rights in the Americas. “After an absence of more than 20 years, the partnership with HexArmor clearly signals the return of the uvex safety group to the American safety products marketplace,” said Stefan Brueck, CEO of uvex safety group. “HexArmor is a trusted advisor to safety professionals and workers across North America. The HexArmor brand represents innovation and high-performance in hand protection, a perfect platform for the uvex safety group in the Americas. Additionally, their track record of growth, even through the market events of the past two years, is quite impressive.”

There will be no changes in leadership, personnel or culture at HexArmor. HexArmor will continue its unwavering commitment to safety focused innovation. Customers may anticipate many new offerings from both HexArmor and uvex safety group in the coming months. uvex safety group’s innovative products, including eye, head and hand protection, will be sold under the HexArmor brand in the Americas, while HexArmor’s high-tech hand, arm and body protection will be sold by the uvex safety group in certain markets in the Eastern Hemisphere.

About HexArmor®

Founded in 2004, HexArmor is based in Grand Rapids, Michigan. Co-founded by Steve VanErmen and Brent Lohrmann, HexArmor has defined the market for high-performance cut, puncture and needle resistance. It also leads the industry in hand impact protection. HexArmor employs more than 150 safety professionals who work hard each day to solve difficult hand protection problems for leading companies in oil and gas, construction, energy, lumber, pulp and paper, transportation and other industrial segments.

About uvex group

The uvex group brings together three globally active companies under one roof: the uvex safety group, the uvex sports group (with uvex sports and Alpina Sports), and Filtral. The uvex group is represented in 22 countries by 48 subsidiaries but chooses to do most of its manufacturing in Germany and Europe. Two thirds of the company’s 2.300-strong workforce (as at 31 July, 2016) is employed in Germany. uvex sports group is a global partner to international elite sport and equips a host of top athletes. The mottoprotecting peopleis at the heart of the company’s activities. uvex group develops, manufactures and distributes products and services for the safety and protection of people at work, in sport and for leisure pursuits.

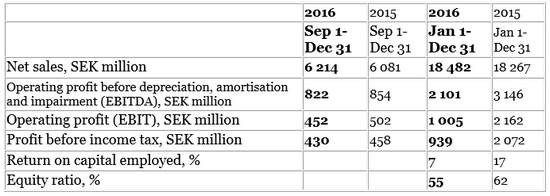

Södra's operating profit SEK 452 million for the third four-month period

Södra’s operating profit for the third four-month period amounted to SEK 452 million (502). The full-year profit is in line with expectations and the board proposes a distribution of profit totalling SEK 602 million.

“2016 was a year of transition for Södra, with major changes due to robust investment and restructuring but also lower prices for our finished goods. Against this background, operating profit of SEK 452 million for the third four-month period is a show of strength, while full-year profit of SEK 1,005 million is completely in line with expectations”, says Lars Idermark, President and CEO, in a statement.

“2016 was a year of transition for Södra, with major changes due to robust investment and restructuring but also lower prices for our finished goods. Against this background, operating profit of SEK 452 million for the third four-month period is a show of strength, while full-year profit of SEK 1,005 million is completely in line with expectations”, says Lars Idermark, President and CEO, in a statement.

Consolidated net sales for the third four-month period amounted to SEK 6,214 million (6,081), and for the full-year 2016 amounted to SEK 18,482 million (18,267). The operating profit for the period totaled SEK 452 million (502) and for the full-year SEK 1 005 million (2 162). Return on capital employed was 7 percent (17) and the equity ratio was 55 percent (62).

“Södra’s efforts to create a stronger company in a more global and competitive market are continuing. The extensive investments of recent years are among the largest in Södra’s history, and we are strengthening our customer offering and securing markets for our members’ forest products,” says Lars Idermark.

Södra was founded in 1938 and is the largest forest-owner association in Sweden, with a membership of more than 50,000 forest owners. We engage in modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. Through value-generating relationships and a long-term approach, Södra is leading the way for the next generation of forestry.

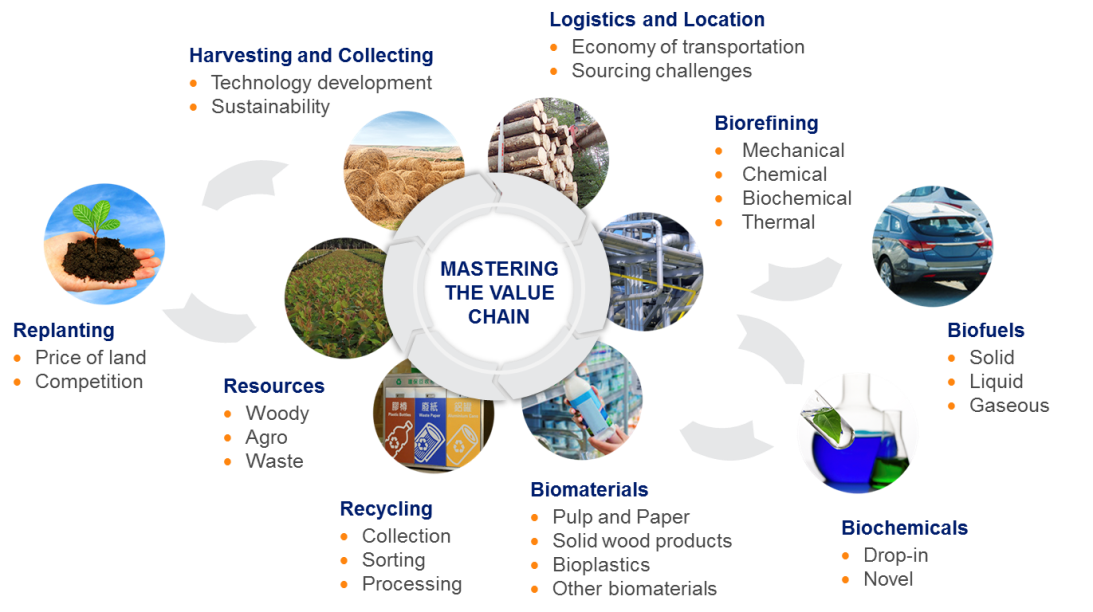

Pöyry at Lignofuels 2017: Mastering the whole value chain a prerequisite for profitable bioproduct business

Advanced biofuels and biomaterials have been high on industrial companies’ agendas for several years. Investments in R&D, pilot projects and development initiatives have also generated some commercial scale production, but a lot of potential is still untapped.

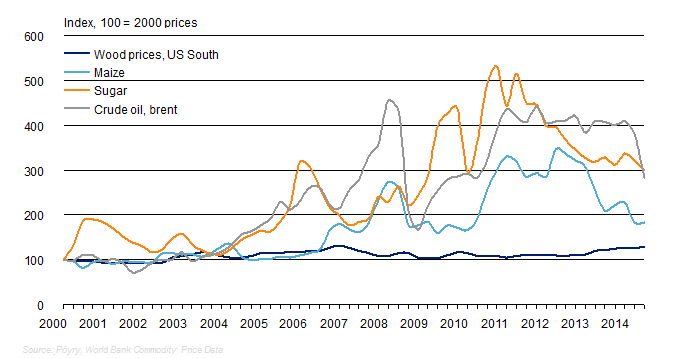

Nicholas Oksanen, President of Pöyry’s Industry Business Group, recently gave a presentation at the Lignofuels 2017 Conference in Helsinki, Finland, about advanced biofuels and materials and a European market overview. In his presentation, Oksanen noted that woody biomass is gaining interest as a feedstock for biofuels while its use is still rather limited.

The benefit of advanced, or 2nd generation feedstocks (lignocellulosic feedstocks, non-food crops, industrial waste and residues), is that they are more sustainable compared to 1st generation, food or feed based feedstocks such as corn, sugarcane, soybean oil or rapeseed oil. Secondly, compared to crude oil, sugar and maize, the price level of wood has remained stable through the 2000s and 2010s while the prices of the alternative feedstocks have experienced great fluctuation. Also, by using harvesting and side-stream residues as biofuel and materials feedstock instead of burning them for energy, companies are able to maximise added value.

Woody biomass is gaining interest as feedstock for bioproducts

source: Pöyry

“Biobased products also present new product opportunities for industry players. For example lignin, nanocellulose, hemicelluloce or tall oil open new business potential for bioenergy, biofuels and biochemical sectors and the packaging industry,” Oksanen said. “The EU’s ‘Renewable Energy Directive’, which prioritises waste and residues, has also increased the industry’s interest in 2nd generation feedstocks.”

Bioproduct opportunities for Pulp & Paper companies

source: Pöyry

While the opportunities are lucrative, there are challenges that have slowed down larger scale bioproduct investments. At the moment, one of the major challenges is caused by political uncertainty and the direction of the EU legislation, imposing a market risk for companies. Also, country-based biofuel policy mechanisms would require harmonisation. With the exception of wood, advanced feedstock sourcing and the supply chain is still immature and requires further development before it can be relied on.

“For companies, the main focus is to find a valid business case in which the feedstock price plays a big role. However, it is crucial to master the whole value chain from feedstock to markets to ensure profitable business and investment,” Oksanen summarises.

source: Pöyry

About Pöyry

Pöyry is an international consulting and engineering company. We deliver smart solutions across power generation, transmission & distribution, forest industry, chemicals & biorefining, mining & metals, transportation and water. Pöyry's net sales in 2016 were EUR 530 million. The company's shares are quoted on Nasdaq Helsinki (POY1V). Approximately 5500 experts. 40 countries. 130 offices.

Stora Enso plans to shut down one SC paper machine at Kvarnsveden Mill in Sweden

Stora Enso will start co-determination negotiations with employees at its Kvarnsveden Mill in Sweden regarding a plan to reorganise the mill, including a permanent closure of paper machine (PM) 8. The planned actions would affect a maximum of 140 employees. The paper machine has an annual capacity of 100 000 tonnes of super-calendered uncoated magazine paper (SC) and it is planned to be shut down by the end of the second quarter of 2017.

The plan would result in annual cost savings of EUR 12 million. Stora Enso will book restructuring charges of approximately EUR 17 million as an item affecting comparability (IAC) in its Q1/2017 results, of which about EUR 14 million will be cash costs. The planned closure would not have material impact on Stora Enso’s sales or operational EBIT.

The plan would result in annual cost savings of EUR 12 million. Stora Enso will book restructuring charges of approximately EUR 17 million as an item affecting comparability (IAC) in its Q1/2017 results, of which about EUR 14 million will be cash costs. The planned closure would not have material impact on Stora Enso’s sales or operational EBIT.

“We plan to reorganise Kvarnsveden Mill to ensure its competitiveness in the structurally declining paper market. This plan includes the permanent shutdown of PM8, which, due to its small size and technical age, is unfortunately no longer competitive in the current market conditions. We appreciate the efforts taken by the employees, and regret that this plan would be necessary to support the competitiveness of Kvarnsveden Mill going forward,” says Kati ter Horst, EVP Paper division.

The closure of PM8 at Kvarnsveden Mill would not impact Stora Enso’s SC paper offering. In Europe, Stora Enso continues to produce SC paper at Kvarnsveden Mill PM12 as well at Maxau Mill in Germany and Langerbrugge Mill in Belgium. The group also serves its SC customers from Dawang Mill in China.

No decisions regarding the planned reorganisation or employee impact will be taken until the co-determination negotiations have been concluded. Production at Kvarnsveden Mill would continue on two lines, PM10 for improved newsprint paper and PM12 for SC papers.

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Our aim is to replace fossil based materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 25 000 people in more than 35 countries, and our sales in 2016 were EUR 9.8 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com