Ianadmin

Verso Introduces NK Series of Lightweight Natural Kraft Machine Glazed Papers for Foodservice and Flexible Packaging

Verso Corporation (NYSE: VRS), a leading producer of flexible packaging, technical, and label and converting papers, have just announced the introduction of its NK Series, a family of lightweight, machine-glazed natural kraft papers manufactured using unbleached virgin fiber. The NK Series will be produced at Verso's Androscoggin Mill in Jay, Maine, with an initial focus on foodservice and flexible packaging applications such as quick service restaurant and concession bags, sandwich wraps, pouches, microwave popcorn bags, and specialty tape and waxing base.

"Market demand continues to grow for unbleached fiber papers as more and more consumer brands incorporate a natural look and feel into their product packaging and foodservice papers," said Ed Buehler, Verso Vice President of Business Development, Specialty. "Lightweight natural kraft papers are the latest addition to Verso's industry leading portfolio of top-performing American-made specialty papers, all of which are backed by the same exceptional level of service that printers and converters have come to trust from Verso."

"Market demand continues to grow for unbleached fiber papers as more and more consumer brands incorporate a natural look and feel into their product packaging and foodservice papers," said Ed Buehler, Verso Vice President of Business Development, Specialty. "Lightweight natural kraft papers are the latest addition to Verso's industry leading portfolio of top-performing American-made specialty papers, all of which are backed by the same exceptional level of service that printers and converters have come to trust from Verso."

Verso will produce uncoated machine-glazed natural kraft papers using unbleached fiber with basis weights (3000 sq. ft.) ranging from 15 lb. to 40 lb. These natural kraft products will join the Androscoggin Mill's growing portfolio of established specialty papers designed for a wide variety of foodservice, label, release liner and packaging applications.

"Our new NK Series focuses on natural kraft papers with specific performance attributes such as oil and grease resistance, low porosity for moisture holdout, and high strength for demanding converting processes," said Buehler. "These unbleached products complement our well established lightweight bleached foodservice and flexible packaging papers, and provide us with an excellent base for long-term growth and development of natural kraft specialty papers."

For additional information on Verso's NK Series of lightweight natural kraft machine glazed papers or our broad portfolio of other specialty paper products, visit versoco.com/specialtypapers or email This email address is being protected from spambots. You need JavaScript enabled to view it..

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online atversoco.com

Valmet receives an order for an online condition monitoring system from Anhui Shanying Paper in China

Valmet has received an order for an online condition monitoring system from Anhui Shanyin Paper Industry Co., Ltd. in Ma'anshan, Anhui province, China. The new system will be installed on the mill's paper machines 1, 2, 3, 5 and 6 to secure high process availability, efficient maintenance and safety.

The order was included in Valmet's fourth quarter 2016 orders received. The value of the order is not disclosed. Typically, the order value of these kinds of automation system deliveries is below EUR one million. The system will be delivered in March 2017.

The order was included in Valmet's fourth quarter 2016 orders received. The value of the order is not disclosed. Typically, the order value of these kinds of automation system deliveries is below EUR one million. The system will be delivered in March 2017.

"This investment is in line with our plan for Paper Industry 4.0 to improve the paper machines' automation level and running efficiency. We will proceed toward smart manufacturing step by step. First, we will utilize advanced technology and solutions to get data from our processes and machines. Then, we will benefit from advanced analytics and performance optimization. We believe that through cooperation with Valmet, we will be able to take the automation level of our production lines to the next level," says Liu Wenming, Vice President of Anhui Shanyin.

"The Valmet DNA Machine Monitoring system will increase the reliability of the mill's production equipment by automatically detecting mechanical faults and giving early warnings to operators and maintenance personnel. Additionally, the mill will be able to optimize its maintenance process and reduce costs as corrective actions can be planned well ahead based on accurate machine condition information," notes Harri Mustonen, Director, Automation Systems Product Group, Valmet.

Technical information about Valmet DNA Machine Monitoring

Valmet DNA Machine Monitoring offers condition information for process operators and maintenance personnel through one common user interface. The displays can be viewed both in the control room and the maintenance office. Operators are immediately alerted if there is a risk of severe machine failure. Tools for more detailed signal analysis are available for maintenance personnel.

Process control and condition monitoring are fully integrated in the Valmet DNA automation system. Process data and machinery condition information can be easily combined for efficient analysis and problem solving. Collecting pieces of information from several sources or building data links between separate systems is no longer needed.

Valmet DNA Machine Monitoring is a central element of the reliability solutions in Valmet's Industrial Internet portfolio. It offers modern tools for onsite predictive maintenance as well as an efficient platform for remote condition monitoring services by Valmet experts.

Information about the customer Anhui Shanying Paper Industry Co., Ltd.

Anhui Shanying Paper Industry Co., Ltd. is one of the largest industrial papermaking enterprises and packaging board manufacturers in China. The company was established in 1999 and is listed on Shanghai Stock Exchange since 2001. In 2013, the company was restructured as part of Ji'an Group Co., Ltd.

The company has successively established subsidiaries in Anhui, Zhejiang, Jiangsu, Fujian, Hubei and Tianjin provinces, among others. It has set up wholly owned companies, for example, in the US, UK, Germany, Netherlands, Japan, Australia and Hong Kong. The company has an annual yield of 3,050,000 tons of paper and 1 billion square meters of cardboard and paper carton, ranking top within the industry in terms of scale.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

EU MEPS enters its final stage… but there’s more to come

2017 sees the final stage of EU MEPS, taking IE3 down to 0.75 kW motors. But it looks like this stage is far from being the last leg of the European Commission’s drive to cut energy. Further energy efficiency measures are being considered that could pack an even bigger punch.

The past five years has seen some significant changes in the world of low voltage motor efficiency levels, culminating in January 1, 2017 being the final stage for the European Minimum Energy Performance Standard (EU MEPS). You may be well-aware that from that date motors from 0.75 kW to 375 kW must conform to IE3 - or IE2 if fitted with a variable-speed drive (VSD).

Yet the energy-efficiency landscape is about to get a lot more interesting. The European Commission (EC) is now focusing on the energy efficiency requirements of a power drive system (PDS) – which comprises VSDs and electric motors. It is even expected to target more extensive systems containing, for example, the load such as a pump. Here’s why.

The EC has some tough energy saving commitments that it must meet. It needs to hit its 2030 greenhouse gas emission levels with cuts of up to 40 percent compared to 1990 levels. It also has to reduce energy consumption by 27 percent by that date. The EC has spotted that by extending electric motor energy-efficiency regulations it could save a further 22.3 TWh per year across the European Union by 2030.

However, while final decisions and dates are still some way off, among possible policy options are to:

- expand the IE3 requirement for large motors both in LV and MV from 375 to 1000 kW

- remove the current option of using an IE2 motors with a VSD

- introduce regulations for smaller motors down to 120 W for both single- and three-phase motors

- remove low efficiency VSDs from the market

- expand the types of motors included such as explosion proof and brake motors

It is estimated that some 9.9 TWh/year, or 44 percent of the total being targeted, can be achieved by introducing an IE2 minimum efficiency level for three-phase motors rated from 120 W to 750 W. The intention is to include those motors integrated into products in an attempt to avoid loopholes. A similar measure for single-phase motors in the same power range will save a further 4.6 TWh/year.

The EC is also targeting both low- and medium- voltage motors rated from 375 kW to 1,000 kW, with the proposal to make IE3 the minimum efficiency. Despite sales of these motors being relatively small, their high power ratings and long operating hours means the potential to save energy is significant. The annual savings from these measures would amount to 3.1 TWh for the LV motors and 1.1 TWh for the MV machines, according to the EC.

The EC wants to remove the current option of using an IE2 motor with a VSD, instead of having to specify an IE3 machine, for motors with ratings from 7.5 kW to 375 kW. This, it is anticipated, will simplify the regulations and market surveillance, as VSDs are not needed in all applications. For instance, with fixed loads, a soft-starter can be a better option. Removing the VSD+IE2 option will save an estimated 2.7TWh/year by 2030. There is even, for the first time, a proposal to bring VSDs within the scope of the EC’s mandatory energy-saving regulations.

The current EU MEPS regulation excludes certain motors such as explosion proof and brake motors. The EC wants to extend the regulations to include these motors. This will save an estimated 0.9 TWh/year by 2030. Brake motors will still be excluded if the brake is an integral part of the motor that cannot be separated for testing purposes.

Among those motors that are likely to be exempt from the regulations are DC machines with mechanical commutators; motors in cordless or battery-operated equipment; motors in hand-held equipment whereby the weight is supported by the hand during use (because high-efficiency motors tend to be heavier and this equipment tends to have shorter operating hours); and motors integrated into machines that cannot practically be tested separately.

“ABB fully supports and backs all the requirements related to high efficiency,” says Marco Veeckman, sales and marketing manager of ABB’s motors and generators business. “We see them as a good, positive development and endorse the Commission’s efforts. However, we understand that LOT 30 and the associated schedule for implementation is delayed, but that shouldn’t stop users getting up to speed with what the current regulations mean.

“With the regulations potentially extending to low- and medium voltage motors and PDS’, there is a lot to consider for users of motor-driven applications. It can be a confusing landscape with the regulations meaning different things to OEMs, machine builders, system integrators and end-users. It’s more important than ever, therefore, to align yourself with a reputable supplier. One than can answer questions like: Which motor is most suitable for your application? When do you need a VSD? Is your application dimensioned correctly? What is the optimum solution for your process or machine?”

While seeking the right advice can be critical, the simplest advice is to ensure you use a well-established motor supplier. The fact is that MEPS is a truly global issue and only those manufacturers with a grasp of all the subtle differences in the regulations are able to supply the right motor. “You need global support and advice as well as solid, reliable products,” argues Veeckman.

About ABB

ABB (ABBN: SIX Swiss Ex) is a pioneering technology leader in electrification products, robotics and motion, industrial automation and power grids, serving customers in utilities, industry and transport & infrastructure globally. Continuing more than a 125-year history of innovation, ABB today is writing the future of industrial digitalization and driving the Energy and Fourth Industrial Revolutions. ABB operates in more than 100 countries with about 135,000 employees. www.abb.com

Inapa concludes acquisition of Papyrus France and divests of Switzerland

Inapa, the only company listed in the paper merchant sector in Europe, concluded the acquisition of the French operation of Papyrus, announced in September of this year, and divested of its operation in Switzerland.

Market trends in the paper distribution industry call for the need of consolidation. Inapa is having an active and leading role in such process with the transaction now announced in France and Switzerland. With the acquisition of Papyrus France, dedicated to the paper distribution for the graphic and office sector, Inapa reinforces its presence in the French market, which is currently one of the countries that most contributes to its turnover.

Market trends in the paper distribution industry call for the need of consolidation. Inapa is having an active and leading role in such process with the transaction now announced in France and Switzerland. With the acquisition of Papyrus France, dedicated to the paper distribution for the graphic and office sector, Inapa reinforces its presence in the French market, which is currently one of the countries that most contributes to its turnover.

“This is a very important step in our strategy. France currently accounts for 25% of the Group's turnover and, with this acquisition, it will represent approximately 35%, allowing the operation to strengthen its leadership position in the local market” states the CEO, Diogo Rezende.

Last year, in France, Papyrus had a turnover of 156 million euros and Inapa of 165 million euros. "The combination of these two companies will accelerate our Group’s growth strategy, enabling us to improve our level of efficiency and customer service, now that we will have a strong position in the efficiency scale. We are thrilled to welcome all employees, customers and suppliers of Papyrus France and excited with our future together", explains Diogo Rezende.

At the same time, Inapa has decided to sell its operation in Switzerland (Inapa Schweiz) to Papyrus Group. "We believe that Papyrus's growth strategy in Switzerland will provide a strong and stable future for both companies, benefiting customers, with a better service, and employees, with a stronger and sustainable business. I would like to convey our gratitude towards all employees and customers of Inapa Schweiz" adds Diogo Rezende. Inapa Switzerland in 2015 had a turnover of 52 million euros.

These transactions are part of Inapa Group's strategic plan for 2016-18, allowing it to continue its strategy to improve paper business’ efficiency. With these transactions, Inapa expects to increase its turnover, strengthen its position in one of the largest European markets in France, and benefit from the efficiency of scale. They are also fully aligned with the strategic vector of improving the Group sustainability, as the transactions are done without additional debt.

About Inapa Group

Inapa has changed a lot since its foundation, in 1965, as the first Portuguese paper mill. Over the years, the focus and business strategy changed and the geographical boundaries of the Group expanded. In 2000, Inapa has gone from being a national paper producer to be an international group operating in the paper distribution and in two areas of complementary business: packaging and visual communication.

With a team of 1400 employees, the Inapa Group is currently present in 8 countries - Germany, France, Spain, Portugal, Belgium, Luxembourg, Turkey and Angola - serving more than 70,000 customers.

Inapa - Investimentos, Participações e Gestão, SA is the company that consolidates the Group's operating companies that operate in the sectors of paper, packaging and visual communication.

The Group has nowadays an important position in the European market of paper distribution, with annual sales of approximately 900 million euros, and is the only Portuguese company listed on the stock exchange in the paper distribution in Europe.

About Papyrus Group

With net sales of EUR 1.5 billion in 2015, Papyrus is a leading business-to-business distributer of business essentials and provides more than 65,000 customers across 19 countries in Europe with Printing & Creative solutions, Facility solutions, and Industrial packaging solutions. www.papyrus.com.

A.Celli Safety Upgrade: safety first!

The best choice to manage the adaptation and compliance of industrial machinery or plants.

The A.Celli Group has always retained technological developments and the safety aspects of machines to be its key growth factors. The Group’s approach to occupational safety is a foundational theme for the company, and the high number of plants sold throughout the world in relationship with a practically inexistent history of accidents on the job is the most evident proof of this philosophy.

Today, the complexity of industrial systems requires increasingly attentive consideration of the theme of safety. Preventing accidents on the job is not a calculation based on a single machine but an outcome of the management logic adopted throughout the production process.

And in addition to the normal risk factor, unpleasant unexpected events can arise from deficiencies at the operating phase, lack of clarity in procedures, negligence by operators or human errors. Without forgetting that year after year, international norms and directives to regulate the issue abound.

For this reason, A.Celli offers its customers the complete solution for plant modification, repair, verification and/or compliance.

The service offered includes:

- Analyses surveys and assessment of customer demands

- Engineering study on components sizing and on plant design with reference to binding norms in the country in question.

- Project management, document handling and issuing of certifications.

- Installation, commissioning and start-up

- Software modification and updating of electrical and pneumatic diagrams.

- Review of manuals and layout of new safety devices.

- 24/7 technical support hotline

- 12-month warranty from the date of completion of the modifications.

The best choice to manage the adaptation and compliance of industrial machinery or plants.

So what are you waiting for?

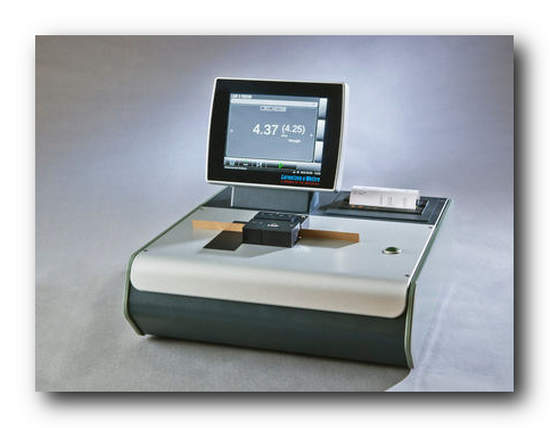

ABB launches L&W S-Tester for predicting compressive yield strength of fluting medium

The L&W S-Tester is based on a new, quick test method for determining the quality of fluting medium in corrugated packaging material. It expands ABB’s laboratory quality measurement offering to help paper producers improve quality and reduce costs.

The S-test method was developed by a group of fluting producers (CCB-CEPI) to provide a more reliable and easy measurement method than the time-consuming flat crush of corrugating medium CMT test (Concora Medium Test). This new test method can be fully automated.

ABB’s L&W S-Tester offers a better method for strength classification of medium fluting. Better and easier than the classic corrugating medium test.

The new S-test method correlates well with the compressive yield strength potential of fluting medium in a CMT test. This yield strength is more relevant than standard CMT when predicting the ability of fluting medium to keep the liners apart, without losing its own strength in a corrugated board construction.

The L&W S-Tester will provide quick and accurate feedback; it can also perform automated S-tests in L&W Autoline (complete paper quality measuring system) to add even more impact to mills producing fluting-medium when it comes to saving production costs. These measurements will help to reduce energy consumption through the elimination of over-refining, optimize the use of starch additives, and improve overall quality by generating a uniform paper product.

”This test method, developed by a group of industry partners, is now offered as a fully-supported product only by ABB,” says Thomas Fürst, Global Product Manager, ABB Pulp & Paper products.

ABB (ABBN: SIX Swiss Ex) is a pioneering technology leader in electrification products, robotics and motion, industrial automation and power grids, serving customers in utilities, industry and transport & infrastructure globally. Continuing more than a 125-year history of innovation, ABB today is writing the future of industrial digitalization and driving the Energy and Fourth Industrial Revolutions. ABB operates in more than 100 countries with about 132,000 employees www.abb.com

A complete turn-key project to Grupo Corporativo Papelera

A.Celli Paper actively participates in the production growth of Mexico with the supply of a new tissue machine to Grupo Corporativo Papelera.

In October 2016, A.Celli Paper received an order confirmation by Grupo Corporativo Papelera for the supply of a high-speed Tissue Machine with a production capacity of 34,000 tonnes per year (110 tonnes per day).

The investment is part of the Mexican Group’s growth plan that aims at an important increase in production capacity. Sure base for success, in which A.Celli Paper technology will play an important part.

The new Tissue Machine, with a 2,650-mm paper width at the pope reel and a maximum operating speed of 2000 m/min, is part of a complete turn-key project that includes the “Control & Automation” system, together with all ancillary equipment. The latest-generation hood design and the 16-foot Yankee dryer are the additional elements of technological excellence, a distinctive sign of A.Celli that makes its Turn-key offer the right choice for the many demands of the market in terms of experience and expertise – a true added value for customers. A 100% pure cellulose pulp preparation system designed to process long and short fibres and a slitter/rewinder complete the supply.

Grupo Corporativo Papelera S.A. de C.V.

Leading manufacturer of private label tissue products in Mexico, which was created by a group of leading Mexican entrepreneurs in transportation consulting nationwide.

Valmet introduces a new online analyzer for wood chip and bark moisture measurement

The Valmet Chip 'n' Bark Moisture Analyzer (Valmet CBA) offers pulp mills a new tool to advance productivity and efficiency. Continuously measuring wood chip moisture provides the means to accurately control cooking liquor to chip mass ratio for improved digester operation. When applied to monitor biomass moisture, better boiler efficiency is enabled by the continuous indication of heating value to optimize fuel feeding control and supplementary fuel use.

Improved process performance by innovative analyzer

Valmet CBA replaces time consuming oven dry laboratory measurements by utilizing microwave technology to continuously measure chip, bark, forest residue biomass or recycled wood moisture. A sample flow is taken from the conveyer chute, pushed through the unobstructed measurement chamber and then returned to the chute. Disturbances that affect conveyor mounted instruments have been eliminated with the innovative design and measurement concept.

Valmet Chip 'n' Bark Moisture Analyzer (Valmet CBA)

"As chip and biomass moisture have such a great effect on productivity and efficiency, the continuous measurement provided by Valmet CBA can be effectively used in real time control and provide a rapid return on investment. Together with Valmet's other successful analyzers and controls, it is another tool for the complete optimization of the pulp mill and power plant", says Antti Kokkonen, Product manager, Automation business line, Valmet.

Robust, continuous measurement of wood chip or biomass moisture from 0 to 70%

The robust construction of Valmet CBA, equipped with an integral screw feed sampling unit, is designed for trouble free and straightforward installation. A combination of microwave resonance, Q-value and sample temperature is used to accurately measure moisture content from 0 to 70% and optional heated screw tubes are available where the possibility of ice or frozen material exists. With Industrial Internet functionality, measurement data, alarms and diagnostics are all remotely accessible. Not requiring any special certification or safety procedures, Valmet CBA is applicable to all wood species and forest biomass moisture measurements.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

ANDRITZ to upgrade board machine for Consorzio Cartiere in Tivoli, Italy

International technology Group ANDRITZ was awarded an order from Consorzio Cartiere in Tivoli, Italy, to upgrade the board machine and related stock preparation line at the mill in Tivoli. After start-up, which is scheduled for the beginning of 2018, the capacity of the board machine will be increased from 78,000 to over 100,000 t/a.

The paper machine has a design speed of 1,000 m/min and produces fluting, testliner, corrugated medium and imitation-kraft papers with a basis weight range of 90-170 gsm. The raw material is 100% waste paper.

The paper machine has a design speed of 1,000 m/min and produces fluting, testliner, corrugated medium and imitation-kraft papers with a basis weight range of 90-170 gsm. The raw material is 100% waste paper.

ANDRITZ’s scope of supply comprises:

- Upgrade of the stock preparation line and approach flow system

- Upgrade of the board machine including a PrimeFlow SW headbox with dilution control for the bottom layer, rebuild of the top and fourdrinier wires and press sections with a PrimePress X shoe press

- Rebuild of the pre-dryer and after-dryer sections to adjust drying capacity to the new production targets

- New ropeless tail threading system

- New broke pulpers

- Engineering, supervision, commissioning, start-up, training, spare part packages

The ANDRITZ design provides innovative, high dewatering performance for the production of corrugated base paper grades. With the upgrade, Consorzio Cartiere in Tivoli aims at a significant improvement of the paper quality, enhanced runnability and increased production.

With this order, ANDRITZ PULP & PAPER is confirming its position as leading supplier for major rebuilds of paper and board production lines.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,500 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers, recovery and reuse of chemicals, preparation of paper machine furnish; the production of paper, tissue, and board; calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF) as well as recycling plants are also allocated to the business area.

ANDRITZ to supply equipment for fiberline upgrade to Altri Celbi, Portugal

International technology Group ANDRITZ has been selected to upgrade the brown stock washing process in the fiberline at the Altri Group’s Celbi mill in Portugal. Start-up is scheduled for autumn 2017. The new DD-Washer and other fiberline equipment supplied by ANDRITZ will substantially improve the washing efficiency and increase the capacity of the hardwood fiberline.

ANDRITZ Drum Displacer (DD) Washer “Photo: ANDRITZ”.

This is a repeat order for ANDRITZ at the Celbi mill, thus demonstrating the very successful, long-term business relationship between the two companies. The latest deliveries of ANDRITZ technology were the pulp drying line and cooking process systems in 2014 and 2015, respectively.

Altri is headquartered in Porto, Portugal, and is one of the leading producers of bleached eucalyptus pulp in Europe.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,500 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.